PRIMARY PACKAGING Designed to secure pharma products safely

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary

Index ABOUT MARCHESINI GROUP ................................................. 4 KEYPOINT ............................................................................... 5 ORAL SOLID DOSE .................................................................. 6 Tablet counting ...................................................................... 6 Blister ................................................................................... 11 Strip ...................................................................................... 17 Rigid Tube ............................................................................. 18 Under containment .............................................................. 19 LIQUIDS ................................................................................. 21 Stickpack .............................................................................. 21 Sachet ................................................................................... 22 Bottles/vials ......................................................................... 24 CREAMS ................................................................................ 28 Squeezable tubes ................................................................ 28 Jar ......................................................................................... 30 POWDERS ............................................................................. 31 Stickpack .............................................................................. 31 Sachet ................................................................................... 32 OUR COMPANIES

We at Marchesini Group are proud leaders in manufacturing and integrating complete lines since 1974.

We produce stand-alone machines and complete lines to handle the entire packaging process for the pharmaceutical industries. Today, the Marchesini Group caters for the whole packaging process of pharmaceuticals, from start to finish. It creates stand-alone machines and complete lines to package products such as vials, syringes, carpules, bottles and blisters through to putting the individual products into bundles, cases and on pallets.

The finished product - machines capable of packaging all kinds of pharmaceutical products - is a combination of craftsmanship integrated with robotics and technology. This result has been achieved thanks to the expertise of the Group’s branches which specialize in designing and manufacturing packaging machines with specific productive technologies, such as aseptic packaging, Blister packaging, Labelling, Inspection, all to manage every kind of pharmaceutical product, oral solid dose, liquid, cream or powder that can be put in every kind of pack. Every brand of the Group develops and manufactures specific machines for the whole packaging process in its plants located throughout Italy, while complete line assembly is coordinated from our Headquarters.

4

Keypoint

Industry 4.0 Compliant

The Marchesini machines are designed in accordance with cGMP regulations and feature the latest IoT technologies.

Our machines are designed to reduce total changeover time and maximize performance.

Small footprint to optimize the factory floor space.

Our patented robotic solutions are developed in-house to connect different machines together in-line.

Accessible and ergonomically designed machines ensure a positive operator experience in terms of machine management, inspection and service.

New models are constantly developed in our in-house R&D. department.

We provide a complete range of machines for the entire packaging process.

5

Tablet Counting COMPACT SERIES

Featured Model COMPACT24

Counting Filling and Capping monoblock machine for solids.

Monoblock machine for filling and capping bottles with tablets, capsules or pills.

On the Compact Series, innovation is put at the service of simplification in format change, to meet the increasingly pressing needs of maintaining the highest quality standards and performances, even in the presence of different products and counts in small or medium-sized batches.

To achieve this result, an innovative magnetic movement transport system was used (Compact24 model). It allows to overcome the typical limits of normal transport systems, by means of the totally autonomous handling of each single bottle: positioning, grouping, speed of movement are just some of the parameters that make this system unique.

• HIGHER production rates (Newer counting technologies enable higher bottle rates)

• VERY FAST change-over times

• HIGHER product quality (Complete control of the bottle, Pre or post checkweighing, High speed electronic counter, Rotary chuck capper)

• MORE EFFICIENT floor space utilization

TECHNICAL DATA

MECHANICAL SPEED:

Bottles-cycles/minute

Tablet Ø

• HIGHER equipment efficiencies (2D and 3D control for the product verification, HarleNIR system for the verification of the active principle contained in the product, Rejection system for the single no-compliant product, Dual head cotton feeding group, Desiccant feeding group) COMPACT

“A”

ORAL SOLID DOSE

Diameter of round bottle. “G” Total bottle height, without closure.

(mm)

size (A) (G)

Up to 75 5 - 20 000 - 5 from 18 to 90 mm from 35 to 180 mm

Capsules

COMPACT 12

Up to 150 5 - 20 000 - 5 from 30 to 125 mm from 50 to 220 mm COMPACT 12 VALIDA Up to 75 5 - 13 000 - 5 from 18 to 90 mm from 35 to 180 mm COMPACT 24 VALIDA Up to 150 5 - 13 000 - 5 from 30 to 125 mm from 50 to 220 mm 6

24

Tablet Counting VALIDA SERIES

Featured Model VALIDA

The main concept of this solution is the “VALIDATION” of the counting process.

VALIDA includes at least a 2D vision control, where 4 cameras placed immediately over the last vibrating tray, check shape, color and dimensions of travelling product; each tablet is univocally traced and followed up to its falling at the end of the tray.

VALIDA can includes a 3D control too. Thickness verification is obtained by a couple of special pattern projectors. A series of 12 gates are capable to intercept and reject a SINGLE bad product. In addiction the Valida solutions can be equipped in the NIR Technology. It works within the region of the infrared frequency, where the molecules used in pharma production are highly reactive and show a well defined chemical footprint. This is also possible thanks to our innovative detection systems: in fact a normal camera acquires what it sees. An hyperspectral one instead does not take a single image, but several consecutive frames, which contain info related to the spectrum of each point of the product.

