Improving PCR Volume and Quality for your Packaging Applications

Scott Trenor, Ph.D.

Technical Director, APR

February 28, 2024

2023 The Association of Plastic Recyclers

©

Agenda

• Introduction to APR

• Recycling in US

• APR Design® Guide for Plastics

• Categorization and importance

• Label focused guidance from recycling collection to pellets

• Packaging design generalizations

• Innovations enabling circularity

Who is APR?

Who is APR?

APR is a US-based international non-profit and the only North American organization focused exclusively on improving recycling for plastics.

What Do We Do?

Our mission is simple: RECYCLE MORE PLASTICS to reduce waste.

APR Member Sampling

RECLAIMERS/RECYCLERS

AFFILIATES

Together, APR’s 300+ members span the entire value chain and shape the future of our industry.

• Reclaimers/Recyclers

• Brand Owners

• Retailers

• Converters

• Equipment Manufacturers

• Testing Laboratories

• Certifiers

• Label & Ink Manufacturers

• Resin Manufacturers

• Additives Manufacturers

• Researchers

• Technical Consultants

• And more!

View all APR Members »

APR Primary

Goals

Increase Supply

Ensure plastic gets into the recycling system and stays out of landfills and the environment

Enhance Quality Guide companies on design and processing to reduce contamination and improve recyclability

Expand Demand

Identify solutions to expand use of post-consumer recycled content and reduce extraction of natural resources

Communicate Value

Ensure policy makers and companies recognize the value of recycled content and the recycling process

