Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary

Index ABOUT MARCHESINI GROUP ................................................. 4 KEYPOINT ............................................................................... 5 VIALS PROCESSING ............................................................... 6 AMPOULES PROCESSING ...................................................... 8 SYRINGES PROCESSING ...................................................... 10 Debagging & Delidding “RTU” containers ......................... 12 Washing & Sterilizing “BULK” containers ......................... 14 Filling & stoppering/sealing ............................................... 16 Capping ................................................................................. 20 Containment by RABS or Isolator ....................................... 21 Inspection & leak test .......................................................... 22 OUR COMPANIES

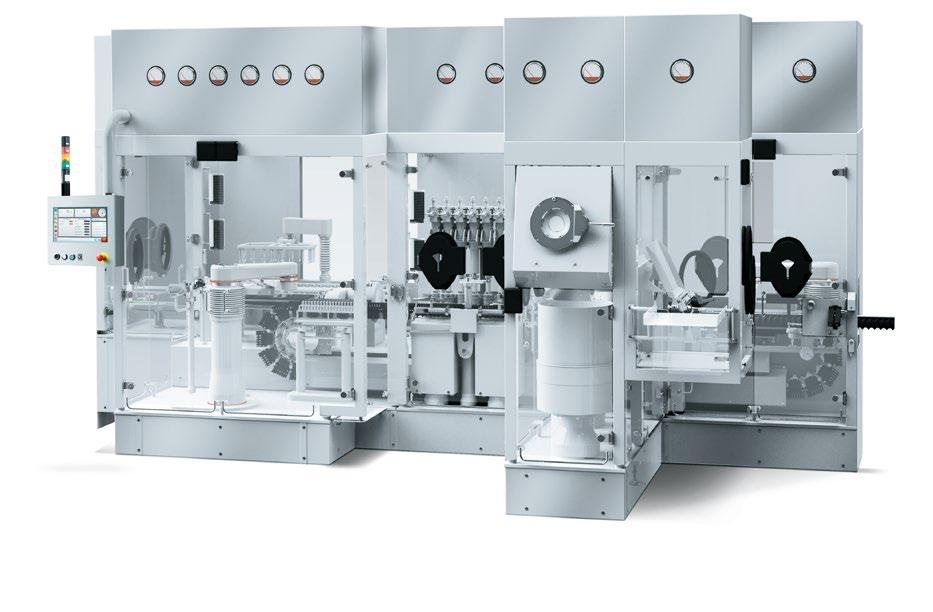

We at Marchesini Group are proud leaders in manufacturing and integrating complete lines since 1974.

division and CMP Pharma, Marchesini Group is able to offer complete lines for injectable products in pre-filled syringes, vials and ampoules, from the Washing process of the primary container to Filling, Inspection and Secondary Packaging down the pallet.

The Marchesini Group combines CORIMA and CMP proven experience in machine manufacturing for injectable products and high technological Inspection machine with the Group’s advanced technological robotic solutions.

This winning combination translates into the development of new solutions aimed at improving efficiency and safety in the aseptic drugs production, using the most innovative technologies.

4

Keypoint

Customizable solutions to inspect different types of containers and products.

All machines comply with GMP and FDA guidelines.

Balcony-style improves the laminarity of the air flow over the filled containers and facilitates cleaning process.

Fully automated In Process Controls and containment cabinets in Isolation Technology have been implemented, to reduce the risk of microbial contamination and minimize operator interference during the aseptic process.

Flexible solutions for inspection and integrity control of pharmaceutical products.

New models are constantly being developed in our in-house R&D department.

High-speed machines provide solutions aimed at reducing total changeover time and maximising the pharmaceutical process performance.

Wall installation enables maintenance to be carried out from the back-side of the machines in a non-classified technical environment.

5

Small volume parenteral containers

Small volume parenteral containers

VIALS

VIALS PROCESSING

PRIMARY PACKAGING

SECONDARY PACKAGING

INTERNAL WASHING LABELLING

END OF LINE

LABELLING

DEPYROGENATION BUNDLING WRAPPING

FILLING/STOPPERING LABELLING

FREEZE-DRYING (MACHINE BY THIRD PARTY)

ALU CAPPING CASEPACKING

EXTERNAL DECONTAMINATION

PLASTIC TRAY PACKAGING PAPER BOARD TRAY PACKAGING CARTONING

LABELLING

CODING PALLETTIZING

VISUAL INSPECTION

LIQUID WASHING

TRAY PACKAGING INTO CARTON

LABELLING

The above chart illustrates the complete Marchesini line, whereas the contents of this catalogue detail the primary packaging machines. For information on secondary packaging and end of line machines, visit our website marchesini.com

7

Small volume parenteral containers

Small volume parenteral containers

AMPOULES

AMPOULES PROCESSING

PRIMARY PACKAGING

SECONDARY PACKAGING

END OF LINE

INTERNAL WASHING

DEPYROGENATION

FILLING/SEALING

EXTERNAL DECONTAMINATION

LABELLING

PLASTIC PACKAGING TRAYS

PAPERBOARD PACKAGING TRAYS

BUNDLING WRAPPING

LABELLING

CARTONING

LABELLING

VISUAL INSPECTION

CASEPACKING

LABELLING

PALLETTIZING

LABELLING

LIQUID FILLING

The above chart illustrates the complete Marchesini line, whereas the contents of this catalogue detail the primary packaging machines. For information on secondary packaging and end of line machines, visit our website marchesini.com