ORAL SOLID DOSE

Diameter of round bottle. “G” Total bottle height, without closure. TECHNICAL DATA MECHANICAL SPEED: Bottles-cycles/minute Tablet Ø (mm) Capsules size (A) (G) VALIDA 12 Up to 60 5 - 13 000 - 5 from 20 to 100 mm from 55 to 185 mm VALIDA 24 Up to 120 5 - 13 000 - 5 from 20 to 110 mm from 55 to 185 mm 7

“A”

Tablet Counting

SYNCHRO

Featured Model SYNCHRO

Counting and capping monobloc for medium/high speeds, equipped with synchro-dynamic groups for the collection of the stopped count and the continuous transfer inside the bottles. The transport is equipped with continuous motorized adjustment, to adapt to the different dimensions of the bottles. The capping unit is equipped with 8 heads, each with its own motor, for accurate control of the applied torque.

• The transfer of the product starts during the tracking of the bottle and therefore progressively, making use of all the available time/cycle. This system considerably reduces the criticality of product transfer through the neck of the bottle

• Inside the monoblock, it is possible to integrate silica-gel feeding systems and/or cotton insertion systems

TECHNICAL DATA

• The continuous transport of the bottles allows the use of a capping group which is also of the continuous type and therefore able to contain the necessary spaces, in addition to requiring a single channel for feeding the caps

ORAL SOLID DOSE

Diameter

Total

“A”

of round bottle. “G”

bottle height, without closure.

Bottles-cycles/minute Tablet Ø (mm) Capsules size (A) (G) SYNCHRO-24 Up to 150 5 - 20 000 - 5 from 30 to 70 mm from 50 to 140 mm SYNCHRO-36 Up to 220 5 - 20 000 - 5 from 30 to 70 mm from 50 to 140 mm SYNCHRO-24 VALIDA Up to 150 5 - 13 000 - 5 from 30 to 70 mm from 50 to 140 mm 8

MECHANICAL SPEED:

Tablet Counting ELECTRA

Featured Model ELECTRA

Electro-mechanical counting unit for counting and checking of tablets, dragees and capsules at high speed. Counting is done volumetrically, stacking products vertically in adjacent columns.

The system allows the installation of a vision system placed in front of the accumulation columns, which checks the shape, size and number of stacked products, immediately before their release. Following the release, the same vision system checks the complete emptying of the counting channels. The machine can fill up to 6 bottles at the same time, depending on the size of the bottle itself and the required count.

• Machine of extremely compact dimensions compared to the achievable production speeds

• Vision check of product integrity and counting, with single bottle reject system in case of defective product or incorrect counting

• Integrated upstream and downstream systems for sorting and subsequent grouping of bottles (up to 6 rows)

TECHNICAL DATA

MECHANICAL SPEED:

Bottles-cycles/minute

Tablet Ø (mm)

Capsules size (A) (G)

ELECTRA

Up to 180 5 - 12 000 - 5 from 20 to 50 mm from 40 to 100 mm

ORAL SOLID DOSE

“A” Diameter of round bottle. “G” Total bottle height, without closure.

9

Tablet Counting FTC SERIES

Electronic counters in stand-alone version with 12 or 24 channels, which can be equipped with “twin flap” or “twin funnel” systems to increase performance with medium/low counts. The machines can be equipped with standard bottle conveyor systems or with positive screw conveyor systems.

FTC Series allows to guarantee maximum flexibility with respect to the products/counts required, minimizing costs and format changeover times.

• Great flexibility in the possible configurations and in the management of even very different products/counts

• Excellent recovery and containment system for dust emitted during product transfer and transport

• Optical sensors (transmitters and receivers) integrated in a dedicated box, equipped with RS485, accelerometer and self-calibration functions

“A”

Model FTC ORAL SOLID DOSE

Featured

TECHNICAL DATA MECHANICAL SPEED: Bottles-cycles/minute Tablet Ø (mm) Capsules size (A) (G) FTC-12 Up to 75 5 - 20 000 - 5 from 20 to 100 mm from 55 to 185 mm FTC-24 Up to 150 5 - 20 000 - 5 from 20 to 110 mm from 55 to 185 mm 10

Diameter of round bottle. “G” Total bottle height, without closure.