APR Programs Are Circular by Design®

Together, we can reduce plastic waste and move towards a circular economy

APR Design® Guide

APR Global Design Catalog

APR Design® Training

APR Design® Recognition

APR Model Bale Specifications

APR Demand Champions

APR PCR Certification

Buyers & Sellers Directory

Policy Education

Policy

APR’s Policy Efforts

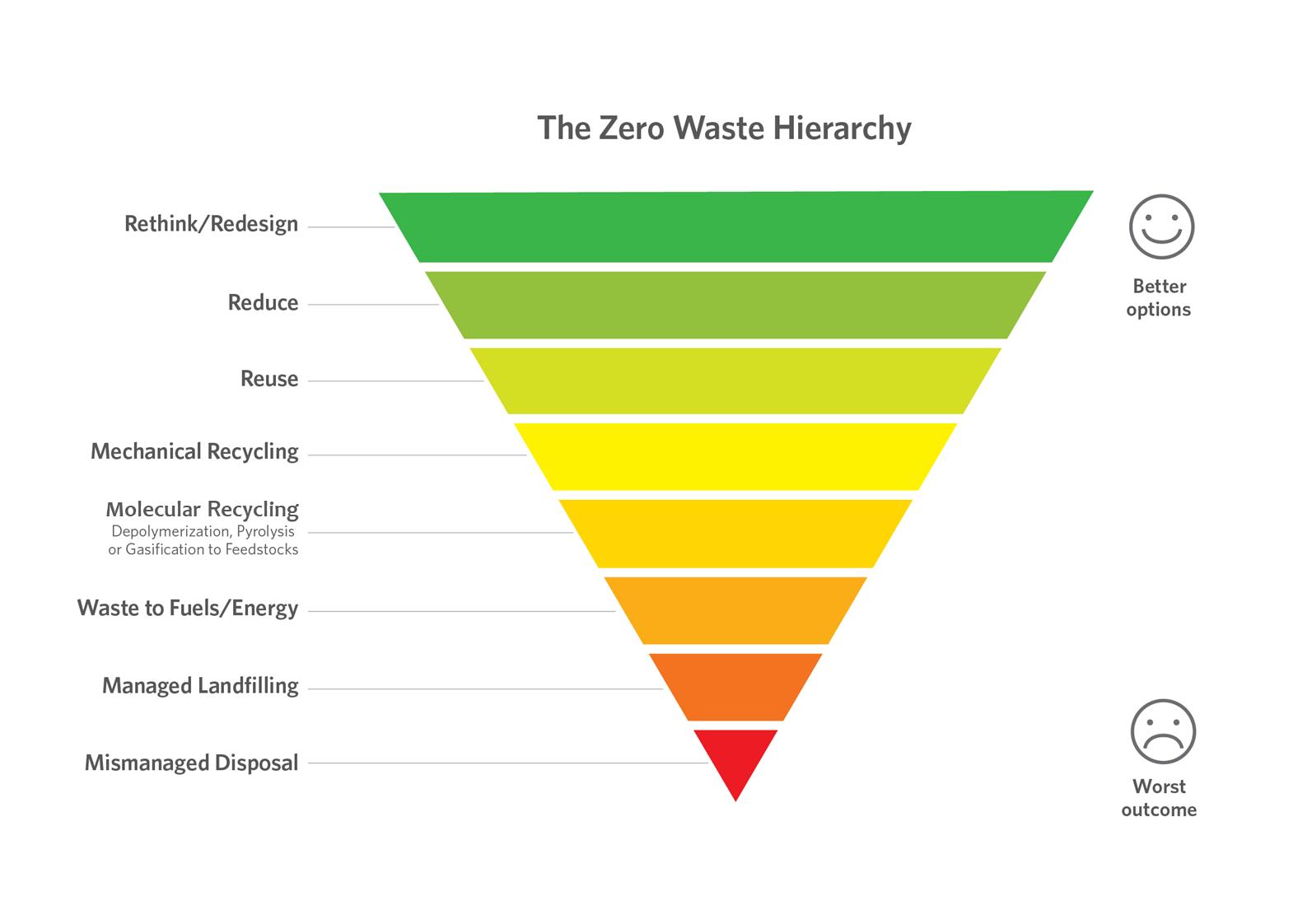

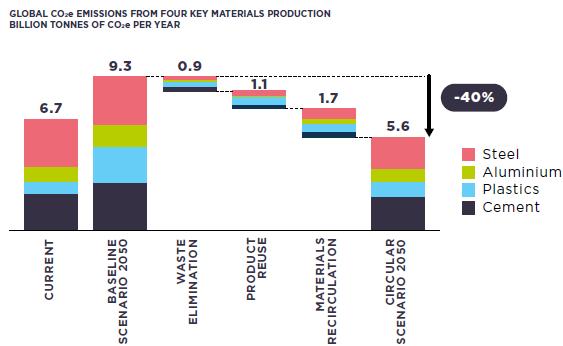

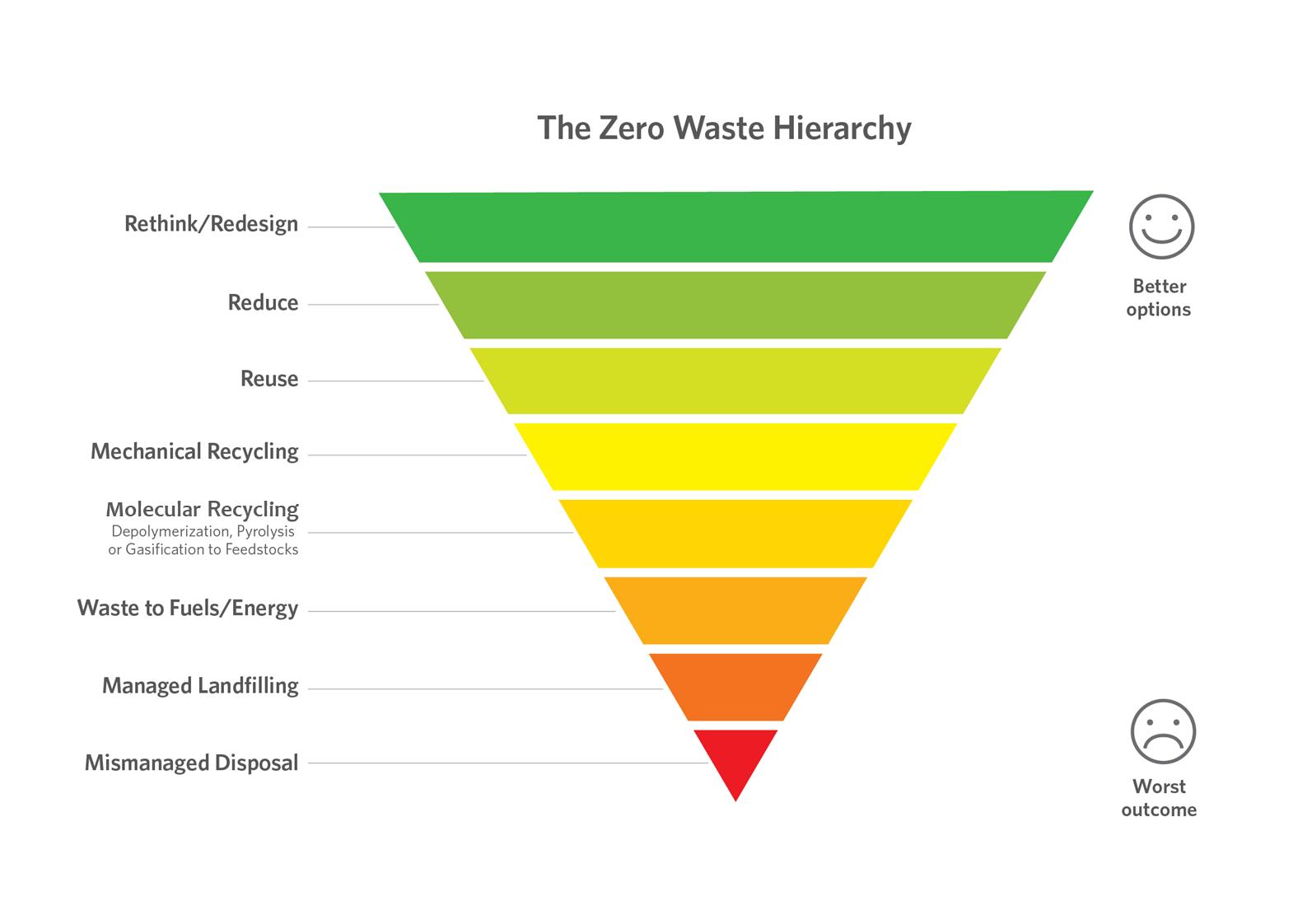

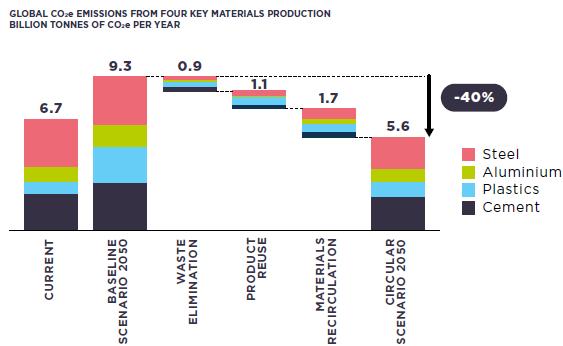

Reduction & Circularity Across All Materials to Reduce GHG Emissions

Better management is necessary1

Circulatory essential to reducing GHG emissions2

1: Stijn Billiet & Scott Trenor ACS Macro Lett. 2020, 9, 9, 1376-1390 2: Ellen MacArthur Foundation, Completing the picture: How the circular economy tackles climate change (2021)

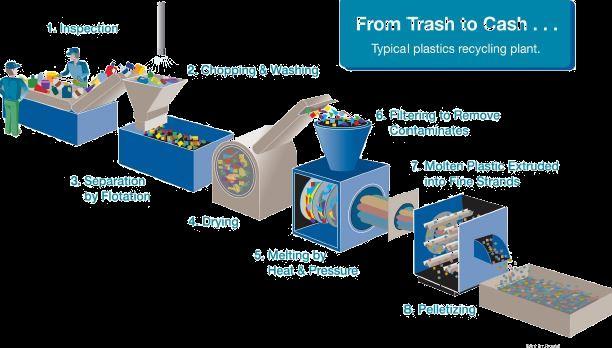

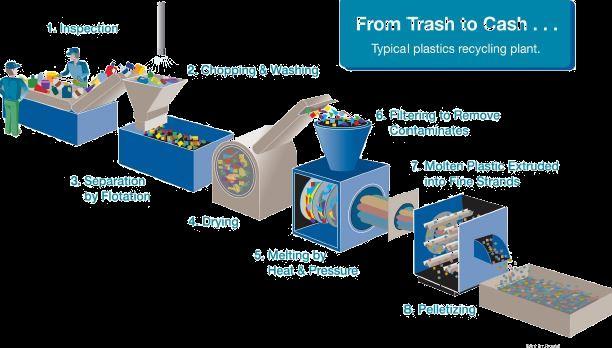

Mechanical Recycling – Smallest Loop & Lowest

https://albertaplasticsrecycling.com/resources-education/plastics-recycling-in-four-simple-steps/