9

Small volume parenteral containers DISPOSABLE SYRINGES

Small volume parenteral containers DISPOSABLE SYRINGES

SYRINGES PROCESSING

PRIMARY PACKAGING

TUB DEBAGGING

HANDLING & ASSEMBLING

DENESTING/ DETRAYING

VISUAL INSPECTION

TUB DELIDDING

VISUAL INSPECTION

SECONDARY PACKAGING

PACKAGING INTO PLASTIC TRAYS

PACKAGING INTO PAPERBOARD TRAYS

END OF LINE

BUNDLING WRAPPING

TRAYS PACKAGING INTO CARTON LABELLING

LABELLING RENESTING/ RETRAYING CARTONING

CASEPACKING

FILLING/STOPPERING

ASSEMBLING

DENESTING/ DETRAYING LABELLING

LABELLING PLUNGERING AND LABELLING

PALLETTIZING

BACKSTOP ASSEMBLING SAFETY DEVICE ASSEMBLING LABELLING

LIQUID STOPPERING

The above chart illustrates the complete Marchesini line, whereas the contents of this catalogue detail the primary packaging machines. For information on secondary packaging and end of line machines, visit our website marchesini.com

11

Tub debagging and delidding FREETUB SERIES

Featured Model FREETUB 10-A

Manual or Automatic machines for removal of the tub’s external bag, lid and liner.