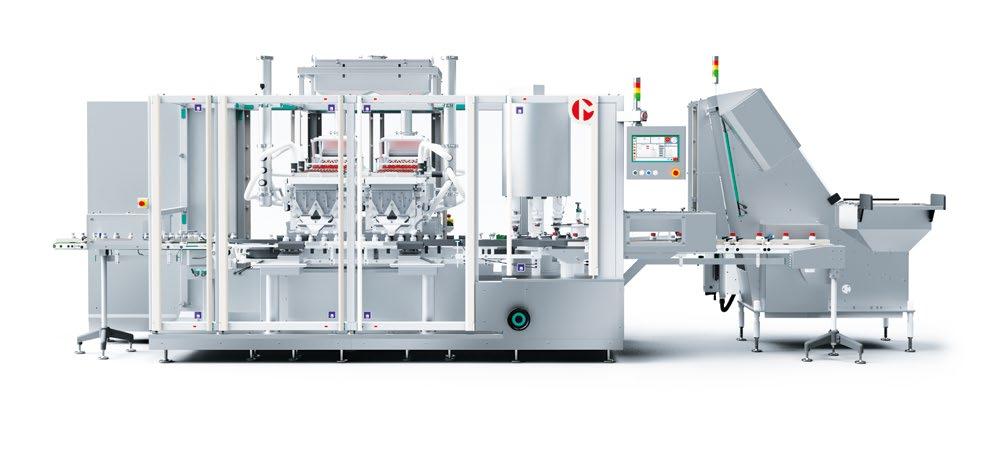

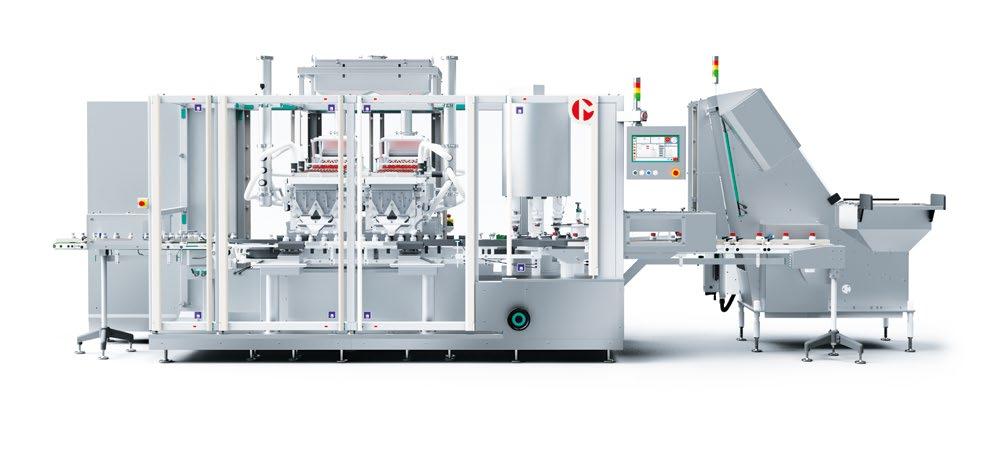

Blister INTEGRA SERIES (220 – 220V)

Complete blister lines designed to provide maximum manufacturing efficiency and higher ergonomic standards in accordance with cGMP norms.

The main mechanics as well as the packaging reels are stored at the back of the machine to facilitate accessibility. As a result, the operators can benefit from a wider working area to carry out tasks safely and easily.

• Suitable to be equipped with containment technologies

• Feeding section with or without enclosure

• Suitable for manual product feeding

• Rapid size change-over operations

• Each group managed by servo driven motors

• Quick-release system to easily replace of various infeed units

• Flat sealing station

• Intermittent-motion cartoning section

• Stand alone blister section available under request

• Suitable for small-batch production

INTEGRA 220 ORAL SOLID DOSE (*) Nominal production speed. SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) Cartoning (cartons/min) SIZE RANGE Blister Width Blister Height Blister Length Forming Depth Carton Width Carton Height Carton Length 220 Up to 65 Up to 220 Up to 150 SPEED RATES* 30 - 80 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 30 - 85 mm 16 - 70 mm 65 - 150 mm

Featured Model

220V Up to 65 Up to 220 Up to 220 SPEED RATES* 30 - 86 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 35 - 90 mm 15 - 90 mm 75 - 150 mm 11

Blister INTEGRA SERIES (320)

Featured Model INTEGRA 320

Integrated continuous motion monoblock machine.

The blistering section is managed by servo motors and features two splicing tables with hidden cutter and automatic grip vacuum. A rotating unit picks up the blisters from the die cutter and positive deposits it on the connecting conveyor.

Thanks to a 3 axis translation, the ROBOCOMBI, a robotized blister feeding system, carries out different kinds of blister stackings on the bucket belt of the cartoning section.

• 1 lane

• Flat sealing

• Splicing tables

• Cartoning section with specially designed belt conveyor for blister

• 2 servo driven independent pushers

• Minimum product and materials load control

• Cross control product-carton-leaflet

SPEED RATES*

BLISTER SECTION:

Forming (cycles/min)

Cutting (blisters/min)

Cartoning (cartons/min)

SIZE RANGE

Blister Width

Blister Height

Blister Length

Forming Depth

Carton Width

Carton Height

Carton Length

ORAL SOLID DOSE (*) Nominal production speed.

320 Up to 75 Up to 320 Up to 260 SPEED RATES* 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm 12

Blister INTEGRA SERIES (420 – 420V)

Designed to comply with cGMP regulations, the INTEGRA 420 and 420V feature a balcony structure to improve accessibility.

The machines are composed of two main sections, the blister Thermo/cold-forming unit and the cartoning section. Focusing on the blister part, it features an ergonomic working area thanks to the rear position of both the forming reels and the preheating and forming station. This also allows a compact footprint, as required of today’s industry. Multiple options of product feeding units are available in order to perform any kind of production. Sealing, coding and cutting operations run over servo driven independent groups. The ROBOCOMBI transfers, pursuits and stacks the blister into the cartoning section.

