Designed to deliver the highest flexibility and efficiency

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary

Index ABOUT MARCHESINI GROUP ................................................. 4 KEYPOINT ............................................................................... 5 Syringe assembling & labelling ........................................... 6 Bottle labelling .................................................................... 15 Cartridges/ampoules/vials labelling ................................ 16 Multi product labelling ........................................................ 18 Thermoforming .................................................................... 20 Paper tray forming .............................................................. 23 Cartoning intermittent ......................................................... 25 Cartoning continuous .......................................................... 27 Cartoning .............................................................................. 33 Labelling & serialization ..................................................... 35 Wrapping .............................................................................. 39 Casepacking & depacking ................................................... 42 Palletizing & depalletizing .................................................. 48 Robotic handling and special application .......................... 53 OUR COMPANIES

We at Marchesini Group are proud leaders in manufacturing and integrating complete lines since 1974.

We produce stand-alone machines and complete lines to handle the entire packaging process for the pharmaceutical industries. Today, the Marchesini Group caters for the whole packaging process of pharmaceuticals, from start to finish. It creates stand-alone machines and complete lines to package products such as vials, syringes, carpules, bottles and blisters through to putting the individual products into bundles, cases and on pallets.

The finished product - machines capable of packaging all kinds of pharmaceutical products - is a combination of craftsmanship integrated with robotics and technology. This result has been achieved thanks to the expertise of the Group’s branches which specialize in designing and manufacturing packaging machines with specific productive technologies, such as aseptic packaging, Blister packaging, Labelling, Inspection, all to manage every kind of pharmaceutical product, oral solid dose, liquid, cream or powder that can be put in every kind of pack. Every brand of the Group develops and manufactures specific machines for the whole packaging process in its plants located throughout Italy, while complete line assembly is coordinated from our Headquarters.

4

Keypoint

Industry 4.0 Compliant

The Marchesini machines are designed in accordance with cGMP regulations and feature the latest IoT technologies.

Our machines are designed to reduce total changeover time and maximize performance.

Small footprint to optimize the factory floor space.

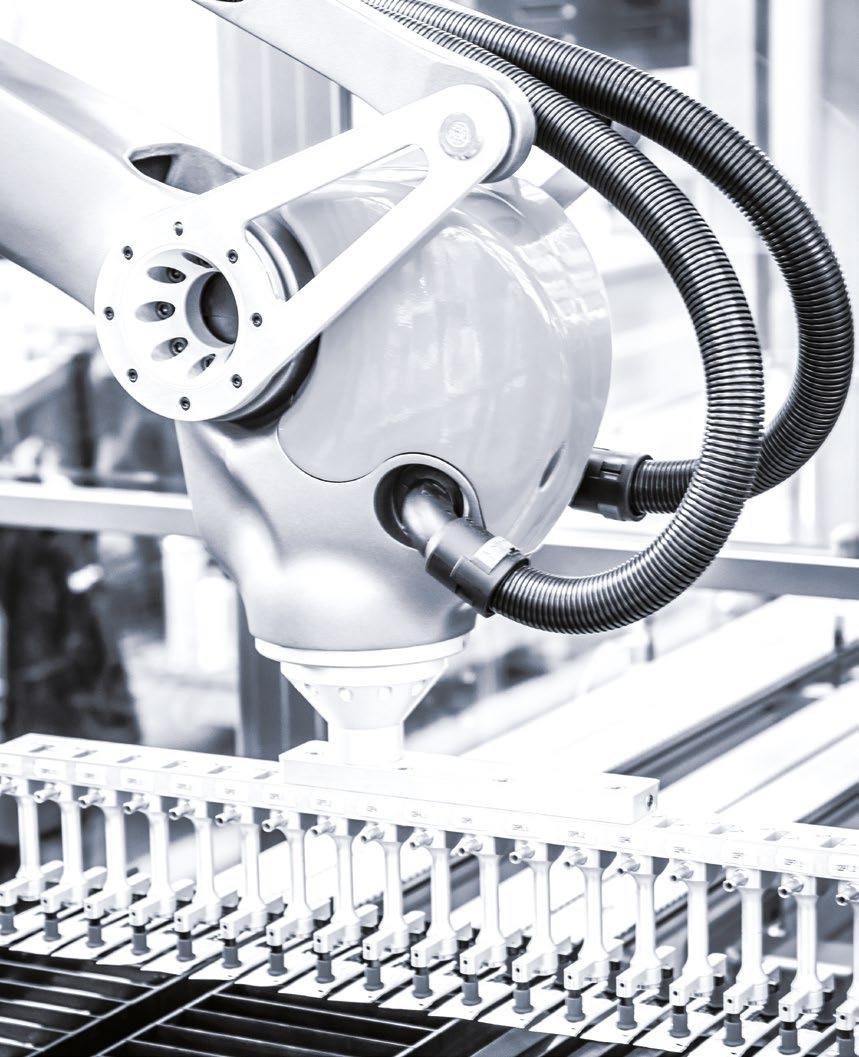

Our patented robotic solutions are developed in-house to connect different machines together in-line.

Accessible and ergonomically designed machines ensure a positive operator experience in terms of machine management, inspection and service.

New models are constantly developed in our in-house R&D. department.

We provide a complete range of machines for the entire packaging process.

5

De-nesting NEXTRA SERIES

Featured Model NEXTRA-N10

Automatic machine for syringe extraction from Nest and transferring to downstream process.

• Infeed Tub buffering with FIFO policy

• Decoding of Pre-printed data on the Tub by a vision system

• Automated Nest Removal from Tub

• Empty Tub and Nest stacking units

• Gentle transfer of syringes onto the unload guide

• Also available in No Glass-To-Glass Contact version

• For automated Inspection Lines: Empty Nest re-positioning on Tub with empty Nest automatically transferred to down-stream Re-Nesting machine (e.g. bridged conveyor)

OUTPUT

Up to 36.000 syringes / h

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

SYRINGE ASSEMBLING & LABELLING

6

Re-nesting NEXTRA SERIES

Featured Model NEXTRA-N15

Automatic machine for re-arranging inspected syringes into the Nest.

• Compact arrangement thanks to the integrated robotized renesting head

• Possibility of automatic Tub/Nest loading from the de-nester with a “bridge conveyor”

• Vision check for Nest completeness

• Data printing on the Tub (“direct imprint” or “print & apply labelling”)

• Also available in No Glass-To-Glass Contact version

OUTPUT

Up to 36.000 syringes / h

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

SYRINGE ASSEMBLING & LABELLING

7

De-traying NEXTRA SERIES

Featured Model NEXTRA-T20

Automatic machine for syringes or safety devices feeding from Rondo-Tray.

• High capacity loading system for stacked trays, designed to guarantee the stability of narrow Tray stacks

• Vision system control for load orientation and Tray rotation

• Gentle removal of Syringe or Safety Device by star-wheel or robot (for No-Contact version)

• Empty Tray stacking unit

OUTPUT

Up to 24.000 syringes / h

PRODUCT RANGE

Syringes, Safety Devices and other hangable objects supplied in trays

SYRINGE ASSEMBLING & LABELLING

8

Re-traying NEXTRA SERIES

Featured Model NEXTRA-T25

Automatic machine for re-arranging inspected syringes into Rondo-Trays.

• Automatic Loading of stacked empty Trays (all arranged with the same orientation)

• Walking-beam continuous re-traying by robot, with rondo-tray running in horizontal position

• Vision check for Tray completeness

• Automatic rejection of incomplete Trays

• Full Tray stacking

• Also available in No Glass-To-Glass Contact version

OUTPUT

Up to 24.000 syringes / h

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

SYRINGE ASSEMBLING & LABELLING

9

Bulk feeding AVS SERIES

Featured Model AVS SERIES

Elevator with Plates for automatic feeding of syringes or similar objects.

• 12 mobile plates driven by an independent motor

• Unload conveyor driven by an independent motor with step-less speed adjustment

• Integrated high-capacity pre-feeding hopper, driven by an independent motor

• Complete, easy and quick emptying and cleaning of the elevating plates area and pre-feeding hopper

• Possibility to integrate the AVS on the downstream machine or make it an independent unit equipped by its own control system and HMI display

OUTPUT

Up to 36.000 pcs /h

PRODUCT RANGE

Syringes, Safety Devices and other hangable objects

SYRINGE ASSEMBLING & LABELLING

10

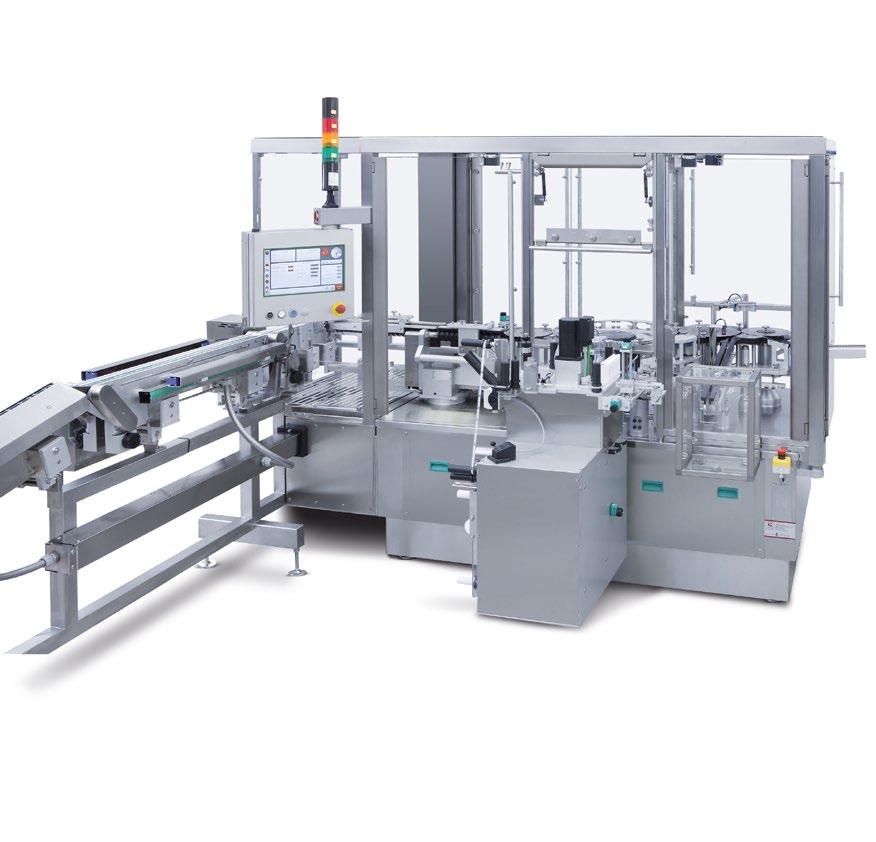

Labelling COMBI SERIES

Featured Model COMBI-1LAB

Automatic, continuous motion machine for syringes or Safety Device labelling.

• Objects are processed to avoid contact with machine’s metal components

• Highly flexible feeding & unloading sections

• Customizable Label Feeding, Printing and Dispensing system

• In Process Controls (IPC) performed by sensors and vision systems

• Individual counting for each reject type

• Also available in No Glass-To-Glass Contact version

OUTPUT

Up to 36.000 syringes / h

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

Round-shaped Safety Devices

SYRINGE ASSEMBLING & LABELLING

11

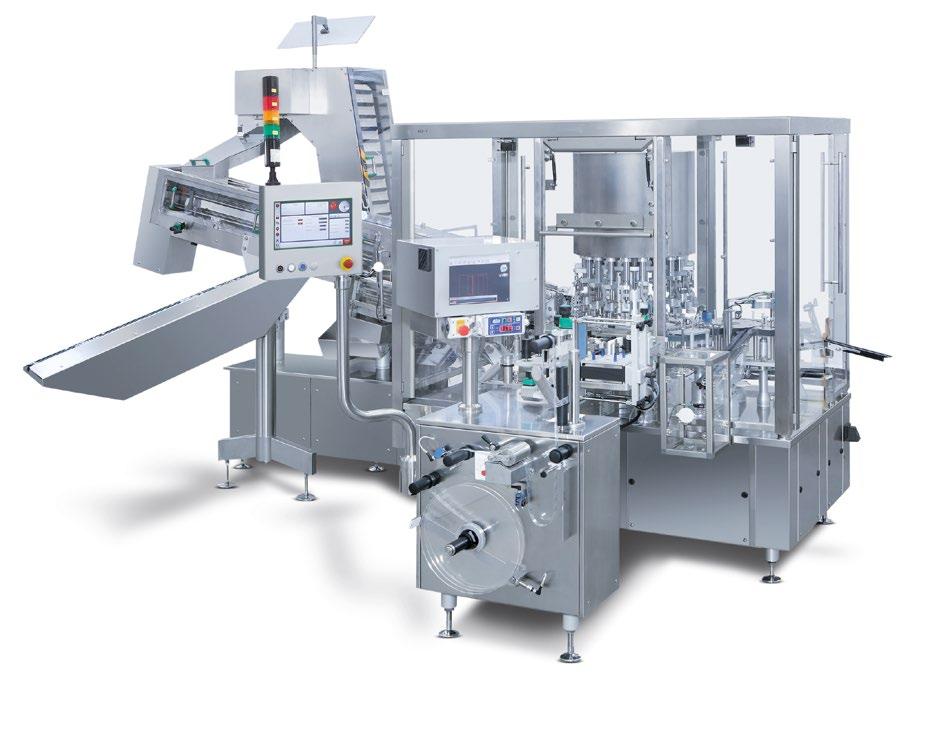

Plungering & labelling COMBI SERIES

Featured Model COMBI-2PL

Automatic, continuous motion machine for syringe plungering and labelling.