OUTPUT

Up to 6 TUB per minute

DEBAGGING & DELIDDING “RTU” CONTAINERS

12

Detail of FREETUB 10-A

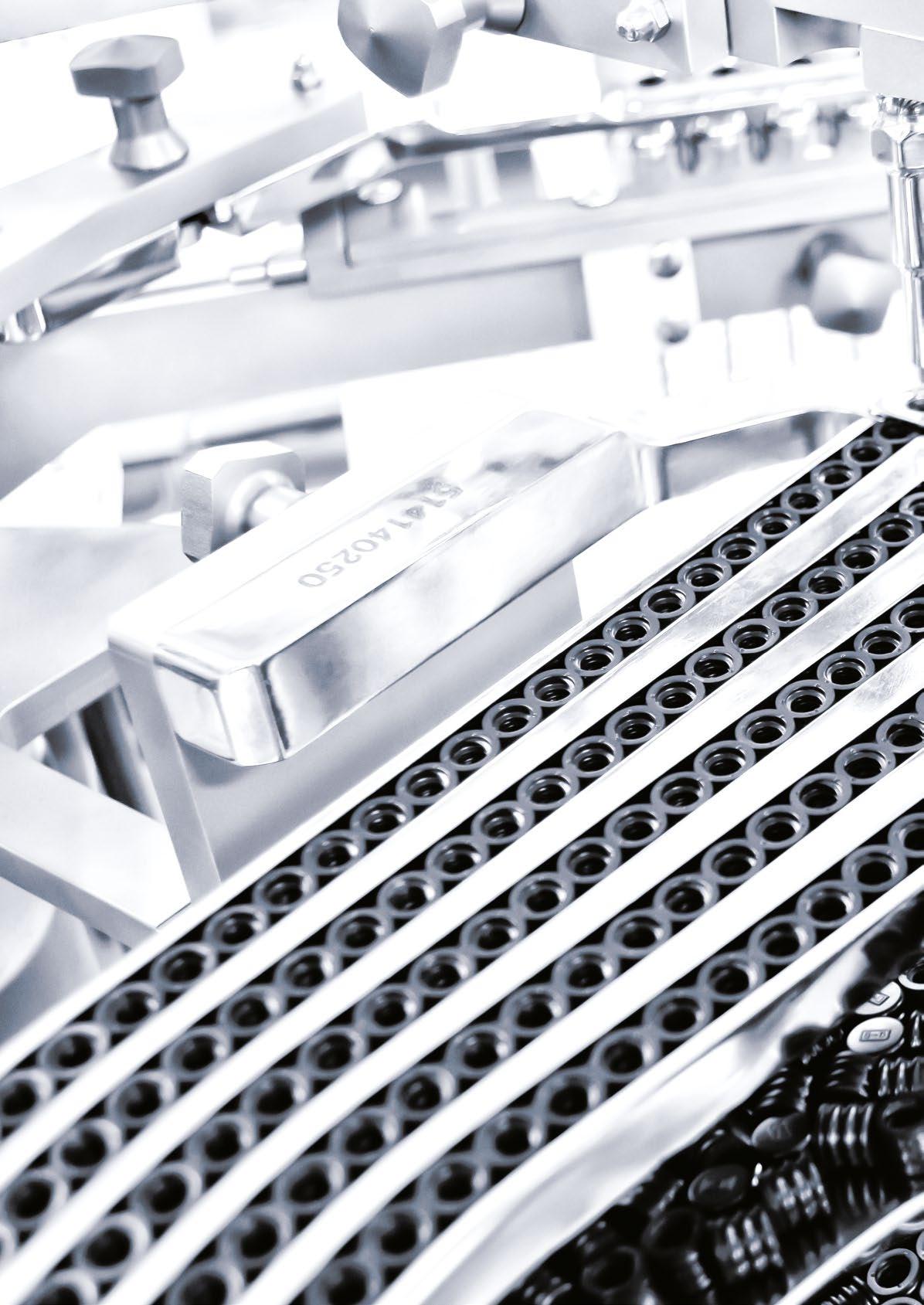

WASHING

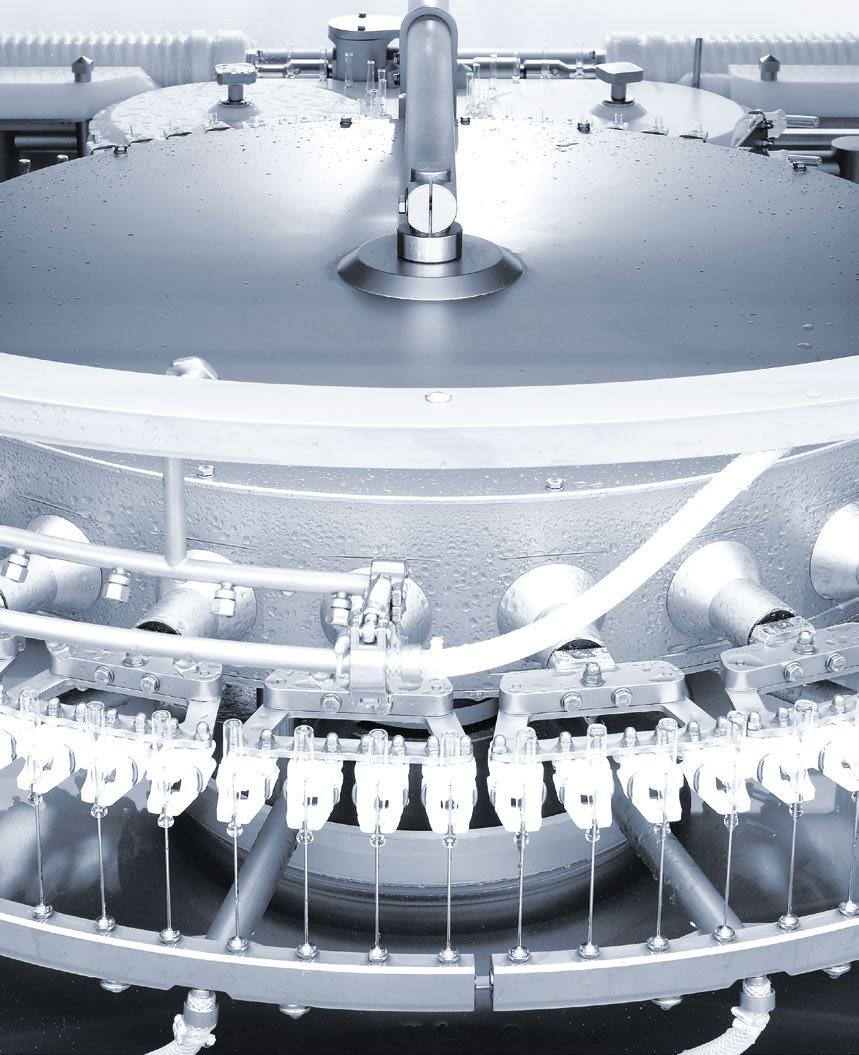

Internal washing WR SERIES

Featured Model WR24

Rotary continuous motion machines for internal washing and drying of ampoules and vials for Small Volume Parenteral (SVP).

• 8 internal and 3 external washing/blowing stations

• Pre-washing in Ultrasonic Bath

• Water Recycling

• Automatic drainage and drying

• Container siliconizing

OUTPUT 3.000 / 30.000 pcs / h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 500 ml

& STERILIZING “BULK” CONTAINERS 14

WASHING

Depyrogenation DEPYR SERIES

Featured Model DEPYR601

Depyrogenation Tunnels for ampoules and vials for Small Volume Parenteral (SVP).

• Hot chamber with dedicated make-up unit and air-flow control

• Automatic balancing and air flow adjustment

• Pressure cascade according to process requirements

OUTPUT

3.000 / 24.000 pcs / h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 500 ml

• Outfeed chamber with dedicated cooling coil and 100% air recycling

• Dry-Heat sterilization of outfeed chamber

& STERILIZING “BULK” CONTAINERS 15

FILLING & STOPPERING/SEALING 16

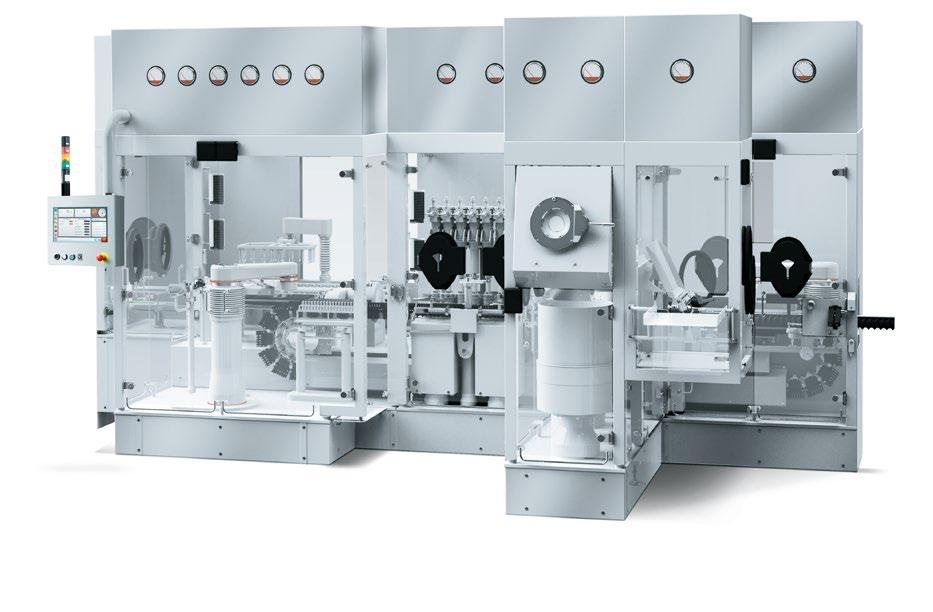

Filling & stoppering STERY SERIES

Featured

Filling and stoppering machines for liquid or lyo products, suitable for filling vials for Small Volume Parenteral (SVP) in an aseptic process with complete or partial closure using rubber stoppers.

• Intermittent or continuous motion

• Balcony or traditional table-top arrangement

• Statistical or 100% weight check

In Process Control (IPC)

• Dosing system: rotary piston and/or peristaltic pumps

OUTPUT

3.000 / 30.000 pcs / h

PRODUCT RANGE

• Inert gas flushing

• Easy integration with RABS or Isolator

• Cleaning and Sterilization in Place (CIP/SIP) Model STERY-LC

2R / 500 ml

Filling & sealing RSF SERIES

Filling and sealing machines for liquid products, suitable for filling open or closed ampoules in an aseptic process.