• New track feeding system

• 1 or 2 lanes

• Forming depth up to 12mm

• Vertical position of the heating plates

• Overheating and stretching control system

• Servo driven motors

(*)

ORAL SOLID DOSE SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) Cartoning (cartons/min) SIZE RANGE Blister Width Blister Height Blister Length Forming Depth Carton Width Carton Height Carton Length 420 Up to 50 Up to 420 Up to 260 SPEED RATES* 30 - 86 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 35 - 90 mm 15 - 90 mm 75 - 150 mm 420V Up to 50 Up to 420 Up to 400 SPEED RATES* 30 - 66 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 25 - 70 mm 15 - 85 mm 65 - 150 mm

Featured Model INTEGRA 420V

Nominal

speed. 13

production

Blister INTEGRA SERIES (520 – 520V)

The Integra 520 and 520V robotized blister lines combine fast size changeover with an improved footprint. Independent servo-driven motors manage each section of the entire production process. Both the machines can be equipped with different product feeders, according to manufacturing specifications. Quick-release fasteners provide a tool-free change-over of loading and feeding units. The new rotating drum* for cartons opening and transfer combined with the “Cinquecento”* product insertion unit represent cutting-edge mechanical innovations.

(*) Available on Integra 520V only

• Monoblock machine designed in accordance with cGMP norms

• Fast format changeover

• Indipendent servo-driven motors

• Two splicing tables with hidden cutter and automatic grip vacuum

• Preheating and forming station in the rear side of the machine

• Horizontal sealing station that follow the motion for pressure uniformity

• Cooling plates of the film after the sealing

• Robotized blisters feeding system (Robocombi)

(*) Nominal production speed.

INTEGRA 520 ORAL SOLID DOSE SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) Cartoning (cartons/min) SIZE RANGE Blister Width Blister Height Blister Length Forming Depth Carton Width Carton Height Carton Length 520 Up to 65 Up to 520 Up to 260 SPEED RATES* 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm 520V Up to 65 Up to 520 Up to 500 SPEED RATES* 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm

Featured Model

14

Blister INTEGRA SERIES (720 – 720V)

Featured Model INTEGRA 720V

Fully compliant with cGMP regulations with an ergonomic design that provides full accessibility to mechanisms, consumables and for maintenance (rear side), as well as a user-friendly working area at the front of the machine.

The blistering section passes the blister to the ROBOCOMBI, then its fast 3 axis movement smoothly transfers the products to the cartoner. Here the rotating drum delivers the cartons to the “Cinquecento”* insertion mechanism to complete the process with outstanding precision.

(*) Available on Integra 720V only.

• Balcony style design

• Designed in accordance with cGMP regulations

• 1 or 2 or 3 lanes

• Each group managed by servo driven motors

• Size parameters set on the PC for fast changeover

• Compact line

• Automatic pitch adjustment

• Integrated Robocombi

• High-speed continuous motion cartoning unit

ORAL SOLID DOSE

Nominal production speed. SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) Cartoning (cartons/min) SIZE RANGE Blister Width Blister Height Blister Length (2 lines) Blister Length (3 lines) Forming Depth Carton Width Carton Height Carton Length 720 Up to 65 Up to 720 Up to 260 SPEED R 30 - 86 mm 3 - 9 mm (12 mm opt.) 70 - 140 mm 70 - 90 mm Up to 12 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm 720V Up to 65 Up to 720 Up to 500 SPEED 30 - 86 mm 3 - 9 mm (12 mm opt.) 70 - 140 mm 70 - 90 mm Up to 12 mm 30 - 90 mm 15 - 90 mm 75 - 155 mm 720M Up to 65 Up to 720 Up to 360 SPEED 30 - 86 mm 3 - 9 mm (12 mm opt.) 70 - 140 mm 70 - 90 mm Up to 12 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm 15

(*)

Blister MB SERIES

Featured Model MB422

Cutting-Edge “stand alone” Machines.

Marchesini Group is able to offer a wide range of stand alone machines suitable to meet all customer needs, ensuring maximum reliability in terms of performance and production flexibility.

• MB Series machines can be installed very easily in any type of line, thanks to the compactness and easy connection to every exixting downstream cartoning machine

• Suitable for different layout needs

• Maximum accessibility and safety

• Easy and fast size change over

(*)

ORAL SOLID DOSE

Nominal production speed. SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) SIZE RANGE Blister Width Blister Height Blister Length Forming Depth MB422 Up to 65 Up to 220 30 - 80 mm 3 - 12 mm 70 - 140 mm Up to 12 mm MB432 Up to 75 Up to 320 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm MB442 Up to 50 Up to 420 30 - 86 mm 3 - 12 mm 70 - 140 mm Up to 12 mm MB452 Up to 65 Up to 520 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm 16

Strip MST SERIES (Vertical)

Featured Model MST300

Automatic machines for packaging solid products in strips (tablets and/or dragées, capsules and effervescents etc). These machines are designed to minimize the layout, in order to make the operator oversee the entire production process. Efficiency and flexibility are provided by the fast format changeover and the balcony structure. The MST Series are available in standalone version or can be connected to cartoners (in line or 90 degrees).

• cGMP compliants

• Drive unit separated from functional modules

• Parts in contact with the product made of FDA approved materials

• Different feeders available, according to the product to

ORAL SOLID DOSE

STRIP PACKER Nr. of channels Max output (strokes per channel/min) Max. output (Cycles/min) Reel width (mm) Reel Ø (mm) MST200 Up to 8 Up to 250 Up to 75 220 400

MST200MINI Up to 8 Up to 250 220 400 MST300 Up to 12 Up to 250 Up to 75 340 400 MST300MINI Up to 12 Up to 250 340 400 17

be machined

Rigid tube MT 1000

Featured Model MT1000

Tubes filler-capper for tablets.

