VOLUME 55 | NO 4 DECEMBER 2022 ISSN 1037-7107 Official Publication of the Institute of Materials Engineering Australasia Limited Trading as Materials Australia | A Technical Society of Engineers Australia www.materialsaustralia.com.au CONFERENCES APICAM2023 PAGE 17 LMT2023 PAGE 21 MISE2023 PAGE 27 UNIVERSITY SPOTLIGHT The University of Sydney PAGE 40 Online Short Courses PAGE 59 Powering The Future: Materials Science Paving the Way Towards Net Zero CL I C K A B LE L I N K S

Welcome to the December 2022 edition of Materials Australia Magazine

As for my previous messages, things continue to be extremely busy in materials science and engineering around Australia, and in fact globally. Some of the more unusual enquiries I have seen recently reinforces the idea of this message, that as an organisation we must aim to be not only the trusted voice of the materials community in Australia, but also the technical voice of the science and engineering of materials, and to share our expertise. It is sometimes easy to forget that sometimes our technical know-how, our competencies, capability and experience is invaluable to many within the wider community, who may benefit from what we can offer. It may be as simple as providing an interesting fact on a particular technological development, or it may be more significant, such as helping to solve a problem for an industry colleague who does not have the same technical background as our members might.

When we travel to conferences or materials research facilities and businesses globally we gain insights and information that we can share with our colleagues and peers. Sometimes we see some really eye opening developments where a particular problem or issue has been solved, overcome, or pre-empted. For example, recently I attended the Titanium USA conference in Orlando Florida, and was able to get a better understanding of how large aerospace companies are coping with the common problems of

materials shortages, energy prices, labour pressures and changes to the country of origin of many strategic products. Titanium supply has become a geopolitical issue. Many companies in the titanium sector maintain significant active inventories of titanium products for example, simply to prevent their machining shops from stopping work so that aeroplanes can continue to meet build target schedules. These large companies are also investing in recycling technology and its associated research, with a stand out example for me being the latest generation of electron beam hearth melting furnaces, which can recycle and refine even relatively low-grade titanium feedstocks so they can re-enter the aerospace manufacturing cycle. I also recently visited an industrial facility in Europe with a hybrid plasma hearth melting system that can produce extremely difficult to manufacture alloys of many different types with exceptional homogeneity, ensuring extremely high conformity across the products and processes for which they are used.

Another interesting piece of knowledge I came across recently, was during an OHSE induction at an aerospace manufacturing plant where it was noted that there was a ban on all ballpoint pens within the facility. I queried this out of curiosity, and was informed that some ballpoints may be made of hard materials that would be considered to be critically detrimental if they reentered a closed loop manufacturing system or supply stream for aerospace products, where they can act as a relatively significant inclusion. As it turns out of course, the aforementioned electron beam hearth melting systems and the hybrid plasma melting systems I saw separately, have the major advantage of being able to remove hard particles, carbides and foreign objects such as drill bits, taps, and pieces of

broken machining tools such that they do not enter the aerospace recycling metal stream.

Overall, I really believe we must strive to share our knowledge and experiences with our colleagues and peers, so that we can all benefit from the collective knowledge of our organisation. As we head into 2023, I would like to encourage everyone to consider attending Materials Australia technical events, conferences and symposiums, and if possible, to share the knowledge of their own expertise. Materials Australia has three significant conferences coming up in 2023, being Apicam and LMT in the middle of the year, as well as MISE towards the last quarter of the year. I also have to make note of the 16th Asia Pacific Conference for Non-Destructive Testing being hosted by the Australian Institute of Non-Destructive Testing to be held in Melbourne, late in February 2023.

On a different topic I am also especially pleased to note that Professor Ma Qian from RMIT University was recently awarded the Materials Australia Silver Medal for his career contributions to Materials Science and Engineering in Australia. This is the highest award that can be granted to a Materials Australia member, and follows on from a strong tradition of outstanding materials professionals being awarded this prize. There is a write up on some of Professor Qian’s achievements later in this publication and I would like to congratulate him on this outstanding achievement.

The year is over, with less than a month left, and I would like to wish you, your family, friends and colleagues the best of health and to stay safe. We all have a lot ahead of us in 2023!

Best Regards

Roger

Lumley National President Materials Australia

the President WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 3 MATERIALS AUSTRALIA MATERIALS AUSTRALIA CONFERENCE APICAM2023 21st - 23rd June 2023 The University of Sydney MATERIALS AUSTRALIA CONFERENCE LMT2023 9th -12th July 2023 RMIT University MATERIALS AUSTRALIA CONFERENCE MISE2023 29th - 31st October 2023 The University of Queensland

From

17 30 38 MANAGING EDITOR Gloss Creative Media Pty Ltd EDITORIAL COMMITTEE Prof. Ma Qian RMIT University Dr. Jonathan Tran RMIT University Tanya Smith MATERIALS AUSTRALIA ADVERTISING & DESIGN MANAGER Gloss Creative Media Pty Ltd Rod Kelloway (02) 8539 7893 PUBLISHER Materials Australia Technical articles are reviewed on the Editor’s behalf PUBLISHED BY Institute of Materials Engineering Australasia Ltd. Trading as Materials Australia ACN: 004 249 183 ABN: 40 004 249 183 Cover Image From feature article on page 44. Letters to the editor; info@ glosscreativemedia.com.au VOLUME 55 NO 4 DECEMBER 2022 Official Publication of the Institute of Materials Engineering Australasia Limited Trading as Materials Australia | A Technical Society of Engineers Australia APICAM2023 PAGE 17 LMT2023 PAGE 20 LMT2023 PAGE 27 The University of Sydney Online Short Courses Powering The Future: Materials Science Paving the Way Towards Net Zero L K A CONTENTS 4 | DECEMBER 2022 WWW.MATERIALSAUSTRALIA.COM.AU CLI C K A B LE L I N K S Reports From the President 3 Contents 4 Corporate Sponsors 6 Advertisers 7 Materials Australia News WA Branch Meeting Report - 12 September 2022 8 WA Branch Meeting Report - 10 October 2022 9 VIC | TAS Branch Report 10 VIC | TAS Branch ReportRobert C Gifkins Annual Lecture 2022 12 The Art of Science Communication Workshop 12 NSW Branch Report 14 Materials Australia Awards Professor Ma Qian their Highest Honour; the Silver Medal 15 NSW Branch Report 16 APICAM2023 17 QLD Branch Report - 2022 in Review 18 Materials Australia Education Chair - Alan Todhunter 18 Profile: Rou Jun TohPostdoctoral Fellow SEAM RMIT University 19 ARC Training Centre in Lightweight Automotive Structures (ATLAS) 20 LMT 2023 21 CMatP Profile: Andrew Gregory 22 Our Certified Materials Professionals (CMatPs) 24 Why You Should Become a CMatP 25 MISE2023 27

magazine

Materials

and

Australia

interested

not accept

those contributions,

Australia does not accept responsibility

claims

advertisers.

communication should be

Materials Australia National Office PO Box 19 Parkville Victoria 3052 Australia T: +61 3 9326 7266 E: imea@materialsaustralia.com.au W: www.materialsaustralia.com.au NATIONAL PRESIDENT Roger Lumley 45 40 39 CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU DECEMBER 2022 | 5 Industry News RAYMAX: Making Light Work for You 26 3 Ways Phenom ParticleX SEM Supports Additive Manufacturing 28 Scientists Supercharge Search for Key Ingredient of Next-Gen Lithium Batteries 30 For the Longest Time: Quantum Computing Engineers Set New Standard in Silicon Chip Performance 32 HRL Technology Group: What Makes Them Different 33 End-Of-Life Plan Needed for Tens of Thousands of Wind Turbine Blades 34 Hitachi: Inspiring the Next Generation of XRF Analysis 35 TENSOR –TEM Capabilities with theEase-of-Use of SEM 36 Optimising CT Systems for Large, Dense Specimens with Linear Detectors 37 How 3D Printing has Made Chemistry More Accessible for Visually-Impaired Students 38 Lastek: Photonics Technology Solutions 39 University Spotlight - The University of Sydney 40 Breaking News 44 Feature - Powering The Future: Materials Science Paving the Way Towards Net Zero 48 MA - Short Courses 59 https://www.materialsaustralia.com.au/training-courses-andworkshops/online-training Join Now! 60

This

is the official journal of

Australia

is distributed to members and interested parties throughout Australia and internationally. Materials

welcomes editorial contributions from

parties, however it does

responsibility for the content of

and the views contained therein are not necessarily those of Materials Australia. Materials

for any

made by

All

directed to Materials Australia.

