Editor’s Choice

Superdielectrics launches next generation Faraday 2 battery

LOCTITE celebrates over 20 years of supporting future engineering talent with formula student sponsorships

Priya Lakhani OBE announced as first keynote speaker at The PPMA Total Show® 2025

Doncasters’ Groton expansion reaches major milestone with new shell line commissioning as part of $13M investment drive

Infomaniak data centre in Geneva integrates Trane heat pumps for largescale heat recovery

Experience thermography – technical lectures and demonstrations plus professional exchanges

ABB

Chile’s Antofagasta Minerals progresses new project at Centinela mine with ABB Gearless Mill Drives

Register today to confirm your attendance

Guidance automation launches payper-hour automation model to unlock productivity in manufacturing

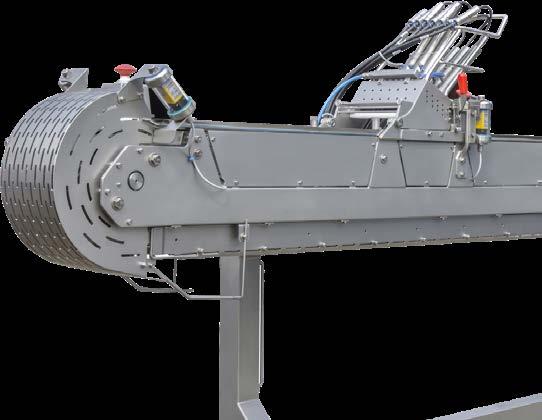

KABELSCHLEPP

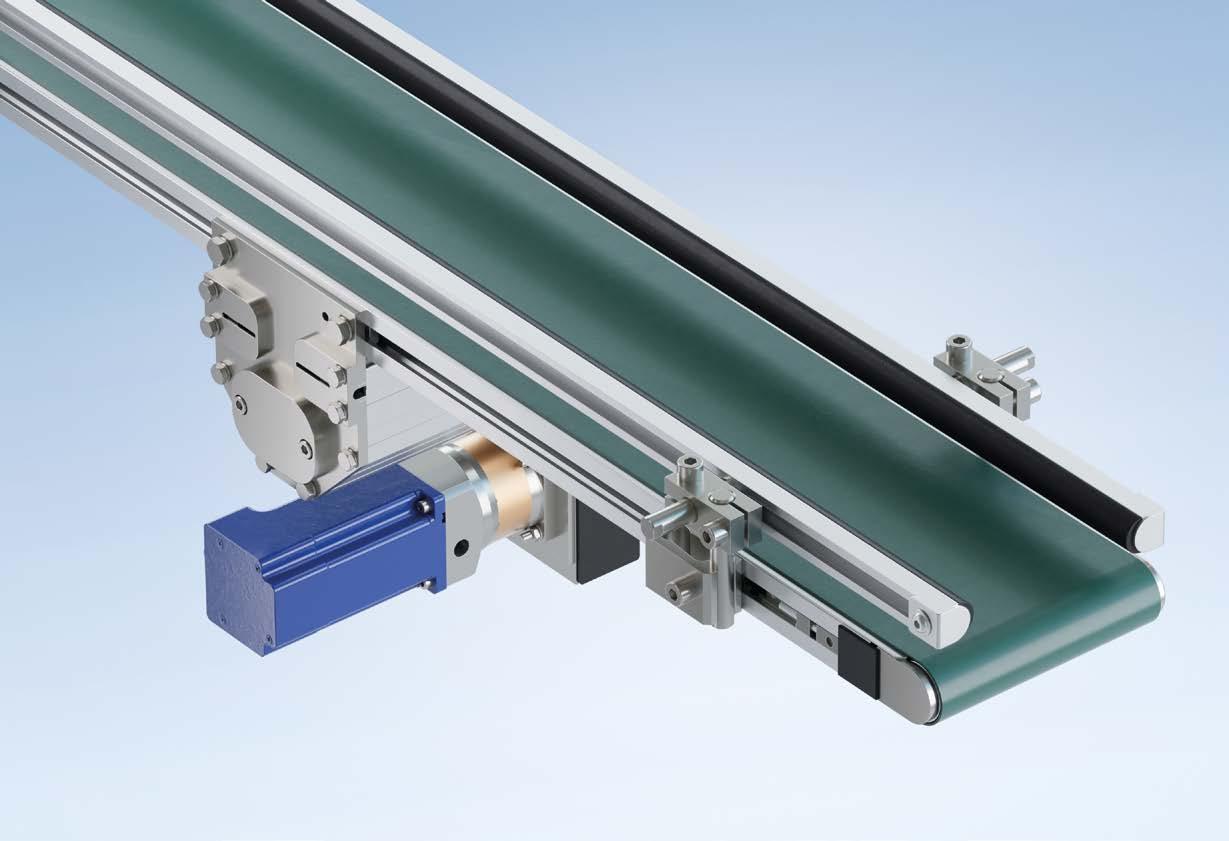

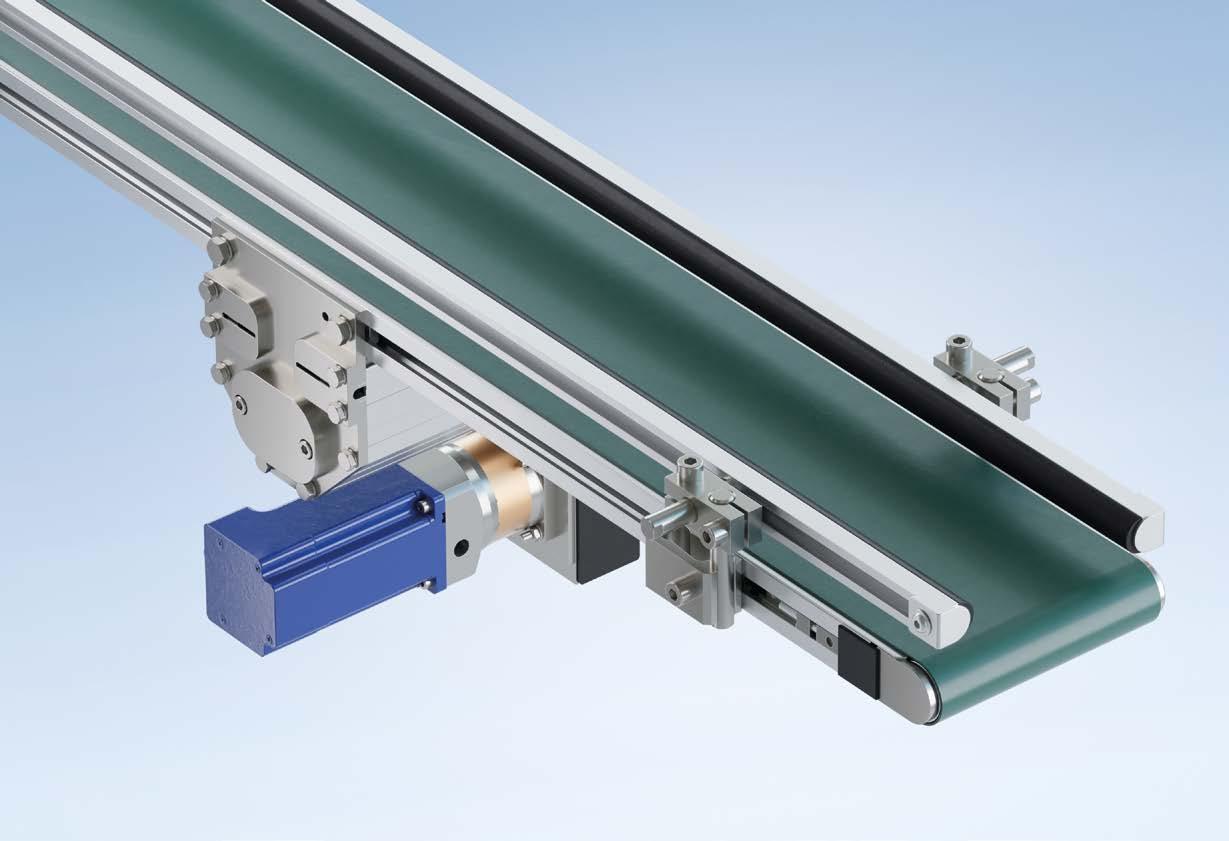

Kabelschlepp Metool configures

TOTALTRAX systems for XXL filling systems

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 158,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices. All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Jake Page jake@pecm.co.uk Tel: 01227 937174

SALES MANAGER

Martin Richardson martin@pecm.co.uk Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk Tel: 01227 936971

Please

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk Tel: 01304 806039

DIGITAL ASSISTANT

Stacey Goodwood Tel: 01227 936971

MH Media Global Ltd. 18/20 Newington Road, Ramsgate, Kent, CT12 6EE Tel 01304 806039 l Fax: 08721 152240 l www.pecm.co.uk

The Cambridge-based energy storage technology company, Superdielectrics, has announced the launch of its next generation aqueous polymer battery, the Faraday 2.

This launch marks a major milestone in the company’s mission to revolutionise energy storage with a safer, more sustainable, and costeffective alternative to traditional lithium-ion batteries. The Faraday 2 builds on the success of the Faraday 1 prototype, being a major step towards the offering of a fridgesized residential energy storage unit capable of reducing household electricity bills by 85% or more. SUPERDIELECTRICS

Developed from advances in contact lens polymers, Superdielectrics’ internationally patented technology uses abundant, non-toxic materials and contains no critical or rare earth metals. With a full charge time of just 30 minutes, significantly faster than a traditional battery, the Faraday 2 is designed to store surplus renewable energy efficiently, enabling flexible tariffs and greater energy independence for homes. This innovation addresses the growing need for scalable energy storage across Europe’s rapidly expanding renewable energy sector, and also offers a transformative solution to

lower electricity costs, enhancing energy security.