Automatic machine suitable to count and introduce positively tablets in plastic or metallic rigid tubes, cylindrical-shaped (patented solution). Final tube closure with pressure cap and discharge of the tubes correctly filled on a bucket conveyor at machine outfeed, with cap facing the operator side.

• This machine has been designed to ensure both high efficiency and quality

• Balcony type

• Steel an aluminium frame with AISI304 stainless steel panels

• Patented tube feeding and orienting system

• Direct tubes discharging system on transport chain

• Two parallel belts conveyors with independent motorization

• 4 groups of 12 tubes holding bushes coupled on belts

• Sinchro-dynamic mode

(*) Optional

TECHNICAL DATA

MAX MECHANICAL SPEED: Tablets/min (tubes/min)

TUBE DIMENSIONS*

Cap diameter (mm)

Tube ext diameter (mm)

Tube height (mm)

ORAL SOLID DOSE

MT1000 1000 100 SPEED RATES* 18 - 44 16 - 40 60 - 160 18

Under containment INTEGRA SERIES

All process steps are first defined with the customer, in order to guarantee line flexibility and to protect the operative while they are handling products and materials.

• Machine setup

• Bulk product feeding

• Cleaning procedure

• Troubleshooting procedures

• Operatives can work without special protective clothing

• No time-consuming entry and exit procedures for people and material

• Cross-contamination is reliably ruled out

• Significantly reduced effort required for format changeovers and cleaning (*)

ORAL SOLID DOSE

Nominal production speed. SPEED RATES* BLISTER SECTION: Forming (cycles/min) Cutting (blisters/min) Cartoning (cartons/min) SIZE RANGE Blister Width Blister Height Blister Length Forming Depth Carton Width Carton Height Carton Length INTEGRA 220V Up to 65 Up to 220 Up to 220 SPEED RATES* 30 - 86 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 35 - 90 mm 15 - 90 mm 75 - 150 mm INTEGRA 220 Up to 65 Up to 220 Up to 150 SPEED RATES* 30 - 80 mm 3 - 12 mm 70 - 140 mm Up to 12 mm 30 - 85 mm 16 - 70 mm 65 - 150 mm INTEGRA 320 Up to 75 Up to 320 Up to 260 SPEED RATES* 30 - 86 mm 3 - 9 mm 70 - 140 mm Up to 9 mm 30 - 90 mm 15 - 90 mm 75 - 150 mm Featured Model INTEGRA 320 UNDER CONTAINMENT 19

Under containment COUNTING SOLUTION

Featured Model COMPACT 12

Counting Filling and Capping machine for solids with Containment System (RABS) fully integrated with machine. A multi-chamber isolator design to house the filling, counting and capping process equipment including all of the associated product separation and filtration equipment to process batches of tablets containing highly active or toxic pharmaceutical ingredients.

• The isolator’s chamber is designed so as to define an active barrier between the process area and the surrounding environment

• Full access within the equipments installed in the isolators

• Large glazed areas to provide the best possible view of all process operations

• Negative pressure between the enclosure and the surrounding environment to ensure all potential contamination is contained within the product handling enclosure

• Oval glove ports positioned in order to facilitate the operator-process interface and reduce operator fatigue

• Ergonomic improvement to facilitate format changeovers and cleaning operations, also thanks to an internal trolley specifically designed for loading and unloading pieces in complete safety

ORAL SOLID DOSE 20

Stickpack

MT SERIES

Featured Model MT1500

The MT machine is an intermittent motion filler for packaging tubular sachets sealed on 3 sides called “sticks”. In particular the Liquid Dosing Unit is indicated for liquid at different viscosity (from watery to highly viscous product including stringy).

COMPLETE TURNKEY LINE:

The Stickpack machine can be linked to a Cartoning Machine thanks to a special conveyor. IN-LINE outfeed combination or ORTHOGONAL (90°) outfeed combination are applicable to be adaptable on available space at production hall.

The stacking of sticks in boxes can be in 3 ways: on bulk / ordered / on edge.

• Cleanliness: the machine mechanical parts are clearly separated from the product and film passage

• CIP/SIP dosing unit design compliant

• Fast release function: all filler machine stations are totally dismountable to speed up the size change-over, cleaning, mainteinance operations

TECHNICAL DATA

Number of lanes

Max. mechanical speed

Reel sizes

Format range

MT1100

4 - 12 lanes

Up to 60 cycles/minute

Width max. 550 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

MT1300

4 - 18 lanes

• Dosing unit: for every single project the technical department carries out detailed testing to classify the product specifications, based on that the team choose, designs and builds the most suitable dosing unit

Up to 60 cycles/minute

Width max. 750 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

MT1500

4 - 22 lanes

Up to 60 cycles/minute

Width max. 950 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

MT1800

4 - 20 lanes

Up to 60 cycles/minute

Width max. 1250 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width:

26 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

LIQUIDS

21

Sachet MS235

The MS235 is a Vertical intermittent motion Sachet machine.

High reliability, easy cleaning and extreme accessibility make the MS235 suitable for the pharmaceutical market. The vertical sealing takes place through the mechanical approach of the sealing plates and concluded with the pneumatic expansion action of a membrane mounted on one of the 2 plates. This system allows maximum welding efficiency, guaranteeing homogeneity of sealing pressure for a perfect tightness.

The sachet machines are set up both for standalone production and for in-line production by inserting an AS237 elevator conveyor to carry out the sachets transferring, stacking and counting ready for the final box. The system can be further expanded by adding the statistical weighing system directly on the AS237 elevator.