• Syringe loading by adjustable motorized rollers without format-change

• Universal Plunger rod sorting unit (format-change free), with integrated high capacity pre-feeder

• Single adjustment (manual or motorized) of the plunger-rod feeding and assembling system according to rubber stopper position

• Plunger rod release & re-grabbing system to compensate stopper position variability

• Dynamic centering during Plunger Rod insertion

• Also available in No Glass-To-Glass Contact version

OUTPUT

Up to 24.000 syringes / h

PRODUCT RANGE

Syringes 0,5 / 20 ml

SYRINGE ASSEMBLING & LABELLING

12

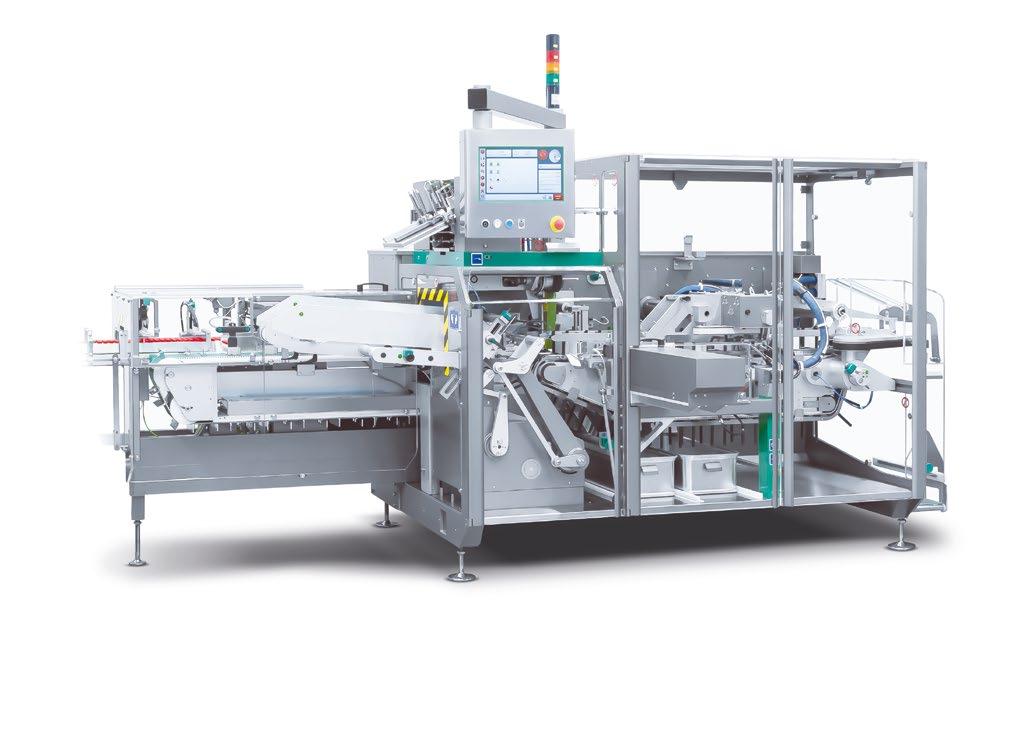

Plungering, labelling & backstop assembling COMBI SERIES

Featured Model COMBI-3BS

Automatic, continuous motion machine for syringe plungering, labelling and Backstop assembling.

• High capacity Backstop pre-feeder

• Rotary or linear vibrating Backstop feeder with reduced format parts changeover

• Backstop assembling control

• With Closed-type Backstop, the assembling station is positioned before the Plunger Rod assembling turret (COMBI-3BSR version)

• Also available in No Glass-To-Glass Contact version

• The simple Backstop assembling unit is also available as an independent machine (COMBI-1BS model)

OUTPUT

Up to 18.000 syringes / h with backstop

Up to 24.000 syringes / h without backstop (by-pass mode)

Up to 24.000 syringes / h for the COMBI-1BS model

PRODUCT RANGE

Syringes 0,5 ml / 20 ml

SYRINGE ASSEMBLING & LABELLING

13

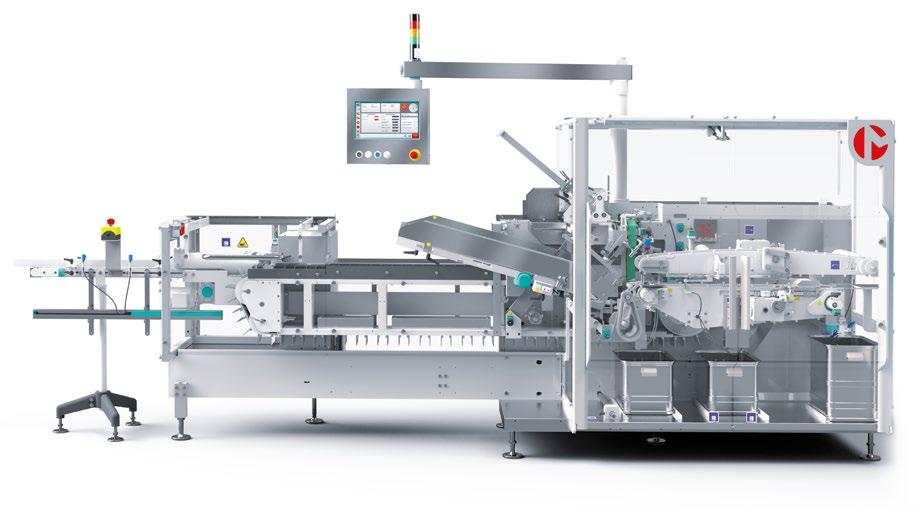

Plungering, labelling & safety device assembling COMBI SERIES

Featured Model COMBI-3/4SD

Automatic, continuous motion machine for Syringes and Safety Devices assembling and labelling.

• Combining the standard features of the plungering & labelling machine with Safety device assembling

• Safety device loading from bulk feeders or from trays (manual or automatic)

• Safety Device assembling control by a camera

• Possibility of labelling the syringe and / or the safety device body

• Integrated By-pass mode for producing standard syringes without Safety Device

• Also available in No Glass-To-Glass Contact version

• The simple Safety Device assembling and labelling unit is also available as an independent machine (COMBI-2SD model)

OUTPUT

Up to 24.000 syringes / h

PRODUCT RANGE

Syringes 0,5 / 5 ml

Round or Square shape

safety devices

SYRINGE ASSEMBLING & LABELLING

14

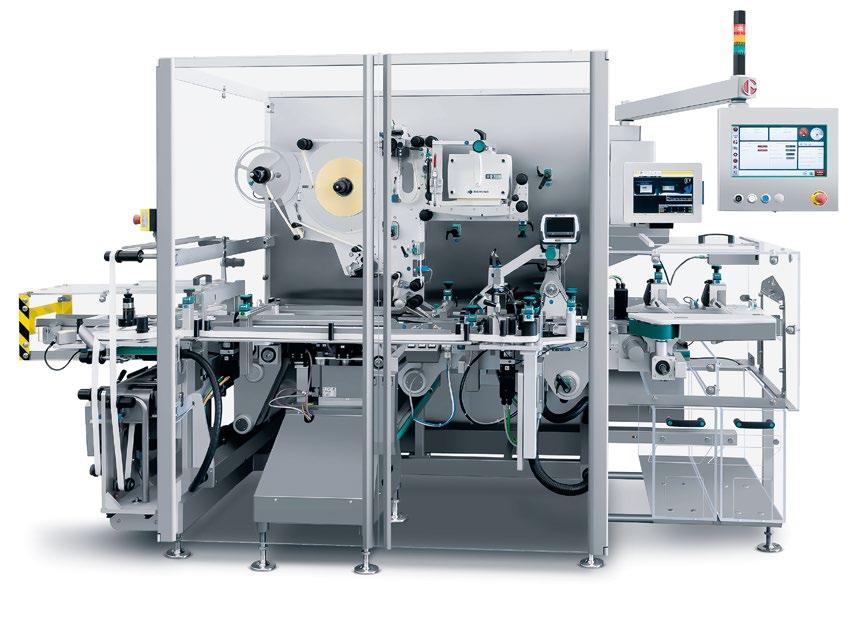

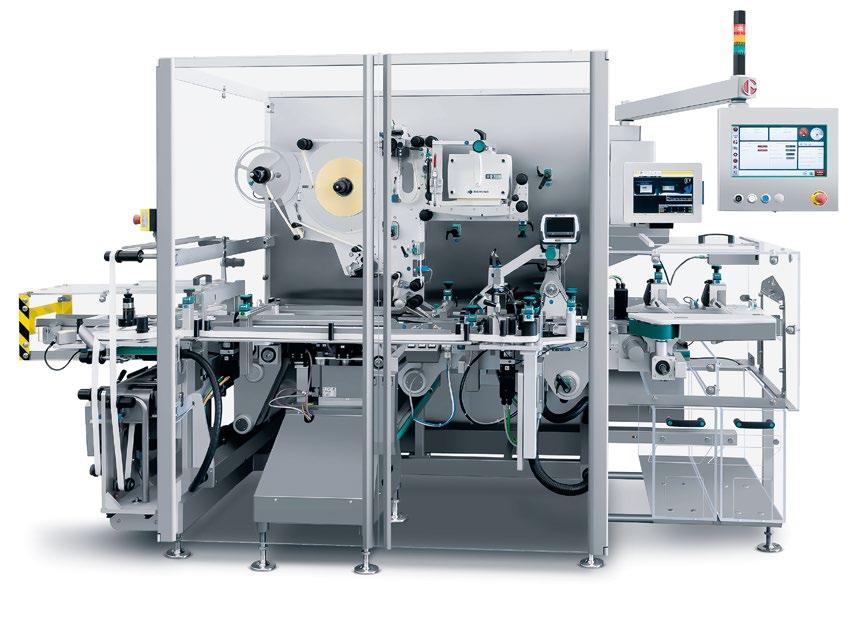

Linear labeller SL-F SERIES

Featured Model SL-F230

Labelling machines with stainless steel frame designed to grant easy access for set-up, inspection and maintenance. An advanced control system syncronizes the independent servo driven motors and supervises the process for the best, performing and reliable labelling operations.

• Self-learning system of label length, bar code and overprint position

• Power driven unwinder with adjustable loop

• Micrometric adjustment of the label and overprint position

• Self-diagnosis on touch screen display

• Automatic reject for: missing label, printing and code errors

BOTTLE LABELLING

TECHNICAL DATA Mechanical speed (pcs/min) Labelling heads (Nr.) CONTAINER SIZE Product diameter Ø Product height LABEL SIZE Label height Label length SL-F220 150 1 15 - 90 mm 30 - 250 mm 10 - 120 mm 13 - 190 mm

SL-F230 180 2 15 - 90 mm 30 - 250 mm 10 - 120 mm 13 - 190 mm SL-F425 400 1 15 - 90 mm 30 - 250 mm 10 - 120 mm 13 - 190 mm BL-F425 400 1 15 - 90 mm 30 - 250 mm 10 - 120 mm 13 - 190 mm 15

Rotary labeller RL-F SERIES

Featured Model RL-F100

Solidity, efficiency and reliability, are the factors that have determined the success of these labelling machines. They have been designed for intermediate production volumes.

• One labelling head

• In-line belt feeding system

• Continuous mode speed adjustment

• Self-learning system of label parameters

• Label dispenser powered by servo driven motors

• Automatic reel unwinding unit

• Fail-safe logic reject

TECHNICAL DATA

Mechanical speed (pcs/min)

Labelling heads (Nr.)

CONTAINER SIZE

Product diameter Ø

Product height

LABEL SIZE

Label height

Label length

CARTRIDGES/AMPOULES/VIALS LABELLING

RL-F100 150 (Ø 42) - 80 (Ø 60) 1 20 - 60 mm 30 - 120 mm 10 - 80 mm 13 - 190 mm

RL-F200 200 1 10 - 36 mm 40 - 80 mm 10 - 80 mm 13 - 120 mm 16

CARTRIDGES/AMPOULES/VIALS

Rotary labeller RL-F SERIES

High-speed labelling machines with a rotary star wheel transport system, designed to reduce manual operations. The transport star wheel is equipped with a patented rolls adjusting system to handle a wide range of products.

• In-line belt feeding system

• Self-learning system of label parameters

• Synchronized servo motors

• Self-diagnosis on LCD display

• Label presence control system

• Fail-safe logic reject

TECHNICAL DATA

Mechanical speed (pcs/min)

Labelling heads (Nr.)

diameter

Ø

Featured Model RL-F800 LABELLING

Product height LABEL SIZE Label height Label length RL-F300 300 1 10 - 32 mm 40 - 130 mm 10 - 60 mm 13 - 100 mm RL-F500 500 1 8 - 32 mm 40 - 130 mm 10 - 60 mm 13 - 100 mm RL-F800 800 1 8 - 54 mm 35 - 100 mm 10 - 75 mm 25 - 170 mm 17

CONTAINER SIZE Product

Multi head labeller RE SERIES

Featured Model RE202

Full servo-driven rotary labellers suitable to apply self-adhesive labels, or outserts with glue at high speeds, on oval, shaped or cylindrical containers of glass, plastic and metal. Suitable for Track & Trace applications.

• Up to 4 labelling heads, with non-stop operation option

• Angular adjustment of label head for non-standard shapes

• 2D code print&check system

• Self-learning label configuration and memorization system

• Ergonomic balcony construction for easy access

• User-friendly format changeover

MULTI PRODUCT LABELLING

TECHNICAL DATA Mechanical speed (pcs/min) Labelling heads (Nr.) CONTAINER SIZE Product diameter Ø (mm) Product height (mm) LABEL SIZE Label height (mm max) Label length (mm max) RE202 200 2 20 - 120 50 - 220 135 190

RE302 300 2 20 - 120 50 - 220 135 190 RE402 400 2 20 - 120 50 - 220 135 190 RE204 200 4 20 - 120 50 - 220 135 190 RE304 300 4 20 - 120 50 - 220 135 190 RE404 400 4 20 - 120 50 - 220 135 190 18

Modular horizontal labeller BL-H

Featured Model BL-H235

Automatic linear machine suitable to apply labels (stickers, wrap-around or oriented labels) on different shape of containers in horizontal position. Unit operating in line with other machines or as a free-standing unit if connected at the infeed with proper feeding systems.

Bl-H235 is a Modular Horizontal labeller that handle a vast range of product shape and sizes.

• Multiple labeling heads and multiple labels application, with possibility of NON-STOP operation

• Automatic or manual infeed and outfeed stations.

• Customized label smoothing systems and variety of the label print and control systems

• Enhanced integration of robotic technology and fully servo-driven motorization of the main working stations

• Labelling of: Bottle-pack, Autoinjector pen, Aerosol, Spray, Lipstick etc.