6 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU MATERIALS AUSTRALIA

Corporate Premium Corporate Sponsors

MATERIALS AUSTRALIA Corporate Advertisers - DECEMBER 2022 GLOBAL STEEL HEAT TREATMENT WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 7 APICAM2023

WA Branch Meeting Report - 12 September 2022

Ron Cecil Lecture: The ‘Dos and Don’ts’ of Stainless Steel: A Panel Discussion

Stainless steels are widely used in industry, both for structural and pressure containing applications. Whilst they have proven to be of significant benefit and have provided superior performance when compared to other materials, they can also be vulnerable to failure if their properties and performance are not subjected to careful consideration during the design, material selection, fabrication and installation phases.

This year’s Ron Cecil Lecture featured a panel of experts whilst also welcoming contributions of experience, insights and questions from the audience. Many in the audience work regularly with the numerous grades of stainless steel, in design and engineering of equipment and processing systems, welding and installation or monitoring of their performance in asset reliability assessments.

To form the expert panel, Alistair Tawns (LMATS) was joined by Louise Petrick (Materials and Welding Solutions), and Stuart Folkard (Wood), both of whom have presented at Western Australia Branch meetings earlier this year.

Alistair’s 50 years' experience in materials started with his work as laboratory technician in the Royal Aircraft Establishment in Farnborough, focused on the then-new technology of carbon fibre composites. He then worked at DSIR in New Zealand on failure analysis. On returning to the UK, he continued his studies at the University of Leeds, where he gained his PhD on thermite welding of rails. After consulting work in the oil and gas industry in Aberdeen, he moved to Australia, taking on a role at Wood, and later at LMATS, where his expertise on thermite welding is still regularly called on.

Alistair started the meeting by presenting a failure analysis case study concerning leaking at the mechanical joints on a super duplex 2507 grade stainless steel pipe. Extreme pitting corrosion had occurred in-service at room temperature with slightly alkaline seawater. Applying a G48 ferric chloride test confirmed susceptibility to severe crevice corrosion, while microstructural analysis revealed intermetallic precipitates. The combination of susceptibility to pitting and precipitates had led to autocatalytic corrosion.

Alistair showed with time-temperature-transformation curves that the root cause was that the cooling rate during manufacture had been too slow – it had needed to be quenched within less that one minute. Ten years later, the result was failure in service.

Louise then spoke on welding of stainless steels and changes to AS 3992:2020 Pressure equipment welding and brazing. She highlighted issues of dissimilar metal welding in which chromium (ferrite stabilising) and nickel (austenite stabilising) equivalents are key factors, summarised in the Schaeffler diagram. Heat input and cooling rates are also critical. Local

depletion of dissolved chromium, either by dilution adjacent to the weld, or by precipitation of carbides in the solidifying metal, is liable to lead to localised corrosion.

Responding to the invitation to contribute from the floor, Bob Jensen passed around a failed swivel from a yacht anchor chain. This was stamped ‘316 stainless’, but it turned out that the bolt in the centre of the swivel, the part that had broken, was a lower chromium 200 (manganese) series steel.

This led to discussion of the importance of material certification, and questions as to whether procurement departments understand this. Examples of ‘type’ certifications were given, in which purportedly official certificates had been supplied for each order of material, but were all exactly the same, even though it was clear form other information that they had come from different heats and could not have been identical.

The panel and audience then turned to pitting corrosion, emphasising the importance of passivating the stainless steel surface after pickling. The observation was made that 70% of the life of the component subject to pitting corrosion is in forming the pit. Hence, ‘if you provide a crevice, you’ve already lost 70% of the potential service life!’

Stuart wrapped up the meeting by answering questions about cryogenic applications – austenitic stainless steels do not have a ductile-brittle transition – and also on high temperature use. He provided an interesting example of corrosion of exhaust stacks, in which ‘steady state is your friend’, as condensation is an issue when the gas temperature falls below the dew point.

All agreed that the meeting had succeeded in its stated objective of being an “interesting and stimulating opportunity for attendees to learn from the experts; bring and share knowledge and experiences; and to develop beneficial networks within their industry.”

MATERIALS AUSTRALIA

Source: Alistair Tawns (LMATS), Stuart Folkard (Wood), Louise Petrick, Materials & Welding Solutions

8 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

L to R: Stuart Folkard, Dr Alistair Tawns, Louise Petrick

MATERIALS AUSTRALIA

WA Branch Meeting Report - 10 October 2022

Site Visit to Duratec, Technical Laboratory, North Perth

Holloway, National Technical Manager, Duratec Australia

The Western Australia branch recently hosted a site visit to Duractec’s technical laboratory. Duratec Australia specialises in the protection, remediation and life extension of steel and concrete structures. The technical laboratory conducts investigations designed to establish causes of failures, quantify deterioration and to aid in planning and execution of its on-site interventions.

Liam Holloway (National Technical Manager, Duratec Australia) developed the laboratory as a commercial application of the research on nondestructive testing of concrete, which he conducted at Monash University in gaining his PhD. The facilities demonstrated included:

• Concrete petrography laboratory

• 3D reality model capture, delivery and online defect management

• Virtual reality spray painting training system

• Electrochemical and rebound testing of concrete and masonry structures

Concrete petrography, which uses geological microscopy techniques, is used to identify the constituents of the cement paste, classify the aggregate or sand type, map crack and microcrack patterns, identify secondary deposits and much more. This is used to determine which deterioration mechanisms, such as alkali-silica reaction, delayed Ettringite formation, sulphate, acid or soft water attack.

One particularly interesting application is in heritage building conservation, for matching historic mortars and renders. From the petrographic and wet chemistry data, the percentage of portland cement, hydrated lime and sand in the existing mortar is calculated aiding in the mix design for remedial mortars and renders to obtain the best match.

Liam followed the demonstration of petrography with a demonstration of 3D reality model capture, using two examples: the old Fremantle power

station and the Dampier Salt loading jetty.

In the case of Fremantle power station, the model is based on some 35,000 to 40-megapixel images captured by drones. These high-resolution images allow the recording of sub-millimetre features (closer to 0.1mm), and with some supplementary laser scanning, cover the entire external and internal surfaces of the building. It was impressive to ‘fly around the building approaching from a distance and zooming in to fine details of cracked lintels, and so on. This model was used to develop options for stabilising the property, which is rapidly approaching an unsafe state.

The model of the jetty was constructed from 70,000 images from drone boats and flying drones and includes the ability to tag features and defects to each image point. Broadly speaking, it provides the equivalent of ‘close visual inspection’ over the entire structure, including locations that would be difficult to for a human to reach. The model was used to prioritise

defects and to specify and price a $50 million contract. At the time it was made, processing the images took three months, but this is dependent of processing power and is reducing rapidly.

The next demonstration was virtual reality training for spray painters, using a commercial software package ‘Virtual Paint’. The software is also used for planning access intended work, as it can be interfaced with models of structures and scaffolding to confirm accessibility for going to site. The virtual reality headset and manipulators provided visitors with a great opportunity to explore a virtual world. It was so immersive that, for some, it took a bit of time to get reoriented with the actual world!

Other testing equipment on show included rebound hammers, resistivitybased rebar locators. Electrochemical testing for corrosion potentials was demonstrated in conjunction with recently developed hybrid anodes, which are now being introduced for protection of rebar.

Source: Liam

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 9

L to R: Dr Liam Holloway, Paul Howard

VIC | TAS Branch Report

2022 Vic/Tas Branch Borland Forum

Source: Rob O’Donnell

The Borland Forum honours the memory of Dr Doug Borland who made a significant contribution to the study and teaching of metallurgy and materials engineering during his long and distinguished career. The Forum showcases high calibre postgraduate students nominated by their tertiary institution, who give a short presentation on their materialsrelated research project. The top presenter receives the Borland Forum Award and a cash prize.

This year, the Borland Forum was hosted by Melbourne University and in particular by Professor George Franks, from the Chemical Engineering Department in the Faculty of Engineering and Information Technology.

Once again Victoria’s five top Universities were represented. The presentations were of a high calibre and represented a broad mix of materials research activities. The presenters and their respective topics included: University of Melbourne – Yang Cao: Multiscale Characterisation and SubNanometer Engineering of 2D Laminar Membranes

Swinburne University of Technology – Janitha Migunthanna Kariyakaranage: Low Carbon Binders to Replace Portland Cement in Concrete Using Geopolymer Technology

Monash University – Luke Sutherland: Highly Efficient and Roll-To-Roll Processable Perovskite Solar Cells Incorporating Printed Electrodes

Deakin University – Teejay Jeyachandran: Molecular Diagnostics using Micro and Nano Technology

RMIT University – Jiayu Ye: In-Situ Monitoring of Laser Metal Deposition for Additive Manufacturing Materials Australia members, postgraduate students and numerous friends and colleagues came from as far afield as Geelong and enjoyed networking and discussions over a selection of pizzas (always a favourite)

and refreshments. Our thanks go to our sponsors for the night for these refreshments: the ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation On Minerals.