On-board dosing unit for valve syringe control. The group is set up with 2 Brushless motors.

TECHNICAL DATA

LIQUIDS

Max output (cycles/min) MIN. SACHET DIMENSION Width (mm) Length (mm) Reel width (mm) GENERAL (*) optional Reel Ø (mm) MS235 15 - 75 25 - 200 60 - 150 840 2 x 500 (standard) 1 x 800 (optional) CORE Ø 75 / 150 Featured Model MS235 22

Sachet AS SERIES

Featured Model AS FOR LIQUIDS

Continuous-motion vertical sachet filling for medium-high production capacities.

The continuous motion and the use of rotary sealing elements permit to reach extremely high production speeds and therefore give an unmatchable total capacity in sachets per minute.

The “AS” series machines are designed to be versatile and flexible, permitting a fast and easy format change of the sachets, whether in Width as in Length.

The balcony structure, the design of the components and the use of Stainless Steel allow the machine to comply with GMP rules.

All parts in contact with the product are made of Stainless Steel or other FDA-approved material.

Marchesini Group is continuously upgrading its products according to markets needs.

The final technical data for each project could therefore vary depending on the effective machine configuration.

LIQUIDS

SACHET FILLING Number of lanes Maximum mechanical output Reel Width Reel Diameter Format range AS500 1 – 16 lanes Width max. 1000 mm AS300 1 – 10 lanes Width max. 600 mm AS600 1 – 20 lanes Width max. 1200 mm

Up to 200 cycles/minute Diameter max. 600 mm // Core diam. 76 mm Sachet width: 30 - 150 mm // Sachet length: 40 - 250 mm 23

Bottles/vials OPTO 150

Featured Model OPTO 150

Ophtalmics filling and capping machine.

• Automatic filling capping machine with walking beam transport

• Different capping station are avaibale and up to nr. 2 robots to performs capping operations

• Suitable for sterile applications vials and bottles and LAF installation

• Working station: 3 or 4 vials handled per time

• Dosing unit:

Small dosage: 3 or 4 pumps and needles activated

High dosage: Fractioned Dosing logic 50% + 50%

Nozzles with diving motion

• 2 capping stations: 1st station dropper + 2nd station screw cap

TECHNICAL DATA

(A)

LIQUIDS

(with

Output PRODUCT RANGE Dosing Range

volumetric dosage system)

CONTAINER SIZES

ø of round bottle

height

(H) Vials

minim.

(F) ø Internal mouth

150 150 Bottles/min (pitch 4) 120 Bottles/min (pitch 3) PRODUCT 0,5 - 100 ml 16 - 35 mm 35 - 100 mm 5 - 7 mm 10 - 50 mm 24

(H) Closure Height OPTO

Bottles/vials

ML SERIES (Intermittent)

Featured Model

Automatic intermittent motion machines, suitable to fill and close a wide range of liquid containers. Stainless steel covered frame and clear Separation between the bottle transport and mechanical area. Machine motor with electronic speed variation, settings from zero to maximum. Through FLEX-LINK tabletop conveyor for bottle infeed and discharge with adjustable guides in stainless steel AISI304. Independent drive with speed adjustment from Display. Industry 4.0 ready: the machine supports the latest IoT technologies.

TECHNICAL DATA Note

ML639

Automatic, in line, intermittent Caps Retorquer 2, 3 or

Bottles 80-120-160

ML640

Automatic, intermittent Motion Plugger & Capper

ML642

Automatic, intermittent Motion Filler, Plugger, Capper

ML646

Automatic, intermittent Motion Filler, Plugger, Capper

ML643

Automatic, intermittent Filler, Capper 1 capping/

towers

ML642 LIQUIDS

Functions Capping

Product Mechanical speed (pcs/min) Liquid Dosing Range (ml) Container diameter Ø Width x Width square container Long side rectangular container Short side rectangular container Container height

towers

screwing

4

heads

(2, 3, 4 heads)

- 80 mm

- 80 mm

- 100 mm

- 60 mm

140

18

20

20

20

40 -

mm

1,2,3 capping/ screwing towers Bottles 75 cycl./min 18 - 90 mm 20 - 80 mm 20 - 85 mm 20 - 60 mm 35 - 180 mm

1,2,3 capping/ screwing towers Bottles 75 cycl./min 1 - 500 Steel 1 - 300 Ceramic 18 - 90 mm 20 - 80 mm 20 - 85 mm 20 - 60 mm 35 - 180 mm

1,2,3

screwing

Bottles 75 cycl./min 1 - 500 Steel 1 - 300 Ceramic 18 - 90 mm 20 - 80 mm 20 - 85 mm 20 - 60 mm 35 - 180 mm

capping/

towers

screwing

Bottles 100 0,5 - 100 18 - 65

-35 - 150 mm 25

mm

Bottles/vials

ML SERIES (Continuous Motion Linear)

Featured Model ML662

Monoblock linear filler with continuous rotary closures, available in different configurations. Design with clear separation between the dosing-capping section and the drive mechanisms which are placed inside the machine basement. The machine filling area is with balcony design and bottles transport is made on the infeed conveyor.