Key advantages of the Faraday 2 include:

• Safe: Unlike lithium-ion batteries, approximately 50% of the technology is water-based, eliminating the risk of thermal runaway which is a fire-safety hazard

• Low cost: The technology does not rely on critical metals making its materials cheaper than lithiumion batteries with securer supply chains

• Sustainability: Built with readily available, materials that are easily recyclable

• Long lifecycle: Potential for even longer use than existing batteries

• Energy density potential: Currently outperforming leadacid batteries and with ongoing R&D efforts to surpass currently available lithium-ion energy storage capacity in the future

Commenting on the launch, Jim Heathcote, CEO of Superdielectrics, said:

“The launch of Faraday 2 is a major step towards a low cost and clean energy future, as well as a key milestone for us as we work towards a commercial product. As the world shifts towards renewable energy, storage is the technological bottleneck. Our technology is low cost, safe and recyclable, helping the world in the global transition to sustainable energy.”

give millions of homes access to safer, cleaner, and more affordable energy.

Julian Lennertz, Chief Commercial Officer at E.ON Next, said:

“The transition to cleaner energy is about making that energy more affordable and sustainable, and our partnership with Superdielectrics is one of a huge number of ways we are working to help customers take control of their energy by making

The launch of Faraday 2 is a major step towards a low cost and clean energy future, as well as a key milestone for us as we work towards a commercial product.

energy storage widely available. We are delighted to be a part of the Superdielectrics journey, sharing insight into how millions of customers use energy and what they need to benefit from a smarter energy system. The launch of Faraday 2 is an important milestone in the evolution of battery design using readily available materials – and is yet another world-leading innovation designed and developed in the UK.”

With the demand for renewable energy surging, the launch of the Faraday 2 positions Superdielectrics at the forefront of the global energy transition.

Earlier this year, Superdielectrics announced a wide-ranging collaboration agreement with E.ON, one of the UK’s leading energy providers. The partnership is focused on accelerating the development and deployment of Superdielectrics’ battery solution, with the next step being the creation of larger prototypes that can be trialled in customers’ homes. This collaboration aims to For further information, please visit www.superdielectrics.com

Thermal fluid specialist, Global Heat Transfer, has launched a new synthetic heat transfer fluid, Globaltherm® DBT, designed for use in the liquid phase within closed, forced circulation heat transfer systems. Suitable for a wide range of industrial process applications, including chemical and plastics applications — the fluid offers a reliable, high-performance solution for managing temperature.

Globaltherm® DBT is an energy efficient, organic heat transfer fluid that promises consistent, safe heat delivery from -5°C to 350°C without the need for system pressurisation. The fluid offers precise, reliable temperature control across a wide operating range, making it suitable for both heating and cooling applications.

Designed with system compatibility in mind, the fluid is interchangeable with similar products, allowing manufacturers to upgrade without the need to modify existing equipment. This makes it a suitable option for those looking to improve system performance while avoiding costly downtime or engineering changes.

“This is about giving process engineers more control, more uptime and less hassle,” said Dave Dyer, technical sales engineer at Global Heat Transfer. “Globaltherm® DBT has a high boiling point, excellent thermal stability and a low viscosity, all key for reliable performance in high-temperature systems.”

The new fluid is developed for use in closed loop, unpressurised systems, which lowers the risk of leaks, stress on system components and energy loss. It also performs well at startups in colder conditions, reducing the need for heat tracing. When even lower temperature performance is required, it can be safely blended with Globaltherm® L to lower viscosity and ensure reliable flow.

The fluid is non-corrosive and compatible with standard industrial materials, including stainless steel, polytetrafluoroethylene (PTFE) and graphite seals. It operates cleanly, without forming sludge or carbon deposits when used within recommended conditions, making it well suited for long-term use in critical process environments.

Globaltherm® DBT users can also access Global Heat Transfer’s heat

transfer system management programme, Thermocare®. This service includes regular testing and analysis to track fluid condition, allowing operators to identify problems early and avoid more serious system issues. It’s a proactive approach to thermal fluid management that supports longterm system reliability.

“We developed Globaltherm® DBT with the realities of industrial downtime in mind,” added Dyer. “When your process relies on consistent heat, even a small performance dip can have a big impact. This fluid is about helping teams keep production running smoothly — and focus on output, not troubleshooting.”

To find out more about Globaltherm® DBT, or to speak to a thermal fluid specialist, visit the website or call +44 (0) 1785 760555.

For further information, please visit www.globalhtf.com

Schmersal now offers a complete range of innovative command and signalling devices specifically designed for hygiene-sensitive environments in the food processing industry.

Engineered for maximum cleanliness and reliability, these devices feature seamless transitions between sealing elements and surfaces, no protruding parts makes them exceptionally easy to clean. Their robust design withstands high-pressure washdowns and aggressive cleaning agents, meeting the highest hygiene standards.

With 147 device options available including mushroom pushbuttons, selector switches, and potentiometer-rotary switches you have the freedom to configure your control panels exactly how you need them.

Whether you are upgrading existing systems or building new equipment, this range offers the flexibility to design a safe and hygienic human-machine interface that fits your exact requirements.

For added customisation, all devices can be supplied with individual laser marking, including your company logo.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

As an approved TUV trainer representing ROSS Controls for the Certified Functional Safety Expert (CFSE) training program, I am honoured to share insights into this pivotal course designed for professionals in the realm of electrical and fluid power safety systems.

In today’s industrial landscape, the integration of electrical and fluid power safety systems has become increasingly complex. This evolution necessitates a profound understanding of functional safety to ensure operational efficiency, employee safety and compliance with international standards. The CFSE program is meticulously crafted to address this need, equipping participants with the expertise to evaluate, design, and implement robust safety functions across diverse technologies.

Our curriculum is structured to provide a holistic understanding of overall functional safety:

• Hydraulics and Pneumatics Engineering: This course expands on fluid power safety systems not covered elsewhere. Participants explore the intricacies of hydraulic and pneumatic technologies, emphasising their safe integration and operation. Attendees are taught how validation and verification of safety systems are performed to verify the correct performance levels are achieved.

• Electrical Safety Engineering: This module delves into the principles and applications of electrical safety in

In today’s industrial landscape, the integration of electrical and fluid power safety systems has become increasingly complex.

machinery, laying the foundation for understanding potential hazards and mitigation strategies.

• Practical Safety Functions Workshop: This hands-on workshop bridges theory and practice, allowing attendees to apply learned concepts to real-world scenarios, thereby solidifying their understanding.

• Final Examination: Culminating the training, this assessment evaluates the comprehensive knowledge acquired, leading to certification upon successful completion.

1. Global Recognition: Achieving CFSE certification signifies adherence to internationally acknowledged functional safety standards, enhancing professional credibility.

2. Enhanced Competence: The program delves into international standards such as EN ISO 13849 and EN IEC 61508, equipping participants with the knowledge to implement and manage safety protocols effectively across fluid power and electrical safety.

3. Career Advancement: Certified professionals are often preferred for

roles requiring expertise in safetycritical systems, opening avenues for career growth across various sectors.

4. Practical Application: The inclusion of workshops and real-world scenarios ensures that participants can translate theoretical knowledge into practical solutions, directly impacting workplace safety.

5. Compliance Assurance:

Understanding and applying the principles taught in the CFSE program aids organizations in adhering to legal and regulatory requirements, thereby mitigating risks associated with noncompliance.

6. This course is the first to cover fluid power safety, making it an industry first, which in turn allows users to be informed and proficient in pneumatic and hydraulic safety systems.

In an era where industrial safety is both a moral obligation and a regulatory mandate, the Certified Functional Safety Expert training stands out as a pivotal program for professionals aiming to excel in this domain. The comprehensive curriculum which includes fluid power and electrical safety, coupled with global recognition, not only enhances individual careers but also contributes significantly to the overarching goal of safer industrial practices worldwide.

I encourage all professionals involved in the design, development, and maintenance of industrial systems to consider this certification as a means to elevate their expertise and contribute to a safer working environment.

ROSS Pneumatrol enhances machinery safety through tailored fluid power solutions.

With over 100 years of expertise in fluid power safety, ROSS Pneumatrol delivers trusted, innovative solutions that help industries worldwide meet evolving machinery safety standards and operational demands.

Our Services

Training on machinery safety including a TUV-Approved Certified Functional

Safety Expert Training

Machinery conformity and LOTO audits

Machinery Risk Assessments

Class-Leading Safety Valves

Installation Services

ROSS Pneumatrol’s machinery safety services leverage global expertise, offering certified training, conformity audits, and tailored solutions that meet international standards. Our experts help clients achieve compliance and operational excellence across diverse industrial sectors