Rosy Borland (Doug’s daughter) was joined by two other independent judges from the CSIRO and private industry to

determine the best presentation on the night. Whilst the competition was fierce due to the high quality of the science and presentations, the judges awarded the 2022 Borland Forum Award to Luke Sutherland of Monash University for his presentation on Highly Efficient and RollTo-Roll Processable Perovskite Solar Cells Incorporating Printed Electrodes.

MATERIALS AUSTRALIA

10 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

The Borland Forum winner Luke Sutherland with MA Vic/Tas Branch President Ivan Cole

All 5 Borland Forum presenters alongside MA Vic/Tas Branch President Ivan Cole.

gold nanoparticles screening chemicals uorescent microparticles 99.999% ruthenium spheres process synthesis cryo-electron microscopy transparent ceramics diamond micropowder alternative energy dysprosium pellets sputtering targets 3D graphene foam tungsten carbide refractory metals glassy carbon macromolecules isotopes epitaxial crystal growth drug discovery biosynthetics quantum dots superconductors spectroscopy metamaterials platinum ink Fe3O4 rare earth metals spintronics thin lm osmium buckyballs zeolites Nd:YAG enantioselective catalysts dielectrics deposition slugs organometallics janus particles optical glass © 2001-2021. American Elements is a U.S.Registered Trademark mesoporous silica chalcogenides laser crystals calcium wires indicator dyes graphene oxide shift reagents ferro uid metallocenes CVD precursors silver nanoparticles MOFs palladium catalysts nickel foam bioactive compounds III-IV semiconductors metal carbenes ITO pharmacoanalysis nano ribbons nanogels surface functionalized nanoparticles cermet anode excipients ultralight aerospace alloys rhodium sponge nanodispersions cisplatin conjugated nanostructures h-BN MOCVD BINAP InGaAs NMR ZnS AuNPs EuFOD YBCO MBE Now Invent. TM The Next Generation of Material Science Catalogs American Elements opens a world of possibilities so you can Now Invent! Over 30,000 certi ed high purity laboratory chemicals, metals, & advanced materials and a state-of-the-art Research Center. Printable GHS-compliant Safety Data Sheets. Thousands of new products. And much more. All on a secure multi-language "Mobile Responsive” platform. www.americanelements.com 1.00794 Hydrogen 1 1 H 6.941 Lithium 3 2 1 Li 9.012182 Beryllium 4 2 2 Be 22.98976928 Sodium 11 2 8 1 Na 24.305 Magnesium 12 2 8 2 Mg 39.0983 Potassium 19 2 8 8 1 K 40.078 Calcium 20 2 8 8 2 Ca 85.4678 Rubidium 37 2 8 18 8 1 Rb 87.62 Strontium 38 2 8 18 8 2 Sr 132.9054 Cesium 55 2 8 18 18 8 1 Cs 137.327 Barium 56 2 8 18 18 8 2 Ba (223) Francium 87 2 8 18 32 18 8 1 Fr (226) Radium 88 2 8 18 32 18 8 2 Ra 44.955912 Scandium 21 2 8 9 2 Sc 47.867 Titanium 22 2 8 10 2 Ti 50.9415 Vanadium 23 2 8 11 2 V 51.9961 Chromium 24 2 8 13 1 Cr 54.938045 Manganese 25 2 8 13 2 Mn 55.845 Iron 26 2 8 14 2 Fe 58.933195 Cobalt 27 2 8 15 2 Co 58.6934 Nickel 28 16 Ni 63.546 Copper 29 2 8 18 1 Cu 65.38 Zinc 30 2 8 18 2 Zn 88.90585 Yttrium 39 2 8 18 9 2 Y 91.224 Zirconium 40 2 8 18 10 2 Zr 92.90638 Niobium 41 2 8 18 12 1 Nb 95.96 Molybdenum 42 2 8 18 13 1 Mo (98.0) Technetium 43 2 8 18 13 2 Tc 101.07 Ruthenium 44 2 8 18 15 1 Ru 102.9055 Rhodium 45 2 8 18 16 1 Rh 106.42 Palladium 46 18 18 Pd 107.8682 Silver 47 2 8 18 18 1 Ag 112.411 Cadmium 48 2 8 18 18 2 Cd 138.90547 Lanthanum 57 2 8 18 18 9 2 La 178.48 Hafnium 72 2 8 18 32 10 2 Hf 180.9488 Tantalum 73 2 8 18 32 11 2 Ta 183.84 Tungsten 74 2 8 18 32 12 2 W 186.207 Rhenium 75 2 8 18 32 13 2 Re 190.23 Osmium 76 2 8 18 32 14 2 Os 192.217 Iridium 77 2 8 18 32 15 2 Ir 195.084 Platinum 78 18 32 17 Pt 196.966569 Gold 79 2 8 18 32 18 1 Au 200.59 Mercury 80 2 8 18 32 18 2 Hg (227) Actinium 89 2 8 18 32 18 9 2 Ac (267) Rutherfordium 104 2 8 18 32 32 10 2 Rf (268) Dubnium 105 2 8 18 32 32 11 2 Db (271) Seaborgium 106 2 8 18 32 32 12 2 Sg (272) Bohrium 107 2 8 18 32 32 13 2 Bh (270) Hassium 108 2 8 18 32 32 14 2 Hs (276) Meitnerium 109 2 8 18 32 32 15 2 Mt (281) Darmstadtium 110 18 32 32 17 Ds (280) Roentgenium 111 2 8 18 32 32 18 1 Rg (285) Copernicium 112 2 8 18 32 32 18 2 Cn 4.002602 Helium 2 2 He 10.811 Boron 5 2 3 B 12.0107 Carbon 6 2 4 C 14.0067 Nitrogen 7 2 5 N 15.9994 Oxygen 8 2 6 O 18.9984032 Fluorine 9 2 7 F 20.1797 Neon 10 2 8 Ne 26.9815386 Aluminum 13 2 8 3 Al 28.0855 Silicon 14 2 8 4 Si 30.973762 Phosphorus 15 2 8 5 P 32.065 Sulfur 16 2 8 6 S 35.453 Chlorine 17 2 8 7 Cl 39.948 Argon 18 2 8 8 Ar 69.723 Gallium 31 2 8 18 3 Ga 72.64 Germanium 32 2 8 18 4 Ge 74.9216 Arsenic 33 2 8 18 5 As 78.96 Selenium 34 2 8 18 6 Se 79.904 Bromine 35 2 8 18 7 Br 83.798 Krypton 36 2 8 18 8 Kr 114.818 Indium 49 2 8 18 18 3 In 118.71 Tin 50 2 8 18 18 4 Sn 121.76 Antimony 51 2 8 18 18 5 Sb 127.6 Tellurium 52 2 8 18 18 6 Te 126.90447 Iodine 53 2 8 18 18 7 I 131.293 Xenon 54 2 8 18 18 8 Xe 204.3833 Thallium 81 2 8 18 32 18 3 Tl 207.2 Lead 82 2 8 18 32 18 4 Pb 208.9804 Bismuth 83 2 8 18 32 18 5 Bi (209) Polonium 84 2 8 18 32 18 6 Po (210) Astatine 85 2 8 18 32 18 7 At (222) Radon 86 2 8 18 32 18 8 Rn (284) Nihonium 113 2 8 18 32 32 18 3 (289) Flerovium 114 2 8 18 32 32 18 4 Fl (288) Moscovium 115 2 8 18 32 32 18 5 (293) Livermorium 116 2 8 18 32 32 18 6 Lv (294) Tennessine 117 2 8 18 32 32 18 7 (294) Oganesson 118 2 8 18 32 32 18 8 140.116 Cerium 58 2 8 18 19 9 2 Ce 140.90765 Praseodymium 59 2 8 18 21 8 2 Pr 144.242 Neodymium 60 2 8 18 22 8 2 Nd (145) Promethium 61 2 8 18 23 8 2 Pm 150.36 Samarium 62 2 8 18 24 8 2 Sm 151.964 Europium 63 2 8 18 25 8 2 Eu 157.25 Gadolinium 64 2 8 18 25 9 2 Gd 158.92535 Terbium 65 18 27 Tb 162.5 Dysprosium 66 2 8 18 28 8 2 Dy 164.93032 Holmium 67 2 8 18 29 8 2 Ho 167.259 Erbium 68 2 8 18 30 8 2 Er 168.93421 Thulium 69 2 8 18 31 8 2 Tm 173.054 Ytterbium 70 2 8 18 32 8 2 Yb 174.9668 Lutetium 71 2 8 18 32 9 2 Lu 232.03806 Thorium 90 2 8 18 32 18 10 2 Th 231.03588 Protactinium 91 2 8 18 32 20 9 2 Pa 238.02891 Uranium 92 2 8 18 32 21 9 2 U (237) Neptunium 93 2 8 18 32 22 9 2 Np (244) Plutonium 94 2 8 18 32 24 8 2 Pu (243) Americium 95 2 8 18 32 25 8 2 Am (247) Curium 96 2 8 18 32 25 9 2 Cm (247) Berkelium 97 18 32 27 Bk (251) Californium 98 2 8 18 32 28 8 2 Cf (252) Einsteinium 99 2 8 18 32 29 8 2 Es (257) Fermium 100 2 8 18 32 30 8 2 Fm (258) Mendelevium 101 2 8 18 32 31 8 2 Md (259) Nobelium 102 2 8 18 32 32 8 2 No (262) Lawrencium 103 2 8 18 32 32 8 3 Lr Nh Mc Ts Og

VIC | TAS Branch Report

Robert C Gifkins Annual Lecture 2022

Source: Professor Rachel Caruso

On 17 November, the Victoria and Tasmania Branch had the pleasure of Professor Rachel Caruso presenting the 2022 Robert C Gitkin’s Annual Lecture.

