MESSENGER

Look Inside:

Experience & Innovation: Why customers choose us

Project News: Solving production challenges during live operations

ASME Audit Completed - Certifications Reaffirmed

Look Inside:

Experience & Innovation: Why customers choose us

Project News: Solving production challenges during live operations

ASME Audit Completed - Certifications Reaffirmed

M. Davis is the leader you can trust.

A simple tinsmith business started by Edward R Davis in 1870 has evolved into M Davis & Sons, an Industrial Construction and Fabrication provider with over 450 employees and locations in DE, PA & MD

From the early days of working in the Delaware textile mills and breweries, through the Great Depression and into the decades that followed, the Davis family maintained a focus on providing excellent customer service, paired with craftsmanship, commitment and character.

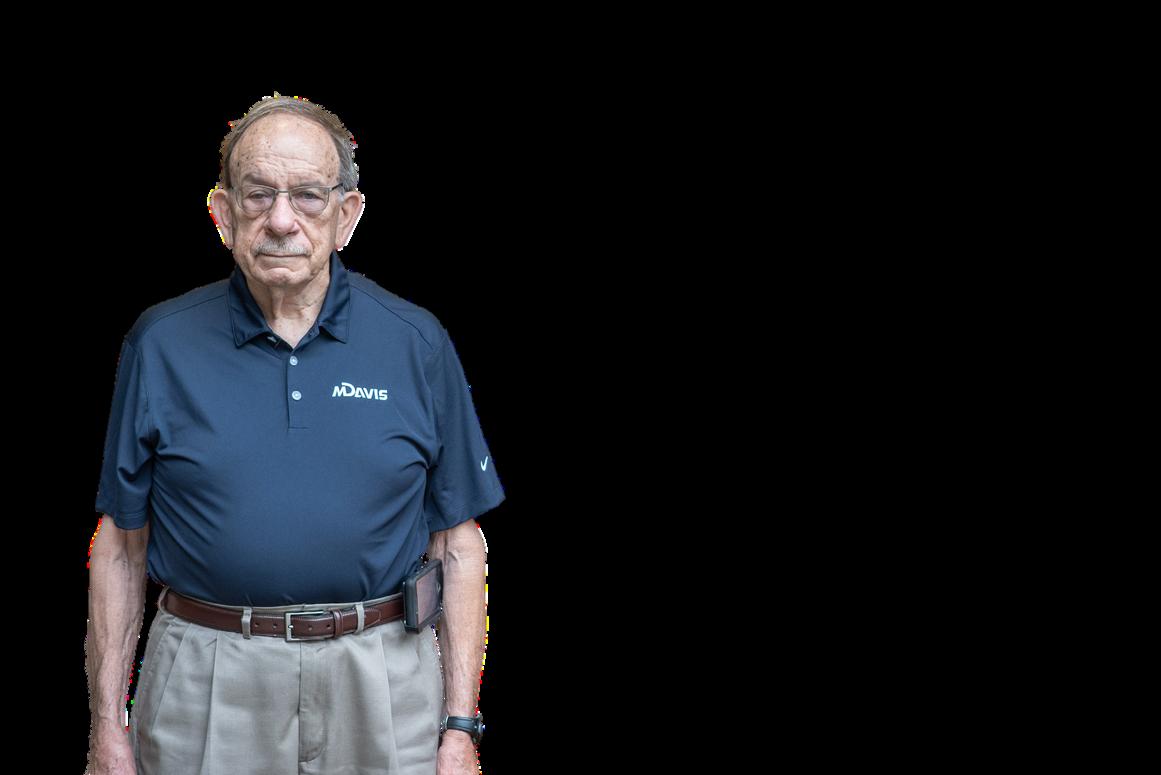

"Many times, over the years, there have been barriers to growth, but we have persevered and continued to grow," states

Charles Davis, Chairman and fourth generation of the Davis Family

In 2008, Peggy (Davis) Del Fabbro assumed the role of CEO and became the generation of the Davis family to lead the organization Through the leaders of the Davis Family alongside their executive team , the company has continued to evolve and innovate by expanding the services and products offered to their customers. A few examples are: the M. Davis Modular Fabrication shop started in 2000, the power distribution equipment manufacturing business (now known as VTi by MDavis) acquired in 2017, and, most recently, the formalizing of an Engineering Group in 2020

The wisdom that comes from over a century of experience can't be matched company's strong commitment to Safety and Quality, we have more than 50 customers Why do these valued clients keep returning to M Davis? Because we provide mechanical and electrical services, preconstruction and fabrication resources, and engineering assistance all under one umbrella. We work diligently to alleviate the stress associated with our clients' projects. We strive to understand our clients' needs and provide comprehensive oversight of projects to deliver an exceptional experience

As we honor the history M Davis has built and embrace the future, we remain committed to delivering value, solutions, and trusted partnerships for generations to come

Recently, the M Davis & Sons team played a significant role in the Dietz & Watson Baltimore Expansion a project that showcased innovation, precision, and collaboration under an aggressive schedule

The 30,000-square-foot addition was designed to enhance the company's high-volume food production capabilities while maintaining the existing facility's full operational capacity Working under general contractor Centurion Construction LLC, with ThermalTech Engineering and other partners, M. Davis was entrusted with the installation of the steam and condensate systems.