For More Information Visit Our Website

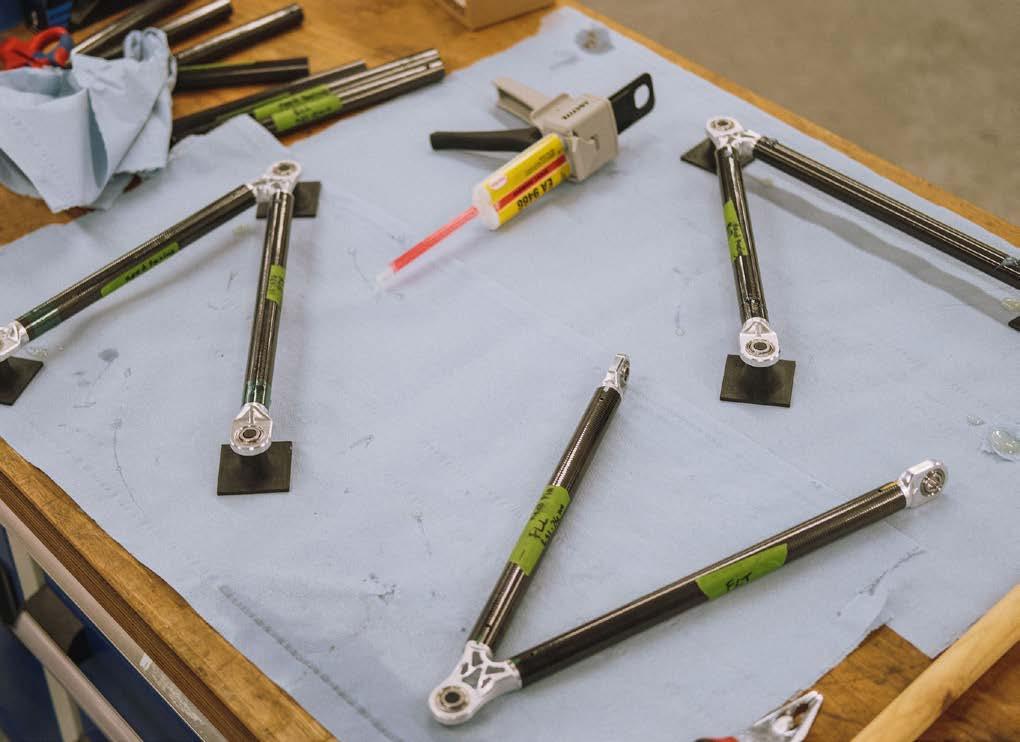

LOCTITE, the global leader in adhesives, sealants and functional coatings, is proud to continue its longstanding sponsorship of Formula Student – the UK’s most established educational engineering competition, run by the Institution of Mechanical Engineers. With more than two decades of involvement, Henkel brand LOCTITE continues to help university teams bring

their innovative race car designs to life with its trusted adhesives and technical know-how.

Taking place this July at Silverstone, Formula Student provides students from around the world with the opportunity to develop, build and race a single-seater car, applying their academic knowledge in a highly practical and competitive

environment. The event attracts more than 100 university teams globally and is widely regarded as a launchpad for careers in motorsport, automotive and advanced engineering.

LOCTITE continues to support student teams by providing advanced adhesives for use in structural, composite and powertrain components, alongside application advice and engineering support.

This year, several teams have benefitted from LOCTITE’s sponsorship, including York and Kingston universities.

“LOCTITE’s support of York Formula Student has been instrumental in advancing our manufacturing processes while ensuring the highest quality standards,” said Tom Comrie, Team Principal of University of York’s racing team. “Most notably, the unique properties of their HY 4070 adhesive have enabled us to securely and reliably bond the Impact Attenuator to the vehicle, giving us full confidence in its performance under all conditions. Their products have not only expanded the team’s engineering capabilities but also supported our commitment to rigorous safety standards.”

Beyond individual applications, LOCTITE’s continued support gives teams access to both materials and expert guidance, allowing them to solve complex engineering problems with confidence. Whether bonding composites or securing critical assemblies, LOCTITE

support and advice allowing us to select the correct products for our project.

LOCTITE’s support of York Formula Student has been instrumental in advancing our manufacturing processes while ensuring the highest quality standards

products have become a trusted part of many teams’ build strategies across the competition.

“The sponsorship from LOCTITE has been invaluable to our team,” added Cameron Thomson, Team Lead of Kingston University’s racing team. “Their support has enabled us to improve the quality and reliability of our car’s bonded components, particularly in our composite suspension design, with technical

“We use several LOCTITE products – from EA 9466 epoxy adhesive for our bonded composite wishbones to LOCTITE 638 bearing retention compound, used in a multitude of assemblies across the car. It’s a partnership that’s helped push the team’s engineering innovation even further and provided us with the confidence to take on new challenges.”

“We’re proud to continue supporting Formula Student and helping the next generation of engineers bring their ideas to life,” added George Hickey, Market & Customer Activation Manager at Henkel. “This initiative not only showcases exceptional technical talent but also reflects the spirit of innovation and collaboration that drives our industry forward.”

LOCTITE is committed to empowering the next generation of engineers through both educational initiatives and hands-on technical support. Its involvement in Formula Student is part of a broader mission to go ‘Beyond the Bond’ to foster innovation, encourage sustainability, and build practical engineering skills that support future mobility challenges.

For more information about Formula Student, visit: https://www.imeche.org/events/formula-student

Priya

Lakhani OBE announced as first keynote speaker at

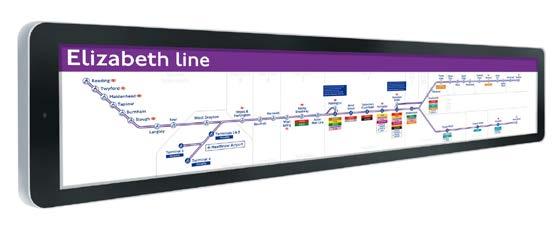

Organisers of the PPMA Total Show®, which returns to the NEC, Birmingham in September, have announced the first keynote speaker for the event: Founder CEO of AI and education technology firm CENTURY, Priya Lakhani OBE.

Visitors to the UK’s biggest processing and packaging machinery, robotics and industrial vision event, which takes place from 23-25 September, will have the opportunity to hear Priya’s keynote speech, AI Everything Everywhere All at Once, on the first day of the show.

Now in its 38th year, the PPMA Total Show® 2025 will showcase more than 350 exhibitors and 1,500 brands, giving attendees access to cuttingedge technology and solutions to optimise performance, reduce costs, and future-proof their businesses.

Organised by Automate UK, the PPMA Total Show®, offers live equipment demonstrations, valuable insight into innovative technologies and networking opportunities to industry professionals from across the entire manufacturing spectrum.

Scott McKenna, Chief Operating Officer for Automate UK, said: “When registrations for the PPMA Total Show® opened last month, we promised visitors access to unique expert-led seminars, and we are thrilled to have secured Priya to deliver the first keynote address at the event.

“As the founder of an award-winning AI and education technology

Most recently, Priya was selected by the World Economic Forum as a Tech Pioneer for her pioneering AI work at CENTURY.

company that develops learning tools for schools, colleges, universities and employers across the world, Priya’s work and knowledge is inspiring, and her presentation aims to demystify AI and leave attendees AI confident and ready to leverage the technology to its full potential.

“Her speech will include use cases and provide key strategic questions for visitors to apply within their own organisations, and we anticipate a great deal of interest from visitors keen to benefit from her expertise,” he added.

The co-host of BBC News’s flagship AI programme, AI Decoded, Priya’s experience is extensive. Further to having launched a successful FMCG business in 2008, Masala, which through its charitable foundation provided millions of meals and 35,000 vaccinations to the underprivileged in India and Africa, Priya went on to be appointed to the UK government’s AI Council in 2019. Priya then cofounded the Institute for Ethical AI for the education sector, prior to being appointed as Non-Executive Board Member to the UK Government Department for Digital, Culture, Media

register, visit: www.ppmashow.co.uk

& Sport (DCMS), with specific focus on online safety and technology.

In 2023 she was an advisor to Patrick Vallance for his Pro-innovation Regulation of Technologies Review and currently advises the government as a member of the Prime Minister’s Council of Science and Technology. Most recently, Priya was selected by the World Economic Forum as a Tech Pioneer for her pioneering AI work at CENTURY.

Last year’s event has been shortlisted as a finalist in the Best UK Trade Show category at the AEO Excellence Awards 2025, and Automate UK have pledged to deliver a show that exceeds expectations this year, with an itinerary of expert speakers, a networking reception and a series of live demos to showcase the latest technology solutions.

One of the standout successes of The PPMA Show® 2024 was Innovations Eleven – a brand-new live demo theatre, in which 11 selected exhibitors launched new technology directly to attendees. The PPMA Total Show® 2025 will expand on the success of this initiative, with the live demo theatre being broadcast in real-time via PPMA Total Show TV.

In addition, expert-led daily innovation tours will be hosted for visitors to expand on the technology being showcased and show them how to harness it within their own businesses.

Attendance for The PPMA Total Show® 2025 is free.

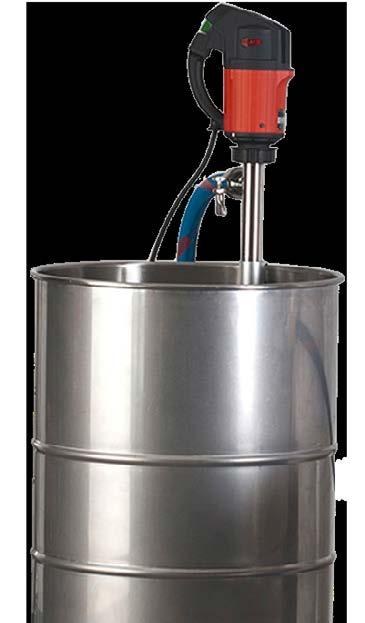

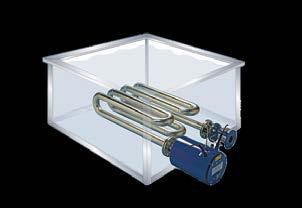

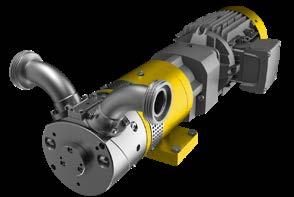

Epoxy resins are well known for their difficulty in pumping. This can be down to several factors ranging from their high viscosity, and sensitivity to shear wot the speed at which they can set when mixed leading to pump clogging or seal failures.

North Ridge were contacted by a company planning to fill small moulds to manufacture test pieces before going into production, using a process known as resin transfer moulding or RTM.

What is resin transfer moulding?

This is a highly effective lowpressure moulding process used to produce fibre plastic composite parts with high levels of strength and durability. The method involves injecting a mixture of resin and catalyst into a closed mould containing dry, semifinished fibre parts in a preform or fibre pack.