• Intermittent motion

• Dosing system: rotary piston and/or peristaltic pumps

• Easy integration with RABS

• In Process Control (IPC)

OUTPUT

6.000 / 24.000 pcs / h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 30R

• Inert gas flushing

• Sealing gas flow controlled by mass flow-meters

• Vials processing capability

• Cleaning and Sterilization in Place (CIP/SIP)

RSF 24 FILLING & STOPPERING/SEALING

Featured Model

17

18

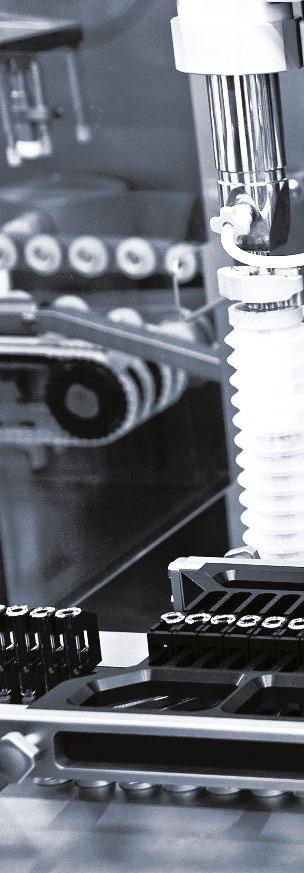

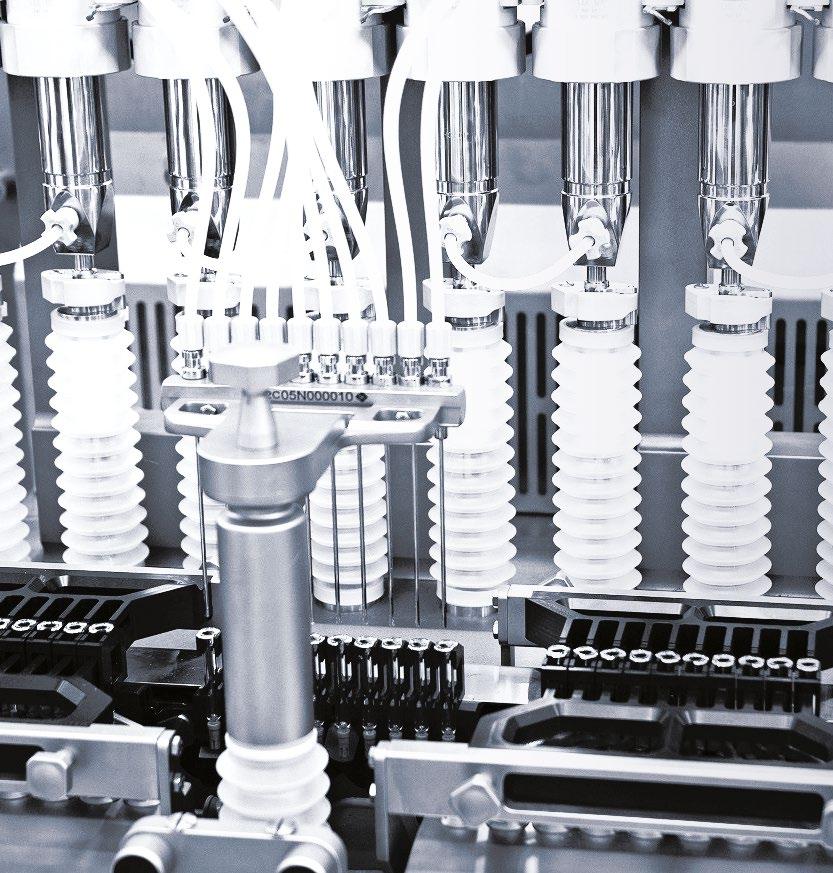

Filling & stoppering EXTRAFILL SERIES

Featured FILLING & STOPPERING/SEALING

Automatic machines for tub lid and liner removal, filling and stoppering of RTU Syringes (glass/plastic), Cartridges and Vials in nest and tray.

• Vacuum filling and stoppering suitable for high viscosity products

• Statistical or 100% weight check In Process Control (IPC)