Timing was everything on this project. The early arrival of seven new oven cabinets set the pace for the entire expansion Mechanical, electrical, and process systems had to be installed in a precise order to keep the timeline on track

To coordinate the work among multiple trades, the team utilized 3D modeling, ensuring that underground piping, concrete flooring, and overhead systems could be built simultaneously without conflict. Crews worked extended hours and multiple shifts to meet the schedule, and the installation of a walkable ceiling became a game-changer allowing different trades to continue overhead work safely while maintaining access to the space below

True to M Davis’ reputation for innovation, the team found creative solutions to deliver greater value to the client

Partnering with AstroPak, they introduced a new method for industrial flushing and de-scaling of steam and condensate piping This improved performance, reduced downtime, and delivered measurable cost savings for Dietz & Watson

Working with Old Dominion Group, M. Davis also identified alternative insulation materials that maintained high performance standards while reducing material thickness cutting both material and labor costs

These innovative choices demonstrated how collaboration and engineering insight can drive efficiency and quality

---continued on next page

Mike Gilmartin CFO

One of the project's most significant challenges involved relocating four existing oven cabinets from the active manufacturing area into the new expansion all while Dietz & Watson maintained full production. To protect clean manufacturing zones, temporary walls were constructed, and process piping systems were rerouted, demolished, and reinstalled in a carefully planned sequence.

Maintaining operations in a live production environment requires constant communication, flexibility, and attention to detail. The team successfully delivered a seamless transition that met the client's stringent standards for safety, cleanliness, and product quality.

The Baltimore expansion nearly doubled Dietz & Watson's production capacity. For M. Davis & Sons, the project is a point of pride a demonstration of technical expertise, innovative problem-solving, and teamwork under pressure.

Don’t miss it: Delaware Careers special issue by Delaware Business Times!

M. Davis is a proud sponsor of the Delaware Careers supplement by Delaware Today Magazine. The issue is all about jobs, training and educational opportunities in the First State. Our very own electrician and instrument tech, Maria Dye, is featured (page 18) Her positive attitude, work ethic and willingness to learn has made her a valuable addition to our team Read more about careers in Delaware here: https://www.pageturnpro.com/Today-Media-Inc/112701-Delaware-Careers25/sdefault.html

“It’s extremely satisfying to build something tangible and prove my skills every day”, states Maria Dye.

Every 3 years, the American Society of Mechanical Engineers (ASME) and the National Board of Boiler and Pressure Vessel Inspectors conduct a comprehensive review of our operations. This triennial audit is required to maintain our ASME and National Board authorizations.

M Davis currently holds three stamps: R, S, and U. These stamps authorize us to perform fabrication, repairs, and alterations on boilers, pressure vessels, and heat exchangers While the stamps enable us to perform this highly specialized work, they are reissued after each successful audit, ensuring we always remain compliant

The audit is designed to confirm that our written procedures align with our actual operational practices Auditors evaluate:

Active Projects - Following a job from design to fabrication, with collaboration, quality checks, and weld inspections

Past projects - Reviewing jobs completed over the last 3 years to ensure consistency across all projects

Team expertise - Verifying skills, certifications, and records to ensure proper documentation throughout

This process ensures materials, welding, inspections, and records are all handled to the highest standards

At its core, the ASME audit is about Safety & Quality Each code requirement exists to protect people, facilities, and equipment By meeting and exceeding these standards, we highlight our commitment to safety on every project

Success comes from doing the right thing consistently, not just when someone is looking. That philosophy reflects the integrity that drives how M. Davis operates every day.

Our ASME Code Services team successfully completed the audit, reaffirming M. Davis & Sons' reputation for excellence in safety and quality. This achievement reflects the hard work and collaboration of our engineering, QA, and fabrication teams, ensuring every project meets the highest national standards.

This successful audit gives our customers confidence, knowing that every weld, inspection, and project meets standards, and is performed with expert craftsmanship

We are pleased to announce that 116 full time M Davis Team Members have enrolled in the State of Delaware Apprenticeship Programs in various construction trades!

Apprentices keep the pipeline of construction workers moving and we are excited to support the men and women who are taking serious steps in their craft

At M. Davis & Sons, we believe that supporting our community is just as important as supporting our customers. This quarter, our team proudly contributed to several local initiatives, including:

Sponsoring the American Heart Association Wilmington Heart Walk

Partnering with ABC Delaware for the annual Student Hygiene Donation Drive

Sponsoring the ABC Delaware Women in Construction Summit

Participating in the ABC Delaware summer BBQ at the Wilmington, DE V.A. Hospital for resident vets featuring food donated by The Well and Mission BBQ and live music

VTi by M. Davis is the brand name of power distribution equipment manufactured by M. Davis. The original business, Val-Tech, was acquired in 2017.

At VTi by M. Davis, our team of electrical engineers and electrical experts manufacture low voltage industrial electrical distribution equipment for customers in all markets. We ship globally to our customers.

We combine engineering, fabrication and testing expertise to provide compact, safe and state-of-the-art power distribution solutions. This line of equipment is designed for a range of applications including:

- In Plant Applications

- Temporary Power for Construction Sites

- Equipment for Critical Process Protection

All products manufactured by VTi by M. Davis are UL-listed and made in the U.S.A. Each product is fully customizable to meet your needs.

Used for high-speed clearing of branch circuit load faults

FDP-DC provides direct current in 24VDC, 48VDC, & 125VDC applications

Engineered, assembled and tested by us

Mission Statement:

Transforming the way the world views the industrial construction and fabrication industry by providing unparalleled craftsmanship and a safe, sustainable environment that allows our Team to have fulfilling careers.