They were looking to fill moulds at a low, predictable flow rate at a controlled pressure which was kept within a tight tolerance and ensure that any fibres pumped within the resin were not pumped at high pressures leading to distortion within the mould leading to premature failure of the test piece.

We selected and specified our DS-M/Lab pump - a small low flow peristaltic metering pump. It’s the ideal option for a low flow, small scale application like this and many other laboratory and pharmaceutical uses including:

• Processing

Precise drug flow control, chemical engineering and injection, corrosive liquid transfer, laboratory reagent and buffer distribution, and sampling

• Microbiology laboratories Distribution of culture media, buffers, diluents and a variety of sterile solutions

• Medical and biotech

Infusion, dialysis, extracorporeal circulation and high-purity liquid analysis

Featuring a quick hose replacement pump head, it has been specially designed for applications where easy and quick hose replacement is vital, without operators needing any tools or training.

To replace the hose simply:

1. Close the valve of the feeding chemical

2. Push the grey hose holding clips apart and release the pump head

3. Pull out the hose and replace

4. Press the clips together on the pump head

It’s also self-priming, works on a single-phase power supply and can run dry without damage.

The DS-M/Lab pharmaceutical peristaltic pump enables users to ensure full traceability and guaranteed results, as one tube is used per chemical, mixture, flavour or dye. As there are no seals present in the pump head, there is zero chance of leakage and should the tubing require replacing, it can be in minutes.

In addition, the client requested that the pump could be reversed if necessary. So this pump has a builtin inverter which allows operators to speed up, slow down or reverse the unit if required.

If you have an application requiring the transfer, circulation or injection of fluids and are looking for an easy-to-maintain solution, speak to North Ridge Pumps to see how we can help.

In fact, we have a whole range of non-clog metering pumps which will give you incredibly precise measurement of gaseous, viscous and shear-sensitive fluids without any loss of flow.

We’re North Ridge Pumps, the UK’s largest pump supplier with over 25 years’ experience. We’re expert at specifying exactly the right pump for every client – not just an off-the-shelf, one-size-fits-all solution.

That’s probably why we’ve completed over 2,000 successful projects for clients all around the world. You can read case studies at www.northridgepumps.com

If you work with commercial refrigeration here in the UK, you’ve probably clocked the rise of the ECR2 motor. Over the years, I’ve seen a lot of kit come and go, but the ECR2 was a genuine shift for our industry. Here’s why. It’s not just about slapping a new, high-tech fan motor into the cabinet. Real value kicks in when you pair it with expert support and technical know-how, think Axairlevel support, not just any wholesaler.

So, what’s the fuss about the ECR2 motor? For starters, it’s a step-change in efficiency. This little beast uses up to 74% less power than the old shaded pole motors we’ve all battled with, meaning fatter savings on your energy bills and a nice bonus for your sustainability tick boxes. Quiet as a mouse, runs cool, and has a fieldtested lifespan of well over a decade. That’s not just marketing fluff, either, a design life of at least 10 years and up to 99.97% field reliability is a big deal for anyone who hates unscheduled downtime.

Now, the ECR2 isn’t just tough, it’s versatile too. We’re talking IP67 ingress protection (that’s proper waterproofing for all those drippy cold stores), quiet operation and it’s got food-grade options for those of us working in food service or medical storage. Got a system that needs ATEX compliance? That’s baked in too, so it’s safe for volatile refrigerants. And with multi-voltage capability, you won’t get caught out on a retrofit or a new install.

Here’s where people trip up, thinking the component is the whole story.

It’s not. The real differentiator comes from who you buy it from. That’s where a supplier like Axair comes in, suppliers that aren’t just box shifters. With a team steeped in refrigeration system design and practical integration, we dig into your application, help you nail the right variant, mounting, and control setup. This saves you from bodged installations, mismatched controls, or those “why’s it not working?” headaches that cost time and money.

Because, let’s face it, every hour of downtime has a measurable cost. Axair puts a lot of stock in pre and after-sales support. We’re not just there to take your order and move on. If things go sideways or you want to upgrade later, you’ve got someone on the other end who understands the details and troubleshoots fast. You get help with technical queries, spare parts, and even proactive advice, things you only get from dealing with a real partner.

It also pays off in compliance. With new regs popping up on energy, safety, refrigerant types, having a

technically competent supplier can save you from nasty surprises down the line. Axair’s team make sure everything’s up to scratch from day one, and if you’re ever audited or upgrading to greener tech, you’re not scrambling.

And, if you’re ever in a pinch for spares, or planning ahead like the smart operators do, you can find ECR2 motors and complete fan packs in stock for quick delivery. You’re not passed to customer service, Axair is geared up for fast turnaround and real, live technical assistance if you need it.

Long story short? The ECR2 motor alone gives you top-tier efficiency, reliability, and compliance. But the true edge, the bit your future self will thank you for, is buying from a team that has your back with deep knowhow and hands-on support.

If you’re in the UK and need advice, spares, or support, get the partnership and expertise that keep businesses running smooth with Axair.

We’re transforming how our customers achieve energy savings, reliability, and compliance in every application. At Axair Refrigeration, our technical expertise means more than just supplying products: we work side-by-side with you to solve heating, cooling, and system integration challenges, ensuring every component solution is tailored for your unique needs. From food retail and cold storage to pharma and process cooling, we’re redefining what’s possible, making refrigeration smarter, more sustainable, and always customerfocused.

With a huge variety of products needing to be handled, when it comes to the food processing industry, no two pump requirements are the same. Getting the right pump, rather than just one that “does the job” is the key to saving yourself from excessive wear, unnecessary maintenance, product waste, process failures and energy costs. This case study is an example of the importance of just that.

Castle Pumps Ltd were approached by a manufacturer of ready to drink cocktails who were looking for pumps for various stages of their cocktail production. They had already installed two pumps supplied by Castle Pumps for the transfer of flavourings, and after six months of excellent service were ready to look at all of their other transfer processes, all with differing challenges meaning differing pumps needed to be specified.

They were looking for seven pumps for the transfer of the finished cocktail products from container to container; an individual pump for each of the premixed cocktail products they offer.

They also required a single pump for transferring 55% proof alcohol that needed to be easily transportable around the plant to dispense at various locations and two pumps for handling cleaning solutions as part of their canning machines’ Clean in Place system.

When it comes to alcohol transfer, flexible impeller pumps are a go to pump design which is what Castle Pumps specified for the seven pumps. Firstly, they are a common cost-effective solution for food transfer applications where the fluid is not being pumped at high pressures, which this application wasn’t. To satisfy the hygienic requirements of the manufacturer, they were specified with a food grade Neoprene impeller, compatible with the alcohol products and Tri-clover connections that meet ISO 2852

standards for hygienic couplings. Secondly when it comes to the handling of drink products, it is often important that the pump applies low shear during the transfer process, which the flexible impeller design does. This is because a pump such as a centrifugal which applies force that agitates the product can lead to frothing and the impact on taste.

For the pump required to pump the 55% proof alcohol there were some additional requirements. The first point Castle Pumps recognised was that we needed to supply the flexible impeller pump with an ATEX motor due to the flammable nature of the fluid. In addition, dry run protection was specified to prevent any overheating to further limit the risk of potential sparks in the environment. With portability a key factor, the pump was supplied trolley mounted for ease of transportation and supplied with an inverter to allow it to be run at different speeds when transferring different quantities from different tanks.

For the two pumps that were being used to transfer cleaning chemicals, the main factor was ensuring material compatibility with the solutions in question. The pumps were also supplied with a reverse operating switch to allow retrieval of any excess chemical in the delivery hose back to the tank.

If you’re looking for the right pump to deliver your process or perhaps have a challenging fluid you need to transfer, contact the pump exerts at Castle Pumps.

Pump smarter, not harder. Use our 15 years’ experience to save excessive wear, process failures, product waste & operator time.

✓ Solid-laden, viscous fluids without clogging/wear

✓ Safe handling of chemicals, fuels & flammables

✓ Highly accurate dosing of chemicals & ingredients

✓ Difficult to pump or delicate, shear sensitive fluids

✓ 99.98% barrel emptying to prevent product waste

✓ FDA & 3A models for food and hygienic applications

Contact our technical sales engineers now!

Doncasters’

Doncasters is proud to announce the successful commissioning of a brand-new, fully automated shell line at its Groton facility - a major milestone within its 2025 Performance Improvement Plan and a key advancement in the company’s long-term manufacturing strategy.

The $13 million capital investment expands the Groton site’s operational footprint by 17,000 square feet and introduces next-generation automation and environmental control systems.

Equipped with three high-precision 6-axis robots and the industryleading IC-Crystal Shell Management System, the new line significantly enhances production capacity, part quality, and operational reliability.

“Our new fully automated shell system isn’t just a machinery upgrade—it’s a strategic leap forward,” said Mike Looney, General Manager at Doncasters Groton.

“This investment dramatically enhances our efficiency, precision, and capacity, enabling us to take on more complex, high-volume aerospace products. It positions us to meet rising industry demand and deliver unmatched quality to our customers around the globe.”

The former shell system - installed in the 1980s - suffered from limited capacity, minimal process control, and frequent downtime due to heavy reliance on manual operations. The new system addresses these challenges with the following benefits:

• Quadruples output capacity - from 10 molds per day to 40 hangers per day

• Minimizes process downtime through full automation and telemetry-enabled quality tracking

• Improves mold quality with precise sanding and dipping performed by 6-axis robotic arms

• Reduces operating costs via advanced environmental controls and efficient processing

• Accelerates turnaround times through stable, rapid drying and optimized shell handling

Key System Features

• 6-axis robotics: Greater motion control reduces mold damage and ensures a superior surface finish

• IC-Crystal Shell Management: Tracks all critical-to-quality

parameters—slurry conditions, equipment status, and environmental controls

• Environmental precision: Maintains strict temperature (±2°F) and humidity (below 20%) to prevent shell defects such as splits or cracks

• Engineered core packs: Eliminate manual handling, freeing up operators to focus on skilled tasks

• Low-maintenance upgrades: New systems replace high-impact equipment like fluidized beds and vertical sanders with more sustainable alternatives.