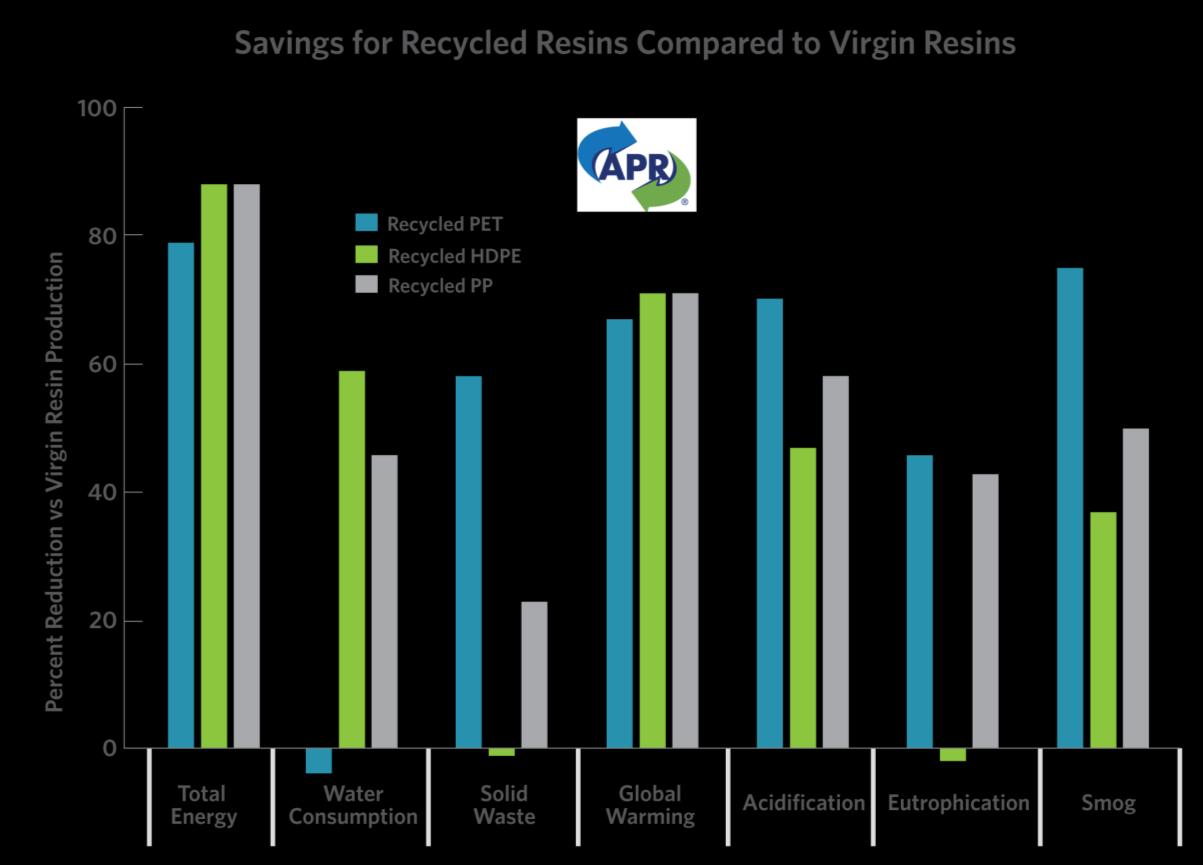

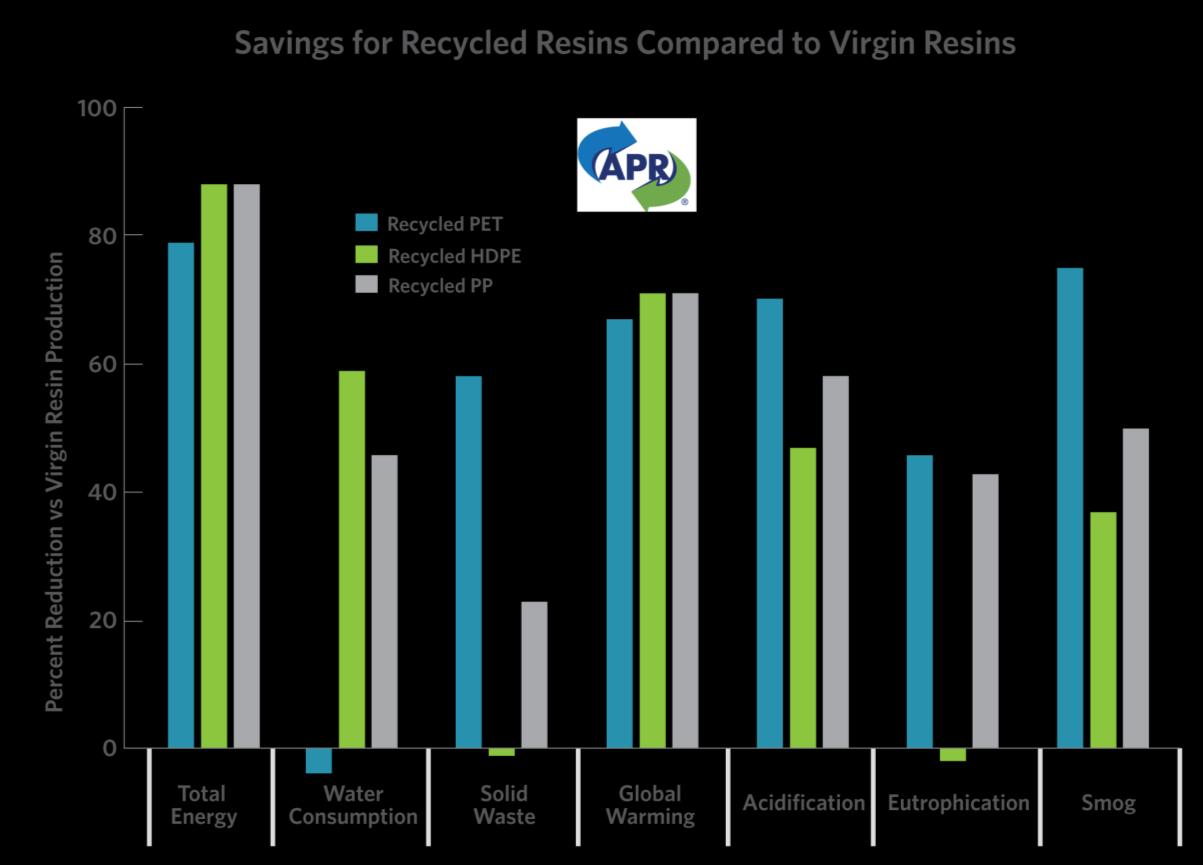

The Association of Plastic Recyclers; Life Cycle Impacts for Postconsumer Recycled Resins: PET, HDPE, and PP

GHGs 1.

2.