MULTI PRODUCT LABELLING

OUTPUT

19

Up to 200 pcs./min.

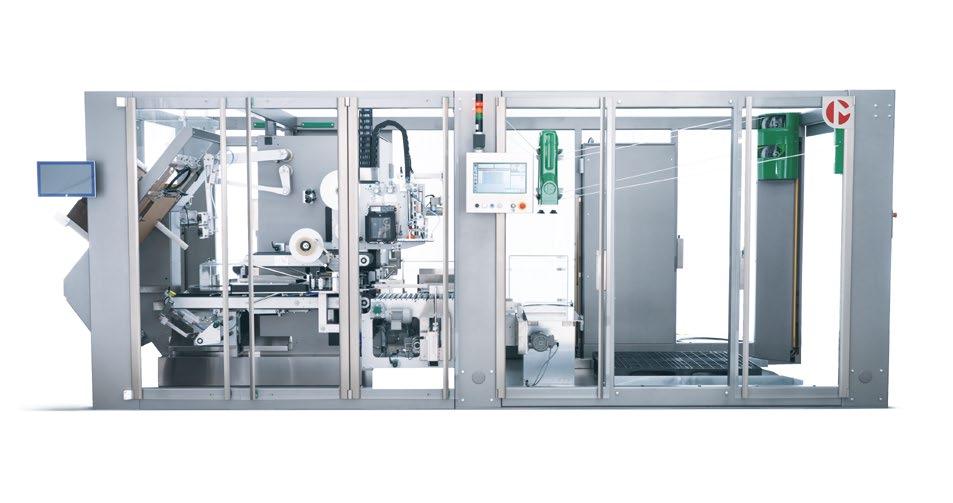

Automatic deep draw thermoformer

Mechanical intermittent motion fully automatic packaging machine, balcony construction, PC-controlled. Designed to suit pharmaceutical-production environments, it forms trays for vials, ampoules, syringes and similar products out of eco-thermoformable films. Its sturdiness, simple operation and the easy, tool-less change-over make it reliable, high flexible, efficient and easy to service in a very small footprint.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Can be supplied with or without heat-sealing station

• Prepared for connection from/to in-line integrated machines

• User-friendly size changeover

• Thanks to the servo main-drive, the machine speed is adjustable from the main HMI, within dedicated recipes

FB SERIES

THERMOFORMING TECHNICAL DATA Mechanical speed (cycle/minute) FORMING AREA Forming draw depth (max.) Pitch Web width DIE-CUTTING AREA Pitch Web width FB220 15-45 28 mm 160 mm 184 mm 154 mm 170 mm FB320 15-45 42 mm 254 mm 220 mm 248 mm 214 mm FB420 15-45 42 mm 254 mm 320 mm 248 mm 314 mm 20

Featured Model FB220

Automatic deep draw thermoformer FBZ SERIES

Featured Model FBZ320

Technical intermittent motion fully automatic packaging machines, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled. Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out of thermoformable films such as PVC, PET, Polystyrene (PS), PP, PLA multilayer laminates etc. Its sturdiness, modular construction, simple operation and the easy, tool-less changeover make it reliable, highly flexible, efficient and easy to service.

• Integrated Robomaster for products Pick-and-Place

• Prepared for connection from/to in-line integrated machines

• High-speed fully automatic positive products feeding systems are available

• High draw depth (up to 42 mm)

• ZERO-WASTE version (FBZ) with quick die-cutter available (subject to the format configuration)

THERMOFORMING TECHNICAL DATA Mechanical speed (cycle/minute) FORMING AREA Forming draw depth (max.) Pitch Web width DIE-CUTTING AREA Pitch Web width FBZ220 15-45 28 mm 160 mm 184 mm 127 mm 170 mm FBZ320 15-45 29 mm 254 mm 220 mm 127 mm 214 mm FBZ420 15-45 29 mm 254 mm 320 mm 127 mm 314 mm 21

Robotized integrated tray line UNICA

Featured Model UNICA

Robotized packaging line integrating both operations of deep draw thermoforming and cartoning as well as both product and tray robotized feeding systems in a single monoblock. The whole line is controlled by a single, common display, and is characterized by a small footprint.

• Easy access to all machine stations, high ergonomics

• High visibility of all units for immediate clearance

• Simple to operate

• Quick and easy tool-less changeover

• High draw depth (28 mm)

• Intermittent motion cartoning section

• Positive product feeding and transfer system by means of 2 integrated Robovision: for product feeding into the deep-draw tray and for tray feeding to the cartoner

• Size parameters set on the control PC-panel, recalled under recipes for fast changeover

• Low-maintenance mechanical parts and long life of drive parts

• Particularly low-noise levels thanks to advanced solutions on product and carton conveyors

TECHNICAL DATA

MECHANICAL SPEED (cycles/minute)

Forming draw depth (max.)

Forming - Pitch

Cutting - Pitch

CARTON SIZE

THERMOFORMING

Length

UNICA 40-120 cart./min. 28 mm 160 mm 154 mm 30

20

75

22

Width (a) Height (b)

(h)

- 130 mm

- 100 mm

- 200 mm

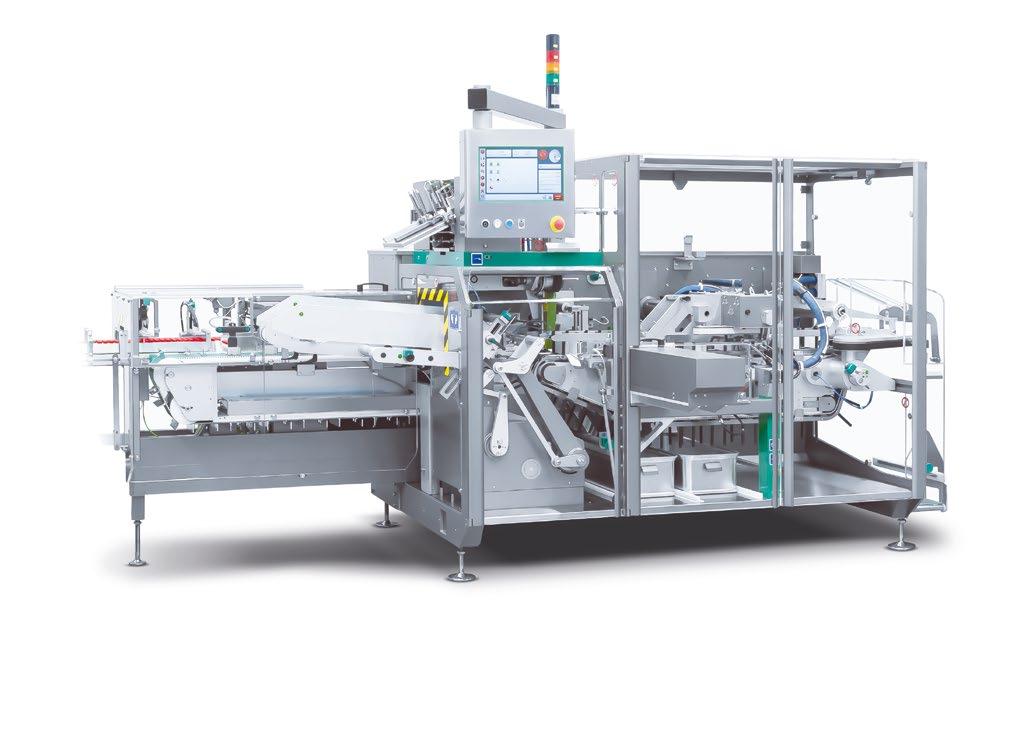

Paper tray line INTERMITTENT SERIES

Featured

Thanks to an experience of over 10 years and a high number of references on the market we are leader in the design and production of packaging lines based on paperboard.

The ideal solution to pack any kind of pharmaceutical or non-pharmaceutical products like syringes, vials, auto-injector pens, inhalers, bottles, tubes and any other product which needs to be packaged in a tray.

The sector of new materials for packaging is growing rapidly, and we’re all committed to increasing sustainability and reduce the use of non eco-friendly materials such as plastic.

The paperboard magazines are combined with Marchesini’s advanced level of automation, the precision and speed of robots and pick up arms allow trays to be fed also in alternate mode. This makes our solution adaptable to the needs of downstream machine.

•

•

•

•

•

Model LINEA PAPER TRAY ALTERNATA PAPER TRAY FORMING

Industry 4.0 compliance

Multi-product cartoners

Efficiency & reliability

Robotized system

Ergonomic design

speeds and limits refer to our cartoning series. 23

Regarding

Paper tray line CONTINUOUS SERIES

A strong experience and the development of dozens of solutions allow Marchesini to offer its customers the paperboard packaging solution suited to their needs. Marchesini has a wide knowledge in product handling and feeding. The tray magazines on our machines are compact, modular and versatile.

What makes this unit stand out is the way the magazines are combined with the advanced level of automation by Marchesini. The precision and speed of the robots and pick up arms allow trays to be fed continuously as our machine operates also in continuous mode. This makes it adaptable to the needs of downstream machines and as more than one magazine can be fitted, its performance in terms of speed and precision is incredibly high.

We have a team that focuses on designing customised trays and cartons for specific product type, sizes and quantities. Using prototypes and mock-ups, the trays and cartons are then fine-tuned so that customers can optimise their entire packaging line, from the handling of the components, to the cartoner and right down to the case-packer and palletizer.

•

•

•

•

•

Model PAPER TRAY LINE PAPER TRAY FORMING

Featured

Industry 4.0 compliance

Multi-product cartoners

Efficiency & reliability

Robotized system

Ergonomic design

speeds and limits refer to our cartoning series. 24

Regarding

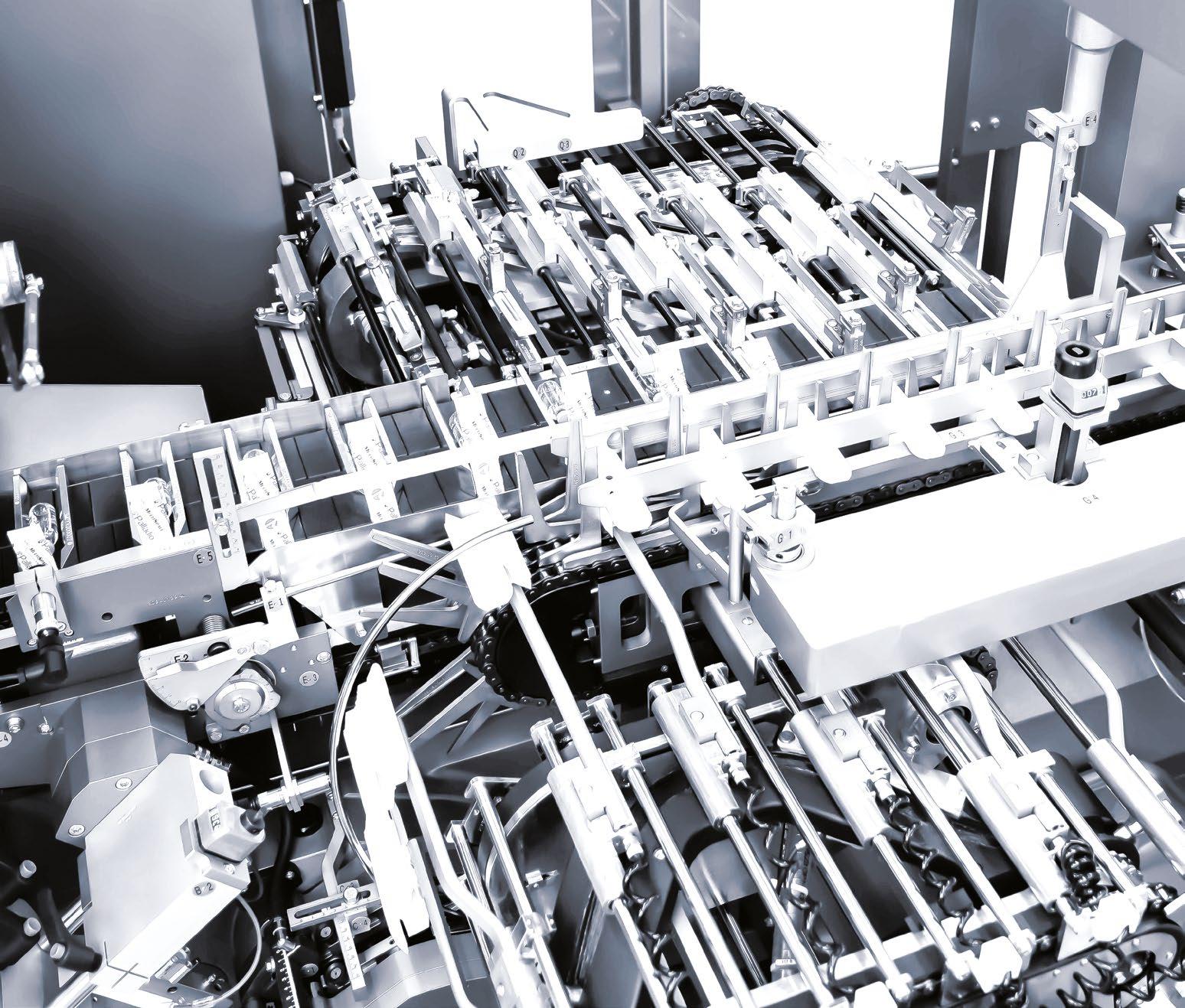

CARTONING

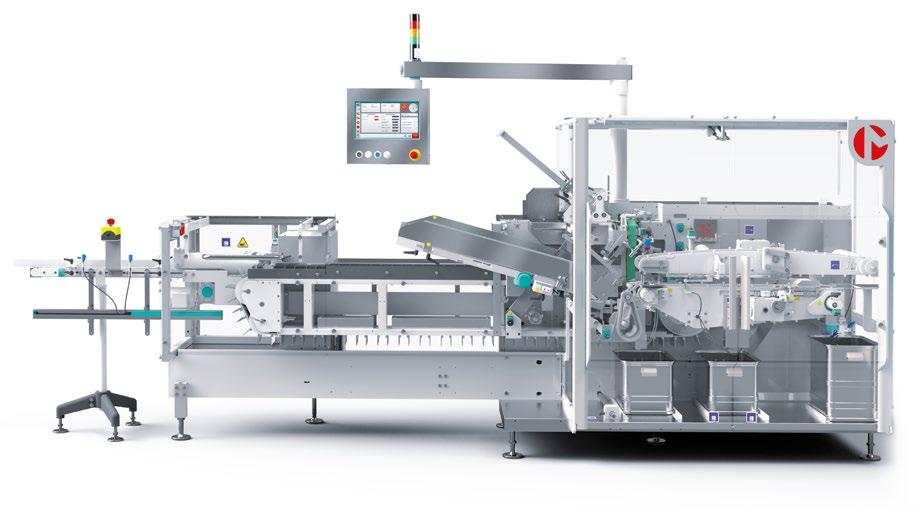

Intermittent motion cartoner series

MA SERIES (50-80)

Featured Model MA80

Intermittent-motion automatic machines with horizontal carton transport, particularly suitable for packing sachets, deep-draw thermoformed trays, as well as vials, bottles and perfumes.