To date, 48 molds across 6 part families have been successfully substantiated in the new system.

The first phase of legacy system decommissioning is nearly complete, with final demolition expected by October.

Menzel Elektromotoren has been certified for the production of large squirrel-cage motors in ignition protection type Ex p pressurization for operation in zone 1 hazardous areas where an explosive gas/air mixture is likely to occur in normal operation. The test specimen, a compressor motor for the petroleum industry, underwent a gas displacement test (test of the air purge system), leak test and pressure test. The German technical inspection service TÜV Nord comprehensively tested and certified the construction method. To win the approval, the manufacturer had to prove its ability to control the purging air flow for all its relevant motor series in such a way that no gas pockets remain inside the motor casing. Menzel can apply this manufacturing procedure to stock motors in a wide output range and is thus able to flexibly and quickly provide competitively priced Ex p motors featuring the product categories 2G and 3G. Pressurized motor construction is typically suitable for squirrel-cage motors from 400 mm shaft height. It is available for all voltage ranges and with air-to-air or air-to-water heat exchangers (cooling types IC 611, IC 616 or IC 81W).

An air-purge system allows potentially flammable gases to be removed from the motor frame before the motor is started and to maintain a constant positive pressure during operation to prevent the ingress of explosive gases. The terminal boxes feature the ignition protection type Ex eb increased safety.

Plant operators often face the challenge that they cannot find suitable replacements for obsolete motors. The choice of explosion-proof drive systems in particular is limited. Up until now, the only alternative was to buy a standard motor with the required explosion-protection rating and adapt the installation site and/ or driven machine, sometimes at considerable time and expense. Menzel’s certification for the construction and manufacture of protected motors now gives customers more freedom of choice and flexibility. The German manufacturer specializing in large electric motors always configures motors for the individual application and installation conditions. Likewise, the air purge system for pressurized motors

is individually calculated and implemented, ensuring that the finished systems meet the highest safety standards.

For a petrochemical company, Menzel has recently manufactured an Ex p compressor motor based on its MEBKSL series, which matches the original motor in all mechanical and electrical interfaces. The compressor motor for an oil refinery is labeled II 3G Ex pzc ec ic IIC T3 Gc for zone 2. It has a rated voltage of 6000 V and a rated output of 1635 kW. Before shipping, the motor was rigorously tested in the company’s inhouse test facility, including load and type testing.

Menzel’s Ex p motors were named the Product of the Year in the 2023 AEMT Awards

For further information, please visit www.menzel-motors.com/pressurized-exp-motors-zone1-operation/

Electrical and maintenance engineers have no time to waste. So, an AVT (absence of voltage test) safety solution which takes almost no time to use and can save them hours – is too good to miss out on. If it also saves money on the cost of maintenance, downtime and lost production, then ignoring it would be shocking.

As all engineers know, before any maintenance can be carried out, the panels have to be disconnected from the power source and have their absence of voltage verified. Disconnection is relatively quick and easy, but the traditional method of verifying absence of voltage is slow, complex, and open to error, complacency and risk.

Panduit’s AVT system minimizes the risk of electrical hazards by confirming that any electrical cabinet is voltage-free before allowing access. Compared to other portable test instruments, plant operators, machine builders and onsite engineers and electricians can check whether an electrically safe environment is present with the touch of one button.

VeriSafe 2.0, automatically ensures that the entire test process is followed for every single test. With a push of a button, operators can achieve tested safety in both 3-phase and 1-phase applications in the extended voltage range up to 1000 V for AC and DC applications. The fail-safe design uses active indicators for plant status and complies with SIL 3 (IEC 61508-1) safety functions. According to the NEC, specified in NFPA 70E, an electrically safe environment must be ensured

1. The system confirms power is available to perform the test

2. Checks health of key circuit elements

VeriSafe 2.0, automatically ensures that the entire test process is followed for every single test

before working with electrical installations without voltage, and the measurement procedure is precisely defined.

Panduit’s solution complies with industry requirements and simplifies the process, saves time and money:

The highly visible and large clear externally mounted test unit, normally positioned on the equipment cabinet door, is easy to use and follows a high effective process: What happens during the test?

3. Verifies threshold circuits in tolerance

4. Checks on known voltage source

5. Verifies connectivity

6. Verifies threshold is under 3V.

VeriSafe 2.0 is ideal for 480/600V CAT IV applications including outdoor, service access and all power distribution equipment including frequency converters and remote motor disconnect switches. The extended VeriSafe increases the possibilities to protect the entire electrical area. If desired, the isolation module can be easily integrated into control systems via redundant semiconductor signal outputs (SIL 3). In addition, a network module for real-time diagnostics and performance reports is available.

Trusted by professionals worldwide, Teknomek manufactures hygienic furniture and equipment tailored to the highest industry standards.

Partnering with premium UK brands to provide trusted lab equipment, we ensure that you always get the high quality Teknomek service you rely on.

• Uncompromising quality & service

• Innovative & bespoke designs

• Premium products at exceptional value

Vision Engineering, a UK based manufacturer of ergonomic microscopy and digital 3D visualisation technology unveils the EVO Cam HALO, a new 4K digital microscope that redefines the standard for clarity, precision and consistency in inspection and measurement tasks.

Suitable for a wide range of inspection applications, EVO Cam HALO combines stunning 4K image quality with advanced, adaptive illumination, and new intelligent software, empowering users to capture the most challenging details with unparalleled accuracy.

HALO’s key features include 4K resolution which reveals previously obscured details with remarkable clarity, ensuring nothing escapes the user’s view. A Super-Wide Dynamic Range ensures the user captures images with exceptional brightness and contrast, even in challenging lighting conditions. Additionally available with HALO comes a new enhanced Illumination package, including a quadrant light, panel light, and white/UV light, to optimise illumination for a variety of inspection needs.

New Intelligent Hardware and Software automatically detects lenses and adjusts magnification settings, ensuring seamless workflow and accurate results. Real-time insights are available providing intuitive image capture, measurement, and analysis tools, enabling faster and more informed decision-making. Vision Engineering’s popular 360 Direct/ Oblique Viewer also works with

HALO, enabling users to inspect details from different angles, revealing hidden features that would otherwise be inaccessible.

HALO is suitable for a wide range of applications, including Medical Devices Manufacture and testing especially in the practices of inspecting translucent tubes, electro-polished devices, and other medical components with enhanced clarity and accuracy.

It is also effective at capturing fine details on small, reflective metal parts for precise inspection and quality control – perfect for Micro Mechanics. In the laboratory HALO cam improve the examination of Petri dishes with translucent samples, enhancing contrast and

clarity for detailed analysis, and in Industrial Manufacturing, intricate assemblies, solder joints, and other components are inspected with much improved precision and efficiency.

Pricing and Availability: EVO Cam HALO is available for purchase from April 2025, with configurations starting at 6500GBP.

Commenting on the launch, Paul Newbatt, Group Sales and Marketing Director at Vision Engineering says “We are delighted to bring EVO Cam HALO to market, confirming our reputation for innovation, whilst improving the inspection performance available within digital microscopy. 4K image quality plus fully controllable lighting and flexible software available in multiple configurations means that our customers in a wide range of sectors can easily choose the most accurate and consistent

HALO’s key features include 4K resolution which reveals previously obscured details with remarkable clarity, ensuring nothing escapes the user’s view.

digital system for their inspection requirements.”

Vision Engineering Ltd is a global leading-edge designer and manufacturer of patented ergonomic stereo optical and digital instruments, used for inspection, manipulation, measurement, and

analysis of manufactured parts, by many of the world’s leading manufacturers and their extended supply chains.

Vision Engineering’s contract manufacturing division offers comprehensive contract manufacturing, design, and commercialisation packages, giving customers access to the latest technology, as well as a team of experienced designers and engineers.

Founded in 1958 and wholly Britishowned, Vision Engineering’s Global HQ, design, and manufacturing facilities are based in state-ofthe-art modern premises in Woking, Surrey, UK, with extensive manufacturing facilities in the UK and the US. Regional sales and tech support offices are located throughout North America, Europe, and Asia, supported by a fully trained network of distributors.

For more information, please visit www.visioneng.com/products/digital-microscopes/evo-cam-halo

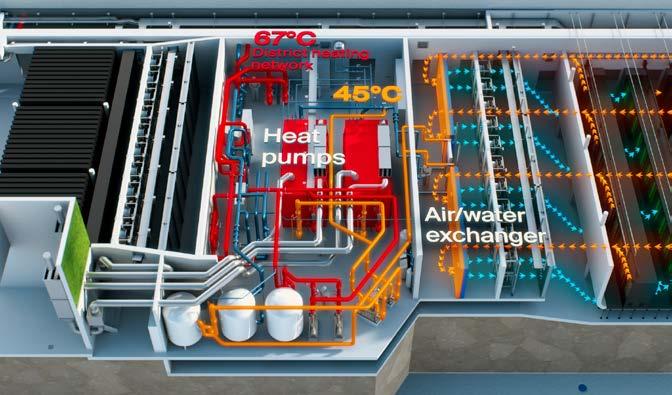

Officially inaugurated in January 2025, the Infomaniak data centre in Geneva, Switzerland sets a new benchmark in sustainable digital infrastructure. Uniquely located in a residential neighbourhood, this underground facility — built beneath a 150-apartment eco-district — has no visual impact on the landscape. Powered entirely by locally sourced renewable energy, it recovers waste heat and recycles 100% of the energy it consumes into usable thermal energy.