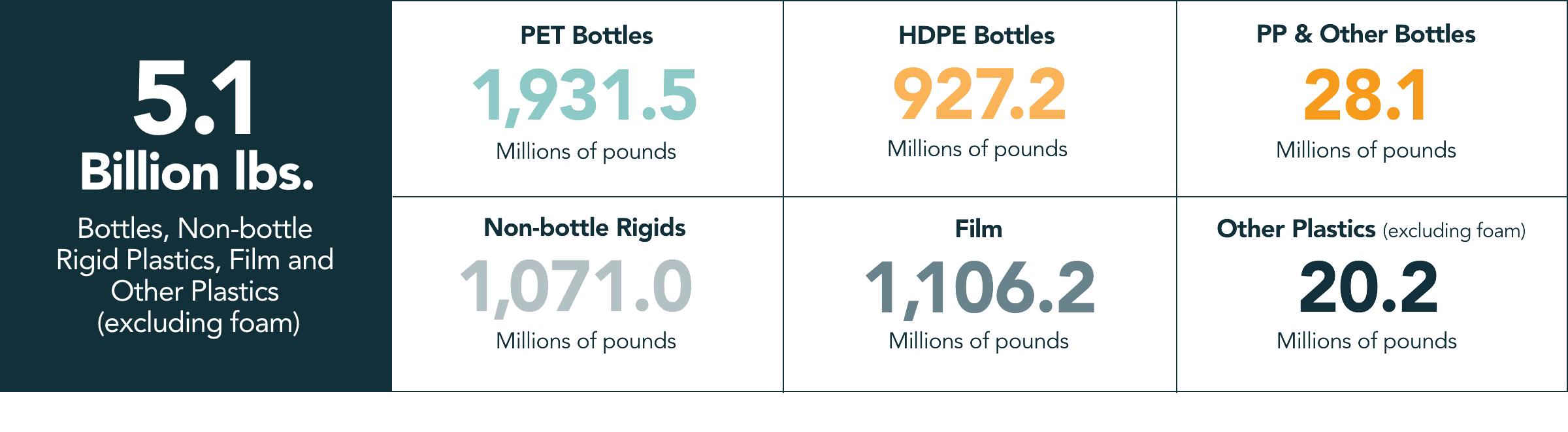

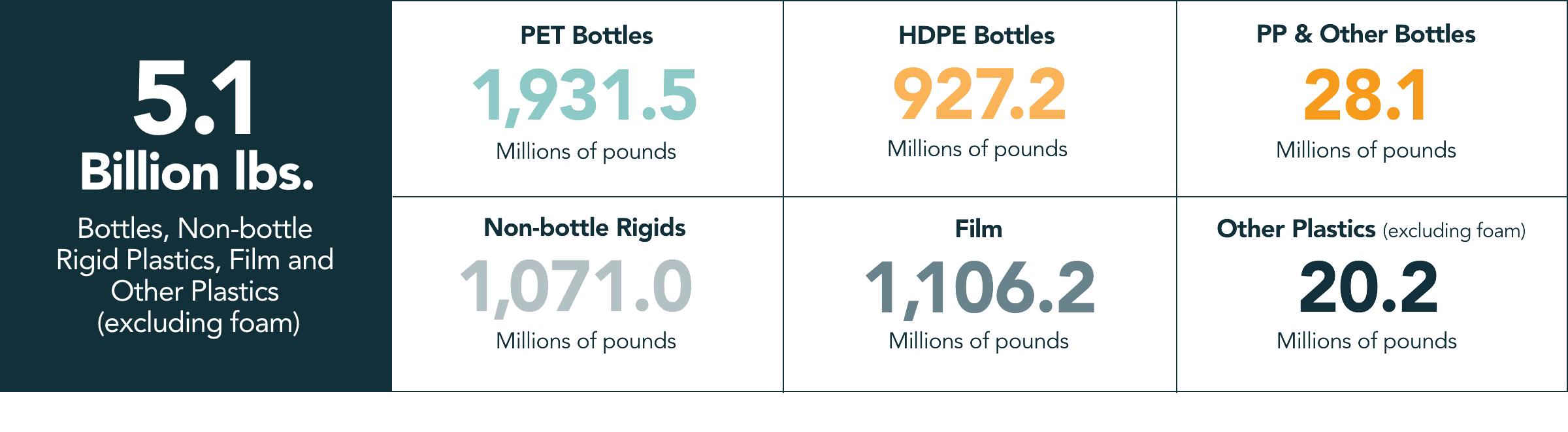

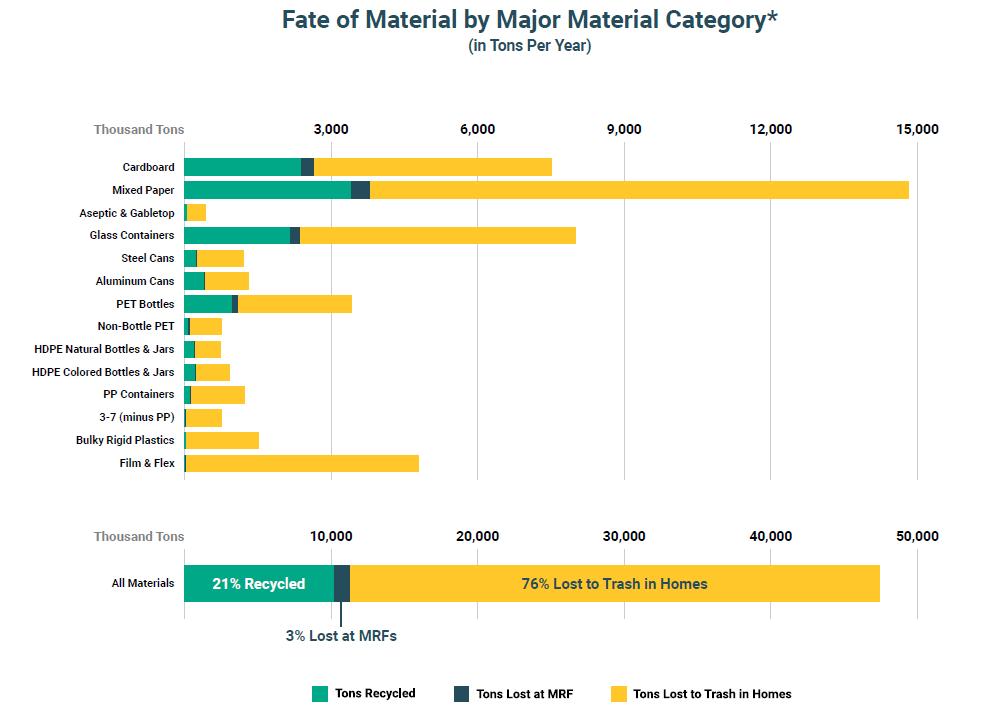

U.S. Sourced Post-consumer Plastic Pounds

Recovered for Recycling in 2021

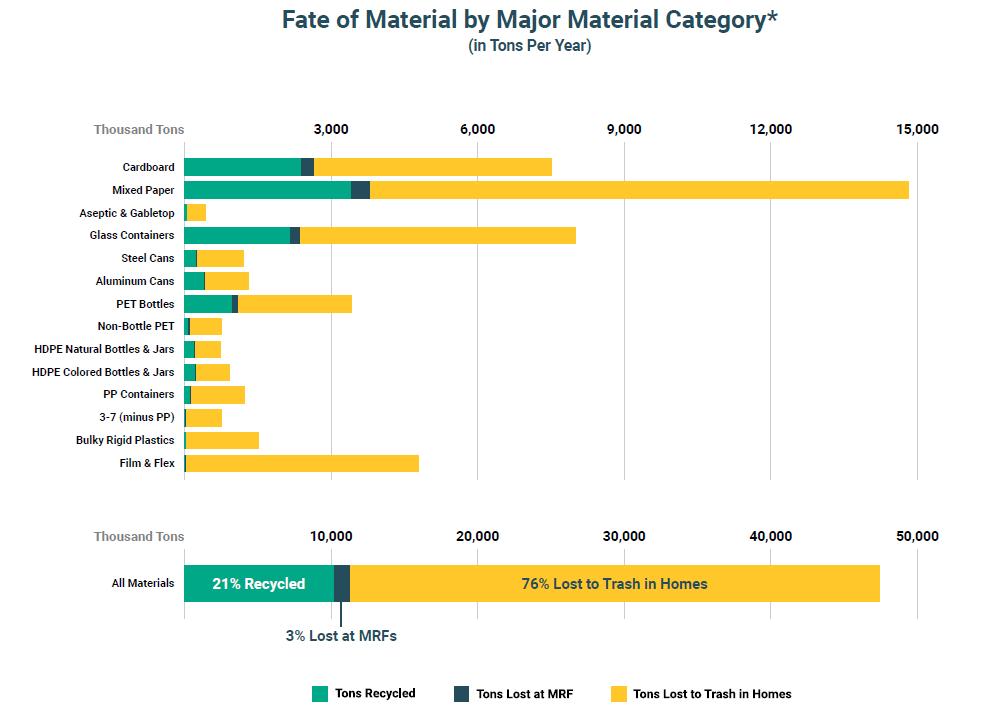

So Much More Potential

Feedstock The Recycling Partnership: State of Recycling The Present and Future of Residential Recycling in the U.S. 2024

APR Design® Guide for Plastics

Is my packaging recyclable?