Based at RMIT University’s School of Science, Professor Caruso has had a distinguished career.

Professor Caruso completed her PhD in the School of Chemistry at The University of Melbourne before

working in Berlin at the Hahn Meitner Institute and the Max Planck Institute of Colloids and Interfaces. She returned to The University of Melbourne, was seconded 50% to the CSIRO. Following this, she moved to RMIT University in 2017, taking on the role of Director of the Advanced Materials Enabling Capability Platform. Her research group has investigated approaches to control the morphology and composition of inorganic materials for photocatalysis, photovoltaics and batteries

Professor Caruso gave a fascinating

lecture on Improving the Effectiveness of Materials through Morphological Control. She presented a range of approaches that can be used to manipulate the morphological properties of materials. This can enhance the accessible surface area and pore structure, increasing the number of surface reactions and the diffusion of reactant and product from the reaction site. The presentation focused on different synthesis approaches used to achieve porous metal oxides and demonstrate their application in photocatalysis, photovoltaics or batteries.

The Art of Science Communication Workshop

Source: Rou Jun Toh

In this workshop for Early Career Researchers (ECRs), Materials Australia and the Surface Engineering for Advanced Materials (SEAM) ARC Training Centre brought together a diverse group of experts to share their knowledge on the art of science communication.

The event was chaired by the VicePresident of Materials Australia, Dr Rou Jun Toh and included speakers Professor Ivan Cole (President of Materials Australia and Engineering Professor at RMIT University), Rachael Vorwerk (Science Communicator at the Integrated Photonics and Applications

Centre, RMIT), and Dr Tom J Carruthers (Co-President of the National Australian Science Communicators).

The event covered three main topics: (1) structure and flow (2) social media as a powerful tool (3) communicating through pictures

Each of the speakers highlighted a specific area of science communication and brought to attention the diverse settings and contexts that researchers can leverage in the modern age of technology. The speakers emphasised the impact of good science communication and provided practical

tips on how it can be achieved. The second half of the workshop was carried out in breakout rooms with Rachael Vorwerk and Dr Tom J Carruthers. The breakout room format was a great space for the ECRs to engage with the speakers and be further equipped to communicate their research effectively. Rachael worked with the ECRs to write their first LinkedIn post while Tom further elaborated on the power and dangers of using pictures. Overall, it was encouraging to see ECRs inspired and equipped with the right tools to communicate their research.

12 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU Advertise with Materials Australia! Advertising with Materials Australia will give you the opportunity to: • Maintain and build on professional relationships • Connect with a highly targeted audience • Showcase your new products and services • Gain instant market feedback • Increase and strengthen brand awareness

Stay at the

Show your dedication to,

Email rod@materialsaustralia.com.au for more information

MATERIALS AUSTRALIA

•

forefront of industry developments and innovations •

and support of, the industry

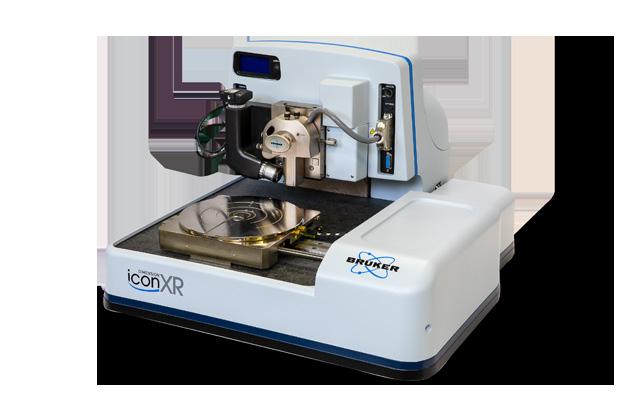

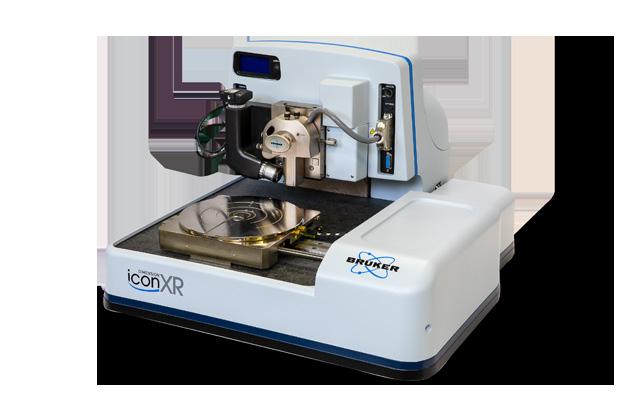

Surface & Dimensional Analysis Optical Profiling Next generation ContourX platforms Improved optical resolution Unmatched precision and repeatability Nanoindentation In-situ TEM/SEM nanomechanical instruments Stand alone nanomechanical test systems Wide range of environmental measurement options High-resolution AFM Microscopes New NanoScope 6 platforms, improved speed and data capability High resolution for all applications, all environments Tribology Universal tribology platforms Fast and cost-effective in-lab rapid screening of new friction materials Bruker Nano Surfaces provides industry-leading surface analysus instruments for research and production. Bruker’s AFMs are enabling scientists around the world to make discoveries and advance their understanding of material and biological systems. Their tribometers and mechanical tests deliver practical data used to help improve development of materials and tribolocial systems. Industry-leading quantitative nanomechanical and nanotribological test instruments are specifically designed to enable new frontiers in nanoscale materials characterisation, materials development, and process monitoring. Whatever your surface measurement and surface analysis needs, materials or scale of investigation, Bruker has a specialised high-performance solution for you. (08) 8150 5200 sales@coherent.com.au www.coherent.com.au

NSW Branch Report

Source: Dr Rachel White

2022 has been a year for adjusting to new ways of working and connecting. We learned over the last couple of years the benefits that online events offer, particularly in terms of reaching more people and providing ways for them to engage with others working in materials. In this branch report, we have two events to report on. We will soon be planning our events for next year and looking to apply what we have learnt in 2022.

MATSOC Careers Event –20 October 2022

The New South Wales (NSW) Branch assisted the University of NSW student society MATSOC with their online careers and networking event. This event attracted a number of professionals from

undergraduate students nominated by their supervisors, from Western Sydney University, University of Newcastle, University of Wollongong and the University of New South Wales.

The talks and posters covered a range of materials, applications and techniques, from lunar analysers through to polymeric nanocomposites. The poster session allowed time for attendees and students to discuss their work and connect. It was fantastic to see students networking during the poster session, creating connections that have been more difficult to create in recent years. The judging panel was made up of Associate Professor Sophie Primig, Han Yeoh from Cochlear, Dr Yi-Sheng (Eason) Chen and last year’s winner Lucy Chen.

Portable EDXRD Mineralogical Analyser for Lunar Applications.

Third Prize Oral Presentation (with a prize of $300) was sponsored by Hasan Kanji, from United Steel. The winner Trang Ngo, UoW, for her presentation on Characterisation of Ternary Carbides for High Temperature Furnace Heating Element.

Fourth Prize Oral Presentation (with a prize of $100) was sponsored by the Australian Centre for Neutron Scattering (ANSTO). The winner was Wendy Ji, UNSW, for her presentation on Numerical Simulations of the Laser Metal Deposition (LMD) Process for the Prediction of Residual Stresses and Distortion.

Fifth Prize Oral Presentation (with a prize

MATERIALS AUSTRALIA

Materials Australia Awards Professor

Ma Qian their Highest Honour: the Silver Medal

Source: Sally Wood

Materials Australia is pleased to announce that Professor Ma Qian has been awarded the institute’s prestigious Silver Medal..

The Materials Australia Silver Medal is presented for outstanding contributions to the advancement of materials science and engineering through management, teaching, innovation, development or research.

According to Materials Australia President, Dr Roger Lumley, CMatP, “Over the course of his career, Professor Ma Qian has devoted his life to the study of materials. He has made significant contributions in the fields of physical metallurgy, additive manufacturing, solidification processing, powder metallurgy, metallic biomaterials and thermodynamics of materials.”

“Professor Qian’s research has made major contributions to industry, impacting on manufacturing processes such as casting, powder sintering, metal injection moulding and additive manufacturing. He is a most deserving recipient of Materials Australia’s highest honour: the Silver Medal.”