This project marks a key step in the regional energy transition, transforming a traditionally energyintensive facility into an active example of circular energy use.

Designed to accommodate around 10,000 servers at full capacity in the 1800 m2 basement area of a residential neighbourhood, the data centre operates with a highperformance waste heat recovery system enabled by Trane® XStream™ RTWF heat pumps. This technology plays a crucial role in recovering and converting the low-temperature heat

energy emitted by servers, inverters, ventilation, and other elements of the data centre infrastructure into a valuable resource for the nearby community. The use of heat pumps allows Infomaniak to utilise energy that would otherwise be wasted, enabling them to supply the recovered thermal energy to the city’s district heating network, enough to heat around 6,000 Minergie-A homes in winter or provide daily five-minute showers for 20,000 people in summer.

All the electricity consumed by servers, inverters, ventilation, and other components is entirely converted into low temperature heat, which is then boosted by Trane heat pumps and injected into the canton’s district heating network, providing hot water for thousands of households year-round. At full capacity the data centre generates an estimated annual output of 1.7 MW or 14.9 GWh. By using energy

that would otherwise be lost, the system helps avoid the combustion of 3600 tCO2eq of natural gas or 5500 tCO2eq of pellets per year. This also eliminates more than 200 heavy vehicle trips annually to transport the pellets, further reducing emissions and particulate pollution associated with vehicle fuel combustion.

This project serves as a practical, replicable model for sustainable energy practices within the data centre and technology sectordemonstrating the potential for information and communication (ICT) infrastructure to be seamlessly integrated with residential areas. Infomaniak has documented the full operation of this world-first innovation in open source, in collaboration with EPFL, IMD, and the University of Lausanne, as part of the E4S program on the website d4project.org

Infomaniak’s data centre cooling system operates without traditional chillers, relying instead on two innovative modes that eliminate the need for conventional mechanical cooling and reduce environmental impact.

In normal mode, the heat generated by the servers is captured and upgraded by heat pumps, then fed into the district heating network. The cold released during this process is used to cool the servers, creating a highly efficient, circular energy system.

In backup mode, if the heat pumps are temporarily inactive (for example, when the heating network

cannot absorb the recovered energy), the system switches to direct free cooling using filtered outside air — with no active cold production involved.

At the heart of the energy recovery system are two Trane RTWF heat pumps, which raise the temperature or recycled low-grade server-heat from 45°C to 67°C in summer and up to 85°C in winter. This temperature range is required to match the specifications of the local district heating operator (Geneva’s Industrial Services - SIG).

Prior to installation at the site, the Trane heat pumps have been tested and performance-validated under rigorous laboratory conditions at Trane’s state-of-the art laboratory in Charmes, France. This testing confirmed their ability to deliver consistent performance even in demanding operating environments.

The Infomaniak data centre facility not only showcases energy recovery and reuse but also encourages a shift in how data centre efficiency is measured. In addition to Power Usage Effectiveness (PUE), the company advocates for Energy Reuse Effectiveness (ERE) and Energy Reuse Factor (ERF), which account how much energy is reused outside the facility.

Infomaniak’s founder and strategic director Boris Siegenthaler emphasizes: “Today, PUE is no longer sufficient in the face of the climate emergency. We must also consider ERE and ERF, which provide a more

This project marks a key step in the regional energy transition, transforming a traditionally energyintensive facility into an active example of circular energy use.

complete picture of how effectively energy is reused, for example to supply heat to which evaluates the energy actually consumed compared to that reused, and ERF, which measures the share of the total energy of the data centre reused for other uses, such as district heating. Together, these three indicators provide a more complete picture of true energy efficiency of digital infrastructures.”

The Geneva facility is aligned with national and regional sustainability policies aimed at reducing reliance on fossil fuels and increasing renewable energy integration. The project has received multiple accoladed, including the Swiss Ethics Prize and the Cantonal Sustainable Development Prize, acknowledging its contribution to climate mitigation and responsible innovation.

Currently operating at 25% capacity, the data centre is expected to reach full operational capacity by 2028

and continue its heat supply for at least two decades.

Trane’s Role in Energy Transition

Trane’s high-temperature and highefficiency heat pump technology is a key enabler of this transformation. Its application in Geneva demonstrates how even energyintensive data centre facilities can become contributors to clean, circular energy systems.

Lauri Salmia, Applied Portfolio Manager at Trane summarises: “With the exponential growth of cloud services, the volume of waste heat generated by data centres is increasing rapidly. This energy must be reused rather than lost. Leveraging existing technology, connecting these installations to district heating networks, and designing them with thermal recovery in mind, is essential. The Infomaniak site in Geneva demonstrates a model that can influence cloud infrastructure developments worldwide, proving that performance and sustainability can go hand in hand.”

Infomaniak Data Centre - Key figures

• Total area: 1,800 m2.

• Full server capacity: approx. 10,000 servers (200 x 47U racks).

• Average thermal energy output: 14.9GWh (1.7MW)

• Average PUE: 1.09 (EU average: 1.6 ).

• ERE and ERF: see online

• Heat pump system: 2 x Trane XStream™ RTWF with a total capacity of 3.2 MW.

• Linked solar power plant capacity: 130 kWp (364 modules).

The company - Food Technology Thielemann has developed a clever Vertical Slicer that can thinly cut the roasted poultry breast fillets while retaining their natural shape. Using slim, hygienic linear motors made of stainless steel from LinMot, the high-output vertical slicer has been kept simple in design for high energy efficiency and performance.

Meat is typically cut into strips by circular, sickle-shaped or oscillating blades but this is not suitable for poultry fillets. You need 14 blades acting in parallel to cut 10mm slides from a filet that averages 160 mm in length.

With circular blades, which are at least 2.5 mm thick, the total displacement would be 35 mm. The meat would get stuck between the blades or torn to bits.

Thanks to the LinMot linear motors, a precision linear cutting motion can be achieved with narrow blades resulting in a quality cut fillet.

The secret to maintaining the shape of the fillet while cutting thin slices is to hold the fillet in a carrier during cutting and transporting. The idea is based on the egg slicer which is the only way to successfully cut a hardboiled egg!

Thielemann found that the best way of cutting is to use linear oscillating blades. To drive them, mechanical

mechanisms would be large and complicated and pneumatic cylinders would be noisy and have very high energy consumption.

The best solution they have found is using linear electric motors from LinMot.

LinMot SSCP - Stainless Steel Linear motors.

The machine builder’s interest was piqued when LinMot introduced its new line of SSCP motors dedicated for use in the food products and pharmaceutical industries. They are made of 1.4404 stainless steel (AISI 316L), meet protection class IP69, and use FDA-approved polymer bearings.

The new motors include the variant PS01-23x160H-HP-SSCP-R20 (stator), which Thielemann selected for his new machine due to its extremely narrow form factor and high drive force. A total of seven linear motors are mounted in two offset rows above the product level.

“Their small diameter of 28 mm made it possible to position the motors so close together that we

get 10 mm thick slices without any sort of linkage,” says the company’s founder. There was even enough space to mount the motors in an enclosing metal tube.

Maintaining the shape to the consumer

The chicken breast filet to be cut up is placed in a product carrier with slits for the cutting blades. This is used to transport the meat along a conveyor chain to the cutting unit.

Once it leaves the conveyor, the product carrier is covered with a packaging tray, flipped over, and fed into a packaging machine to be sealed. This sequence ensures that the natural shape of the poultry breast remains intact while it is cut up and packaged, up to the point of consumption.

Huck® fasteners have long been a trusted solution in industries requiring high-strength, vibrationresistant fastening. These fasteners play a crucial role in ensuring structural integrity and safety in a wide range of applications and industries. Given their significance, many engineers and professionals frequently turn to search engines with technical queries about Huck® fasteners. In this article, we address some of the most commonly asked questions about these specialised fasteners.

What are Huck® fasteners?

Huck® fasteners are advanced fastening solutions designed to provide secure, high-strength joints that resist vibration and loosening over time.

What are the different types of Huck® fasteners?

Huck® fasteners come in various types, each designed for specific applications.

HuckBolts®: also known as LockBolts® are a two-piece, highstrength fastening system consisting of a pin and a collar, designed for permanent, vibration-resistant joints. They are installed using a swaging process, which eliminates the need for re-tightening, making it ideal for structural, transportation, and heavy-duty applications requiring superior strength and longterm reliability.

Huck® Blind Fasteners: are highstrength, one-sided (blind-side) fastening solutions used when access to the blindside of a joint is restricted. They provide vibration resistance, high shear strength, and consistent clamping force, making them ideal for aerospace,

automotive, rail, and structural applications where reliability and quick installation are essential.

Which industries use Huck® fasteners?

Huck® fasteners are widely used across multiple industries, including:

Automotive & Heavy-Duty

Trucks: Common in truck chassis, suspensions, and trailers for secure, maintenance-free fastening. They can be used in anything, including defence vehicles and F1 racing cars!

Railroad & Transportation: Applied in railcar construction and track infrastructure to withstand constant vibrations.

Construction & Infrastructure: Utilised in bridges, portable buildings and large metal framed structures for strong, permanent joints.

Solar Energy: Huck® fasteners are used in solar panel mounting systems to secure structures against wind loads and environmental stress.

Wind Turbines: Huck® fasteners are used in tower assembly, nacelles, and rotor components for secure, vibration-resistant connections.

Shipbuilding & Marine: Resistant to corrosion and extreme conditions, making them ideal for naval and commercial ships.

Manufacturing & Industrial Equipment: Used in a multitude of production lines for durable and efficient fastening solutions.

Aerospace: Used in aircraft assembly for their lightweight strength and vibration resistance.

If there’s a fastening requirement, Huck® fasteners have a solution.