• Versatility and efficiency in a small footprint

• Balcony design

• Synchronized servo motors

• User-friendly format changeover

• Cross control product-carton-leaflet

• Belt conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories.

“G” Longer conveyor to perform extra steps of closure.

“L” Larger conveyor to machine products with wider “h” length.

INTERMITTENT

TECHNICAL DATA Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) A+B max OPTIONS “G” Long Base Length (h) MA50 230 mm Up to 70 SPEED 40 - 190 mm 20 - 105 mm 75 - 200 mm 270 mmMA80 160 mm Up to 120 SPEED 30 - 130 mm 20 - 100 mm 75 - 200 mm 230 mm ✔ MA50L 230 mm Up to 60 SPEED 40 - 190 mm 20 - 105 mm 75 - 250 mm 270 mmMA80 L+G 160 mm Up to 70 SPEED 30 - 130 mm 20 - 100 mm 75 - 250 mm✔ 25

Intermittent motion cartoner series

MA SERIES (100)

Featured Model MA100 with vial feeder

Intermittent-motion automatic machine with horizontal carton transport, particularly suitable for packing blister, tubes, mascara and lipsticks.

• Versatility and efficiency in a small footprint

• Balcony design

• Synchronized servo motors

• User-friendly format changeover

• Cross control product-carton-leaflet

• Belt conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories.

CARTONING INTERMITTENT

TECHNICAL DATA Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) MA100 110 mm Up to 100 SPEED 20 - 85 mm 16 - 65 mm 60 - 170 mm MA100 V 110 mm Up to 150 SPEED 20 - 85 mm 16 - 70 mm 60 - 150 mm 26

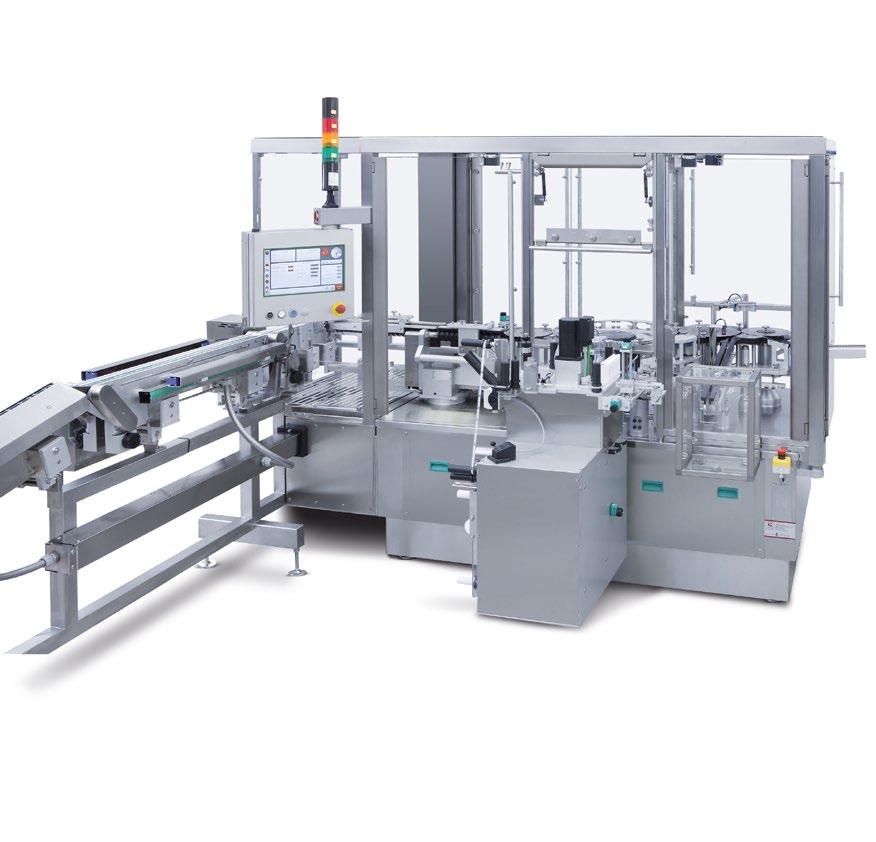

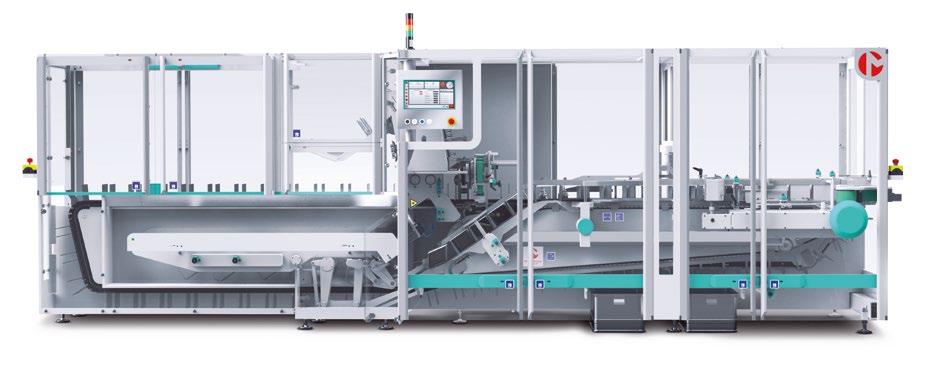

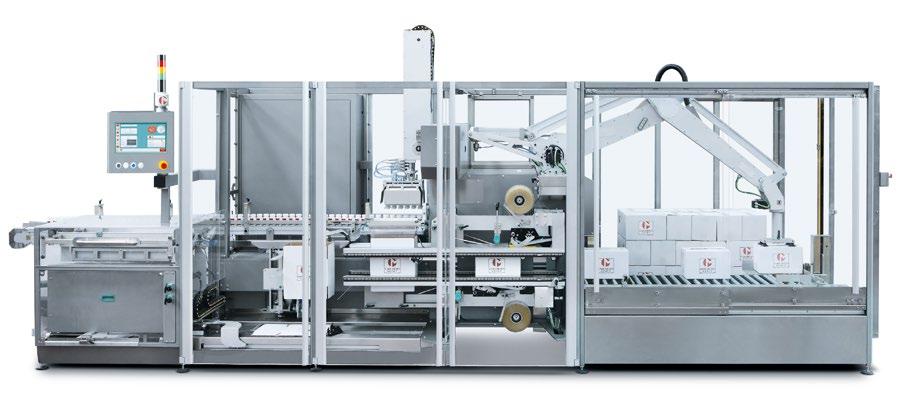

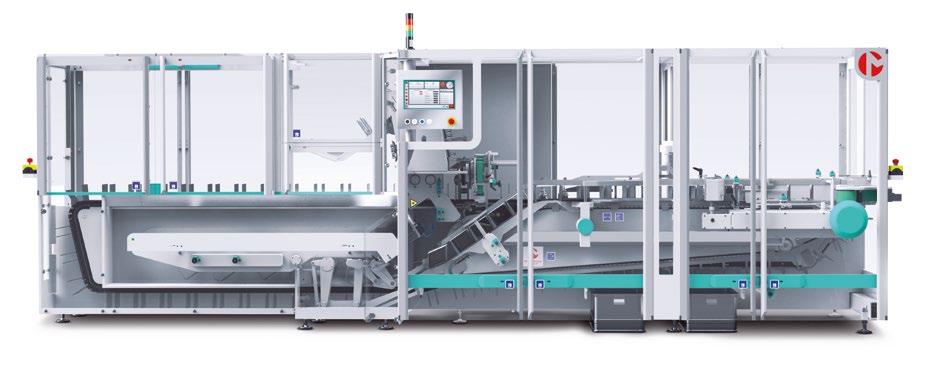

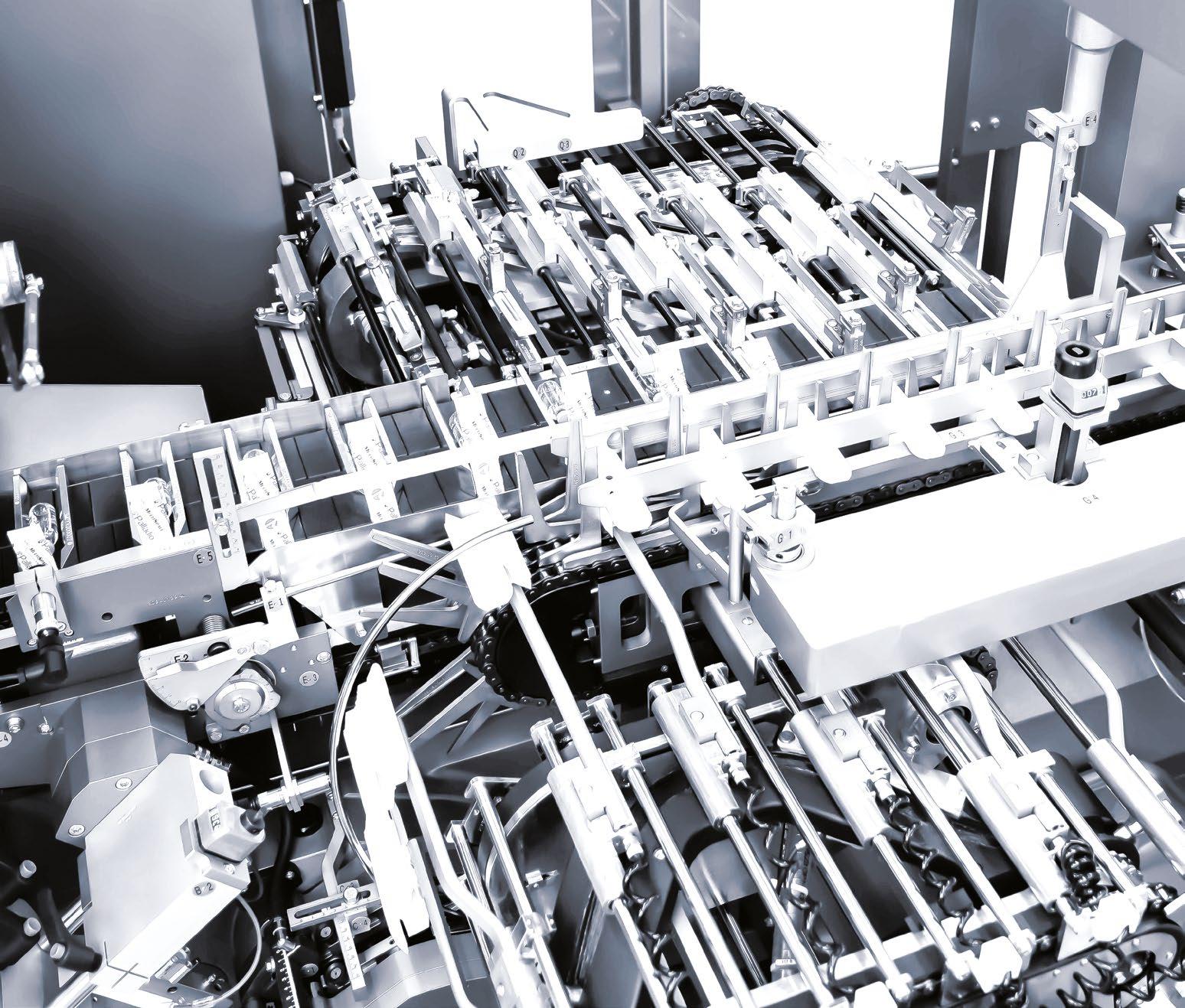

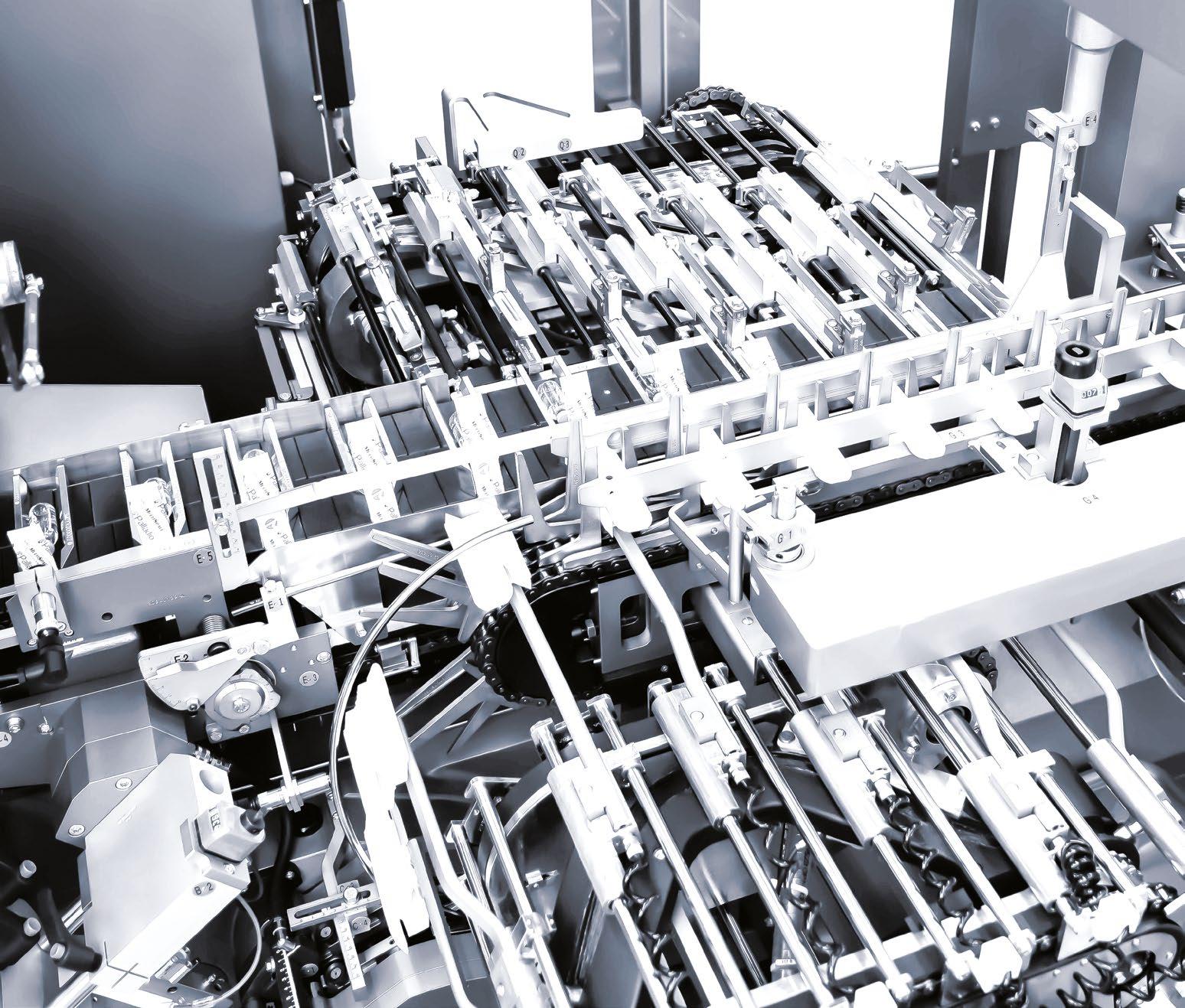

Continuous motion cartoner series

MA SERIES (155-255-305)