• Variable speed for all the machine belts

• Robotized machine functions driven by servo motors

• Quick size changeover with minimum adjustments or replacement of parts

• Industry 4.0 ready: the machine supports the latest IoT technologies

• Designed in accordance with GMP regulations

• Possibility to equip the machine with CIP/SIP/WIP system

• Different dosing system available

TECHNICAL DATA

Note

Functions

Capping towers

Product

Mechanical speed (pcs/min)

Liquid Dosing Range (ml)

Container diameter Ø

Width x Width square container

Long side rectangular container

Short side rectangular container

Container height

ML661/1T

ML662/2T

Linear /continuous rotary Filler, Capper 2 (16-Heads)

LIQUIDS

Linear

(8-Heads) Bottles 250 0,5 - 500 Steel 0,5 - 300 Ceramic 18 - 70 mm 20 - 70 mm 20 - 70 mm 20 - 60 mm 35 - 180 mm

/continuous rotary Filler, Capper 1

250 0,5 - 500 Steel 0,5

Ceramic 18 - 70 mm 20 - 70 mm 20 - 70 mm 20 - 60 mm

180

Bottles

- 300

35 -

mm

26

Bottles/vials

ML SERIES (Continuous Motion Rotatory)

Featured Model ML618

Availability of pure capping machines in continuous motions or Monoblock for filling and capping. The high speed rotary monobloc machine can be equipped with filling pumps and one or two capping turrets according to the kind of product to be handled.

• Different dosing system available

• Possibility to equip the machine with CIP/SIP/WIP systems

• Designed in accordance with cGMP regulations

LIQUIDS

TECHNICAL DATA Note Functions Capping towers Product Mechanical speed (pcs/min) Liquid Dosing Range (ml) Containe diameter Ø Width x Width square container Long side rectangular container Short side rectangular container Container height - 10÷100 30÷300 Bottles Automatic Continuous rotary Capper Filler, Capper ML 618/1T 1 (8-heads) 300 ML 618/2T 2 (8+8 heads) 300 ML636/1T 1 (16-heads) 500 ML667/1T 4 Heads 250 ML668/2T 2 (4 + 4 Heads) 300 ML636/2T 2 (16+16 heads) 500 18 - 80 mm 18 - 40 mm 18 - 70 mm 20 - 80 mm -20 - 100 mm -20 - 60 mm -40 - 200 mm 40 -100 mm 50 -180 mm 27

CREAMS

Squeezable tubes COLIBRÌ

Featured Model COLIBRÌ

Automatic tube filling and closing machine. Designed for filling and closing metal, plastic, polyfoil or laminate tubes, it is constructed to work in a pharmaceutical environment according to the highest technological standards to garantee the maximum productivity and quality.

• Capsized tube control service

• 12-position turntable

• 316 L parts in contact with the product with tri-clover connections

• Fixed injector with positive shut-off valve and nozzle cleaning by air blow

• Safety coupling to protect mechanical parts from overload dosing unit

• Special execution enabling to transfer the dosing group, still totally assembled (hopper, filling valve, filling valve housing, piston, cylinder, injector and nozzle), from the dosing area to the washing and sterilization area

• Predisposition for LF-Exhaust

• Industry 4.0 Software Functions Package for the management of the machine

TECHNICAL DATA

Note

Functions

Mechanical speed (pcs/min)

Dosage range (ml)

Tube ø (mm)

Total tube length with cap (mm)

COLIBRÌ

Automatic Intermittent Rotary Filling, sealing 80 (100)

1 - 390

11 - 40 (Alu)

10 - 50 (PE, Polyfoil® PE, Polyfoil® PP, Recycle PE Tube, PCR, Reduce, Bio-Based Tube, Wood/Carton/Paperbased Tube)

50 - 250

28

Squeezable tubes MILLENIUM SERIES

Intermittent motion linear automatic machine for filling and sealing aluminium, polyethylene and laminate tubes. Cantilevered frame design to improve accessibility, maintenance and cleaning operations.

Main frame and base of the machine in AISI 304 stainless steel. Parts in contact with the product in AISI 316L stainless steel. Machine suitable to operate under laminar flow and sterile environments. Independent servo motors to allow a great versatility in the configuration and make each function independent. Automatic adjustment of the tube height managed at each size changeover.

Bi/Tricolors products dosing unit available.

Prearrangement for any variable data printer (inkjet or laser) and related OCV/OCR cameras control. Easy installation of sensors and cameras for tube quality controls: correct tube orienting, correct filling, cutting and sealing tubes. Available 100% tubes check weight control with feedback signal to dosing piston to improve a product filling control. Quick size changeover without tools.

TECHNICAL DATA

Note Functions

Mechanical speed (pcs/min)

Dosage range (ml)

Tube ø (mm)

Total tube length with cap (mm)

MILLENNIUM 120

Automatic Intermittent Linear

Filling, sealing 120

1 - 350

11 - 40 (Alu)

10 - 50 (PE, Polyfoil® PE, Polyfoil® PP, Recycle PE Tube, PCR, Reduce, Bio-Based Tube, Wood/Carton/Paper-based Tube)

50 - 250

MILLENNIUM 200

Automatic Intermittent Linear Filling, sealing 200

1 - 350

11 - 40 (Alu)

10 - 50 (PE, Polyfoil® PE, Polyfoil® PP, Recycle PE Tube, PCR, Reduce, Bio-Based Tube, Wood/Carton/Paper-based Tube)

50 - 250

CREAMS

MILLENIUM

Featured Model

200

29

CREAMS

Jar MV545

Featured Model MV545

Intermittent motion Monoblock machine suitable for the filling and capping of jars. Design, manufacturing and ergonomics, in accordance with cGMP norms.