• Dosing system: rotary piston and/or peristaltic pumps

OUTPUT

• Inert gas flushing during filling and/or stoppering

• Easy integration with RABS or Isolator

5.000 / 36.000 syringes / hr

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

Vials 2R / 30R

Cartridges 1 ml / 3 ml

• Cleaning and Sterilization in Place (CIP/SIP) Model EXTRAFILL 10A

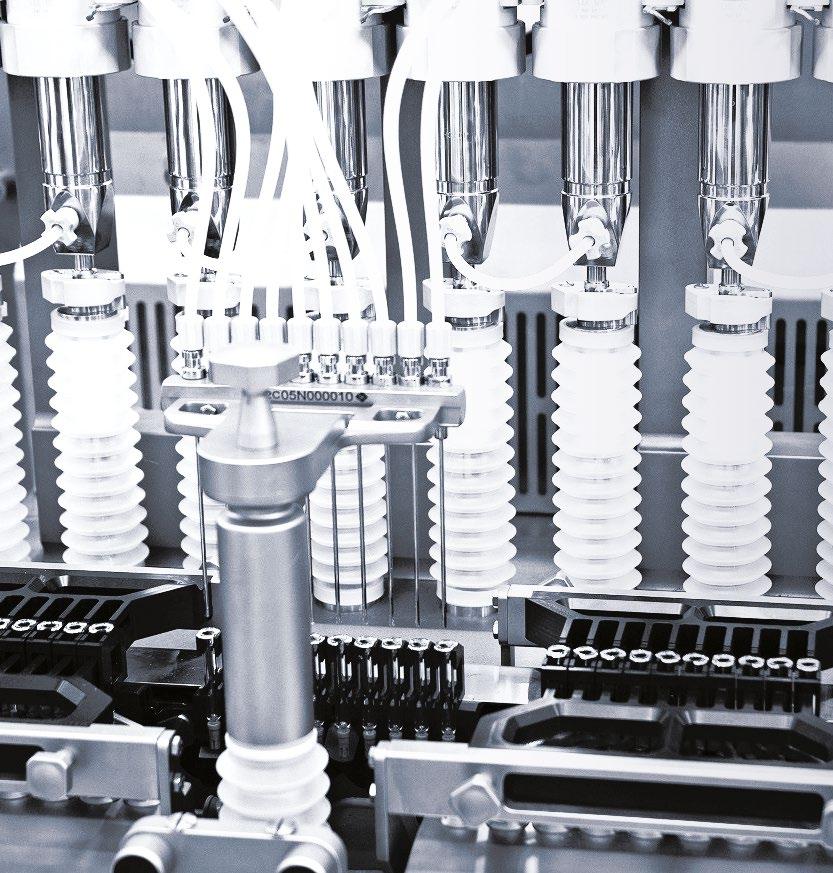

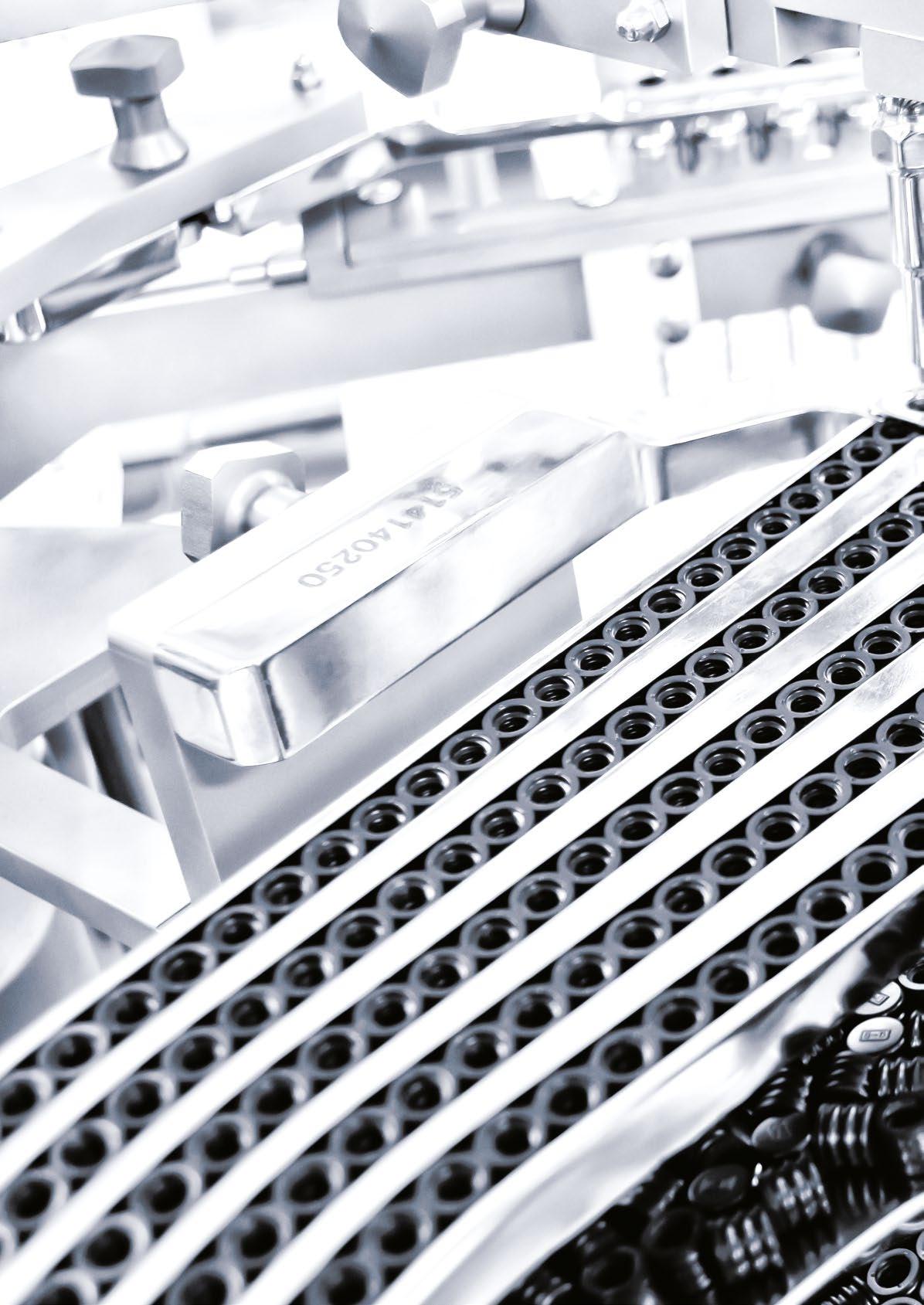

Filling & stoppering FSP SERIES

Automatic machines for filling and stoppering of RTU Syringes (glass/plastic), Cartridges and Vials in nest.