Featured Model MA255 fully configured

Continuous motion medium-speed horizontal cartoning machines, particularily suitable for packing tubes, blister, vials and bottles.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Motorized adjustment of carton length quota

• User-friendly size changeover

• Cross control product-carton-leaflet

• Chain conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories. “G” Longer conveyor to perform extra steps of closure. “L” Larger conveyor to machine products with wider “h” length.

CARTONING CONTINUOUS

TECHNICAL DATA Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) OPTIONS “G” Long Base MA155 127 mm Up to 140 SPEED 25 - 100 mm 15 - 85 mm 65 - 150 mm ✔ MA255 127 mm Up to 190 SPEED 25 - 100 mm 15 - 85 mm 65 - 150 mm ✔ MA305 127 mm Up to 240 SPEED 25 - 100 mm 15 - 85 mm 65 - 150 mm ✔ MA155 L 127 mm Up to 120 SPEED 25 - 100 mm 15 - 85 mm 65 - 190 mm ✔ MA255 L 127 mm Up to 180 SPEED 25 - 100 mm 15 - 85 mm 65 - 190 mm ✔ MA305 L 127 mm Up to 230 SPEED 25 - 100 mm 15 - 85 mm 65 - 190 mm ✔

27

28

Continuous motion cartoner series

MA SERIES (200-202)

Featured Model MA202

Continuous motion, medium-speed, horizontal cartoning machines particularly suitable for packing large tray formats, vials, bottles and stacked blister.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Servo-powered adjustment of carton length quota

TECHNICAL DATA MA200 190,5 mm Up to 200 SPEED 30 - 160 mm 20 - 110 mm 80 - 160 mm

• User-friendly size changeover

• Sloping surfaces to convoy the ejected items

• Cross control product-carton-leaflet

• Chain conveyor

MA200 L 190,5 mm Up to 190 SPEED 30 - 160 mm 20 - 110 mm 80 - 220 mm

(*) The output depends on product characteristics, feeding groups and installed accessories.

MA202 158,75 mm Up to 240 SPEED 30 - 130 mm 20 - 110 mm 80 - 160 mm

MA202 L 158,75 mm Up to 230 SPEED 30 - 130 mm 20 - 110 mm 80 - 220 mm

CARTONING CONTINUOUS

“L” Larger conveyor to machine products with wider “h” length. Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h)

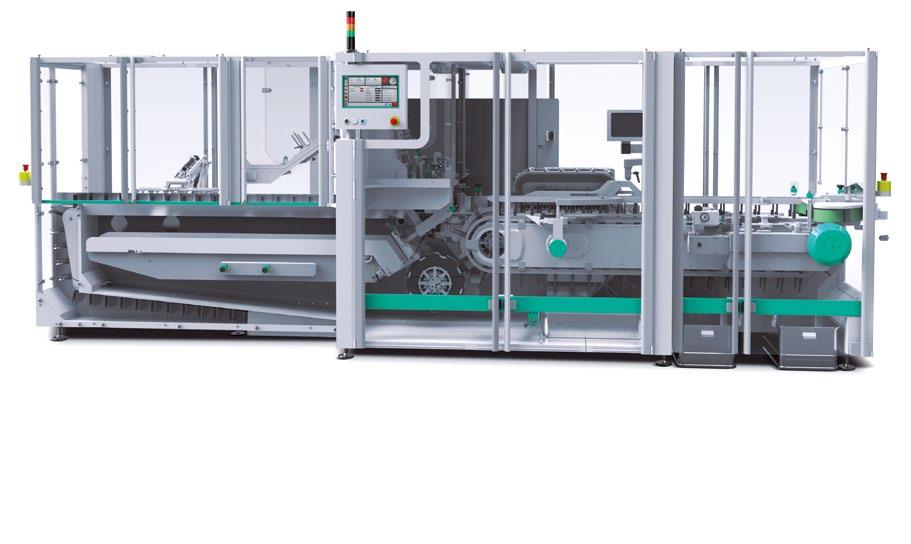

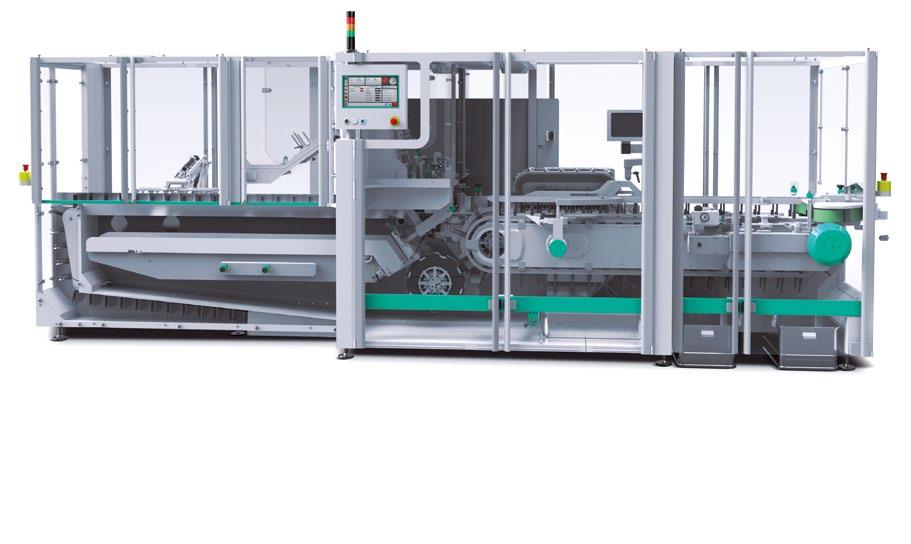

Continuous motion cartoner series

MA SERIES (300-400)

Featured Model MA400 fully configured

Continuous motion high-speed horizontal cartoners, particularly suitable for packing vials and bottles, blister and syringes.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Motorized adjustment of carton length quota

• Carton opening by rotating drum

• User-friendly format changeover

• Cross control product-carton-leaflet

• Chain conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories. “G” Longer conveyor to perform extra steps of closure. “L” Larger conveyor to machine products with wider “h” length.

CARTONING CONTINUOUS

TECHNICAL DATA Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) A+B max OPTIONS “G” Long Base Length (h) MA300 127 mm Up to 300 SPEED 25 - 100 mm 15 - 85 mm 65 - 150 mm 165 mm ✔ MA300 L+G 127 mm Up to 280 SPEED 25 - 100 mm 15 - 85 mm 65 - 190 mm 165 mm ✔ MA400 95,25 mm Up to 400 SPEED 25 - 70 mm 15 - 85 mm 65 - 150 mm 165 mm ✔ MA400 L+G 95,25 mm Up to 370 SPEED 25 - 70 mm 15 - 85 mm 65 - 190 mm 165 mm ✔

29

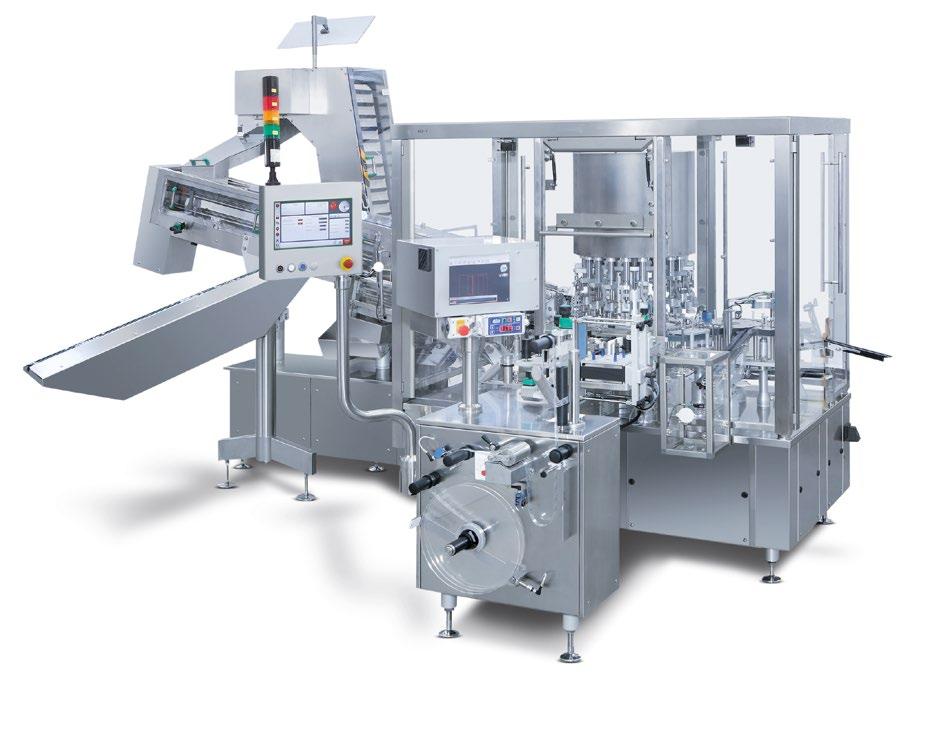

Continuous motion cartoner series

MA SERIES (252-302)

Featured Model MA252

Continuous motion medium-speed horizontal cartoners, paritcularly suitable for packing deep-draw thermoformed trays for ampoules and syringes.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Motorized adjustment of carton length quota

DATA

• User-friendly format changeover

• Long carton magazine

• Cross control product-carton-leaflet

• Chain conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories.

“L” Larger conveyor to machine products with wider “h” length.

CONTINUOUS

CARTONING

TECHNICAL

Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) MA252 158,75 mm Up to 140 SPEED 25 - 130 mm 15 - 85 mm 65 - 150 mm MA302 158,75 mm Up to 210 SPEED 25 - 130 mm 15 - 85 mm 65 - 150 mm MA252 L 158,75 mm Up to 130 SPEED 25 - 130 mm 15 - 85 mm 65 - 190 mm MA302 L 158,75 mm Up to 200 SPEED 25 - 130 mm 15 - 85 mm 65 - 190 mm

30

Continuous motion cartoner series

MA SERIES (260)

Featured Model MA260 with vial feeder

Continuous motion medium to high-speed horizontal cartoners, particularly suitable for packing blister, vials and bottles.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Motorized adjustment of carton length quota

• User-friendly format changeover

• Cross control product-carton-leaflet

• Belt conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories.

“G” Longer conveyor to perform extra steps of closure.

TECHNICAL DATA

Pitch

Output (cartons/minute)*

CARTON SIZE

Width (a)

Height (b)

(h) OPTIONS

“G” Long Base

CARTONING CONTINUOUS

Length

MA260 110

Up to

SPEED 30

15

90

75 - 150 mm ✔ 31

mm

260

- 90 mm

-

mm

Continuous motion cartoner series

MA SERIES (360-500)

Featured Model MA500

Continuous motion high-speed horizontal cartoners, particularly suitable for packing blister, vials and bottles.

• Versatility and efficiency in a small footprint

• Balcony design for easy access

• Oil-bath main drive units

• Synchronized servo motors

• Motorized adjustment of carton length quota

• User-friendly format changeover

• Long cartons magazine

• Cross control product-carton-leaflet

• Belt conveyor

(*) The output depends on product characteristics, feeding groups and installed accessories.