“Materials Australia would like to congratulate Professor Qian on his outstanding achievements and acknowledge him as a worthy winner of the 2022 Materials Australia Silver Medal,” said Dr Lumley.

Innovative Research

With a career that spans over 40 years, Professor Ma Qian is a Distinguished Professor of the School of Engineering at the Royal Melbourne Institute of Technology (RMIT University) in Melbourne. He joined RMIT University in 2013, having been the Reader in Materials Engineering, in the School of Mechanical and Mining Engineering at The University of Queensland. Prior to this, he held various academic positions, including at Portsmouth University and Brunel University in the United Kingdom, the National University of Singapore, Kyushu Institute of Technology in Japan, and Tsinghua University in China.

Professor Qian began his research at the CAST Cooperative Research Centre (CRC) on aluminium wrought alloys for Comalco before moving onto the development of a superior Magnesium Zirconium (Mg-Zr) grain refining master alloy for Australian Magnesium. The resulting master alloy was patented, and Professor Qian spent time in the USA optimising the consumption of Zirconium and the performance of the process of grain refining commercial castings. The master alloy is currently available from Magontec, and is considered to be the best performing master alloy in terms of effectiveness and cost.

Along with his team, Professor Qian has also recently developed an ultrasound assisted metal 3D printing process which could be applied to improve the mechanical strength of titanium alloy 3D printing. The printing of 3D metal is widely used in aerospace and biomechanical applications. However, it was determined that the use of ultrasound addressed the long-lasting challenges in fusion-based metal 3D printing. It is hoped that this could eventually become a commercially useful process for 3D printing of small metal parts. The release of this research saw an audience reach of 146 million people within three weeks of publication.

More recently, Professor Qian and his team have developed a robust bulk micro-nano hierarchical copper material possessing exceptional bactericidal efficacy. This new copper surface can eliminate golden staph in two minutes—120 times faster than a normal copper surface. The audience reach within three weeks of the publication of this work through a RMIT news release was 276 million.

Conferences and Publications

Alongside his research fellows, PhD students and collaborators, Professor Qian has published 291 peer- reviewed journal articles and four Elsevier books on titanium alloys, including Titanium Powder Metallurgy: Science, Technology

and Applications, Light Alloys, Titanium in Medical and Dental Applications, and Titanium for Consumer Applications.

Professor Qian has received nine research awards including the 2006 American Society for Metals (ASM) Henry Howe Marion Medal, the 2003 TMS Light Metals Magnesium Technology Award, the inaugural 2003 Australian CAST-CRC Industry Partners Award, and the 2019 RMIT Engineering Executive Dean's Research Excellence Award - Level E (professorial level).

Professor Qian also serves as an Associate, Advisory and Series Editor for a number of well-respected journals and publications including Acta Materialia, Scripta Materialia, and Elsevier Additive Manufacturing Book Series.

Professor Qian holds a Bachelor of Engineering, a Master of Science, and a Doctorate of Engineering in Foundry Metallurgy, as well as a Postgraduate Certificate in Higher Education. He is also an elected Fellow of the American Society for Metals International (FASM), the World's foremost professional society for materials scientists, engineers and technicians.

Materials Australia would like to congratulate Professor Qian on his outstanding achievements and acknowledge him as a worthy winner of the 2022 Materials Australia Silver Medal.

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 15

MATERIALS AUSTRALIA

NSW Branch Report

Source: By Dr Cameron Chai.

On October 31, Ric Wuhrer and his team (Daniel Fanna and Laurel George) at Western Sydney University Advanced Materials Characterisation Facility hosted the NSW branch for a seminar entitled “New dimensions to micro-CT imaging: Fast dynamic CT imaging and spectral CT on TESCAN micro-CT systems”, presented by Frederik Coppens from TESCAN (Belgium) and Kamran Khajehpour from AXT. As we all know microCT is

growing rapidly in popularity with its ability to non-destructively image in 3D, making ideal for applications such as additive manufacturing.

Frederik’s presentation concentrated in dispelling a couple of myths about microCT, i.e.

1. MicroCT scans take many hours

2. MicroCT doesn’t provide any chemical information

He demonstrated how system like the UniTOM XL and DynaTOM can generate complete 3D datasets in as little as 5 seconds while maintaining sub-micron resolution successfully dismissing the first myth. This is thanks to the synchronisation of a high flux (300W) X-ray source and high-speed detector (up to 100fps), which in turn allows true 4D microCT studies to be performed.

The high-speed scanning capability was demonstrated using in situ scanning of collapsing beer foam, also made possible by the stationary sample and gantry mounted optics. The practical application of this relates directly to optimising the taste of beer. A further example presented involved looking a fluid flow through porous rock which has implications in filtration, catalysis and CO 2 storage.

To overcome with the second myth, TESCAN have developed an energysensitive photon counting detector, enabling Spectral CT, or the ability to perform chemical analysis, complementing conventional structural CT data. This detector can be added to some TESCAN microCTs and enables users to identify elements heavier than Mo and was illustrated by successfully identifying gold particles a geological core sample with no sample prep, also relevant to other applications in the mining industry. In a second case study, scanned a bunch of Lego pieces. Polymers typically have very little contrast difference between them when viewed with CT, however, using spectral CT it was possible to distinguish various colours of Lego with a high degree of confidence.

16 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Asia-Pacific International Conference on Additive Manufacturing

21st - 23rd June 2023

The University of Sydney

The 3rd Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industrial application focused conference of 2023.

The 5th Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industry conference of 2023. APICAM was created to provide an opportunity for industry professionals and thinkers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

APICAM was created to provide an opportunity for industry professionals and academic researchers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

Some of the leading minds in the industry will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as 3D printing and additive manufacturing in the automotive, biomedical, defence and aerospace industries will be covered by experts from each respective field.

Some of the leading minds in the field of additive manufacturing will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as applications of additive manufacturing in the, biomedical, defence and aerospace industries will be covered by experts from each respective field.

The event is being curated by Materials Australia, the peak Australian materials technology body, which has drawn on its considerable pull in the industry to create a world-class event that is a must-attend for anyone involved in the additive materials industry.

The purpose of this conference is to provide a focused forum for the presentation of advanced research and improved understanding of various aspects of additive manufacturing.

CALL FOR ABSTRACTS

You can submit an abstract in the following areas of interest:

Additive Manufacturing Defence Application

Abstracts are able to be submitted in the following areas:

Additive Manufacturing Green/Clean Energy Additive Manufacturing Space Application

Additive Manufacturing of Metals

Additive Manufacturing of Polymers

Additive Manufacturing PostProcessing

Additive Manufacturing of Concretes

Bioprinting and Biomaterials

Advanced Characterisation Techniques and Feedstocks

Ceramic and Concrete Additive Manufacturing

Computational Modelling of Thermal Processes for Metallic Parts

The APICAM2023 organizing committee is seeking abstracts for either an oral or poster presentation.

The main features of APICAM 2023 will include presentations by experts as well as workshops that will help attendees sharpen their skills and then be able to pass on this knowledge to other industry professionals. The event has been designed to allow for ample networking time so that important knowledge-transfer can take place and partnerships can be created that will enrich the industry.

Enquiries:

Design, Qualification and Certification Digital Manufacturing

Part Design for Additive Manufacturing Failure Mechanisms and Analysis

Emerging Additive Manufacturing Technologies

Mechanical Properties of Additively Manufactured Materials

Metal Additive Manufacturing Modelling and Simulations

New Frontiers in Additive Manufacturing Process Parameter and Defect Control

Enquiries:

Tanya Smith | Materials Australia +61 3 9326 7266 | imea@materialsaustralia.com.au www.apicam2023.com.au

Tanya Smith | Materials Australia

+61 3 9326 7266 | imea@materialsaustralia.com.au

Process-Microstructure-Property Relationships

Polymer Additive Manufacturing Sustainability

Testing and Qualification in Additive Manufacturing

APICAM2023

CALL FOR ABSTRACTS www.apicam2023.com.au CLICK HERE TO SUBMIT YOUR ABSTRACT

APICAM2023

CLICK

-

HERE TO SUBMIT

Abstracts close 31 January 2023

21st - 23rd June 2023 | The University of Sydney

QLD Branch Report 2022 in Review

Source: David Haynes

Looking back over the year, the Queensland Branch continued to provide our members with training and knowledge sharing opportunities. I am particularly proud of our small and dedicated committee of volunteers who meet each month to schedule and organise events. As volunteers with work and family commitments our available time is small. Yet, we continue to make steady progress in an effort to better engage with industry, academia, government and the wider community around materials technology.

We took the opportunity to catch up with Roger Lumley in May when he was in Brisbane for the Australian Foundry Institute seminar at South Bank. In June, we hosted an online event with Andy Reilly from Total Materia whose presentation: Materials Selection, Choice and its Importance to Engineers provided us insight into engineering materials databases that assist in managing IP, compliance and which also integrate with FMEA software.