The APR Design® Guide is your tool to ensure a package design is compatible with the North American recycling system.

To be considered recyclable*, companies must consider all the following criteria:

• Design for recyclability

• Consumer access to recycling

• Acceptance of a package in the recycling stream

• End markets for products made from the recycled plastic

Design

* For unqualified claims in the U.S., refer to FTC Green Guides

Access Markets

Acceptance

APR Guidance Covers Entire Recycling

Process: Collection to Pellets

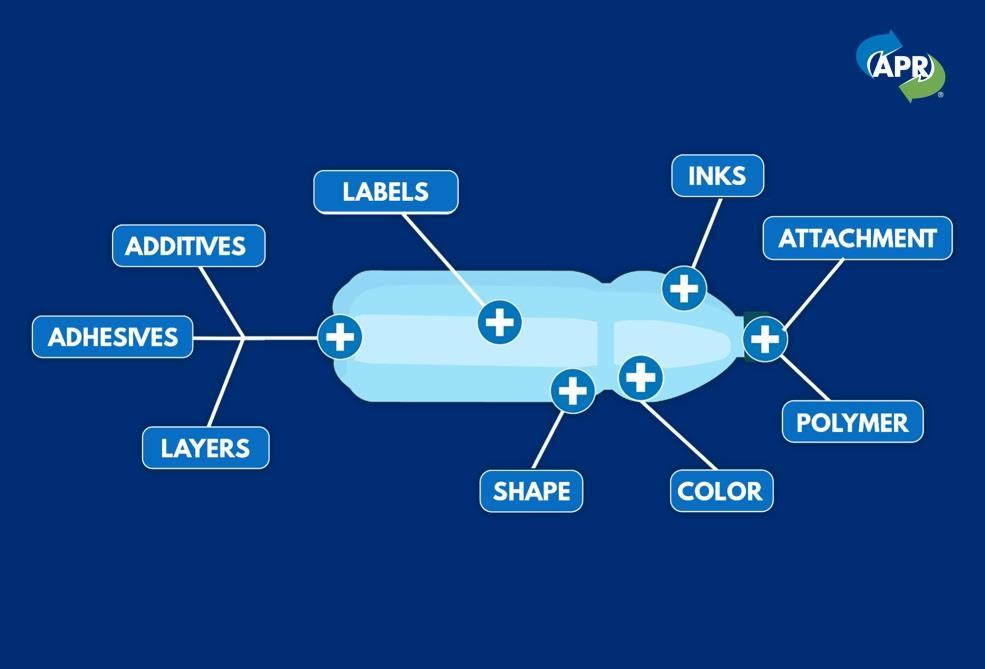

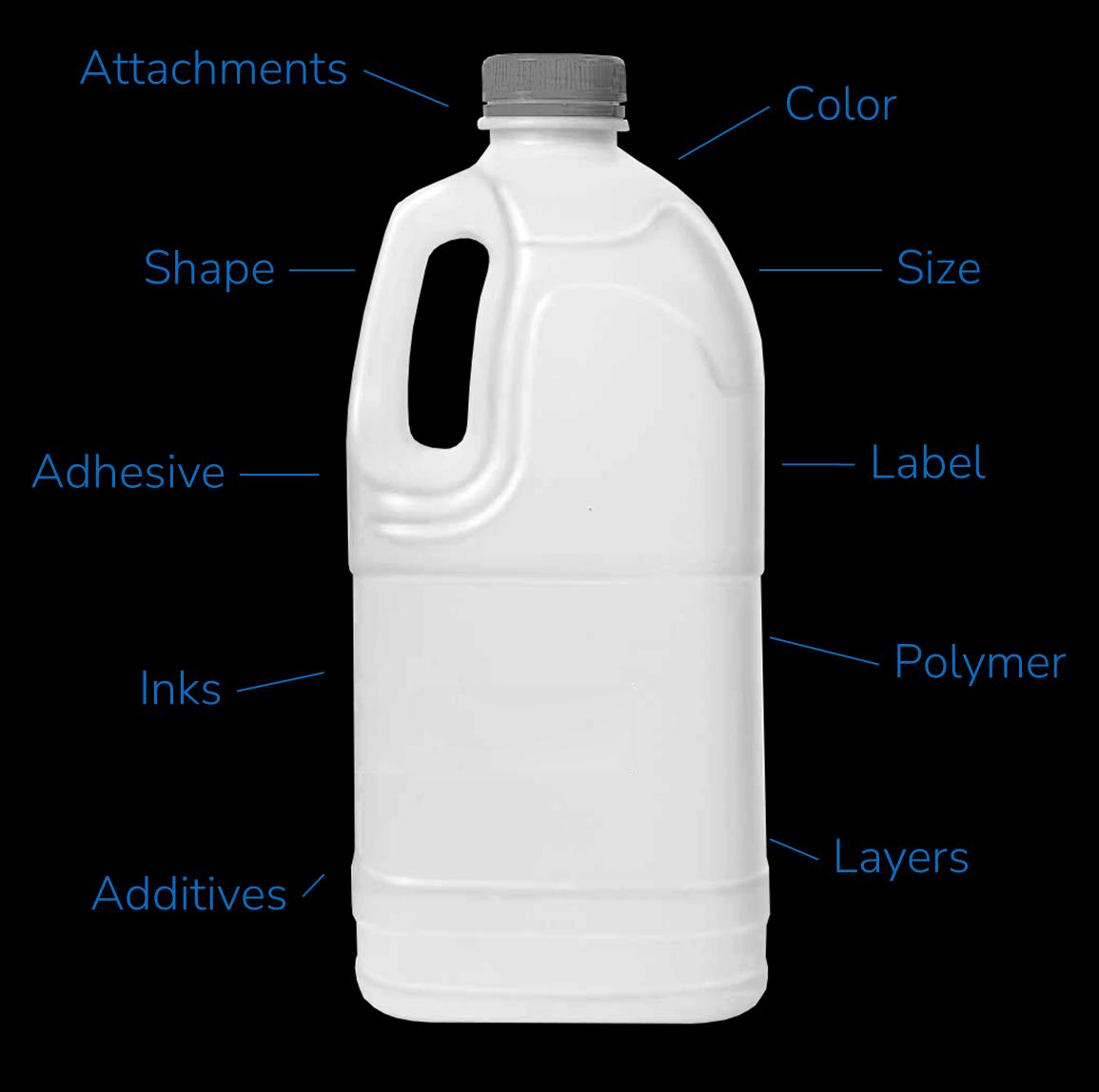

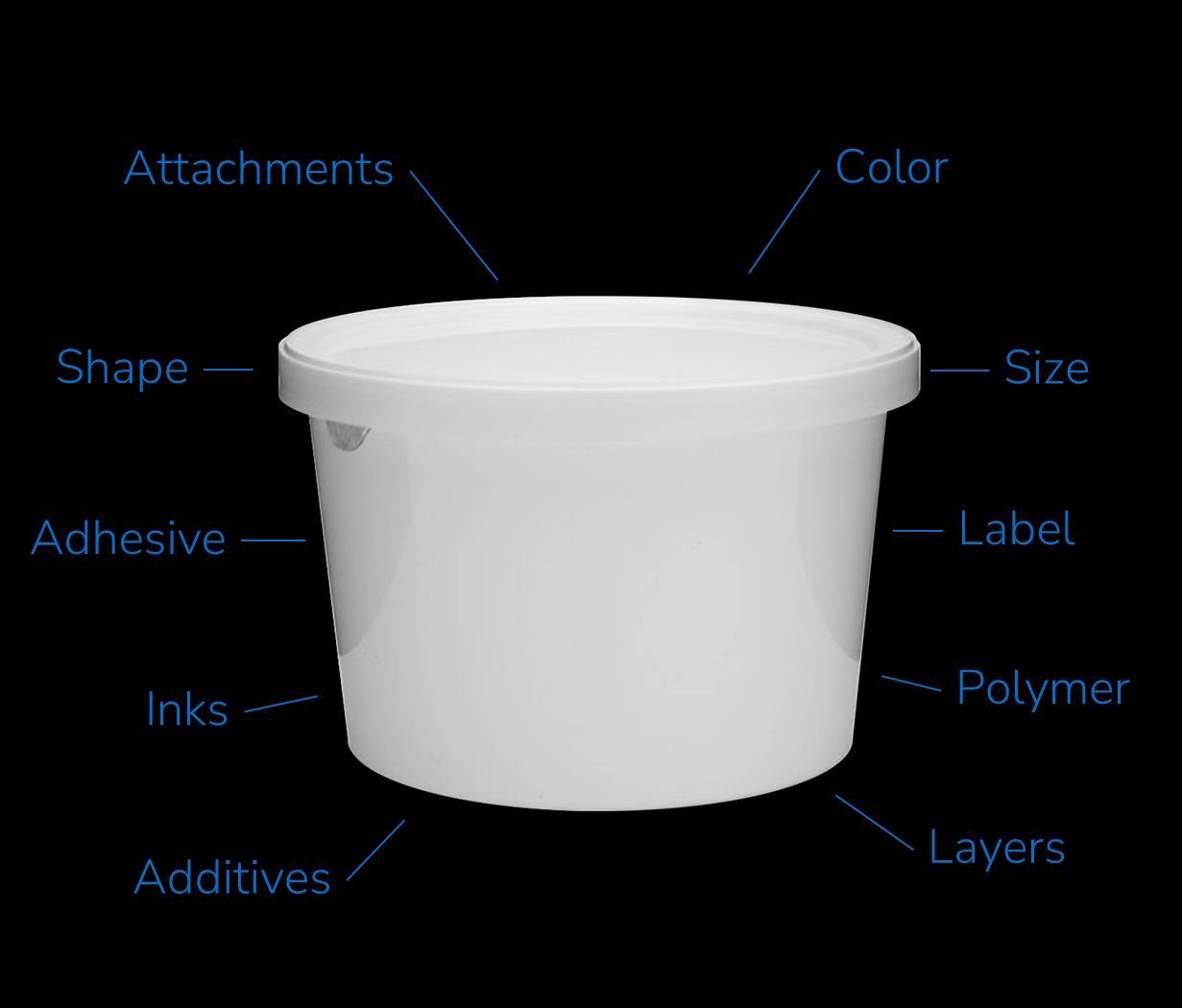