How do Huck® fasteners differ from traditional bolts?

Huck® fasteners differ from conventional bolts in several ways:

Vibration Resistance: Unlike bolts and nuts that can loosen over time due to vibrations, Huck® fasteners maintain their hold, making them ideal for high-vibration environments.

Installation Speed: Huck® fasteners are installed using hydraulic, pneumatic and battery tools, making the process faster and more efficient than tightening a bolt and nut.

Structural Integrity: The swaging process of Huck® fasteners creates a permanent joint, eliminating the need for re-torquing or maintenance.

What installation tools are required to install Huck® fasteners?

Installing Huck® fasteners requires specialised tools. These tools include:

Pneumatic: Powered by compressed air, these tools are commonly used in high-volume assembly lines.

Hydraulic: Used for heavy-duty applications, providing more force for larger fasteners.

Battery-Powered: Offering mobility and flexibility for production and field applications.

Are Huck® fasteners reusable?

No, Huck® fasteners are designed to be permanent. Once installed, they cannot be removed without damaging the fastener. If disassembly is required, the fastener must be mechanically removed and replaced.

Reusing nuts and bolts can also compromises structural integrity due to thread deformation, fatigue, and reduced clamping force.

Torque relaxation and material wear increase failure risks, especially in high-load or vibrationprone applications.

For safety and reliability, engineering best practices recommend new fasteners to maintain precise tension and prevent mechanical failure.

How do Huck® fasteners compare to welding?

Many industries choose Huck® fasteners over welding due to the following advantages:

Speed of Installation: Huck® fasteners can be installed in seconds, whereas welding is time-consuming.

Consistent Strength: Welds can be inconsistent due to material variations and operator skill, whereas Huck® fasteners provide uniform strength.

Safety: Welding requires specialised training and safety precautions, whereas Huck® fasteners can be installed quickly with minimal training and risk.

No Heat-Affected Zones: Welding can weaken surrounding materials, whereas Huck® fasteners maintain the integrity of the structure.

How do you select the right Huck® fastener for your application?

Choosing the right Huck® fastener depends on several factors:

Load Requirements: Determine the strength needed for the application.

Material Compatibility: Ensure the fastener material matches or is compatible with the materials being joined.

Environmental Conditions: Consider factors like corrosion resistance, temperature, and exposure to chemicals.

Accessibility: Choose between blind (one-piece) or LockBolts® (twopiece) fasteners based on assembly constraints.

What are the maintenance requirements for Huck® fasteners?

Since Huck® fasteners create a permanent joint, they require little to no maintenance. Unlike traditional fasteners, which need periodic re-tightening, Huck® fasteners maintain their strength and integrity throughout their service life. However, regular inspections of the structure in which they are used are still recommended to ensure overall safety.

Huck® fasteners have revolutionised fastening technology with their strength, durability, and vibrationresistant properties. As industries continue to seek reliable and maintenance-free fastening solutions, the demand for Huck® fasteners remains strong. Whether you’re an engineer, technician, or procurement specialist, understanding the fundamentals of Huck® fasteners can help you make informed decisions about their applications and benefits.

How can Star Fasteners help with Huck® fasteners?

Star Fasteners UK Ltd is a leading distributor and expert in Huck® fasteners, offering comprehensive support to help you make informed decisions about their applications, benefits, and installation. Here’s how we can assist:

Expert Technical Advice: Our team provides specialist guidance

on selecting the right Huck® fasteners based on load requirements, material compatibility, and environmental conditions.

Product Range & Availability: We offer a wide selection of Huck fasteners, including LockBolts®, blind fasteners, and installation tools, ensuring you get the right solution for your needs.

Installation Support:

We supply pneumatic, hydraulic, and batterypowered installation tools and can provide training on proper usage for efficient and secure fastening.

Cost & Performance Optimization:

We can help to identify costeffective fastening solutions while ensuring long-term reliability in high-vibration and structural applications.

After-Sales Service: We provide ongoing support, maintenance advice, and troubleshooting to ensure your fastening solutions perform optimally.

Do Star Fasteners offer a tool repair and hire service?

Tool Repair Service: We provide comprehensive maintenance and repair services for installation tools, ensuring your equipment remains in optimal condition.

Tool Hire Service: Star Fasteners offers short- and long-term tool hire options, ideal for busy periods or specific projects requiring specialised equipment. We also provide service hire tools while your equipment is under repair in our workshop.

By addressing these frequently asked questions, Star Fasteners hopes to provide valuable insights for those considering Huck® fasteners for their projects. Their superior performance and reliability make them a leading choice for industries where strength and durability are paramount.

On 3 September 2025, interested parties and thermographers from science and industry will have the opportunity to learn more about the possibilities of thermography in the demanding field of research and development. At InfraTec’s user conference “Thermography Compact”, our speaker will describe the various applications of thermography.

Lecture: Thermography for Industrial Automation: Quality Assurance at the Highest Level

Participants get to know at first hand what technology is currently capable of, how camera technology is constantly developing and what evaluation possibilities the latest software offers. At this online event interesting measurement tasks will be presented – with a focus on topics from research and development.

At this cost-free thermography user conference, colleagues meet

for professional exchange and get to know innovative new products and system solutions from InfraTec. The insight into the methodology of experienced users will help the participants to better assess the potential of thermography with regard to their respective requirements.

“Thermography Compact – Enter the World of Infrared Technology”

Date: Wednesday, 3 September 2025 / Time: 02:00 PM – 05:00 PM (CEST)

Registration: www.attendee.gotowebinar.com/register/836201026709149272?source=PR-extern

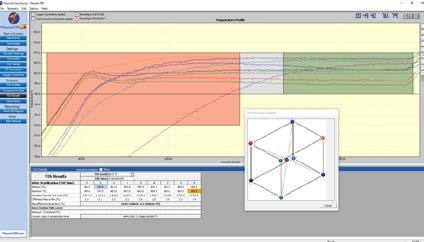

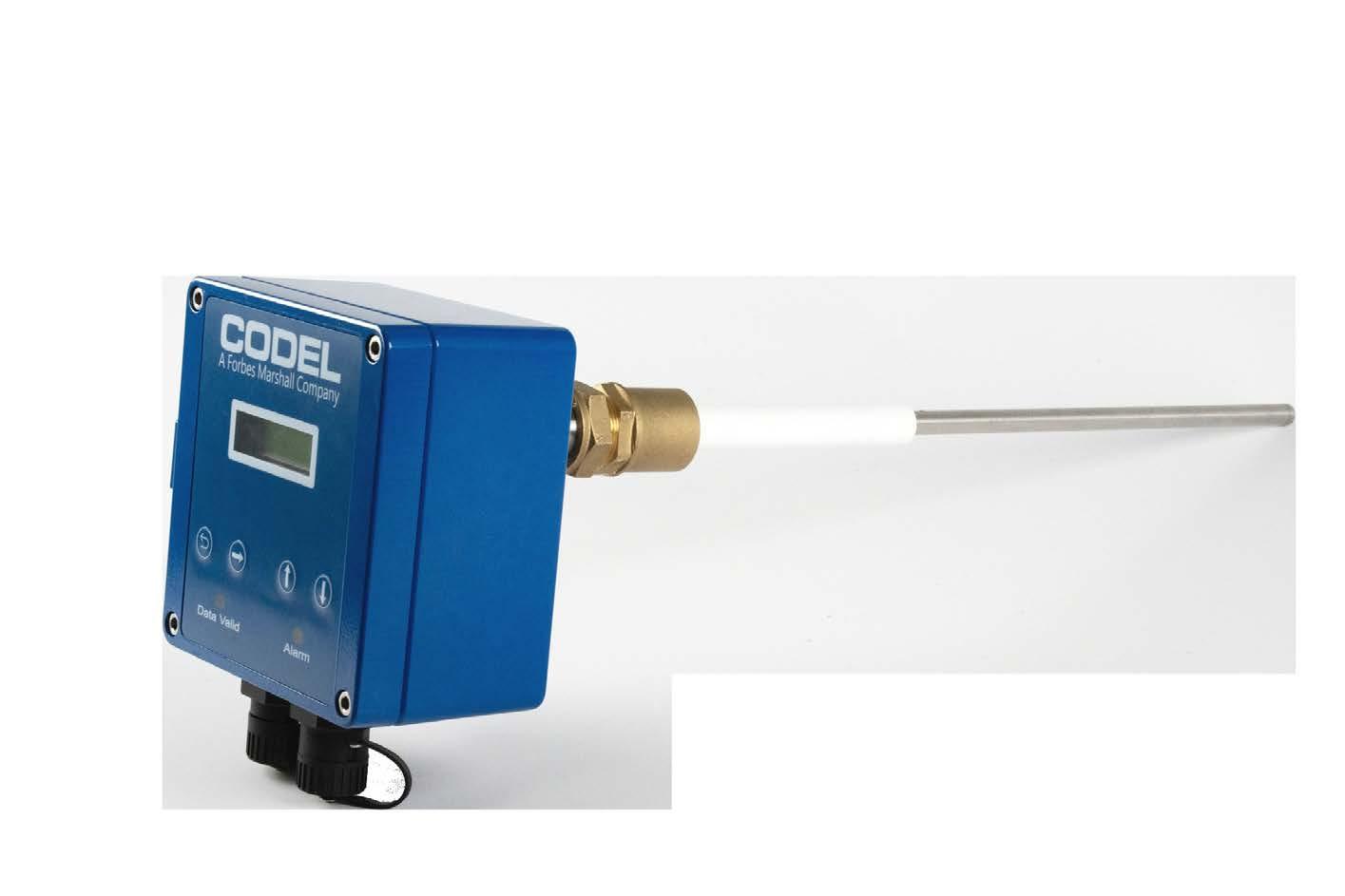

• No trailing thermocouples so quick, safe and effective

• Measure from up to 20 thermocouples with a single data logger

• Ideal for surveying semi-continuous, continuous or modular furnaces

• Live RF telemetry TUS data collection options

• Oil, salt and water quench thermal barrier options

• Efficient real time TUS of static furnaces

• Robust compact external data logger design

• Easy to transport and set-up

• Thermocouple type and plug connection options for quick installation

• Cold junction compensation to give accurate data in changing environmental temperatures

• Fully compliant with AMS2750 & CQI-9

• Full 0.1 °C / 0.1 °F resolution/readability

• Apply accurate data logger and thermocouple correction factors with ease

• Full control over real time data collection and TUS analysis

• Generate your complete TUS reports with efficiency and confidence

Chile’s Antofagasta Minerals progresses new project at Centinela mine with ABB Gearless Mill Drives

Antofagasta Minerals (AMSA) Centinela mine will soon deploy ABB Gearless Mill Drive (GMD) systems for its new copper concentrator project under construction in Chile. The advanced technologies are expected to enhance operational efficiency, deliver real-time insights, support informed decision-making and reduce unplanned downtime at the site.