CONTINUOUS

CARTONING

TECHNICAL DATA Pitch Output (cartons/minute)* CARTON SIZE Width (a) Height (b) Length (h) MA360 110 mm Up to 360 SPEED 30 - 90 mm 15 - 90 mm 75 - 150 mm MA500 110 mm Up to 500 SPEED 30 - 90 mm 15 - 90 mm 75 - 150 mm 32

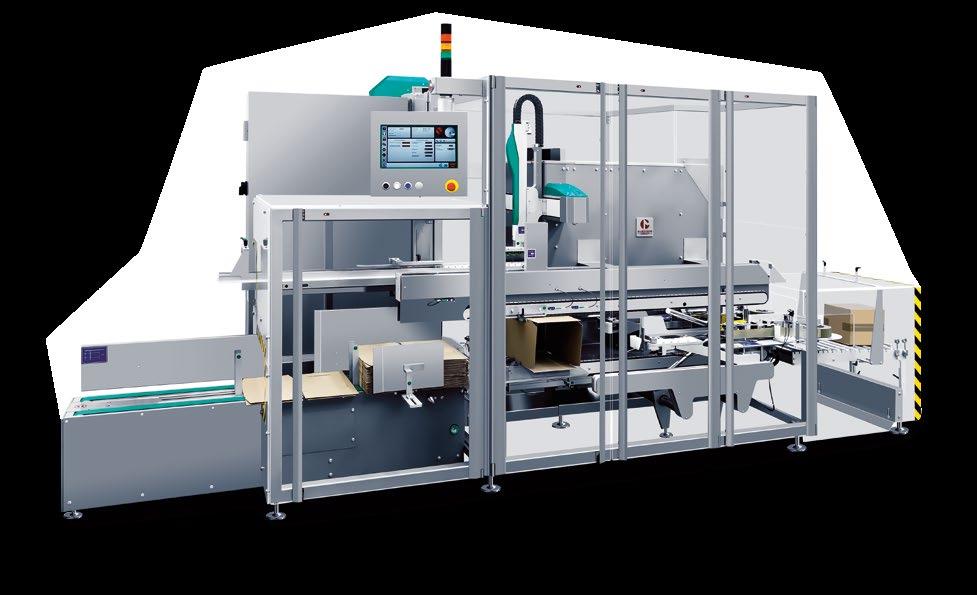

Cartoner MIDCARTON

Side-loading, intermittent motion machine working both as Cartoner and Casepacker. The machine can handle alternatively cartons, corrugated cartons and shipping boxes; it can easily work in bypass mode thanks to a dedicated transport system.

It Is design with a robot for shippers and cartons opening in the forming station and is able to work with multiple closure like glue, tuck-in and by tape.

Based on the product infeed requirements it can be equipped either with a second robot or with additional feeding systems.

MIDCARTON CARTONING

Featured Model

TECHNICAL DATA Mechanical Speed (case-box/minute) CARTON/BOX SIZE Width (a) Height (b) Length (h) GLUE CLOSURE 25SPEE D 50 - 300 mm 50 - 200 mm 80 - 260 mm TAPE 15SPEED 140 - 300 mm 125 - 200 mm 115 - 260 mm TUCK-IN 25S PEED 50 - 200 mm 50 - 120 mm 50 - 260 mm 33

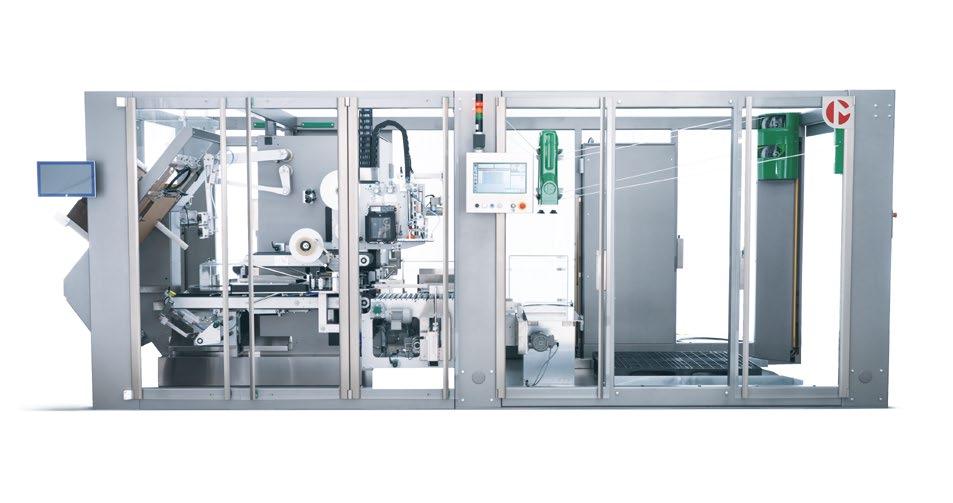

Cartoner FRB/FRT

Featured Model FRB500

Automatic intermittent-motion machine designed to form boxes and trays from flat cardboard. Particularly suitable for the pharmaceutical markets, the product can be closed with a tuck-in flap closure or with Hotmelt glue. The product can be side or top-loaded.

• Designed in accordance with cGMP regulations

• Balcony-style structure for easy access, cleaning and maintenance

• Clear separation between mechanical areas, inside the machine structure, and the product handling area to protect product from dust particles

• Servo-driven motors

• Quick and easy size changeover

• All sizes to be handled are memorized and can be automatically called up from the machine PC

• Machine uses corrugated cardboard from 1 to 3 mm or simple paperboard from 0.5 to 0.7 mm

• Hotmelt glue for flat cardboard

CARTONING

TECHNICAL DATA Mechanical speed (cartons/minute) CARTON SIZE Width (a) Height (b) Length (h) FRB500 40 SPEED 80 - 250 mm 20 - 150 mm 80 - 150 mm FRT500 40 SPEED 80 - 250 mm 20 - 150 mm 80 - 150 mm 34

Continuous motion labeller series

SL-A SERIES (A210–A305)

Featured Model SL-A210

The SL-A305 is a continuous motion labelling machine suitable to apply one (1) self-adhesive vignette on the upper carton surface.

The SL-A210 is the high-end model in this range and features 2D print&check serialization system and a labelling unit for tamper-evident seal.

• Continuous mode speed adjustment

• Twin conveyor belts with adjustable width

• Labels position adjustment

• Fast format changeover without additional parts

• Up to 2 labelling heads (SL-A210 only)

• 15’’ Touch screen control panel for machine and serialization system management (SL-A210 only)

LABELLING & SERIALIZATION

TECHNICAL DATA Mechanical speed (pcs/min) CARTON SIZE Width (a) Height (b) Length (h) LABEL SIZE Vignette height (B) Vignette length (A) TE-Seal height (B) TE-Seal length (A) SL-A210 150 SPEED 25 - 180 mm 17 - 100 mm 70 - 250 mm15 - 30 mm 15 - 60 mm SL-A305 300 SPEED 40 - 180 mm 15 - 80 mm 40 - 200 mm 20 - 60 mm 15 - 80 mm35

Continuous motion labeller series

BL-A SERIES (A309–A415-A415S)

Featured Model BL-A415

Automatic labellers to affix one self-adhesive vignette on the upper face of cartons. The machines are designed for quick installation of Track & Trace units, inkjet, or laser printers and cameras, which mark and read the DATAMATRIX for serialization purposes. As an alternative to vignette application, the BL-A415 can be equipped with two heads for tamper-evident seal application.

• Balcony design to assure an easy access for management, inspection and service

• PC controlled with positive “Fail Safe” logic

• Continuous mode speed adjustment

• Patented cartons indexing device

• Label dispensing on servo driven motor

• Automatic speed synchronization of all motors

• Fast format changeover without parts

• Self diagnosis on display

(*) Conveyor pitch unique size 150 mm.

LABELLING & SERIALIZATION

TECHNICAL DATA Mechanical speed (pcs/min) CARTON SIZE Width (a) Height (b) Length (h) LABEL SIZE Vignette height (B) Vignette length (A) TE-Seal height (B) TE-Seal length (A) BL-A309 300 SPEED 20 - 105 mm 15 - 90 mm 70 - 250 mm 20 - 60 mm 15 - 80 mmBL-A415 400 SPEED 20 - 105 mm 15 - 90 mm 45 - 250 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm BL-A415S* 300 SPEED 25 - 80 mm 15 - 90 mm 70 - 250 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm 36

Continuous motion labeller series

BL-A SERIES (A420–A430-A525)

Featured Model BL-A420

Automatic labellers for the application of self-adhesive vignettes and tamper evident seals. The machines are designed for quick installation of Track & Trace units, for DATAMATRIX printing and verification, as well as printing of relevant human-readable text on the lateral flaps and on the top panel.

• Balcony design to assure easy access for management, inspection and service

• PC controlled with positive “Fail Safe” logic

• Continuous mode speed adjustment

• Patented cartons indexing device

• Label dispensing on servo driven motor

• Automatic speed synchronization of all motors

• Fast format changeover without parts

• Self diagnosis on display

LABELLING & SERIALIZATION

TECHNICAL DATA Mechanical speed (pcs/min) CARTON SIZE Width (a) Height (b) Length (h) LABEL SIZE Vignette height (B) Vignette length (A) TE-Seal height (B) TE-Seal length (A) BL-A420 400 SPEED 25 - 105 mm 15 - 90 mm 70 - 250 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm BL-A430 400 SPEED 20 - 105 mm 15 - 90 mm 70 - 250 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm BL-A525 500 SPEED 20 - 65 mm 15 - 90 mm 70 - 160 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm 37

Continuous motion labeller series

BL-A SERIES (A420CW–A430CW-A525CW)

Featured Model BL-A420CW

Automatic labellers that feature an integrated checkweigher, for carton weighing and checking. As well as other similar models these machines are suitable for applying self-adhesive vignette and tamper evident seals on cartons, at high production speeds. The units are pre-arranged to house Track & Trace applications.

• Balcony design to assure easy access for management, inspection and service

• PC controlled with positive “Fail Safe” logic

• Continuous mode speed adjustment

• Patented cartons indexing device

• Label dispensing on servo driven motor

• Integrated checkweigh unit

• Automatic speed synchronization of all motors

• Fast format changeover without parts

• Self diagnosis on display

LABELLING & SERIALIZATION

TECHNICAL DATA Mechanical speed (pcs/min) CARTON SIZE Width (a) Height (b) Length (h) LABEL SIZE Vignette height (B) Vignette length (A) TE-Seal height (B) TE-Seal length (A) BL-A420CW 350 SPEED 25 - 105 mm 15 - 90 mm 70 - 160 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm BL-A430CW 250 SPEED 25 - 105 mm 15 - 90 mm 70 - 250 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm BL-A525CW 500 SPEED 20 - 65 mm 15 - 90 mm 70 - 160 mm 20 - 60 mm 15 - 80 mm 15 - 30 mm 15 - 60 mm 38

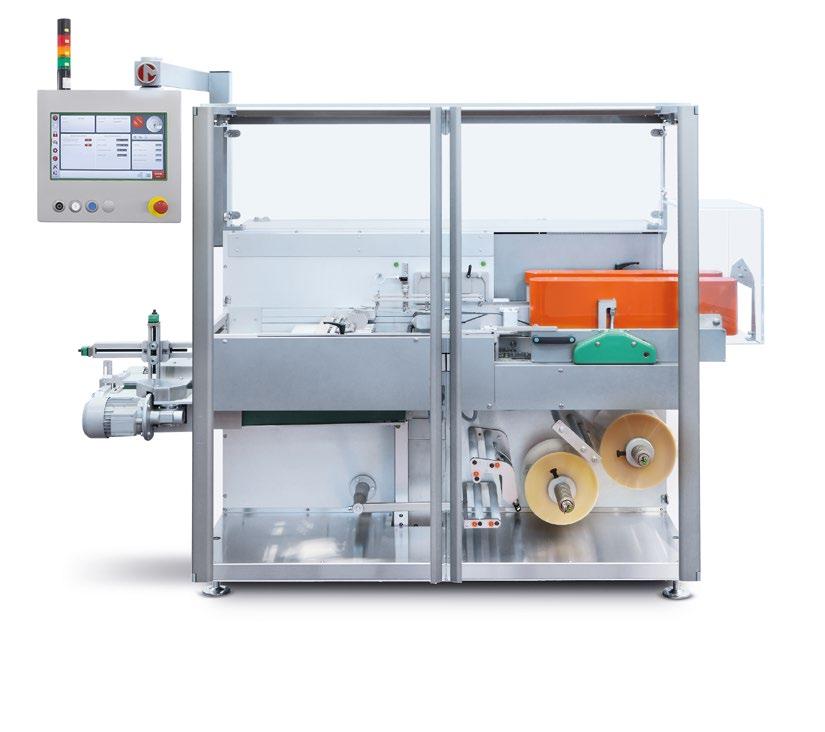

Bundler FA SERIES

Featured Model FA04

Automatic intermittent-motion machine designed in accordance with cGMP standards for wrapping with stretch film. Conceived primarily for the cosmetics and pharmaceutical markets, simplicity of design and high-speed output are its main features.

• Servo driven motor guarantees reliability and synchronized movement even at high speed

• Machine and motors managed by PC

• Balcony style structure with clear division between mechanical parts situated at the rear of the machine and product flow at the front

• Ergonomic structure facilitates machine inspection and provides high workflow visibility

• Simple and linear construction for easy cleaning

• Speed, strokes and single group positions are set up from the PC by programmable logics, making correct machine set-up automatic and size changeover extremely quick and easy

TECHNICAL DATA

Mechanical speed (bundle/minute)

Product Width “a”

Product Height “b”

Product Length “h”

Bundle Width “A”

Bundle Height “B”

Bundle Length “H”

WRAPPING

FA04 40 60 - 350 mm 20 - 100 mm 55 - 200 mm 60 - 350 mm 20 - 220 mm 55 - 200 mm 39

Overwrapper FARPLUS

Featured Model FARPLUS

Automatic machine for overwrapping cartons and regular-shaped single or bundled products.

• A wide range of personalization options available

• Bypass belt for products that must not be overwrapped

• Positive carton transport identify carton position to carry out additional operations and prevent contact between cartons

• Balcony construction for easy access, product visibility, maintenance and cleaning

• Touch screen control panel for machine management,with format size parameter set-up

• Easy and fast, tool-free changeover from operator side

• Centered product stop ensures uniform seal position on all packages

• High quality wrapping

OUTPUT

Up to 80 cycle/min

PRODUCT RANGE

Width (a) 20 - 300 mm

Height (b) 15 - 150 mm

Length (h) 60 - 200 mm

WRAPPING

40

Overwrapper MF SERIES

Featured Model MF910

Automatic overwrapping machine, designed for the pharmaceutical and cosmetic markets. Suitable to operate with several typologies of products, single or banded together, with thermo-sealing film.