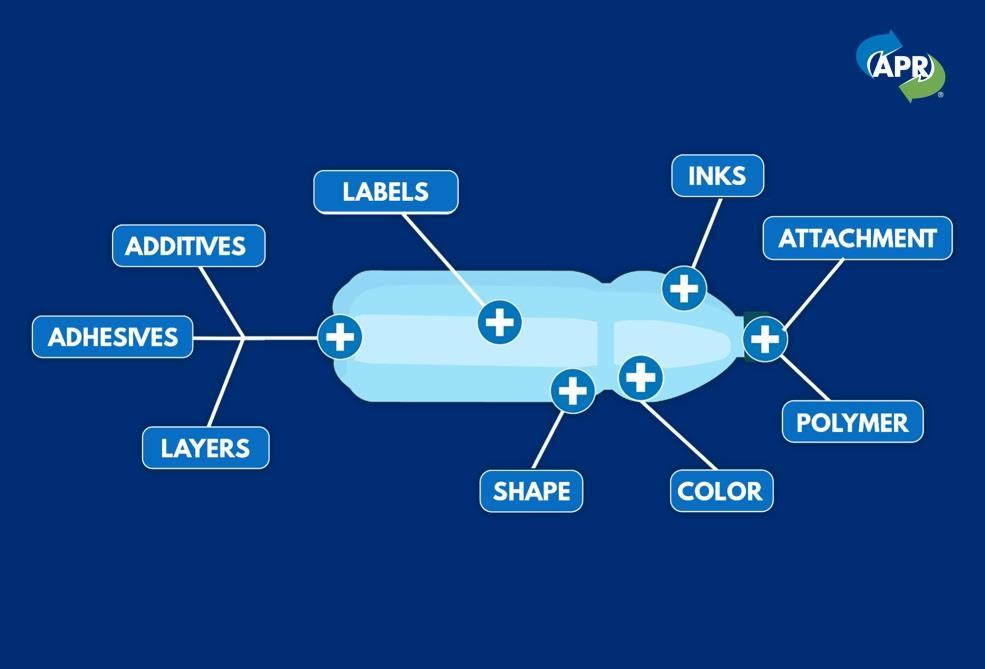

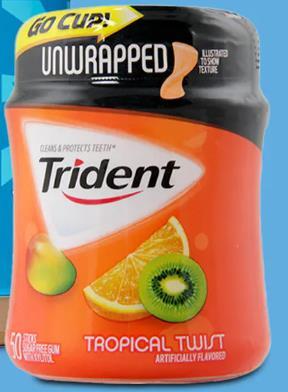

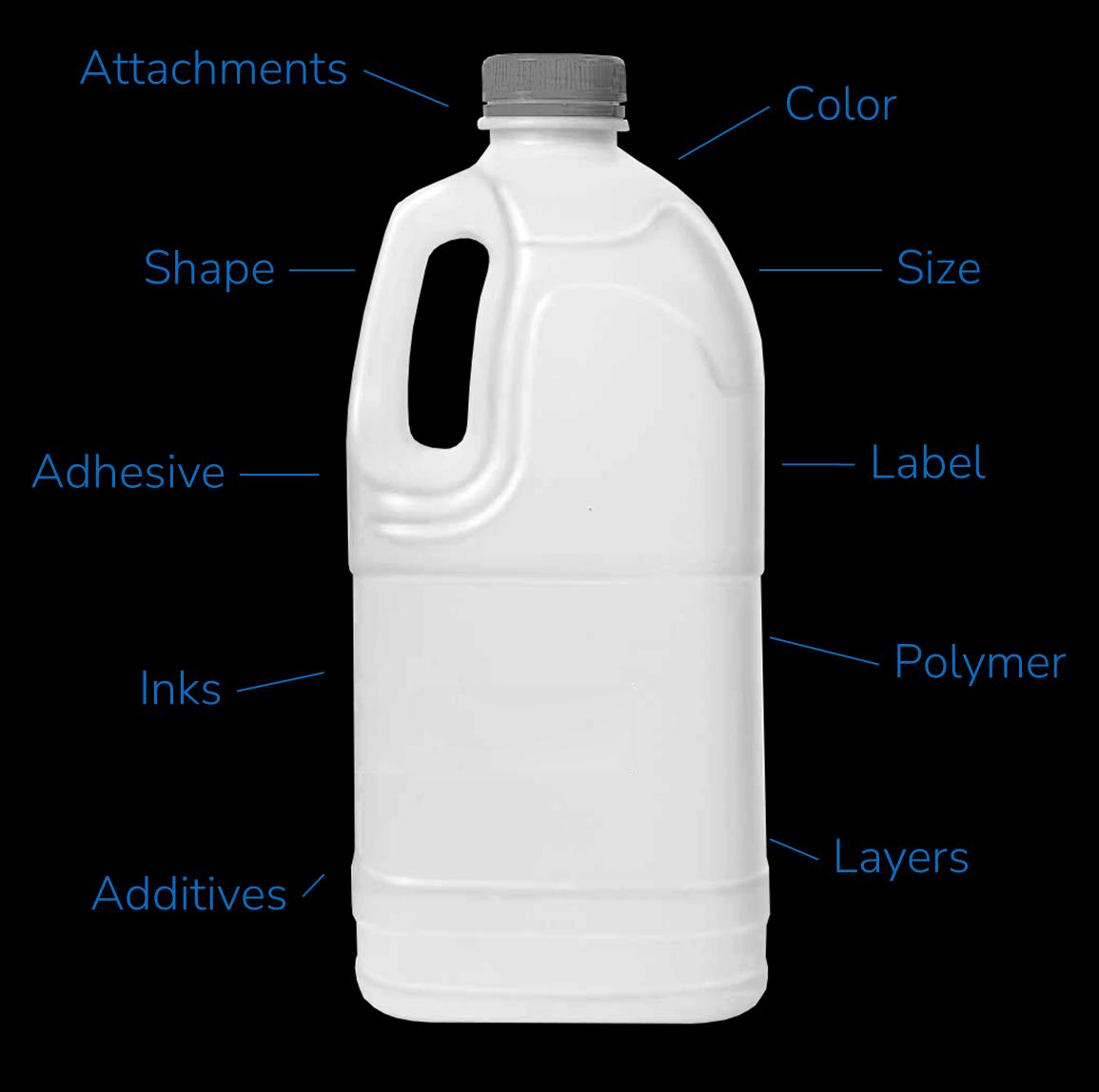

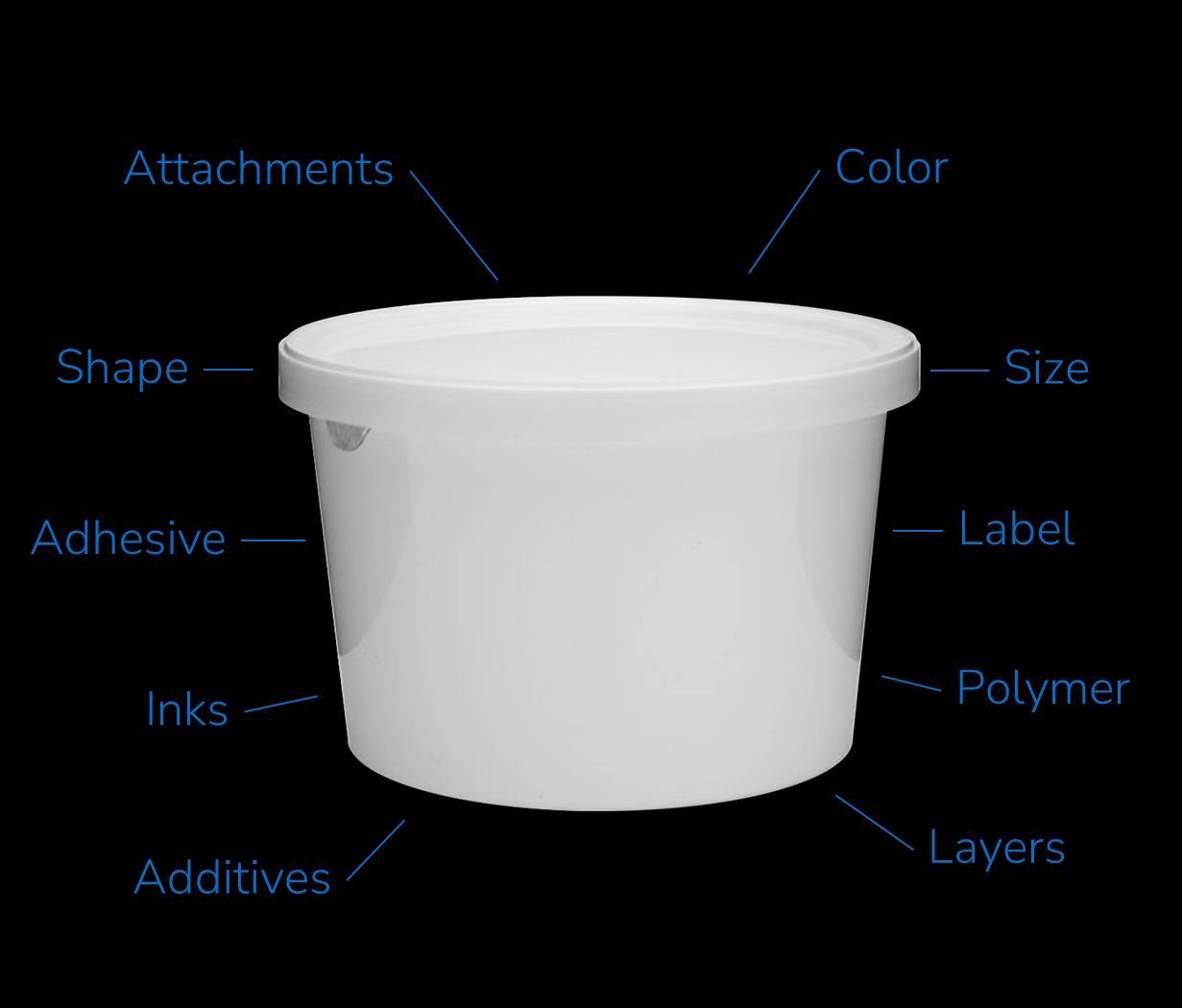

The APR Design® Guide views a package as a compilation of design features

Each design feature is classified into a recyclability category

APR Design® Preferred

Detrimental to Recycling

Renders the Package NonRecyclable

Requires Testing

Why is APR Preferred design important?

In a circular economy, consumer product companies are their own material suppliers. Companies benefit when their packaging is not only recyclable, but also yields high quality post-consumer resin (PCR). This is why APR distinguishes between Preferred and Detrimental features.

Companies whose packaging contains Detrimental features are reducing and lowering the quality of their own future supply of PCR. Improving features so that the entire packaging achieves Preferred Design for Recycling supports a healthy recycling system and increases PCR supply.

Preferred: recyclable with maximum quality and yield

Detrimental: recyclable but reduces yield and/or quality

Design Features Drive Whole Package Assessment

Design Features

Design features are classified according to the APR Recyclability

Categories or test results where testing is required.