• Vacuum filling and stoppering suitable for high viscosity products

• Statistical weight check In Process Control (IPC)

• Dosing system: rotary piston and/or peristaltic pumps

• Inert gas flushing during filling and/or stoppering

• Easy integration with RABS or Isolator

• Cleaning and Sterilization in Place (CIP/SIP)

OUTPUT 5.000 / 12.000 syringes / hr

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

Vials 2R / 30R

Cartridges 1 ml / 3 ml

FILLING & STOPPERING/SEALING

Featured Model FSP05

19

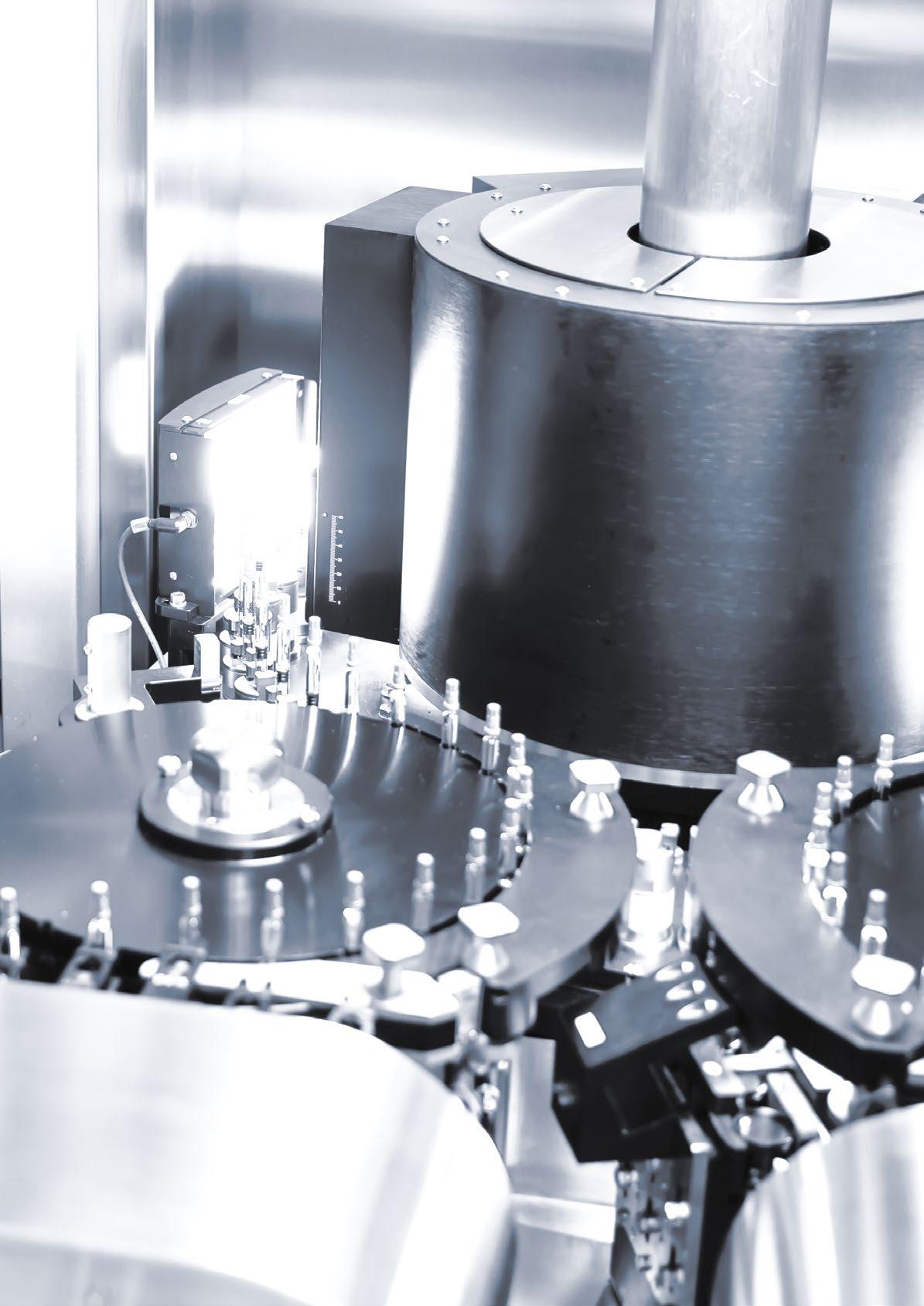

Alu capping CAPSY SERIES

Featured Model CAPSY-LC

Alu Cap sealing machines for liquid or lyo products, suitable for closing vials for Small Volume Parenteral (SVP) in an aseptic process.

• Intermittent or continuous motion

• Balcony or traditional table-top arrangement

• Automatic Sealing Pressure Regulation

OUTPUT

3.000 / 30.000 pcs / h

PRODUCT RANGE

Vials 2R / 500 ml

• Low particle generation

• Easy integration with RABS or Isolator

CAPPING 20

Containment ISOL-AIR SERIES

Containment cabinets suitable for product and/or operator protection within aseptic processes.

• Closed RABS or Isolation technology

• Bio-decontamination with Vaporized Hydrogen Peroxide (VHP)

• All types of aseptic transfer connections available

• Environmental Monitoring (EM) devices

• Bag-IN / Bag-OUT filters

• Washing in Place (WIP)

• HVAC Air Handling Units (AHU)

Featured containment type Closed RABS CONTAINMENT BY RABS OR ISOLATOR

21

Inspection

SV SERIES

SV Series are semi-automatic machines for the inspection of liquid, lyophilized or powder products in ampoules, vials and cartridges or pre-filled syringes. The machines are equipped with brushless motors for fast rotation (before inspection) and slow rotation (during inspection) to guarantee a complete and efficient control of the product.

OUTPUT

Up to 6.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 500 ml

Cartridges 1 ml /3 ml

Syringes 0,5 ml / 20 ml

MADE BY CMP

Featured Model SV INSPECTION & LEAK TEST

22

Inspection SA SERIES

The SA series automatic machines have been designed to meet the needs of those customers looking for a compact solution for the inspection of their products. They can be configured and customized following the production needs of customers.

OUTPUT

Up to 12.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 100 ml

Cartridges 1 ml /3 ml

Syringes 0,5 ml / 5 ml

MADE BY CMP

INSPECTION & LEAK TEST

Featured Model SA12J

23

Inspection

RS SERIES

RS Series are Automatic inspection and leak test machine designed to combine CMP’s know-how and experience in camera visual inspection with HVLD (High Voltage Leak Detection) system.

The machines are equipped with 3 or 4 leak test stations and a rotation system in order to improve the quality of the control (360° total surface inspection).