• The working area is in cantilever (balcony type) layout, with easy accessibility and a small footprint

• Driven by Brushless motors and remotely controlled by a PC, sealing temperatures included. The machine is fitted for a rapid size change over thanks to the employment of the lateral folding unit that allows to minimize the spare parts reducing the time needed to change the product format

• Several arrangements and a wide range of customized solutions are available

• Conformed to the GMP requirements

• All the group placed in ergonomic positions

• Operator touch screen interface for machine management

TECHNICAL DATA

Mechanical speed

Product Width “a”

Product Height “b”

Product Length “h”

Bundle Width “A”

Bundle Height “B”

Bundle Length “H”

WRAPPING

80 cycle/min 20

300 mm 12 - 150 mm 60 - 250 mm 50 - 300 mm 25 - 150 mm 60 - 250 mm 41

MF910/M

-

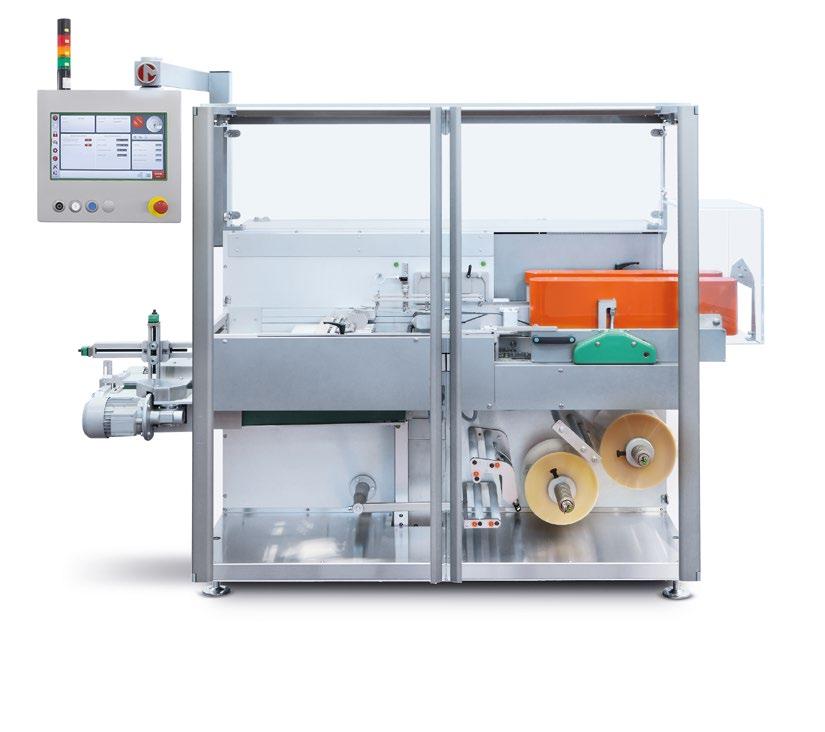

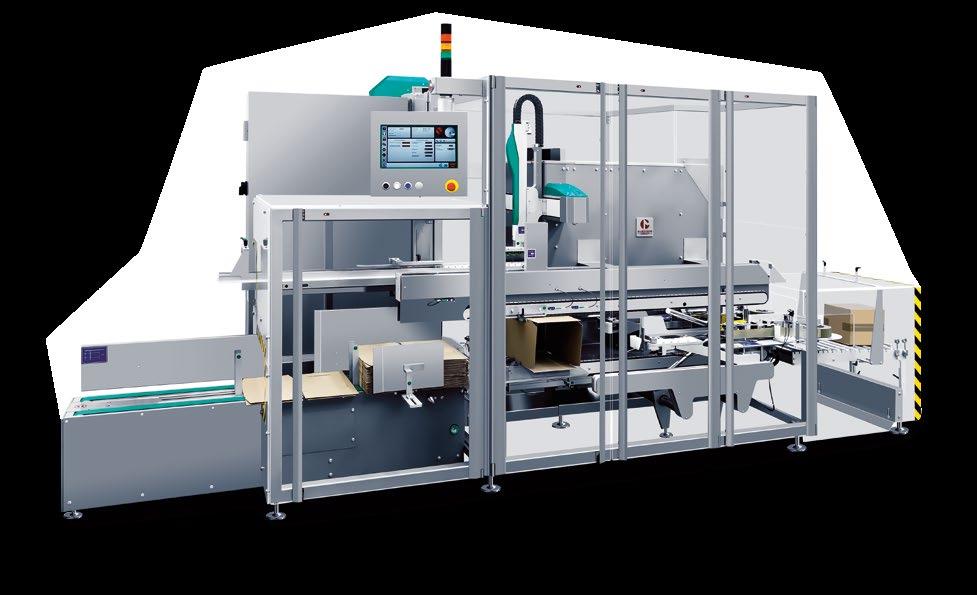

Casepacker BESTPOCKET

Featured Model BESTPOCKET

Automatic casepacker with horizontal infeed and an extremely compact layout.

• The Bestpocket combines innovation and consolidated packing solutions

• The fast format changeover plus customizable outfeeds enable a wide range of products to be processed

• This machine can be easily equipped with DATAMATRIX verification camera and multilevel parent-child aggregation system to aggregate cartons in a case with a serialized

• Machine can be equipped with many accessories such as automatic case magazine, glue closure instead of tape

TECHNICAL DATA

Output (Case/Min)

Case Width “A”

Case Height “B”

Case Length “H”

BESTPOCKET 7 160 - 520 mm 120 - 400 mm

120 - 350 mm

CASEPACKING & DEPACKING

42

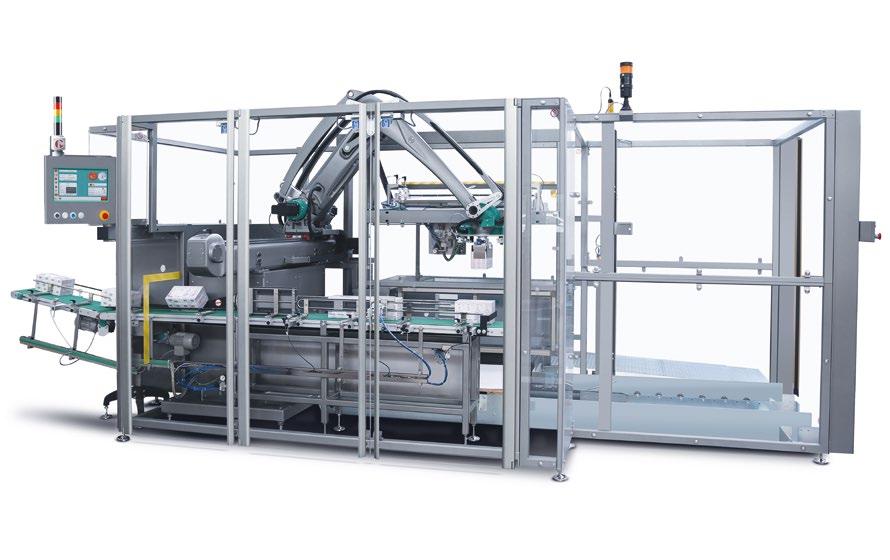

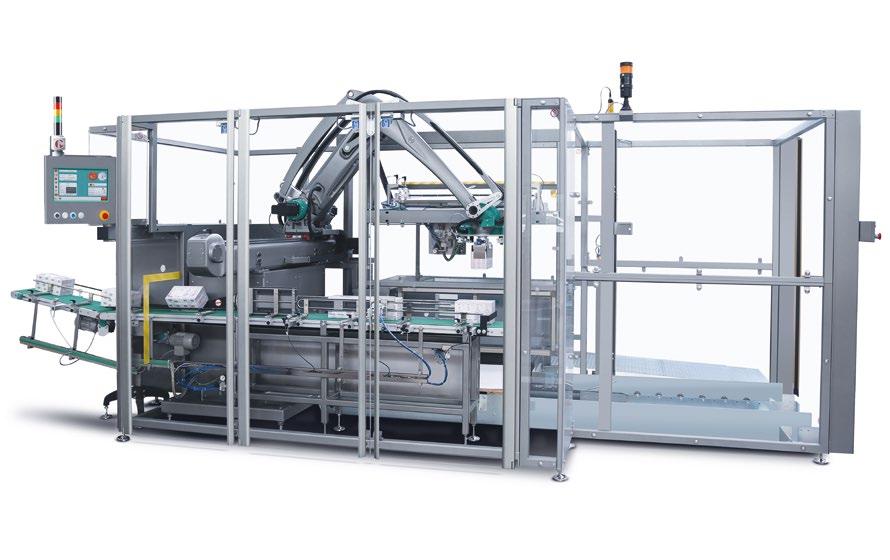

Casepacker MC SERIES

Featured Model MC820TT

Automatic machines for packing single cartons or bundles into cases, closed with adhesive tape or glue. The machines comes fully equipped for serialization and data aggregation (Track&Trace), is controlled by servo-driven motors and PC-managed.

• Designed in accordance with cGMP regulations.

• Balcony-style structure for easy access, cleaning and maintenance

• Clear separation between mechanical areas inside the machine structure and the product handling area to protect product from dust particles

• Servo-driven motors

TECHNICAL DATA

• Size changeover adjustments in width (quota B), and height (quota H) carried out by servo driven motors, controlled directly from the operator panel, length (quota A) is automatically managed by the size format parameters from the PC

• Easy changeover (hopper, Pick & Place suction cups and pusher) by means of quick lock size parts with minimal use of tools

CASEPACKING & DEPACKING

Note Mechanical speed (case/minute) Case Width “A” Case Height “B” Case Length “H” MC82010 140 - 520 mm 120 - 350 mm 120 - 350 mm MC820TT Track & TRACE 10 (7,5 w/serial. on) 140 - 520 mm 120 - 350 mm 120 - 350 mm MC82220 140 - 400 mm 110 - 300 mm 110 - 300 mm MC8246 250 - 600 mm 180 - 400 mm 170 - 400 mm 43

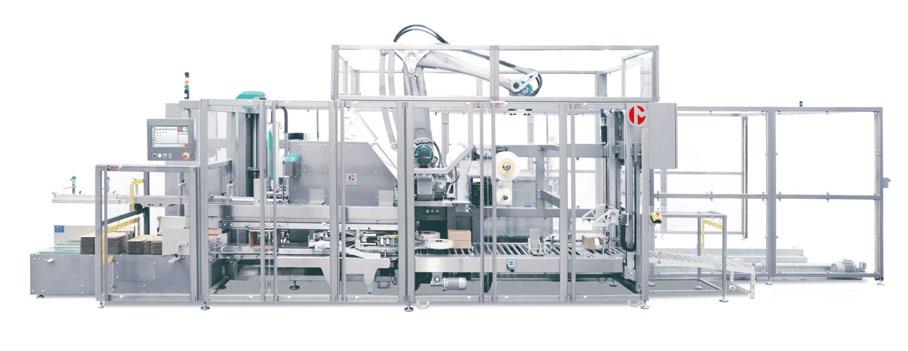

Casepacker PS SERIES

Featured Model PS310

PS Series are very compact Casepacker that can be used also for Track&Trace and aggregation purposes. If during the infeed cycles an incorrect code is being detected, the case or the cartons (depends on the machine model) are carried to a specific position to be manually removed by the operator. Serialized code can be read row-by-row or layer-by-layer.

CASEPACKING & DEPACKING

DATA Note Mechanical speed (case/minute) Case Width “A” Case Height “B” Case Length “H” PS300 SEMI-AUTOMATIC 4 200 - 600 mm 125 - 400 mm 80 - 400 mm PS310 SEMI-AUTOMATIC 4 160 - 450 mm 120 - 350 mm 100 - 350 mm

AUTOMATIC 16 140 - 450 mm 120 - 350 mm 75 - 350 mm

TECHNICAL

PS510

44

Serialization & aggregation unit TRACKPACK

Featured Model TRACKPACK

Continuous motion monoblock machine for serialisation, aggregation and Vignette or Tamper Evident applications, with semi-automatic casepacking. Automatic labelling and semiautomatic casepacking machine for applying at medium speed one (1) selfadhesive vignette on the upper carton side or, two (2) tamper-evident ‘TE’ seals on the carton sides. The machine inserts the product into a manually-opened case, loads it in the hopper and then unloads the filled cases. The machine is set up for tracking devices such as inkjet printers plus relevant cameras, which print and verify 2D codes and humanreadable text. Trackpack operates in line with other machines and is set up for serialisation and aggregation applications.

TECHNICAL DATA

Mechanical speed (case/minute)

Product Width “a”

Product Height “b”

Product Length “h”

Bundle Width “a1”

Bundle Height “b1”

Bundle Length “h1”

Case Width “A”

Case Height “B”

Case Length “H”

70 - 380 mm

200 - 600 mm

- 400 mm

80 - 400 mm

CASEPACKING & DEPACKING

TRACKPACK 4

19

20 - 105 mm

- 90 mm 70 - 250 mm 25 - 580 mm 19 - 380 mm

125

45

Top loader casepacker MCV 850

Featured Model MCV

Automatic top load case packing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life

• Compact-sized machine, with small footprint

• Vertical magazine case feed, conveniently positioned at the front of the machine, with high loading capacity

• Touch screen control panel for machine management, with format size parameter set-up

• Set-up for serialization and aggregation applications

OUTPUT

Up to 12 cases/min

PRODUCT RANGE

Width (a): 140 - 420 mm

Height (b): 120 - 320 mm

Length (h): 120 - 320 mm

CASEPACKING & DEPACKING

46

Depacking & blowing monoblock MD7

Featured Model MD7

Automatic intermittent motion machine, with robotized movements and servo motor drive, to remove the shrinkable PE wrapping from the bundles of round glass bottles and conveying them to the feeding system of the downstream line. Bundles arriving from the De-Palletizer or fed manually are opened and the bottles are conveyed to the downstream machine in single row. The machine can be equipped with a blowing table.