Base Resin

Color

Dimensions

Closures

Labels

Adhesives

Inks

Barriers

Additives

Attachments

Whole Package Assessment

Preferred Design for Recycling

Tolerated but Needs

Improvement

Non-Recyclable

Pathway to circularity

Recyclable

TOLERATED

APR Alignment with Other North American Organizations

BUT NEEDS

DESIGN NON-RECYCLABLE

IMPROVEMENT PREFERRED

Recyclable by California Law

locally Widely recycled

Recycled

Check

Not Yet

CALIFORNIA & PRODUCT DESIGN

• CA Truth in Labeling (SB343): Four criteria to be labeled recyclable, including compliance with APR Design Guide

• CA EPR Program (SB54): Higher fees (ecomodulation) for products that are detrimental to recycling based on APR Design Guide

OCC NEWS OR LEDGER

BULKY RIGIDS

PAPER 2D

NIR WASTE MRF Sorting Steps NIR HDPE PET PP Fe Al Residue NIR NIR = Optional

GLASS

MIXED

3D

1-

Lg Size

–

3

Sm Size

2- Md Size

4- 2d3d

5- NIR

- Eddy IN NIR Alternate Fe location

6- Mag 7

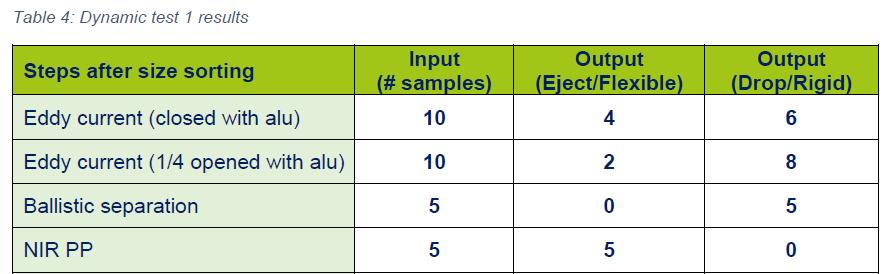

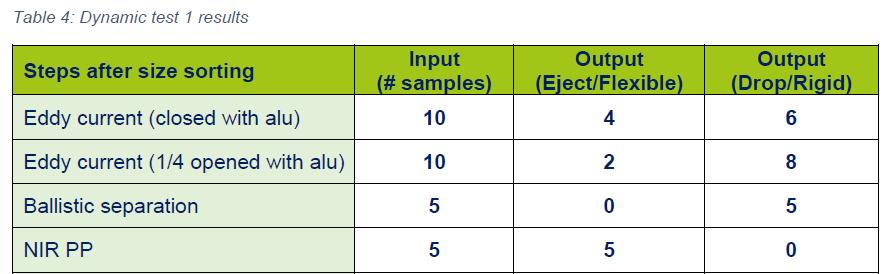

The APR Sorting Potential Protocols

Navigating Through the MRF

Note: More reliable than on-site MRF tests because

✓ They are designed to represent the average MRF

✓ They include the reclaimer sorting process

✓ They are repeatable

https://plasticsrecycling.org/sortation-nir-metals-size

•

•

NIR

Size

2D/3D •

• Metallic

Design Guide Generalizations for MRF

Survival

• Size

• < 2 gallons

• > 2” in 2 dimensions – otherwise requires testing

• 2 dimensional

• If one dimension of the uncompressed package is < 5cm

• If the package is anticipated to be compressed to less than 5cm

• Labels and coverage – must allow for accurate identification of underlying package

• Metal containing pigments, foils, components or metallization requires testing to determine how metal detector sees it.

• Dark colors

• Traditional black colorants prohibit proper sorting

• </= 10% NIR reflectance or L value < 40 requires testing

https://plasticsrecycling.org/sortation-nir-metals-size

APR Guidance Covers Entire Recycling

Process: Collection to Pellets

Reclaimer Unit Operations

• Sort entire articles (NIR & Color)

• Liberate components from each other

• Separate components into independent streams

• Cut articles into flake → pelletize

Copywrite APR – not to be used without express written consent from the APR or Common Sense Solutions

Labels & Reclaimer Unit Operations

Key is Ink / label / adhesive combination

• Sort → properly identify underlying container (NIR & Color)

• Liberate → full bottle wash, wet/dry delabeler

• Adhesive→ designed to enable desired fate

• Separate → sink/float or elutriate

• Ink → retain or release basis label fate

Ejected Flake

Poorly Designed Labels Reduce Quality & Yield

Primary component:

Flake with pressure sensitive label

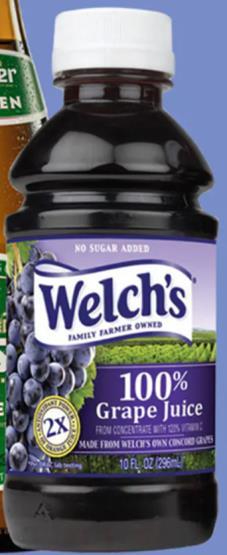

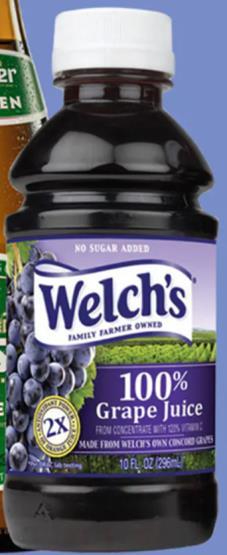

Impact of Paper Labels → Always Detrimental

PET Design Guide

Generalizations

• Color

• Clear, transparent light blue or transparent green – Preferred

• Other colors detrimental

• Not recyclable if not NIR sortable

• Closures: PP or PE

• Labels (meet sorting requirements) +

• Direct print that flakes off

• Pressure sensitive – floating polymer + recycle friendly adhesive + ink that adheres to label

• Wrap around – floating polymer + hot melt adhesive + ink that adheres to label

• Paper is detrimental

• Shrink sleeves

• PO + ink that adheres to label

• CPET + wash off ink

• Pumps/triggers – all plastic made of PE, PP, TPO etc.

https://plasticsrecycling.org/pet-design-guidance

• Color

HDPE Design Guide Generalizations

• Natural & white have most value

• All colors allowed if NIR sortable

• Closures: PE best or PP – limit total PP % to < 10 wt% of total package

• Density ≤ 0.97 g/cm3

• Labels (meet sorting requirements) +

• Direct print that flakes off

• In mold – PP or PP Preferred

• Pressure sensitive – Paper is detrimental

• Shrink sleeves – Any except PVC that allow bottle to be sorted

• Pumps/triggers: All plastic made of PE, PP, TPO etc.

https://plasticsrecycling.org/hdpe-design-guidance

• Color

PP Design Guide Generalizations

• Natural & white have most value

• All colors allowed if NIR sortable

• Closures: PP best or PE – limit total PE % to < 10 wt% of total package

• Density ≤ 0.97 g/cm3

• Labels (meet sorting requirements) +

• Direct print that flakes off

• In mold – PP or PP Preferred

• Pressure sensitive – Paper is detrimental

• Shrink sleeves – Any except PVC that allow bottle to be sorted

• Pumps/triggers: All plastic made of PE, PP, TPO etc.

https://plasticsrecycling.org/pp-design-guidance

Innovations

Enabling Circularity

• Replaces traditional aluminum lidding

• Allows for PP monomaterial packaging

• Decreases loss due to Al lidding

RECYCLING WORKS when

we all work together

FOLLOW OUR PODCAST Thank you! LISTEN © 2023 The Association of Plastic Recyclers Scott

scott@plasticsrecycling.org

Trenor