The productivity, the compact design and the performance level have set these models as leading units in our production range.

RS Series can handle ampoules, vials and cartridges.

OUTPUT

Up to 24.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 100 ml

Cartridges 1 ml /3 ml

MADE BY CMP

Featured Model RS1

INSPECTION & LEAK TEST

24

Inspection & leak test

RS-LAB SERIES

RS-LAB Series were designed to combine CMP’s know-how and experience in camera visual inspection with HVLD (High Voltage Leak Detection) system. Furthermore these models are equipped with an integrated labelling unit for the products which passed all the previous inspections. The machines are equipped with 4 leak test stations and a rotation system in order to improve the quality of the control (360° total surface inspection). RS-LAB Series can handle ampoules, vials and cartridges.

OUTPUT

Up to 24.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 100 ml

Cartridges 1 ml /3 ml

MADE BY CMP

Featured Model RS1-LAB INSPECTION & LEAK TEST

25

Inspection N SERIES

These machines are designed to meet the needs of those customers looking for excellent inspection quality combined with high production speeds. The N series machines can also be equipped with a container integrity control system.

OUTPUT

Up to 36.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 100 ml

Cartridges 1 ml /3 ml

Syringes 0,5 ml / 10 ml

MADE BY CMP

Featured Model N400J INSPECTION & LEAK TEST

26

Leak test LT SERIES

LT Series are our core leak test machines: the rational and compact design makes these units suitable to be inserted in any production context. The system is based on High Voltage Leak Detection technology. It uses a high voltage electrical field and impedance measurement to make each container (ampoules and Vials) to be checked by No. 4 inspection units with customized electrodes. The rotation system before and during inspection guarantee high quality performances. The LT-S version is a further step in the integrity control, and it is suitable for products packaged in single dose plastic strips.

OUTPUT

Up to 24.000 pcs/h

PRODUCT RANGE

Ampoules 1 ml / 25 ml

Vials 2R / 30R

Cartridges 1 ml /3 ml

Plastic Strip: max. h. 110 mm / max. l. 150 mm

MADE BY CMP

Featured Model LT-S INSPECTION & LEAK TEST

27

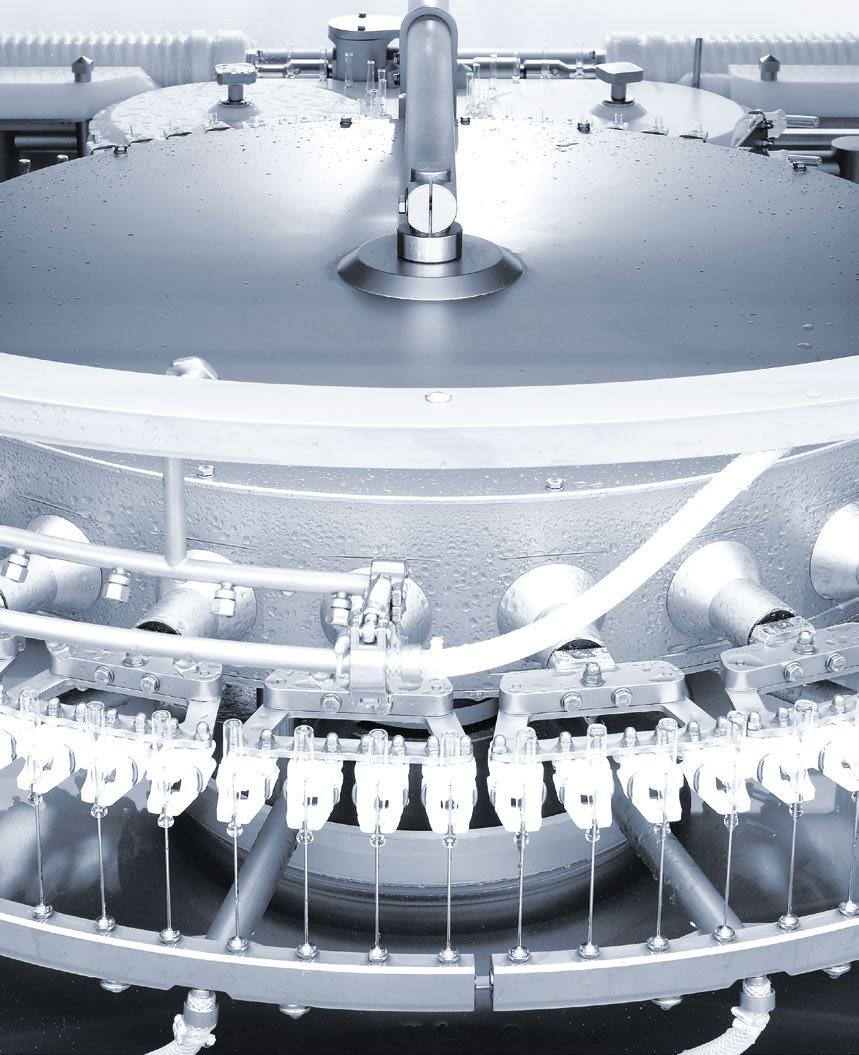

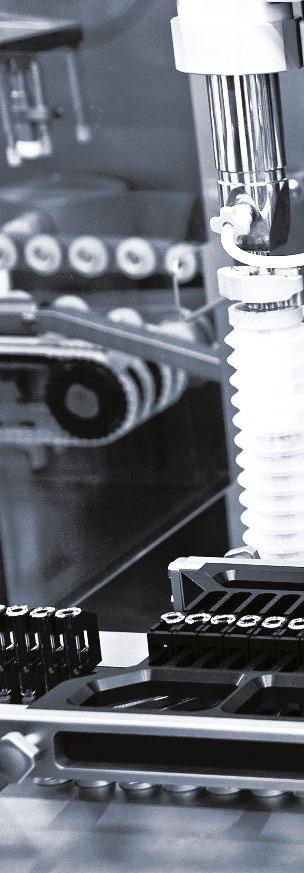

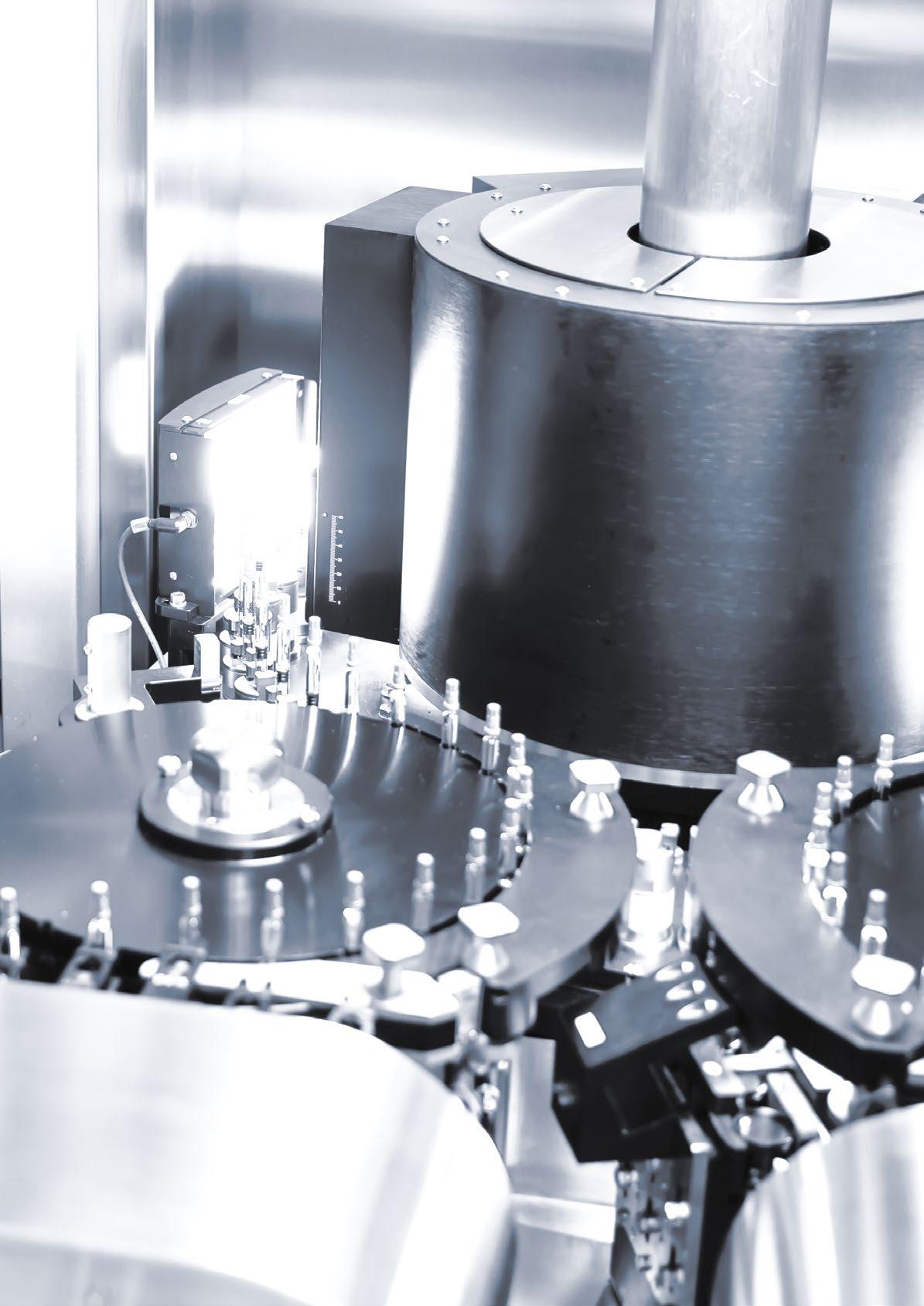

Inspection

No-contact “monobloc” machine for the high-speed automatic inspection of syringes, with integrated denesting and renesting unit.

The monobloc consists of a unit which performs robotised picking of the syringes from tubs/nests and feeds them into the inspection phase in a single row with no contact between syringes or with metal parts.

This part of the machine is able to contain up to 10 inspection stations to inspect every zone of the syringe: flange, stopper, particle detection, filling level, needle shield, defects in the glass walls and integrity inspection using HVLD (High Voltage Leak Detection) technology.

The monobloc features 5 reject lanes which can be customised to differentiate the rejected syringes and is designed to deliver approved syringes in a single row, without any contact between them or with metal parts. It can be equipped with a variety of optional accessories, including a camera to inspect for nest completeness and the relative syringe count, coding of the nest or tub by labelling, inkjet or laser printing.

OUTPUT

Up to 36.000 pcs/h

PRODUCT RANGE

Syringes 0,5 ml / 10 ml

MADE BY CORIMA

NSY 600

NSY SERIES Featured Model

e CMP INSPECTION & LEAK TEST

28

Detail

Detail

of NSY 600

The technical specifications given in this catalogue are subject to change without prior notice or liability.

Size range may vary in accordance with the different applications.

The Marchesini Group constantly updates its products to meet market needs.

Marchesini Group S.p.A.

Via Nazionale 100 • 40065 Pianoro BO ITALY

T +39 051 047 9111 sales@marchesini.com marchesini.com

MARCHESINI GROUP

INSPIRED BY THE EXTRAORDINARY

Edition February 2024

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary

Small volume parenteral containers

Small volume parenteral containers

Small volume parenteral containers

Small volume parenteral containers

Small volume parenteral containers DISPOSABLE SYRINGES

Small volume parenteral containers DISPOSABLE SYRINGES

Detail

Detail