The GMD systems, custom-designed by ABB, recently completed Factory Acceptance Tests (FAT) for the stators that will power the ball mill motors – responsible for the final

stage of ore size reduction in the process.

Manufactured in Bilbao, Spain, the stators were shipped to Puerto Angamos (Mejillones) and then transported to the Centinela Mining District. There, they will play a key role in the GMD’s electrical drive system by generating the magnetic field needed to rotate the ball mills.

These systems were selected with consideration for the harsh outdoor desert conditions. Each includes 27foot diameter ring motors with 19.6 MW of power (paired with a control block) and three cycloconverter

transformers, all designed to maximize performance.

One of the most important features of this technology in terms of efficiency and performance is its variable speed capability, which allows plant operators to respond more quickly to changes in ore composition. Process optimization functions will further enhance grinding availability and efficiency while reducing energy consumption and emissions.

“Antofagasta Minerals’ decision to adopt our Gearless Mill Drive technology marks a significant

will increase copper production by 144,000 tons per year and extend the mine’s life by at least 30 years.

Antofagasta Minerals’ decision to adopt our Gearless Mill Drive technology marks a significant milestone for ABB in the South American mining sector

milestone for ABB in the South American mining sector,” said Wilson Monteiro, Global Business Line Manag-er for GMD, ABB Process Industries.

With global copper demand expected to rise in the coming decades, the expansion of Centinela – known as Nueva Centinela – is a strategic priority for AMSA. The new concentrator

AMSA chose ABB’s Swissengineered GMD systems to boost plant productivity and leverage existing infrastructure.

Since every hour of downtime can cost mining companies hundreds

of thousands of dollars, minimizing these events is critical. According to the manufacturer, the new systems provide a broader set of real-time data to help prevent unplanned failures. Combined with ABB’s remote monitoring capabilities, operators will be better equipped to anticipate maintenance needs and make more informed decisions.

SRC North-West Limited are a well experienced, Greater Manchesterbased roofing refurb and Solar PV company, covering the entirety of the UK. We primarily work in the commercial & industrial sector, with different types of businesses ranging in size, in a wide range of industries, but commonly within the high energy usage sector, such as manufacturing, fabrication, engineering and printing.

As a business, we offer fully managed, turnkey solutions, that take away the stress of arranging the project and various components within it.

We have a demonstratable, proven and historic track record in delivering high value contracts covering multiple disciplines. Our main focus is on providing safe projects at great value, finished to the highest of standards and caliber.

SRC is unlike most, we are not just a Solar PV installer or a Roofing Contractor. From inception, we set out to be both, which often provides greater value for money and financial savings, instead of having to instruct two or more companies to carry out work. We manage the entirety of the project with one point of contact.

Given that often businesses are facing budgetary restrictions due to the rises we have seen in previous years, we are also pleased to offer the very commonly used £0 outlay option of having a PV system installed using a Power Purchase Agreement (PPA) which, if required, can also include roof repairs/refurbs within the package. This method is becoming more popular with large blue-chip companies due to the minimised risk.

They never once hesitated to go that extra mile in order to meet our clients expectations. Responsive , reactive and reliable - quite simply one of the best contractors I’ve dealt with in recent memory.

Jono Garton – CBRE

Commercial Solar Panels are becoming increasingly popular amongst businesses in the UK, with the benefits being a way to save money on energy bills, whilst reducing carbon footprint and assisting with sustainability goals.

With unpredictable energy costs, and growing pressures to demonstrate your green credentials, achieve Net Zero and your ESG commitments, installing Solar Panels can combat all points in one.

We offer free no-obligation site surveys and quotations to advise

on the available solutions and the efficiency of them, as well provide you with 3D-deisgn and full system output simulations.

To discuss the various funding options, and to see how they’ll suit your business get in touch using the details below or, why not come to visit our stand at the Advance Engineering Exhibition on 30th-31st October 2024, at stand F142.

You can contact us by:

Telephone: 0333 772 3015

Emai: Ryan@srcnwltd.co.uk

Linkedin: SRC North West LTD

Instagram: SRCNWLTD

For further information, please visit www.srcnwltd.co.uk

l Controlled Shot Peening

l Laser Peening

l Keronite PEO

l Thermal Spray Coatings

l Dry Film Lubricants

l Organic and Inorganic Coatings

l Parylene Ultra-thin Conformal Coatings

l Superfinishing

l On-site Processing

l Material Testing and Analysis

l FAA, AS9100 Rev D, NADCAP, ISO9001:2015

A leading US automotive supplier revolutionised its aluminium machining and cleaning process with HAKUFLUID® 185 and HAKUPUR 439-1, achieving cleaner parts, extended bath life, and improved sustainability.

Switching to HAKUFLUID® 185 a mineral oil-free, watersoluble coolant, eliminated oil contamination in the HAKUPUR 439-1 neutral cleaner bath, preventing re-contamination of aluminium die-cast housings. This ensured consistent cleanliness and longer bath life—extended from one to three weeks—while maintaining productivity.

Trials confirmed foamfree, stable cleaning baths, reducing maintenance and non-conforming parts. The plant further optimised efficiency by lowering bath

temperatures from 60°C to 40°C, cutting energy costs and enhancing biostability.

By embracing oil-free technology, the supplier not only met strict cleanliness standards but also significantly reduced environmental impact— setting a new benchmark for sustainable aluminium machining and cleaning.

www.kluthe.com

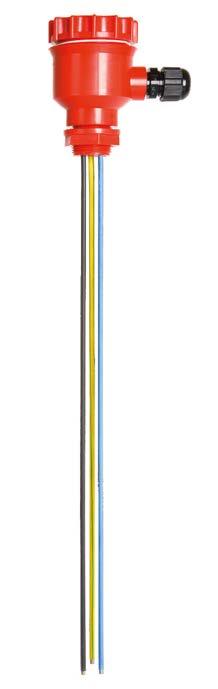

Introducing the Micronics UX5000 Clampon Flow Meter for use in Hazardous Environments. A high performance ATEX USM, made in the UK with a remarkably low price point.

ABLE, as Micronics’ exclusive UK representatives for the Model UX5000, are delighted to announce the arrival of a truly technically elite and commercially advantageous clamp-on ultrasonic flow meter.

The UX5000 flow meter uses a crosscorrelation transit time algorithm to achieve precise flow measurements. It generates an ultrasonic beam at a specific frequency, transmitting it between transducer crystals in two directions: first from the downstream transducer to the upstream, then reversing from upstream to downstream. As the liquid moves through the pipe, it slightly increases the speed of the ultrasound transmission.

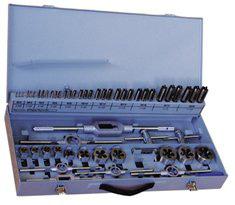

Penico Gauges Ltd (Precision Engineers) is the market leader in the design & manufacture of Mould Gauge Equipment

Converts surface grinders to rotary work

• Inclinable sine table for quick angle settings 0 – 45°

• Motor and Electronic Controller –Waterproof to 1P54 standard

• Variable speed control 0 -150 RPM

For further details contact Penico Guages Limited info@penico.com | 01274 511044 www.penico.com

This time difference, calculated as T1−T2, is directly proportional to the liquid’s flow velocity, providing an accurate measurement of flow rate.

Applications for the UX5000 are many-fold. The UX5000 is ideal for harsh, heavy duty industrial measurement of liquid flow in pipes. Being non-invasive and easy to install, it is particularly well suited to the chemical, water and oil industries.

Key Features:

• Non-invasive, efficient, and easy installation, no process downtime

• Cutting edge technology at its most affordable

• Certified for use in hazardous areas (ATEX)

• Reliable measurement accuracy – up to 0.5% with process calibration

• Separate Display (DCSIU) and Remote Measurement

• Unit (RMU) allows flexibility in installation

• Cost effective metering for harsh, heavyduty applications

• Single and Dual Channel Options

• Remote System Setup and Monitoring

Have a live application? Contact our flow specialists to book a demonstration.

2 days of networking

Josh Surga Manufacturing Engineer Rolls - Royce

5 free CPD accredited forums 1000s of innovative solutions

400+ suppliers

10,000+ engineering professionals

Co-located with

The UK’s largest annual gathering of engineering and manufacturing professionals is back and bigger than ever, and it’s not long until the doors open. Advanced Engineering 2025 returns to the NEC, Birmingham on 29 & 30 October, offering a powerful platform for the entire industrial ecosystem to connect, collaborate and chart the future of high-value manufacturing.

With over 400 exhibitors, including 130 new and 200+ expert speakers, this year’s show is poised to reflect the fast-changing needs of UK industry — from Net Zero targets and digital transformation to skills development and supply chain resilience.