AISI 304 stainless steel frame. Parts in contact with the product in AISI 316L stainless steel.

Pre arrangement of sealing of aluminum foil by pre-cut foil or reel feeding.

Pre arrangement of under cap, plastic lid, by pick & place and vibratory bowl feeder.

Capping unit able to handle both press on cap or screw cap.

Availability of automatic plastic jar and cap feeders/unscramblers.

Pre arrangement for any variable data printer (inkjet or laser) and related OCV/OCR cameras control. Quick size changeover.

TECHNICAL DATA

Note

Functions

Mechanical speed (pcs/min)

Dosage range (ml)

Jar Ø (mm)

Jar height with cap (mm)

Cap Ø (mm)

Cap height (mm)

MV545

Intermittent motion monoblock

Filling, capping

75

3-500

35-100

35-80

from 35 to 100 mm (with cap)

from 10 to 35 mm

30

Stickpack MT SERIES

Featured Model MT1300

The MT machine is an intermittent motion filler for packaging tubular sachets sealed on 3 sides called “sticks”. In particular the Auger Filler dosing unit is indicated for powder/dusty products (not free flowing).

The MT series filler handles powder, granular, liquid and pasty products as well as single pieces.

LINE COMBINATION:

The Stickpack machine can be linked to a Cartoning Machine thanks to a special conveyor.

IN-LINE outfeed combination or ORTHOGONAL (90°) outfeed combination are applicable to be adaptable on available space at production hall.

The stacking of sticks in boxes can be in 3 ways: on bulk / ordered / on edge.

• Cleanliness: the mechanical parts are clearly separated from the product and film passage

• Fast release function: all filler machine stations are totally dismountable to speed up the size change-over operations

TECHNICAL DATA

Number of lanes

Max. mechanical speed

Reel sizes

Format range

MT1100

4 - 12 lanes

Up to 60 cycles/minute

Width max. 550 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

• Dosing unit: for every single project the technical department carries out detailed testing to classify the product specifications. Based on that the team choose, designs and builds the most suitable dosing unit

MT1300

4 - 18 lanes

Up to 60 cycles/minute

Width max. 750 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

MT1500

4 - 22 lanes

Up to 60 cycles/minute

Width max. 950 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 16 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

MT1800

4 - 20 lanes

Up to 60 cycles/minute

Width max. 1250 mm

Diameter max. 600 mm

Core diam. 76/152mm

Stick pack width: 26 - 60 mm

Stick pack length: 60 - 160 mm

(out of standard: 190 mm)

POWDERS

31

Sachet MS235

The MS235 is a Verical intermittent motion Sachet machine suitable also for powders products. The auger dosing is ideal for processing powdery products in which a mechanical action is required, performed through the rotation of the augers, to determine the fall of the powder inside the dosing funnels. Inside the dosing hopper, the product is led from the feed augers to the dosing augers. While the feed augers are controlled by a single Brushless motor, the dosing augers have an independent motorization for each dosing lane.

This independence determines the possibility of correcting the weight of each dosing channel during the production batch and have the possibility of feedback correction from checkweigher.

POWDERS

TECHNICAL DATA Max output (cycles/min) MIN. SACHET DIMENSION Width (mm) Length (mm) Reel width (mm) GENERAL (*) optional Reel Ø (mm) MS235 15 - 75 25 - 200 60 - 150 840 2 x 500 (standard) 1 x 800 (optional) CORE Ø 75 / 150

Featured Model MS235 32

Sachet AS SERIES

Featured Model AS500 (LIQUIDS)

Continuous-motion vertical sachet filling for medium-high production capacities.

The continuous motion and the use of rotary sealing elements permit to reach extremely high production speeds and therefore give an unmatchable total capacity in sachets per minute.

The “AS” series machines are designed to be versatile and flexible, permitting a fast and easy format change of the sachets, whether in Width as in Length.

The balcony structure, the design of the components and the use of Stainless Steel allow the machine to comply with GMP rules.

All parts in contact with the product are made of Stainless Steel or other FDA-approved material.

Marchesini Group is continuously upgrading its products according to markets needs.

The final technical data for each project could therefore vary depending on the effective machine configuration.

POWDERS

SACHET FILLING Number of lanes Maximum mechanical output Reel Width Reel Diameter Format range AS500 1 – 16 lanes Width max. 1000 mm AS300 1 – 10 lanes Width max. 600 mm AS600 1 – 20 lanes Width max. 1200 mm

Up to 200 cycles/minute Diameter max. 600 mm // Core diam. 76 mm Sachet width: 30 - 150 mm // Sachet length: 40 - 250 mm 33

The technical specifications given in this catalogue are subject to change without prior notice or liability.

Size range may vary in accordance with the different applications.

The Marchesini Group constantly updates its products to meet market needs.

Marchesini Group S.p.A.

Via Nazionale 100 • 40065 Pianoro BO ITALY

T +39 051 047 9111 sales@marchesini.com marchesini.com

MARCHESINI GROUP

INSPIRED BY THE EXTRAORDINARY

Edition February 2024

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary