8 minute read

Precautions against Cargo Liquefaction

from Wavelength #80

Marine Operations Precautions against Cargo Liquefaction

Cargo liquefaction occurs when dry bulk cargoes with a high moisture content start to behave like liquids when the ship is moving. Such cargoes shift rapidly in the holds of a ship, resulting in the free surface effect, which renders the ship unstable and at risk of capsizing. Cargo liquefaction remains the By Marios greatest contributor to loss of life and causes the Strongyloudis greatest concern in the bulk carrier industry. Partial liquefaction can also occur in the case of iron ore fines. It will not have a disastrous effect, but it will place a great burden on the ship’s crew and waste valuable resources on cleaning the cargo holds.

Advertisement

Definitions

Moisture Content (MC) is the proportion of water, expressed as a percentage of the total mass of a cargo sample. Flow Moisture Point (FMP) is the moisture content at which a flow state develops. Cargoes with a “moisture content” beyond the FMP are liable to liquefy. Transportable Moisture Limit (TML) is calculated as 90% of the Flow Moisture Point. The TML value represents a 'safe' moisture content, below which the cargo is unlikely to undergo liquefaction and endanger the ship and crew. IMSBC Code (International Maritime Solid Bulk Cargoes Code) by IMO The primary aim of the IMSBC Code is to facilitate the safe stowage and shipment of solid bulk cargoes by providing information on the dangers associated with the shipment of certain types of solid bulk cargoes and instructions on the procedures to be adopted when the shipment of solid bulk cargoes is contemplated. It clearly defines the responsibility of the Shipper: •Provide the Master with a signed certificate of TML and

MC, each issued by an entity recognised by the competent

Authority of the port of loading. •Establish procedures for sampling, testing and controlling moisture content to ensure the moisture content is less than the TML when the cargo is on board the ship. •Facilitate access to stockpiles for the purpose of inspection, sampling and subsequent testing by the ship’s nominated representative. GROUP “A” cargoes are cargoes which may liquefy if shipped at a moisture content in excess of the transportable moisture limit. Some examples of Group A cargoes are: •Iron concentrate •Iron concentrate (pellet & sinter feed) •Iron ore fines •Nickel concentrate •Nickel ore •Coal •Coal slurry The Can test is used to obtain an approximate evaluation of the possibility of flow of the loaded cargo. It is a very simple testing method which can be carried out by the ship’s crew. It should be noted that the can test cannot substitute for the required laboratory testing. Some ports where iron ore shipments have exhibited liquefaction: •Brazil: Ponta da Madeira, Tubarao, Itaguai, Guaiba Island •India:Mangalore, Visakatnam, Paradip •Sierra Leone: Pepel •Philippines: Surigao Common factors encountered in the ports named above: •Loading from exposed stockpiles of iron ore •Loading during the heavy torrential rain season •Stockpiles inaccessible for proper sampling & testing •Laboratories for the required “moisture content” and “flow moisture point” testing unavailable at the remote loading area P&I Clubs and Classification Societies have published relevant circulars highlighting the hazards and mitigating measures to reduce the risk of cargo liquefaction. It is strongly suggested that all crew and office personnel involved in iron ore cargo transportation should refer to the circulars so as to take advantage of the wealth of experience gained in such cases. Important measures proposed for mitigating the risk of liquefaction are: •Check the shipper’s cargo declaration and stated moisture content. •Cargoes are not to be loaded under precipitation. •Heightened vigilance is required during the rainy season (i.e. December to April in Brazilian ports). •Request new moisture content laboratory tests to be carried out if it has rained in the days prior to loading. •Ensure that any document confirming that the cargo is safe to carry is signed by the shipper. •Check the cargo to be loaded in each barge or stockpile for excessive water content. •Should there be any concerns or doubts about the moisture levels in the nominated cargoes, further advice and assistance can be obtained from an independent reputable cargo expert.

In order to maintain the safety of crew and ship and avoid charter party disputes it is important to highlight the recommended procedures throughout the loading, transporting and discharging of iron ore cargoes: •Prior to arrival at the port of loading: The Master must acquire the Shipper’s declaration and confirm that it complies with IMSBC code requirements. The Shipper’s declaration must fully comply with IMSBC code requirements and provide all the necessary information. For GROUP A cargoes (subject to liquefaction), the Shippers are required to provide additional supporting documentation evidencing the moisture content of the shipment, the TML laboratory analysis certificate and proof that this test has been conducted at a lab approved by the Competent Authority of the port of loading. •Loading operation: Brazilian iron ore has a considerable moisture content. Even if many cargoes are described as

GROUP C in the Shipper’s declaration, the Master and crew should treat the cargoes as liable to liquefy. Masters should be vigilant and ensure that the cargo is inspected for any signs of moisture. For example, free standing surface water,

or spattering of cargo as it lands in the holds with resulting run marks are clear warning signs. The Master should always undertake his own can test at regular intervals and at each and every cargo hold. It should be noted that all bilges must be suitably cleaned and bilge covers placed accordingly to facilitate drainage throughout the voyage. Please check IMSBC code provisions with regard to loading under precipitation and ensure all non-working hatches are closed. In the case of loading at anchorage via barges, the IMSBC code provides that same need to be covered. Another factor to consider is the weather conditions since in certain countries the rainy season can heavily impact the nature of the cargo, especially if this is stowed in open areas. •During laden passage: Monitor cargo hold bilges and pump out water as required by keeping the required trim to facilitate the drainage of water. Keep a detailed log since this will be required for the draft survey at the discharge port. The bilge log is to be sent to all parties (Charterers, Agents etc.) on a daily basis. Weather permitting, inspect the cargo and hold edges for water accumulation. •Discharging operation: During the draft survey, it is important to present the bilge log to the surveyors to justify any short cargo and ensure that it is attached to their reports and any relevant remark is inserted in their draft survey reports.

On some occasions, stevedores may request that the cargo remain in the cargo holds if for some reason water has accumulated. This may create ship-shore cargo differences and possible shortage claims from receivers. The discharging sequence can also be arranged so that the affected hold is emptied immediately before the commencement of cleaning alongside. If residues or a small quantity of cargo is left in the holds, accumulated water and iron ore residues will form a hard mud which will be very difficult to remove.

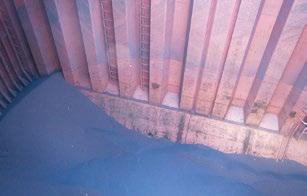

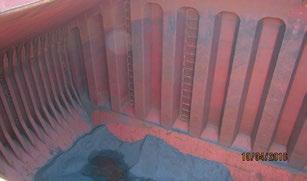

Iron ore cargo in normal condition

Iron ore cargo with minor water accumulation Can Test procedure: (Reference should be made first to Fleet Bulletin #2 / Section Procedures with instructions and details on how to perform a can test) •Use a cylindrical can, preferably a tin can or similar container of about 0.5 or 1 litre capacity and half fill it with cargo. •Hold the can with one hand and bring it down sharply to strike a hard surface such as the deck or a bollard from a height of about 0.2 metres. •Repeat this procedure 25 times at one to two-second intervals. •Examine the surface for free moisture or fluid conditions.

Turn the can upside down and shake it slightly to dislodge the sample. Examine it for free moisture or a fluid condition.

In daylight, the surface of cargoes not to be loaded under precipitation will be glistening. •Keep a log and photograph evidence of the can tests. During the course of loading, it is recommended that the Master or a designated crew member should frequently ‘Can Test’ the cargo as it is being loaded. Samples are to be taken from the cargo pile in the hold (tests on cargo piles in barges/ashore are important but are not as conclusive as the ‘loaded’ state).

Can test: The picture above shows formation of moisture at the surface, indicating that the moisture content may be too high and that more laboratory tests are needed to clarify the true relationship between MC and TML for that consignment.

Partially liquefied iron ore cargo

Reference videos on Youtube: •North P&I Club - Can Test Training Video https://www.youtube. com/watch?v=jB2fSjrQLZ4 •Dynamic separation of bauxite (aluminium ore) in bulk cargo by the Australian Maritime Safety Authority https://www.youtube. com/watch?v=zdyrQSypPBQ •Liquefaction Demonstrated by the Illinois State Geological Survey https://www.youtube.com/watch?v=b_aIm5oi5eA Further reference: 1. "Bulk Carrier Casualty Report, Years 2012 to 2021 and trends" by INTERCARGO 2. "Sierra Leone – Carriage of Iron Ore Fines Cargoes –

Liquefaction Risk" by UK P&I 3. "REDUCING THE RISK OF LIQUEFACTION Operational guidance for vessels that carry cargoes which may liquefy" by the London P&I, TMC Marine & Bureau Veritas 4. “BULK CARGO LIQUEFACTION Guideline for design and operation of vessels with bulk cargo that may liquefy” by DNV