In August, we hosted an in-person

event at the Engineers Australia office in Brisbane with Dr Peter King, from CSIRO who presented on: Metal 3D Printing, Robots and Supersonic Particles. Peter was clearly very knowledgeable around all aspects of 3D metal printing and shared Lab22’s experience of the process and the underlying science.

Finally, in October and in collaboration with the Australian Institute for Bioengineering and Nanotechnology Dr Nasim Amiralian presented on the topic: Next Generation Material Forms –Renewable Nanotechnology.

A special thank you to our committee member Chi Ho, who in his final year of completing his PhD thesis and in his role as student representative, has enthusiastically helped promote Materials Australia to various student associations and was instrumental in organising two of our events this year.

We are now planning for next year with the view to build on our events schedule with talks and industry visits. We have formed a sub-committee and are

collaborating with academics from the University of Queensland, Queensland University of Technology and Deakin University to organise the Materials Innovations in Surface Engineering (MISE) conference. MISE will be held at the University of Queensland in Brisbane from the 29 to 31 October 2023.

The approach we are taking as a branch is to act now with the view to position the Queensland Materials Australia branch where we want to be in five and 10 years’ time. We can, of course, do better and the Queensland committee welcomes your feedback and the involvement of members to help in whatever way, however small.

Branch Chair & Secretary: David Haynes - davidhaynes.qldma@gmail.com

Vice-Chair & Engineers Australia Liaison: Michael Chan CMatP

Treasurer: Richard Clegg CMatP

Student Representative: Chi-Ho Ng

Council Member: Hamid Pourasiabi

QLD Branch Email Address: qld@materialsaustralia.com.au

Materials Australia Education Chair

Alan Todhunter

Alan Todhunter from the Materials Australia New South Wales Committee has taken on the role of Education Chair for Materials Australia.

Alan is a lecturer at Western Sydney University, a Certified Materials Professional (CMatP), a Fellow of the Higher Education Academy and NSW committee member of the Australian Institute of Building. He has been

involved in teaching, curriculum development and subject design for over two decades. Alan also has a focus on Work Integrated Learning and researched different teaching styles applicable to training undergraduates.

Alan will discuss his new role and future plans in the March issue of Materials Australia magazine.

MATERIALS

AUSTRALIA

18 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Profile: Rou Jun Toh

Postdoctoral

Fellow, SEAM RMIT University.

Rou Jun Toh is a Postdoctoral Fellow with the Australian Research Council (ARC) Industrial Transformation Training Centre in Surface Engineering for Advanced Materials (SEAM) with RMIT University.

Rou Jun obtained her PhD in Chemistry and Biological Chemistry (2017) from Nanyang Technological University (NTU), Singapore, where she established herself in the field of materials. She moved to Melbourne for her first Postdoctoral Fellow position with CSIRO in 2017, and subsequently joined RMIT and SEAM in 2020 to work on a university and industry collaboration project with Romar Engineering Pty Ltd and RMIT University in Optimization of surface properties of additive components using an additive/subtractive machine.

Rou Jun’s work on the SEAM project with industry partner organisation, Romar Engineering aims to optimize manufacturing approaches using the DMG Mori Lasertec 65 3D 5-axis

synchronous laser deposition, welding and milling machine. The Lasertec 65 is a 3D printer with unique metal-on and metal-off capability and Romar Engineering is able to provide clients with the exceptional flexibility to create innovative new parts, and repair, replace or renew existing ones. Thus far on this industry project Rou Jun has provided leadership and expertise and developed a 3D visualisation and analytical tool that can be employed for quality assurance and control purposes. Moreover, Rou Jun fulfils a critical leadership role where she works with two doctoral candidates and plays an important role in training two industry ready and fit researchers who will have the ability to operate the Laser 65 autonomously to deliver key outcomes and capabilities to solve crucial materials engineering problems. This will provide commercial benefits to the industry partner. In addition, it will, without a doubt, provide the Australian manufacturing industry with a competitive edge and put it in par with

other global leaders.

As a female scientist and researcher, Rou Jun brings diversity and is an asset to the innovative skilled workforce in Australia. She actively engages with STEM education efforts and the scientific community through inspiring the next generation of STEM talents and facilitating collaboration networks on the international and national level. Rou Jun is currently the vice-president of Materials Australia (VIC/TAS branch). Being in this leadership role has helped Rou Jun grow her network and her ability to connect with people and engage stakeholders which will be valuable for her future endeavours.

The development of female STEM talents like Rou Jun would not have been possible without the grant opportunities provided by the ARC and SEAM and their strong vision for diversity and inclusion. For more information about SEAM, please visit www.arcseam.com.au/ or email seam@swinburne.edu.au.

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 19

Steve Milanoski, Head of Advanced Manufacturing, Romar Engineering and Rou Jun Toh, Postdoctoral Fellow, SEAM RMIT University.

ARC Training Centre in Lightweight Automotive Structures (ATLAS)

Source: Sally Wood

Source: Sally Wood

The ARC Training Centre in Lightweight Automotive Structures (ATLAS) aims to accelerate the transformation of Australia's automotive industry through new research capabilities in lightweight automotive structures design and manufacture.

Administered through RMIT University, ATLAS brings together Deakin University, the Australian National University, lead industry partner the Ford Motor Company and a further 12 local and international partner organisations including the CSIRO to address the challenges in lightweighting.

ARC Chief Executive Officer, Professor Sue Thomas, said the Training Centre will develop new lightweight technologies, manufacturing processes and energy storage designs that will reduce carbon dioxide emissions in transportation.

“Working with industry partnering organisations, the ARC Industrial Transformation Training Centre in Lightweight Automotive Structures will accelerate the transformation of Australia’s automotive industry through new research capabilities and commercialisation of new processes and products,” said Professor Thomas.

“This research Training Centre brings together world-leading scientists and industrial engineers from 16 organisations from Australia, Germany, United Kingdom, and the United States of America, and will provide an outstanding collaborative network to mentor, train and develop Australia’s next generation of researchers in an industry-focused research training environment.”

ATLAS is led by Professor Stuart Bateman (Associate Dean

An Integrated Program of Research

ATLAS is delivering industry relevant research training to early career researchers at the post-doctoral, post-graduate and undergraduate levels who benefit from both academic and industry mentors. An integrated program of research projects aims to deliver critical knowledge and innovative lightweighting technologies to underpin new high-value products for global markets.

Building on strong collaborations between industry and university partners, ATLAS is training urgently needed commercially focused researchers specialising in lightweight multi-material structures obtained through advanced, agile and digital manufacturing technologies.

ATLAS comprises an integrated research program encompassing four themes as outlined below.

Lightweight Materials Research underpinning the development and efficient processing of high-performance lightweight materials like carbon-fibre composites and highly formable metal alloys for the manufacture of next generation lightweight components and assemblies by Australia manufacturers.

Design and Advanced Manufacturing

Advancement of agile and digital manufacturing technologies such as additive manufacturing, flexible roll forming technologies and multi-material joining techniques to enable local

manufacturers to efficiently produce high value products for local and international markets.

Integrated Multi-material Structures

Design and demonstration of smart integrated multi-material structures such as those with gradient physical properties for controlled crush or imbedded functional features like the capacity to store electrical energy for future mobility solutions.

Whole of Life Assessment

Validating the whole of life economic, environmental and societal benefits of next generation lightweight multimaterial structures through quantitative life cycle assessments and the development of decision making tools to help guide design choices.

RMIT University Building 251, 264 Plenty Rd, Mill Park, VIC, 3082

Manufacturing Materials and Mechatronics, RMIT University).

MATERIALS AUSTRALIA 20 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

T: +61 3 03 9925 6048 E:

www.atlas-innovation.com.au

atlas-innovation@rmit.edu.au

FOR ABSTRACTS

AUSTRALIA 10 TH INTERNATIONAL LIGHT METALS TECHNOLOGY CONFERENCE 9-12 JULY 2023 RMIT UNIVERSITY, MELBOURNE, AUSTRALIA The Light Metals Technology (LMT) Conference is a biennial event that focuses on recent advances in science and technologies associated with the development and manufacture of aluminium, magnesium and titanium alloys and their translation into commercial products. The conference presents an opportunity for academic researchers, students and industry to discuss cutting edge developments and to facilitate new collaborations. CALL

You are invited to submit abstracts on topics within the themes of Net Shape Manufacturing, Solid State Transformations and Mechanical Performance, and Translation to Applications. For example, but not limited to: ▶ Alloy development ▶ Solidification and casting ▶ Thermomechanical processing and forming ▶ Machining and subtractive processes ▶ Mechanical behaviour of light metal alloys ▶ Corrosion and surface modification ▶ Advanced characterisation techniques ▶ Joining ▶ Applications in bio-medical, automotive, aerospace, and energy industries ▶ Simulation and modelling ▶ Integrated computational materials engineering Enquiries: Tanya Smith Materials Australia +61 3 9326 7266 imea@materialsaustralia.com.au www.lmt2023.com Opportunities for sponsorships and exhibitions are available, see below for contact details. CONFERENCE SPONSORS Materials Australia

MELBOURNE

CMatP Profile: Andrew Gregory

architectures in supercritical carbon dioxide using controlled radical and enzymatic techniques.