• Overall dimensions are contained

• The design satisfies pharmaceutical packaging expectances by offering easy access from all sides, allowing easy cleaning during size change and at lot end

• The discharge belt may be connected to a rotating or linear table

• Safety guards in Methacrylate

• Safety switches on opening doors

• Easy size change over with hand wheels, clock indicators and millimeter scales

TECHNICAL DATA

CASEPACKING & DEPACKING

MD7 Up to 5 bundles/minute 300 - 600 mm 50 - 160 mm 200 - 400 mm 47

Mechanical speed Product Width Product Height Product Length

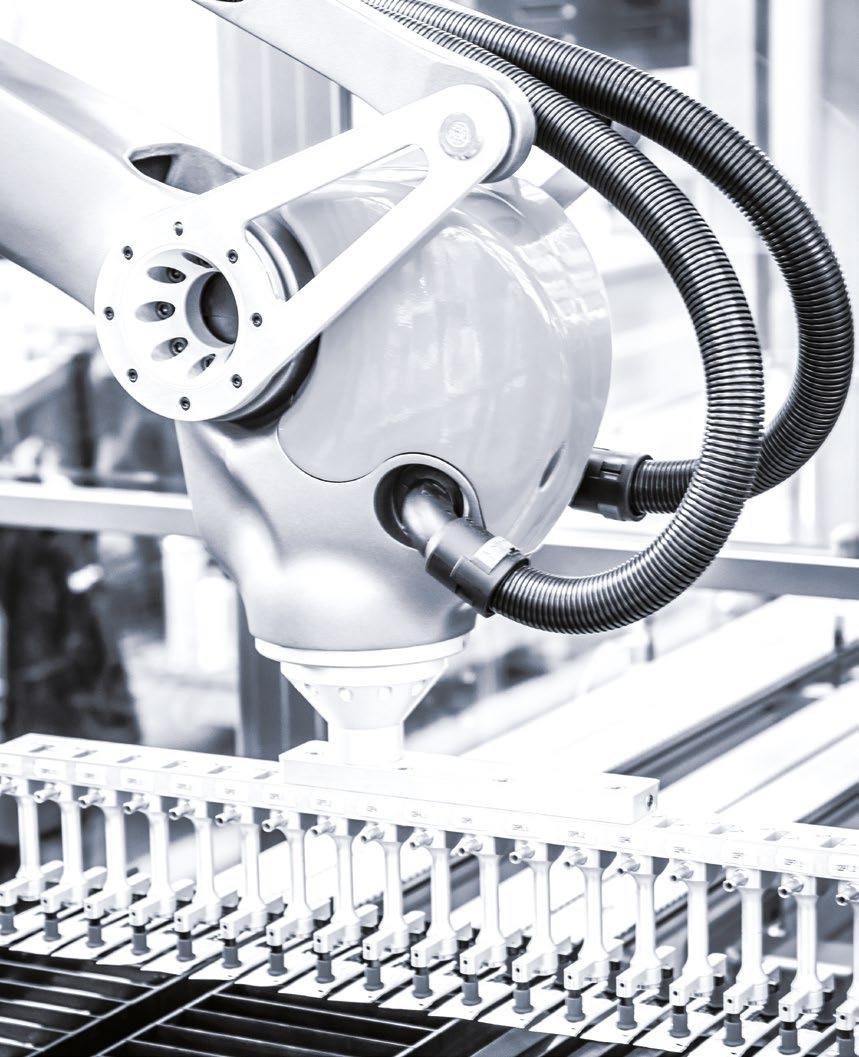

Palletizer & depalletizer

MP830/MDP810

Featured Model MP830

MP830Automatic machine capable of receiving single closed cases on an infeed motorized roller belt, pick-up the shippers and palletize them in requested patterns on a standard wooden pallet. A solid structure in painted steel plates supports the anthropomorphic “Robotic Arm” with 4 free sides movement, which improves performance and flexibility of the application based on the experience of previous Cartesian design.

• Movements achieved through brushless motors, controlled by the PC

• The Pickup head works with vacuum and free rotation over 360 degrees

• Manual empty pallet loading and manual full pallet discharge within dedicated guides with prearrangement for automatic empty pallet loading and discharge

TECHNICAL DATA

Note

Mechanical speed (cycles/minute)

Case Width “A”

Case Height “B”

Case Length “H”

MP830

Robotic Arm

MDP810 Automatic machine for the de-palletizing of single and compact products loaded on a pallet. By means of a pick and place movement, the product is transferred from the pallet to the infeed conveyor of the downstream machine.

• All mechanical movements and control motors are enclosed within the frame

• Movements achieved through brush less motors, controlled by the PC

• The products arrive from a pallet placed on a fixed position in infeed

• Pickup heads with vacuum, rotation freedom all 360 degrees

• Manual pallet loading onto dedicated guides in infeed position

• Machine prearranged for automatic pallet loading and discharge

TECHNICAL DATA

Note

Mechanical speed (cycles/minute)

Case Width “A”

Case Height “B”

Case Length “H”

MDP810

Depalletizer 4-5

220 - 600 mm

220 - 400 mm

50 - 220 mm

PALLETIZING & DEPALLETIZING

10

120

120

140 - 600 mm

- 400 mm

- 400 mm

48

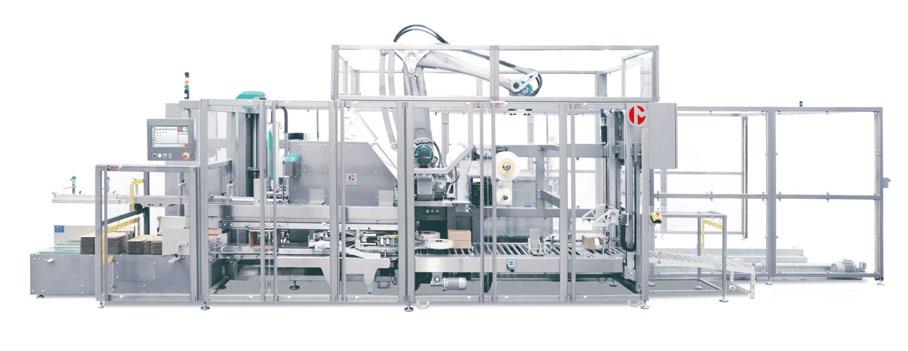

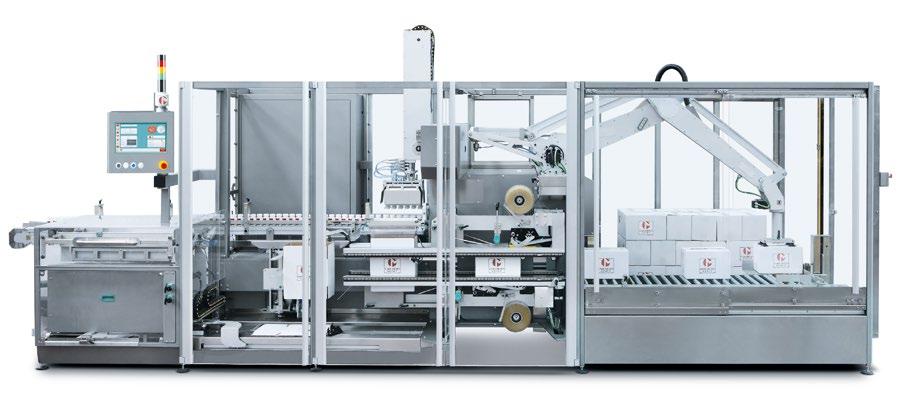

Casepacker & palletizer MCP840

Featured Model MCP840

Automatic horizontal casepacker palletizer combining in a single, compact monoblock the operations of packaging products in cases then palletizing them.

• The machine has been designed and manufactured following the balcony type construction to reduce mechanical maintenance and lubrication

• The mechanical parts are protected against dirt and dust because they are isolated from the working area and the case transport unit

• The electric panel of the monoblock is included inside a sliding cabinet placed on the casepacker rear side, the sliding cabinet makes possible accessibility to all mechanisms

• All the casepacker palletizer motions are driven by servo motors controlled by PC

• Adjustments for case size change over under ‘B’ and ‘H’ quotes are made through servo motors with command directly from the operator panel. “A” is automatically adjusted by selecting the format from the PC

• Quick lock size parts with reduced use of tools

OUTPUT

Up to 10 cases/min

PALLET

Europallet: 800x1000 mm - 1000x1200 mm

Height: Up to 1800 mm

PRODUCT RANGE

Width (a) 140 - 520 mm

Height (b) 120 - 350 mm

Length (h) 120 - 350 mm

PALLETIZING & DEPALLETIZING

49

Top loader casepacker & palletizer MCPV850

Featured Model MCPV850

Monoblock - Integrated Unit capable of receiving products on infeed conveyor, collate them in a requested pattern, forming RSC-case (regular slotted container) taken from magazine, loading product into the case and sealing it with self-adhesive not overlapping tape, transport the closed cases to the pick-up station and palletizing them in a requested patterns.

The machine is formed as a Monobloc by unifying the top loading Case-packer MCV850 and the Palletizer MP830 and including a case transfer section between both.

• Machine frame to which all movements and functions are connected in a balcony type construction. Within the frame are enclosed all mechanical movements and motors

• Movements achieved through brush less motors, controlled by the PC

• Adjustments for size change of the case, width ‘B’ and height ‘H’ by servomotors with indicators shown on HMI screen

• The case length adjusts automatically by case data input on the PC

• Size parts are fitted by quick lock device therefore it is required a minimum use of tools

• The products are transferred directly into the case from the conveyor by a Pick & Place

• A vacuum gauge and/or sensor detects the pickup of each product at each cycle to assure that the defined numbers of product has been collated

• In case of a wrong or missing pick-up the machine stops

PALLETIZING & DEPALLETIZING

OUTPUT Up to 12 cases/min PRODUCT RANGE Width (a) 140 - 420 mm Height (b) 120 - 320 mm Length (h) 120 - 320 mm 50

Palletizer MINISTRATUS

Featured Model MINISTRATUS

Automatic palletizing machine.

• Balcony construction for easy access, product visibility, maintenance and cleaning

• Reliable and robust mechanical construction to reduce maintenance and prolongs machine life

• Compact-sized machine, with small footprint

• Touch screen control panel for machine management, with format size parameter set-up

• Easy and fast changeover

• A wide range of personalization options available

• Each pick up operation is checked during every cycle to guarantee correct case composition

OUTPUT

Up to 8 cases/min

PALLET

Europallet: 800x1200 mm - 1000x1200 mm

Height: Up to 1500 mm

PRODUCT RANGE

Width (a) 140 - 600 mm

Height (b) 120 - 400 mm

Length (h: 120 - 400 mm

PALLETIZING & DEPALLETIZING

51

Automatic carto-paletizer

C-FLY

Featured Model C-FLY

• Automatic carto-palletizer with horizontal introduction, which gathers in a compact monobloc cardboard packaging and palletization operations

• Innovative case/schipper picking system through a robotic head moved by 4 pairs of cables controlled by Brushless motors

• Compact, ergonomic, reliable and robust, it is a machine with innovative design and solutions in small dimensions

• Options to install printers, labellers, code controls

• Construction in full compliance with GMP standards

• Feeding groups located in ergonomic positions

• Touch Screen operator interface, to manage and change the machine functions

• New cable-managed robotic solution: entirely developed and produced in Marchesini R&D

• High precision

• High performance

• Easy setup

• Great flexibility in connection

• Possibility of automatic pallet output, combined with a pallet warehouse

• T&T Ready

• On-board stability control system

• Industry 4.0 ready: the machine supports the latest IoT technologies

PALLETIZING & DEPALLETIZING

CARTON SIZE A B C PALLET Y X Z + W SPEED Cartons/minute C-FLY 160 ÷ 520 mm 120 ÷ 400 mm 120 ÷ 350 mm SPEED 1.200 mm 800 ÷ 1.000 mm 1.550 mm Up to 7 52

Customized unit BUFFER

Based on the customer’s needs the Marchesini Group can design and produce different types of BUFFERS for different kinds of products, in order to achieve the production targets and the best production layout.

Modular FIFO buffers and products in trays managed by robotised Pick & Place are only some examples of solutions we can develop.

Featured Model BUFFER ROBOTIC HANDLING AND SPECIAL APPLICATION

53

Packaging line CONTACT LENS

Featured Model CONTACT LENS LINE

Marchesini packaging Lines meet the highest standards of efficiency, quality and reliability in the PACKAGING of contact lenses. Our machines optimally protect the product. The secondary packaging phase is completely automated, passing from de-traying and ending with palletizing.

CONTACT LENS PROCESS FLOW

ROBOTIC HANDLING AND SPECIAL APPLICATION WRAPPING CASEPACKING PALLETIZING DE-TRAYING SWITCHING BUFFERING LABELLING STACKING PACKAGING PRINTING

54

Label unit

Featured Model BL-H235

An inhaler is a device that gets medicine directly into a person’s lungs. The medicine is a mist or spray that the person breathes in.

The most common type of inhaler is the pressurized metered-dose inhaler (MDI). We are able to manage a complete range of machines in this field, starting from STANDARD to Highly Customized.

INHALER PROCESS FLOW

INHALER

ROBOTIC HANDLING AND SPECIAL APPLICATION WRAPPING CASEPACKING PALLETIZING AEROSOL TEST CHECKWEIGHER LABELLING OPTIONAL FLOW PACKING CARTONING CARTON CHECKWEIGHER CARTON LABELLING PRINTING SERIALIZ.

CANNISTER AND INHALER COUPLING 55

Complete line AUTO-INJECTORS

Featured Model COMPLETE PRODUCTION LINE

Over the years we gained a solid experience in the field of auto-injectors. Many Marchesini lines are handling the auto-injector process: de-traying, labelling, packaging into both PVC and cardboard trays, insertion directly into carton without tray, check weighing, serialization of the carton, case packing and palletizing with aggregation.

Marchesini Group is structured to manage a complete range of machines starting from STANDARD to Highly Customized to ensure the best value creation for our customer.

AUTO-INJECTORS PROCESS FLOW

ROBOTIC HANDLING AND SPECIAL APPLICATION WRAPPING CASEPACKING PALLETIZING DE-TRAYING LABELLING TRAY PACKAGING CARTONING

56

The technical specifications given in this catalogue are subject to change without prior notice or liability.

Size range may vary in accordance with the different applications.

The Marchesini Group constantly updates its products to meet market needs.

Marchesini Group S.p.A.

Via Nazionale 100 • 40065 Pianoro BO ITALY

T +39 051 047 9111 sales@marchesini.com marchesini.com

MARCHESINI GROUP

INSPIRED BY THE EXTRAORDINARY

Packaging solutions inspired by the extraordinary

Packaging solutions inspired by the extraordinary