Technical Additive Manufacturing with 3D printed spare parts revolutionize maritime supply chain By Christos Chatzigiaksoglou

Additive Manufacturing (AM), also known as 3D printing, is an appropriate name to describe the technologies that produce physical 3D objects by adding layer-upon-layer of material, whether the material is plastic, metal, concrete or any other suitable material using a computer-based 3D design. It is considered one of the nine main pillars (Internet of things, Augmented Reality, Simulation, System Integration, Cloud Computing, Autonomous Systems, Cybersecurity, Big Data Analytics) of the Fourth Industrial Revolution and has improved tremendously in the last decade from primarily being used for prototyping to actual production. The story of Additive Manufacturing starts back in 1981, when a form of AM called Stereolithography (SLA) was first introduced by

Dr. Hideo Kodama of the Nagoya Municipal Industrial Research Institute. Unfortunately, Dr. Kodama's patent application was denied because of his failure to file the full patent requirements on time. In 1986 an American inventor named Charles Hull filed the first official patent for SLA, which is the 3D printing technology that we have now become accustomed to.

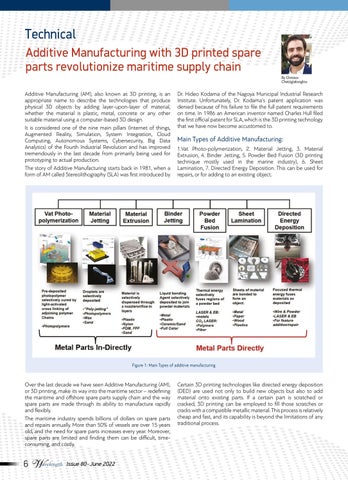

Main Types of Additive Manufacturing: 1.Vat Photo-polymerization, 2. Material Jetting, 3. Material Extrusion, 4. Binder Jetting, 5. Powder Bed Fusion (3D printing technique mostly used in the marine industry), 6. Sheet Lamination, 7. Directed Energy Deposition. This can be used for repairs, or for adding to an existing object.

Figure 1: Main Types of additive manufacturing

Over the last decade we have seen Additive Manufacturing (AM), or 3D printing, make its way into the maritime sector – redefining the maritime and offshore spare parts supply chain and the way spare parts are made through its ability to manufacture rapidly and flexibly. The maritime industry spends billions of dollars on spare parts and repairs annually. More than 50% of vessels are over 15 years old, and the need for spare parts increases every year. Moreover, spare parts are limited and finding them can be difficult, timeconsuming, and costly.

6

Issue 80-June 2022

Certain 3D printing technologies like directed energy deposition (DED) are used not only to build new objects but also to add material onto existing parts. If a certain part is scratched or cracked, 3D printing can be employed to fill those scratches or cracks with a compatible metallic material. This process is relatively cheap and fast, and its capability is beyond the limitations of any traditional process.