As a Postdoctoral Research Associate at the Centre of Advanced Macromolecular Design at the University of New South Wales, Andrew oversaw and coordinated a number of projects focussing primarily on the development of new polymer vehicles for delivering platinum based drugs. His work included collaborating with a highly regarded multinational company developing novel materials, based on commercially viable microspheres, for imaging and therapeutic applications in the treatment of liver cancer.

Who or what has influenced you most professionally?

I have had the pleasure of working with an array of researchers both in academia and in industry. Many of these not only have a firm grasp on the scientific concepts they work with, but also have creativity in order to keep searching and developing the research in their respective fields of expertise.

When I started as a trainee patent attorney, my supervising partner was a great teacher and mentor, not only ensuring that I was aware of the legal and scientific aspects of my role, but making sure that I could relay any information to our clients.

Andrew Gregory is a registered Australian and New Zealand patent attorney and a senior associate in the FB Rice Sydney chemistry team.

His work spans prosecution, coordinating patent portfolios, oppositions, searching and freedomto-operate opinions, drafting, and strategic advisory services. His client base covers universities and global companies in a range of technological areas, including pharmaceuticals, polymers, veterinary sciences, green technology, inorganic materials and nanotechnology.

Andrew’s expertise is backed by technical knowledge gained from his hands on experience from working in laboratories. Over the years he has developed his synthetic and characterisation skills in organic and inorganic chemistry, with a particular focus in the field of polymers. He is able to implement this acquired knowledge in order to assist his clients with both the drafting and the prosecution of his clients’ patents.

Andrew earned a First Class Masters in Chemistry (Hons) from the University of Leicester, graduating top of his year. He went on to receive a PhD in Polymer Chemistry at the University of Nottingham, winning a national scholarship (SOCI Messel Scholar), and graduating in 2008. His thesis focused on the synthesis of various polymer

Where do you work and describe your job

I am a registered Australian and New Zealand patent attorney at FB Rice. My practice covers various aspects of chemistry. However, my focus is providing advice relating to inventions directed to the synthesis, manufacture and application of materials.

My day-to-day work changes all the time, and can include: reviewing an examination report issued by a patent office; drafting a new patent application for a client; and advising counsel on experimental evidence for a court proceeding. The work is an interesting (and challenging) application of knowledge obtained from both the legal and scientific fields.

What inspired you to choose a career in materials science and engineering?

I have always had an interest in science and maths. During my PhD days in the United Kingdom, and my post-doctorate experience in Sydney, I found that I enjoyed collating reviewing and trying to understand obtained data, and then translating this into concise reports.

In my current role, I am continuously exposed to new developments in materials science. I have the opportunity to try and understand the innovations, and then act to protect the developments as intellectual property.

Which has been the most challenging job or project you’ve worked on to date and why?

Providing scientific support to counsel for litigation proceedings, advising on the chemical aspects of the invention.

There is usually a lot at stake as a result of any proceedings, and a lot of time is spent determining what falls within the scope of one or more patent claims. There can be long debates over the interpretation of a single word, and then how this affects the validity or enforcement of a claim.

What does being a CMatP mean to you?

It’s an acknowledgement, and an appreciated recognition, of the work I have put in over the years to increase my scientific knowledge in the materials field and now utilise it my current role for an array of different tasks.

What gives you the most satisfaction at work?

When, after considering and reviewing multiple documents, I am able to devise a strategy to help a client, such as when preparing a response to an examination report. This is particularly true when supporting start-up companies who have both passion and determination in protecting their new innovations.

22 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

AUSTRALIA

MATERIALS

What is the best piece of advice you have ever received?

Given everything that has happened over the past few years, I have been reminded that sometimes it is important to ‘switch off’ and disconnect from the world. This is not always easy, given various personal and professional responsibilities, but gives me the chance to recharge, even if it is just for a moment.

What are you optimistic about?

Research and innovation in Australia. After attending a number of conferences over the past year (as the country has opened up), we have a lot of talented researchers and professionals working in this country, including many

promising students who are both hardworking and inspiring.

What have been your greatest professional and personal achievements?

Being awarded my PhD was a highlight. I was the first member of my family to go to university and I worked hard to then be accepted on the PhD track. My thesis focussed controlled polymerisations in supercritical carbon dioxide and was fraught with a number of ups and downs. I was fortunate to have an understanding partner (now wife), who supported me with the many, many hours focused on the research.

As a patent attorney, my proudest moment to date has been when a patent

application I drafted when I started as a trainee, resulted in the first patent for my client. It took a few years (typical for the patent process), and went through a few rounds of examination, but I was smiling when I sent the resulting Letters Patent to the client.

What are the top three things on your “bucket list”?

• On the home front, to travel back to the United Kingdom soon to see my extended family. It has been a long time since I’ve seen them.

• Professionally, to continue developing my knowledge of global intellectual property practices.

• Personally, it would be great to finally be able to play the guitar I picked up at the beginning of the pandemic.

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 23 Find out more on www.netzsch.com/caliris EQUIPPED FOR ALL OCCASIONS The New DSC 300 Caliris® ∙ Create the perfect fit for your application with userinterchangeable furnace sensor modules ∙ Choose between standard application, highest performance and fastest heating/cooling rates ∙ Maximize efficiency with touchscreen display, LED status bar and 192-position Automatic Sample Changer NETZSCH Australia Pty Ltd Unit 3/591 Withers Rd Rouse Hill NSW 2155 www.netzsch.com/ta

Our Certified Materials Professionals (CMatPs) MATERIALS

The following members of Materials Australia have been certified by the Certification Panel of Materials Australia as Certified Materials Professionals.

They can now use the post nominal ‘CMatP‘ after their name. These individuals have demonstrated the required level of qualification and experience to obtain this status. They are also required to regularly maintain their professional standing through ongoing education and commitment to the materials community.

We now have nearly 200 Certified Materials Professionals, who are being called upon to lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

A/Prof Alexey Glushenkov ACT

Dr Syed Islam ACT

Prof Yun Liu ACT

Dr Karthika Prasad ACT

Dr Takuya Tsuzuki ACT

Dr Olga Zinovieva ACT

Prof Klaus-Dieter Liss CHINA

Mr Debdutta Mallik MALAYSIA

Prof Valerie Linton NEW ZEALAND

Prof. Jamie Quinton NEW ZEALAND

Dr Rumana Akhter NSW

Ms Maree Anast NSW

Ms Megan Blamires NSW

Dr Phillip Carter NSW

Mr Ken Chau NSW

Dr. Igor Chaves NSW

Dr Yi-Sheng (Eason) Chen NSW

Dr Zhenxiang Cheng NSW

Dr Evan Copland NSW

Mr Peter Crick NSW

Prof Madeleine Du Toit NSW

Dr Azdiar Gazder NSW

Prof Michael Ferry NSW

Dr Yixiang Gan NSW

Mr Michele Gimona NSW

Dr Bernd Gludovatz NSW

Dr Andrew Gregory NSW

Mr Buluc Guner NSW

Dr Ali Hadigheh NSW

Dr Nima Haghdadi NSW

Dr Alan Hellier NSW

Prof Mark Hoffman NSW

Mr Simon Krismer NSW

Prof Jamie Kruzic NSW

Prof Huijun Li NSW

Dr Yanan Li NSW

Dr Hong Lu NSW

Mr Rodney Mackay-Sim NSW

Dr Matthew Mansell NSW

Dr Warren McKenzie NSW

Mr Arya Mirsepasi NSW

Mr Sam Moricca NSW

Dr Anna Paradowska NSW

Prof Elena Pereloma NSW

A/Prof Sophie Primig NSW

Dr Gwenaelle Proust NSW

Miss Zhijun Qiu NSW

Mr Waldemar Radomski NSW

Mr Ehsan Rahafrouz NSW

Dr Mark Reid NSW

Prof Simon Ringer NSW

Dr Richard Roest NSW

Mr Sameer Sameen NSW

Dr Luming Shen NSW

Mr Sasanka Sinha NSW

Mr Frank Soto NSW

Mr Michael Stefulj NSW

Mr Carl Strautins NSW

Mr Alan Todhunter NSW

Ms Judy Turnbull NSW

Mr Jeremy Unsworth NSW

Dr Philip Walls NSW

Dr Rachel White NSW

Dr Alan Whittle NSW

Dr Richard Wuhrer NSW

Mr Deniz Yalniz NSW

Mr Michael Chan QLD

Prof Richard Clegg QLD

Mr Andrew Dark QLD

Dr Ian Dover QLD

Mr Oscar Duyvestyn QLD

Mr John Edgley QLD

Dr Jayantha Epaarachchi QLD

Dr Jeff Gates QLD

Mr Payam Ghafoori QLD

Dr David Harrison QLD

Dr Damon Kent QLD

Miss Mozhgan Kermajani QLD

Mr Jeezreel Malacad QLD

Dr Jason Nairn QLD

Mr Sadiq Nawaz QLD

Mr Bhavin Panchal QLD

Mr Bob Samuels QLD

Dr Mathias Aakyiir SA

Mr Ashley Bell SA

Ms Ingrid Brundin SA

Mr Neville Cornish SA

A/Prof Colin Hall SA

Mr Nikolas Hildebrand SA

Mr Mikael Johansson SA

Mr Rahim Kurji SA

Mr Andrew Sales SA

Dr Thomas Schläfer SA

Dr Christiane Schulz SA

Prof Nikki Stanford SA

Prof Youhong Tang SA

Mr Kok Toong Leong SINGAPORE

Mr Madhusudhanan Jambunathan UK

Mr Devadoss Suresh Kumar UAE

Dr Shahabuddin Ahmmad VIC

Dr Qi Chao VIC

Dr Ivan Cole VIC

Dr John Cookson VIC

Miss Ana Celine Del Rosario VIC

Dr Yvonne Durandet VIC

Dr Mark Easton VIC

Dr Rajiv Edavan VIC

Dr Peter Ford VIC

Mrs Liz Goodall VIC

Mr Bruce Ham VIC

Ms Edith Hamilton VIC

Dr Shu Huang VIC

Mr Long Huynh VIC

Mr. Daniel Lim VIC

Dr Amita Iyer VIC

Mr Robert Le Hunt VIC

Dr Michael Lo VIC

Dr Thomas Ludwig VIC

Dr Roger Lumley VIC

Mr Michael Mansfield VIC

Dr Gary Martin VIC

Dr Siao Ming (Andrew) Ang VIC

Dr Eustathios Petinakis VIC

Dr Leon Prentice VIC

Dr Dong Qiu VIC

Mr John Rea VIC

Mr Steve Rockey VIC

Miss Reyhaneh Sahraeian VIC Dr Christine Scala VIC

Mr Khan Sharp VIC

Dr Vadim Shterner VIC

Dr Antonella Sola VIC

Mr Mark Stephens VIC

Dr Graham Sussex VIC

Dr Jenna Tong VIC

Dr Kishore Venkatesan VIC

Mr Pranay Wadyalkar VIC

Mr John Watson VIC

Dr Wei Xu VIC

Dr Ramdayal Yadav VIC

Dr Sam Yang VIC

Dr. Matthew Young VIC

Mr. Mohsen Sabbagh Alvani WA

Mr Graeme Brown WA

Mr Graham Carlisle WA

Mr John Carroll WA

Mr Sridharan Chandran WA

Mr Conrad Classen WA

Mr Chris Cobain WA

Ms Jessica Down WA

Mr Adam Dunning WA

Mr Jeff Dunning WA

Dr Olubayode Ero-Phillips WA

Mr Stuart Folkard WA

Mr Toby Garrod WA

Prof Vladimir Golovanevskiy WA

Mr Chris Grant WA

Mr Paul Howard WA

Dr Paul Huggett WA

Mr Ehsan Karaji WA

Mr Biju Kurian Pottayil WA

Mr Mathieu Lancien WA

Mr Michael Lison-Pick WA

Dr Evelyn Ng WA

Mr Deny Nugraha WA

Mrs Mary Louise Petrick WA

Mr Johann Petrick WA

Mr Stephen Rennie WA

Mr James Travers WA

AUSTRALIA 24 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Why You Should Become a Certified Materials Professional

Source: Materials Australia

Accreditation as a Certified Materials Professional (CMatP) gives you recognition, not only amongst your peers, but within the materials engineering industry at large. You will be recognised as a materials scientist who maintains professional integrity, keeps up to date with developments in technology, and strives for continued personal development.

The CMatP, like a Certified Practicing Accountant or CPA, is promoted globally as the recognised standard for professionals working in the field of materials science.

There are now well over one hundred CMatPs who lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Benefits of Becoming a CMatP

• A Certificate of Membership, often presented by the State Chapter, together with a unique Materials Australia badge.

• Access to exclusive CMatP resources and website content.

• The opportunity to attend CMatP only

networking meetings.

• Promotion through Materials Australia magazine, website, social media and other public channels.

• A Certified Materials Professional can use the post nominal CMatP.

• Materials Australia will actively promote the CMatP status to the community and employers and internationally, through our partner organisations.

• A CMatP may be requested to represent Materials Australia throughout Australia and overseas, with Government, media and other important activities.

• A CMatP may be offered an opportunity as a mentor for student members.

• Networking directly with other CMatPs who have recognised levels of qualifications and experience.

• The opportunity to assume leadership roles in Special Interest Networks, to assist in the facilitation of new knowledge amongst peers and members.

What is a Certified Materials Professional?

A Certified Materials Professional is a person to whom Materials Australia has issued a certificate declaring they have attained all required professional

standards. They are recognised as demonstrating excellence, and possessing special knowledge in the practice of materials science and engineering, through their profession or workplace. A CMatP is prepared to share their knowledge and skills in the interest of others, and promote excellence and innovation in all their professional endeavours.

The Criteria

The criteria for recognition as a CMatP are structured around the applicant demonstrating substantial and sustained practice in a field of materials science and engineering. The criteria are measured by qualifications, years of employment and relevant experience, as evidenced by the applicant’s CV or submitted documentation.

Certification will be retained as long as there is evidence of continuing professional development and adherence to the Code of Ethics and Professional behaviour.

Further Information

Contact Materials Australia today: on +61 3 9326 7266 or imea@materialsaustralia.com.au or visit our website: www.materialsaustralia.com.au

GLOBAL STEEL HEAT TREATMENT

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS DECEMBER 2022 | 25

RAYMAX: Making Light Work for You

Source: Sally Wood

Since 1992, Raymax Lasers has connected those working in science, manufacturing, and industry with precise and sophisticated lasers to achieve their goals.

How does Raymax do it? They start by first investigating the complex outcome you’re looking to achieve:

• Does a unique material need to be cut, welded or cleaned?

• Do you want to improve your production process?

• Do you have a research goal?

Raymax works across a diverse range of industries and sectors:

• Material Interaction Research: laser evaluation and laser process development

• Solutions for Scientific Research: lasers, lithography, spectrometers, and custom optics

• Manufacturing: additive and bionic manufacturing, metal cladding and part repair, heat treatment, infrared and blue lasers, welding and cutting

• Micromachining and Microstructure Engineering Applications: thin wire stripping and processing, surface profiling and modification, metal ablation, micro-

sized welding and cutting

• Hyperspectral Imaging: optical identification

• Product Marking: tracing and identification, anti-counterfeiting and security

can improve operation in ways you might not have imagined possible.

Technical excellence is balanced with commercial interests to ensure that the equipment that Raymax assists you with meets your exact requirements.

Once the most fit-for-purpose and costeffective solution has been identified, Raymax ships and installs the laser or laser equipment for you. They will even train your team on your laser system, leaving you to sit back and relax, thanks to the reliable Australian-based service and support Raymax provides.

Raymax is a secure TRAC compliant company with international ethical accreditation.

The Raymax mission: Making light work: Delivering the best laser and photonics solutions to advance Australian and New Zealand industries and R&D organisations.

When you partner with Raymax Lasers, you’ll be working with a team of physicists and factory-trained engineers – leaders in the supply of laser solutions and optronics equipment. We’re experts in material interaction research. Wherever possible, Raymax works to introduce you to new technology that

The Raymax vision: Facilitate Australian and New Zealand industry to set the global benchmark for excellence and innovation with lasers.

Further Information www.raymax.com.au T: +61 2 9979 7646

INDUSTRY NEWS

26 | DECEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU Make Laser light work for you Raymax distributes specialised laser and photonics solutions Discover what is possible with our advanced Laser and Photonics Solutions • Advanced Manufacturing & Industrial Laser Processing • Micromachining & Microstructure Engineering Applications • Hyperspectral Imaging, Custom Optics, Lithography • Product Marking and Perforation Lasers • Laser safety products and Fume Extraction • Material Interaction Research • Solutions for Scientific Research • Laser Consulting & Engineering www.raymax.com.au

University of Queensland | Brisbane, Australia | 29 - 31 October 2023

The fifth International Materials Innovations in Surface Engineering (MISE) conference will be convened in Brisbane, Australia. The conference will be located at the state-of-the-art St Lucia Campus of the University of Queensland: twenty minutes from the centre of Brisbane.

MISE2023 features eminent academic and industrial plenary, keynote and invited speakers who encompass the engineering modification of a material’s surface to improve its performance.

The conference will cover topics such as: