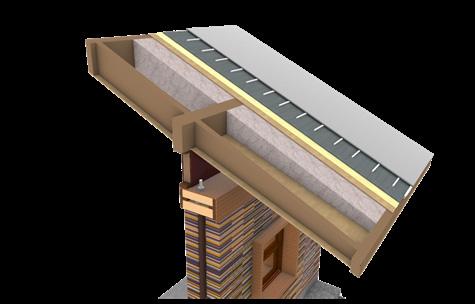

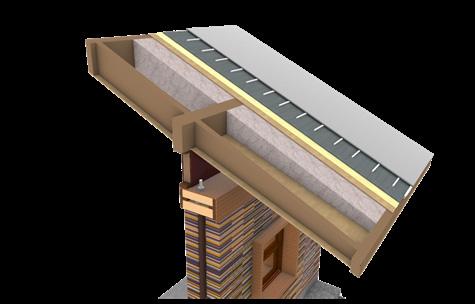

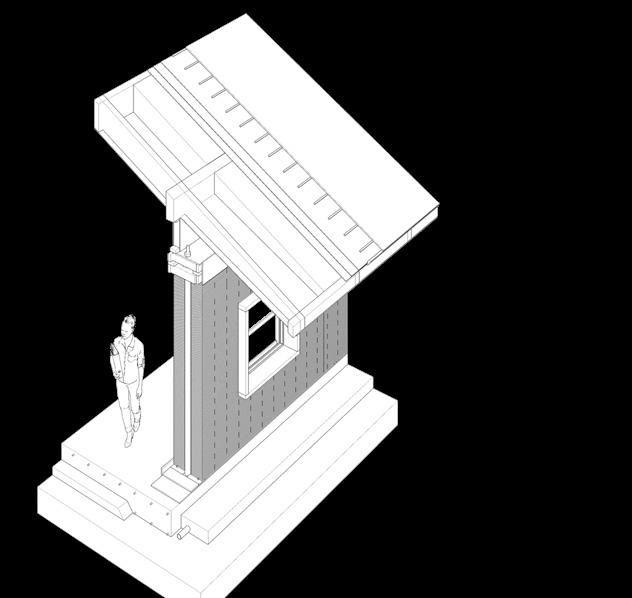

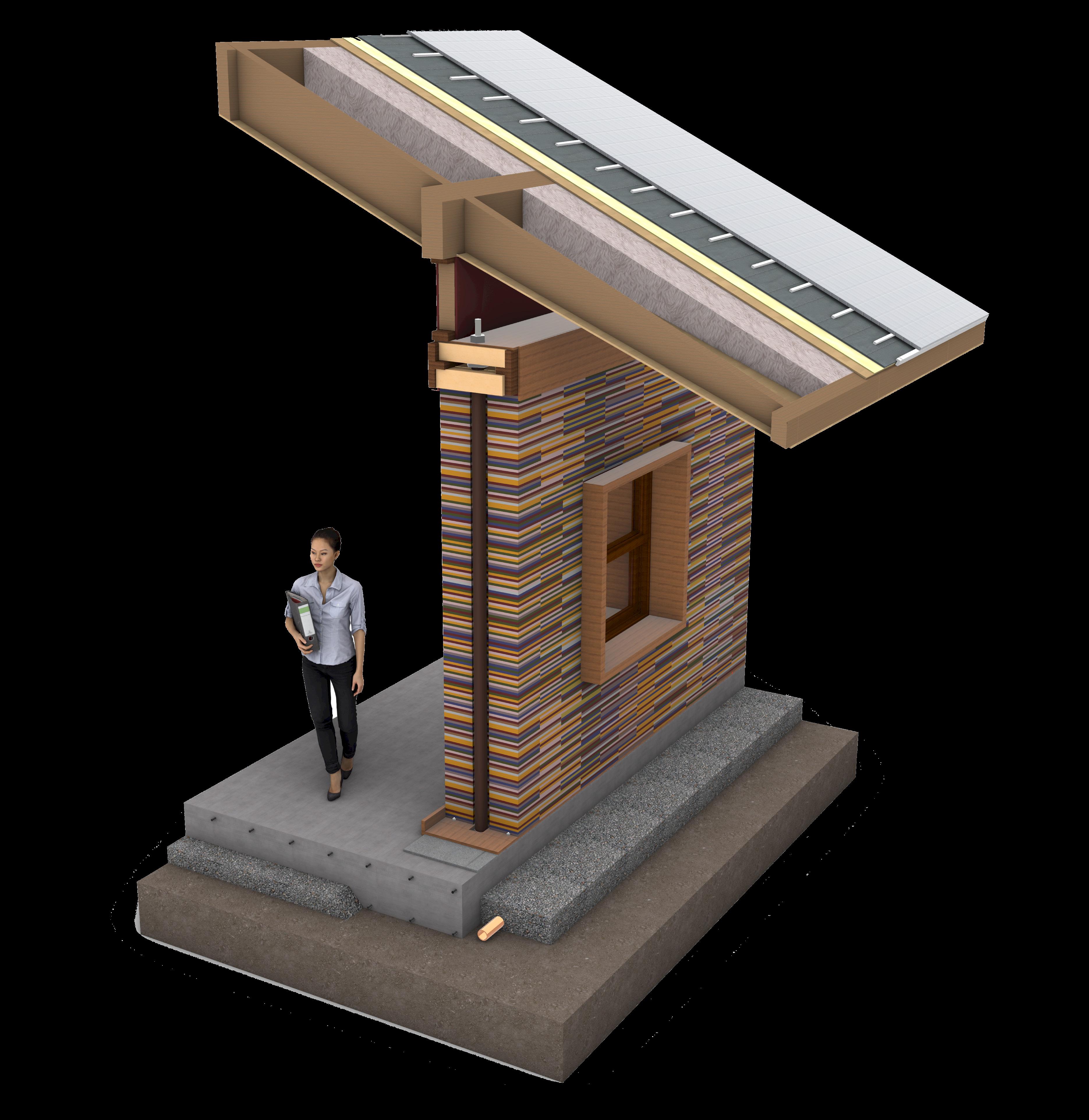

METAL ROOF

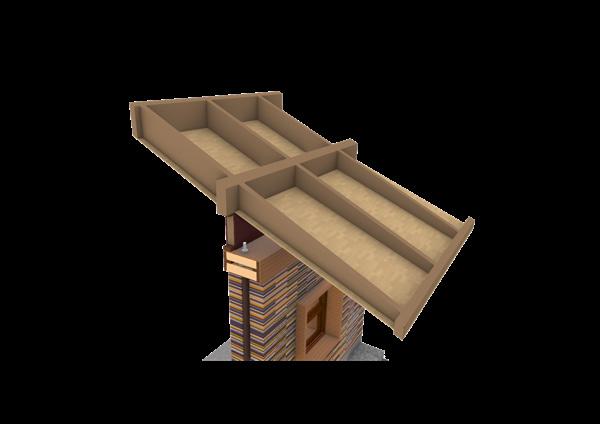

TIMBER FRAME WATERPROOF ROVING

BREATHER MEMBRANE PLYWOOD DECKING

PLYWOOD SHEETING

TIMBER FRAME WITH INSULATION

MINWAX FINISHED TIMBER CLADDING

TIMBER CLADDING

TIMBER PARTITIONS

COMPRESSION BOLT

TIMBER COMPRESSION BEAM

PLYWOOD FASCIA

DOUBLE GRAZING

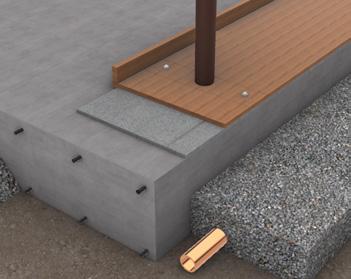

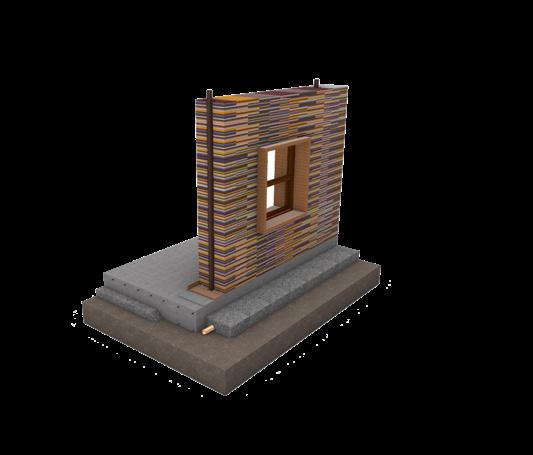

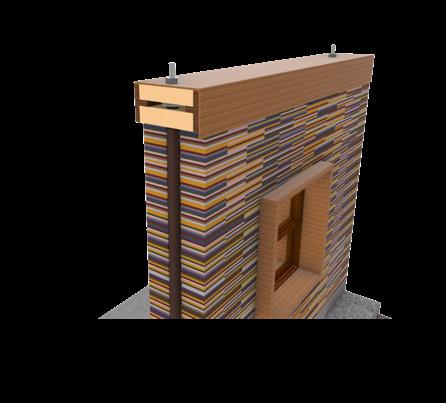

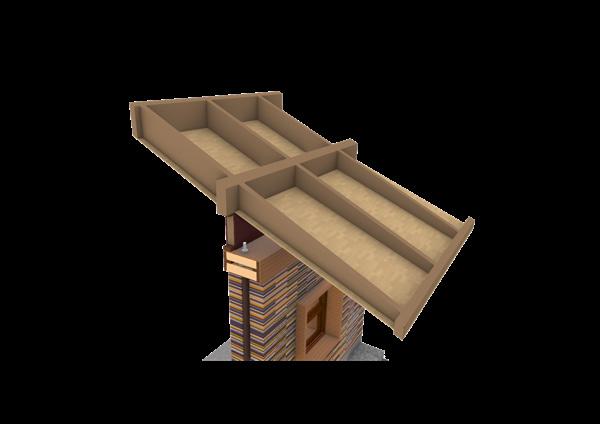

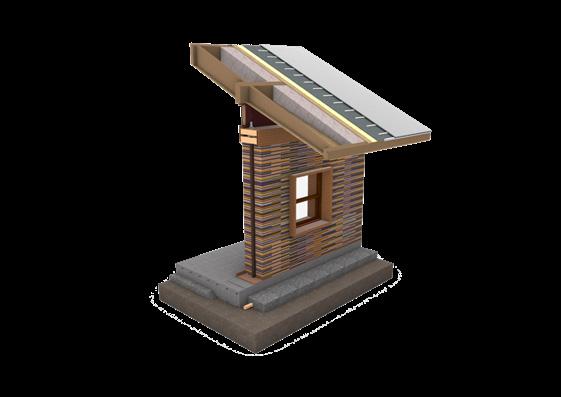

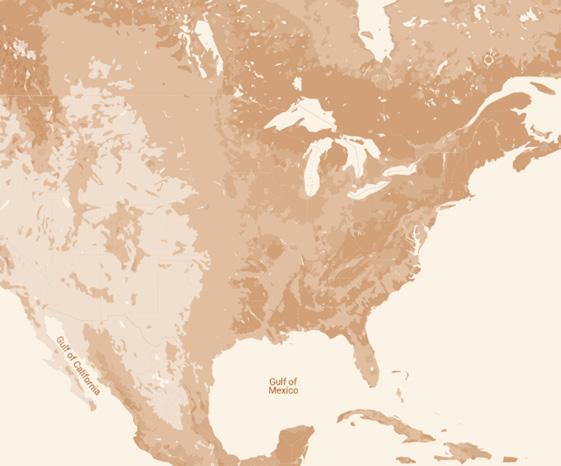

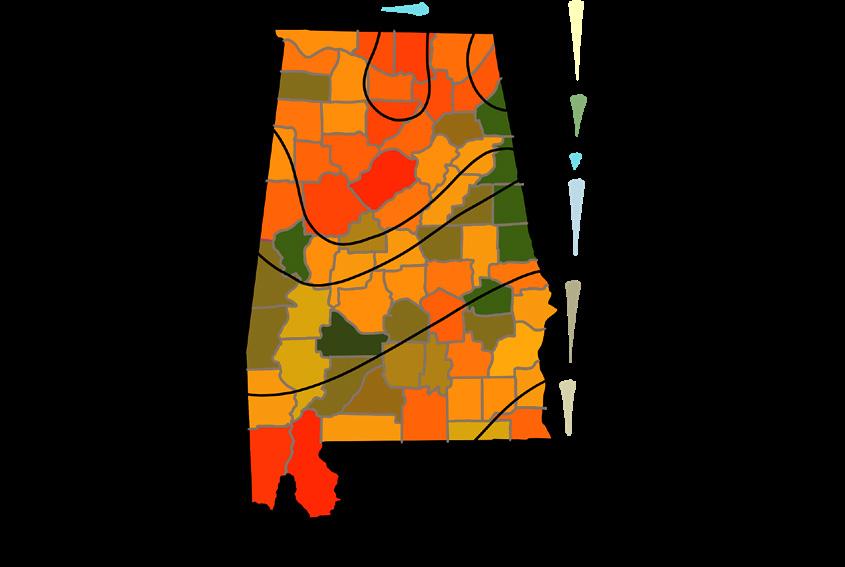

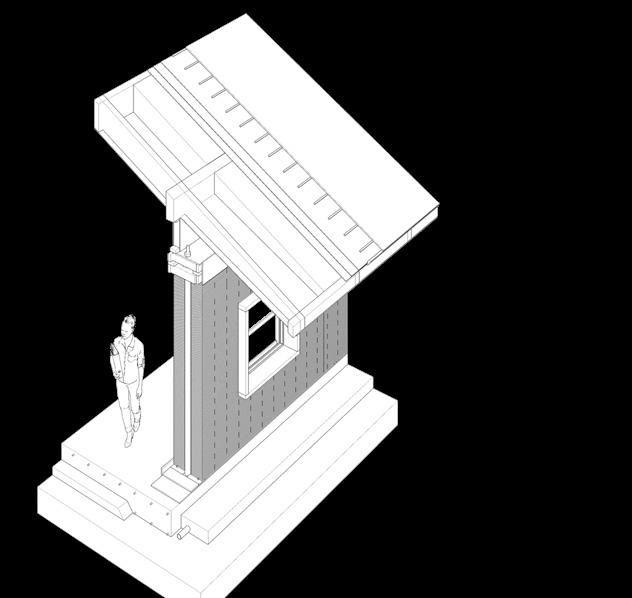

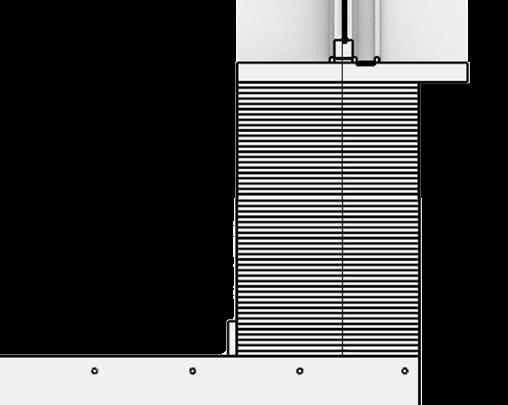

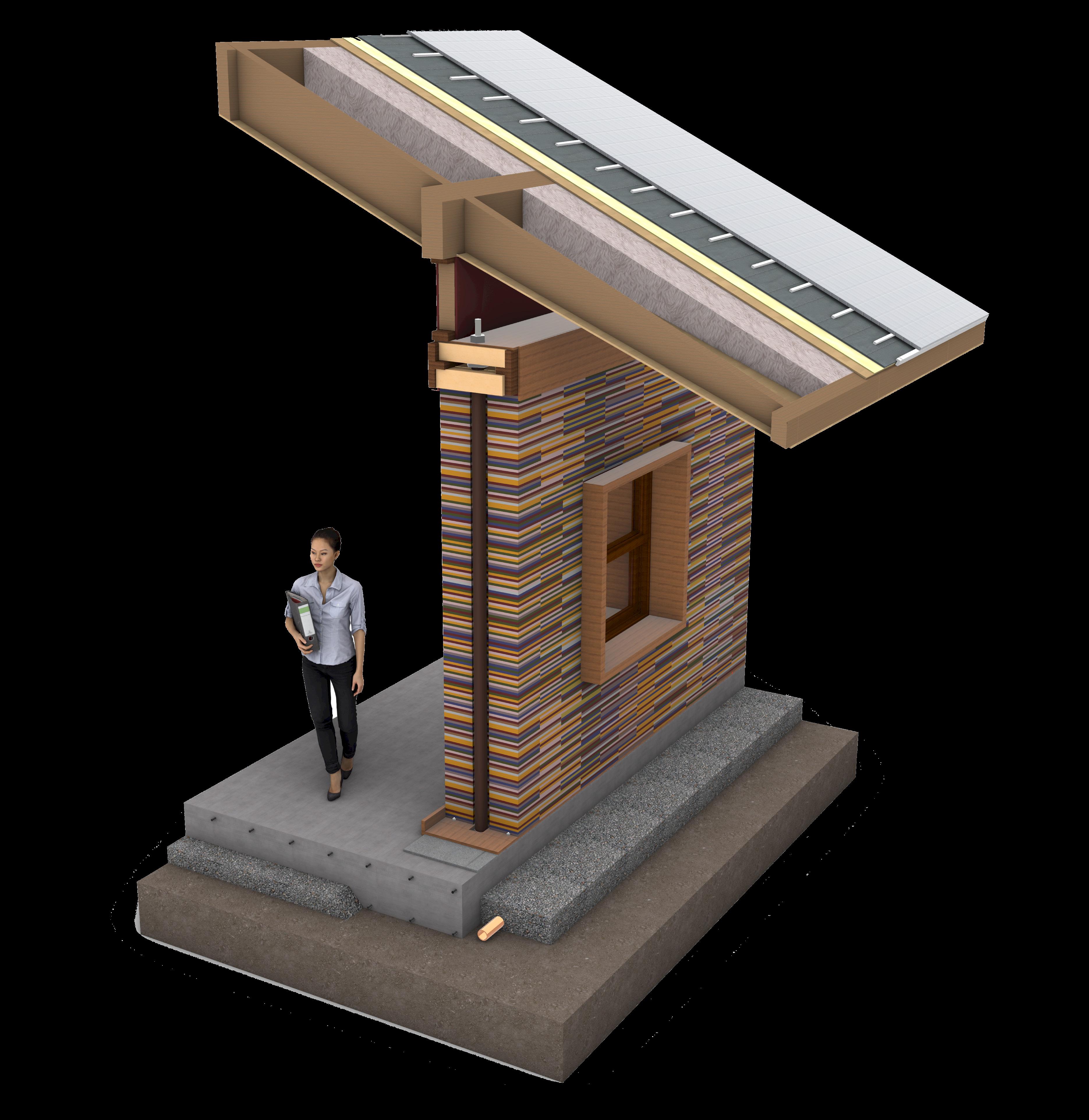

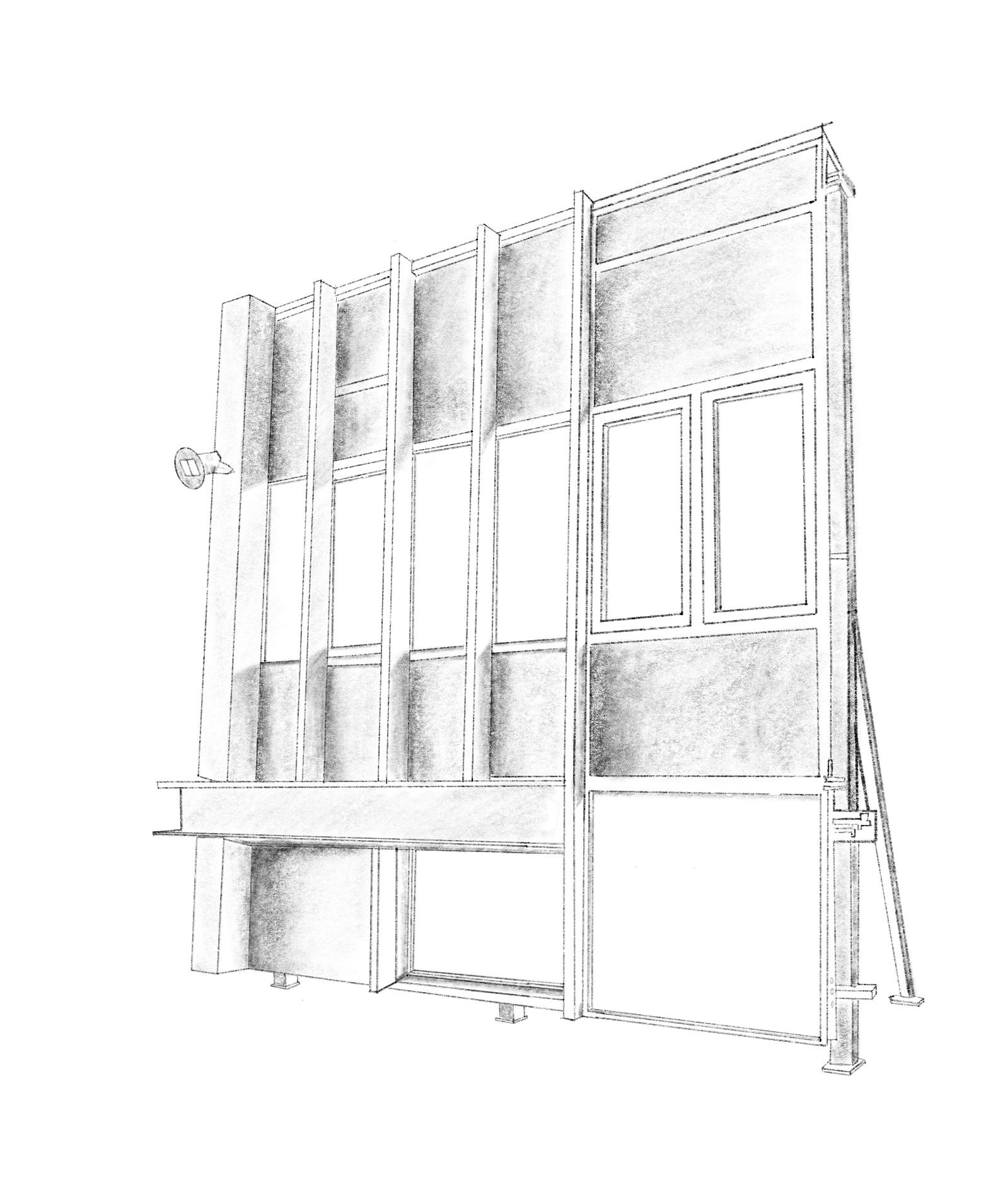

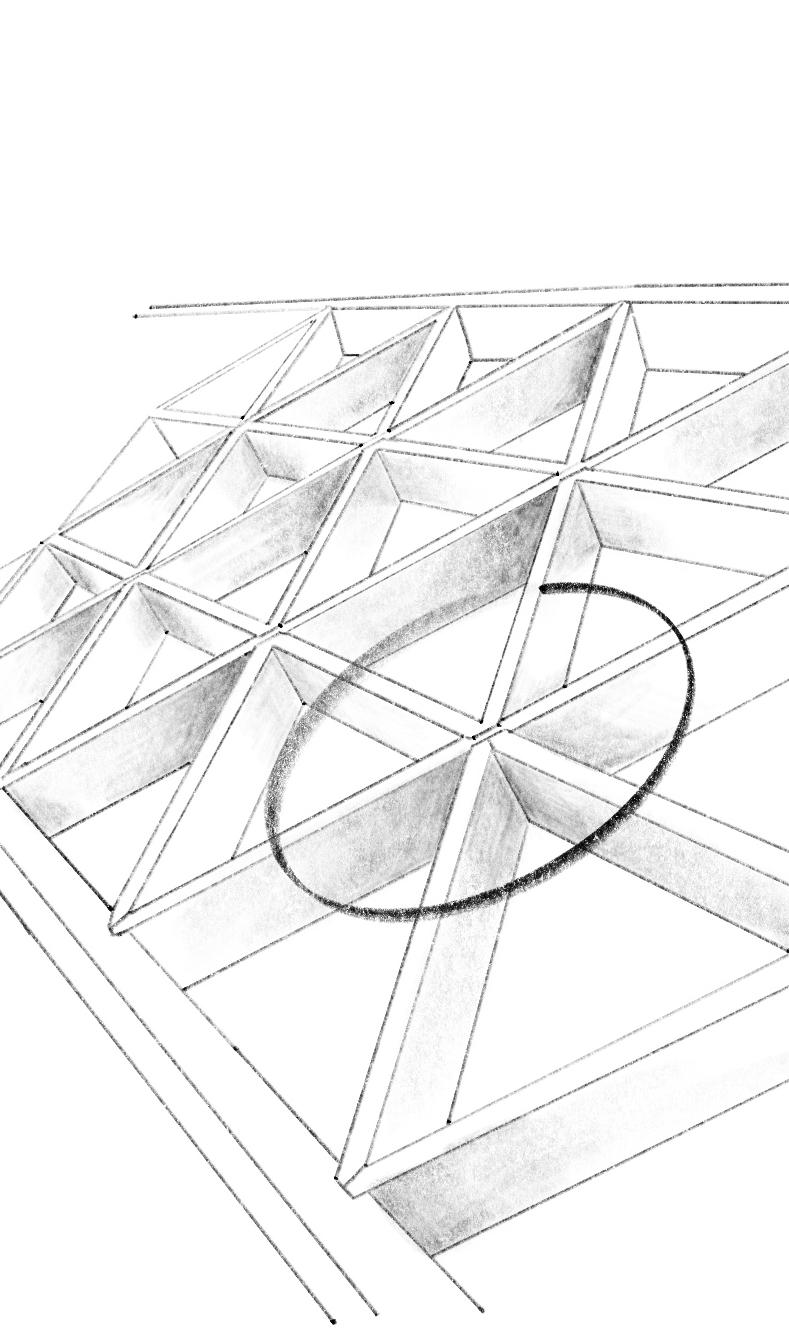

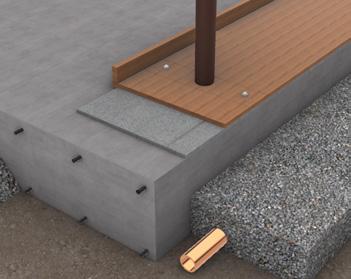

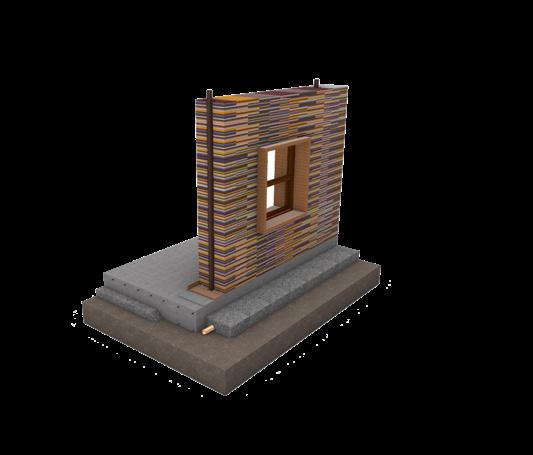

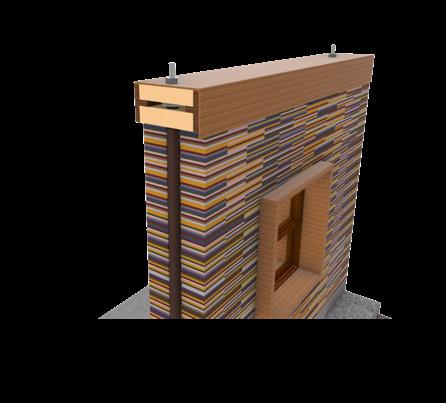

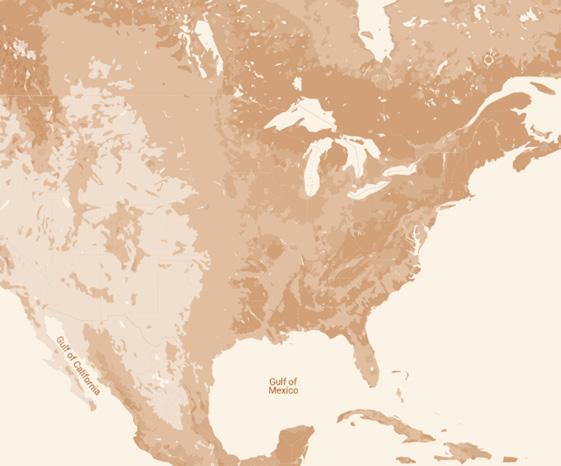

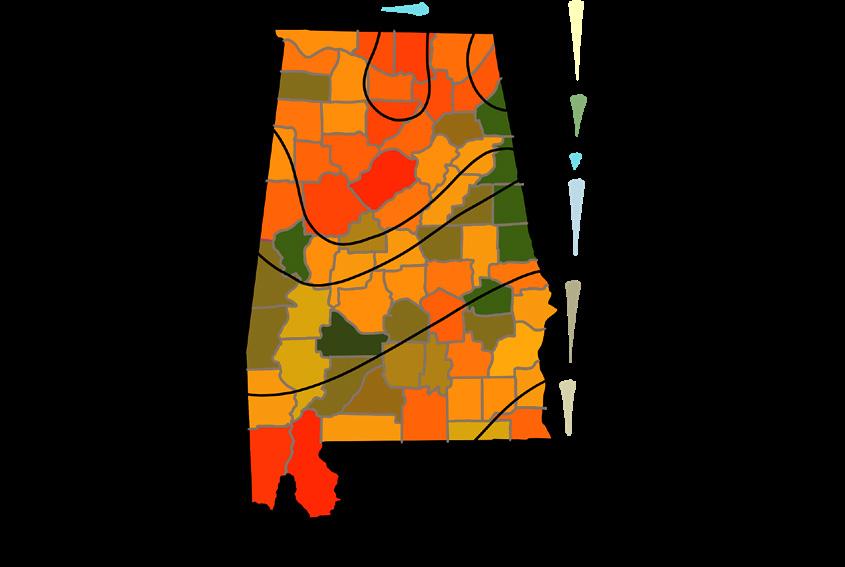

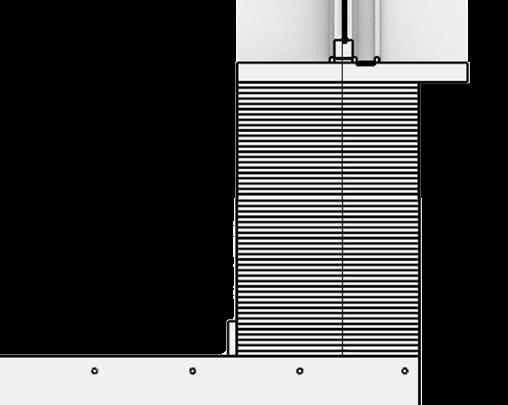

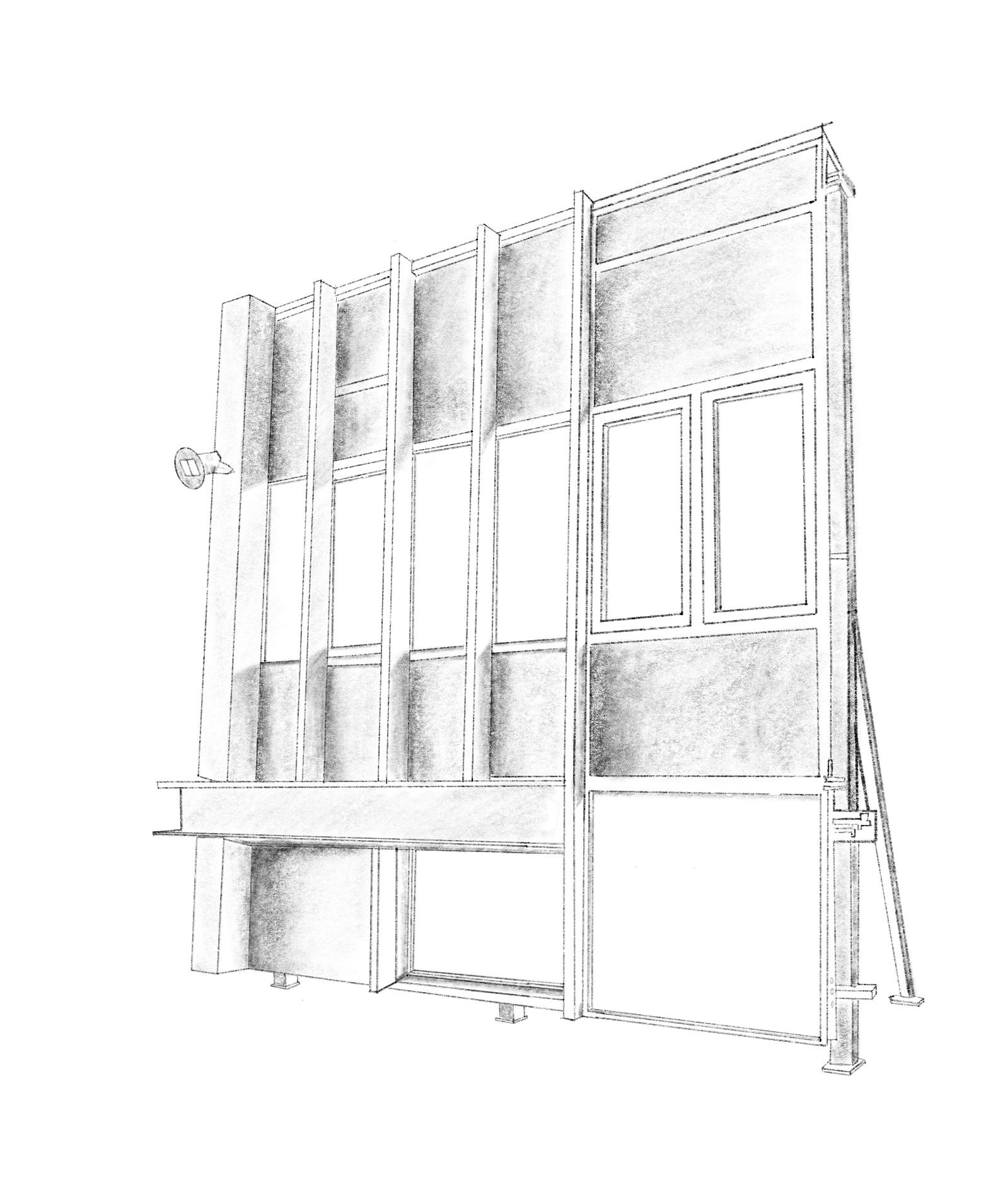

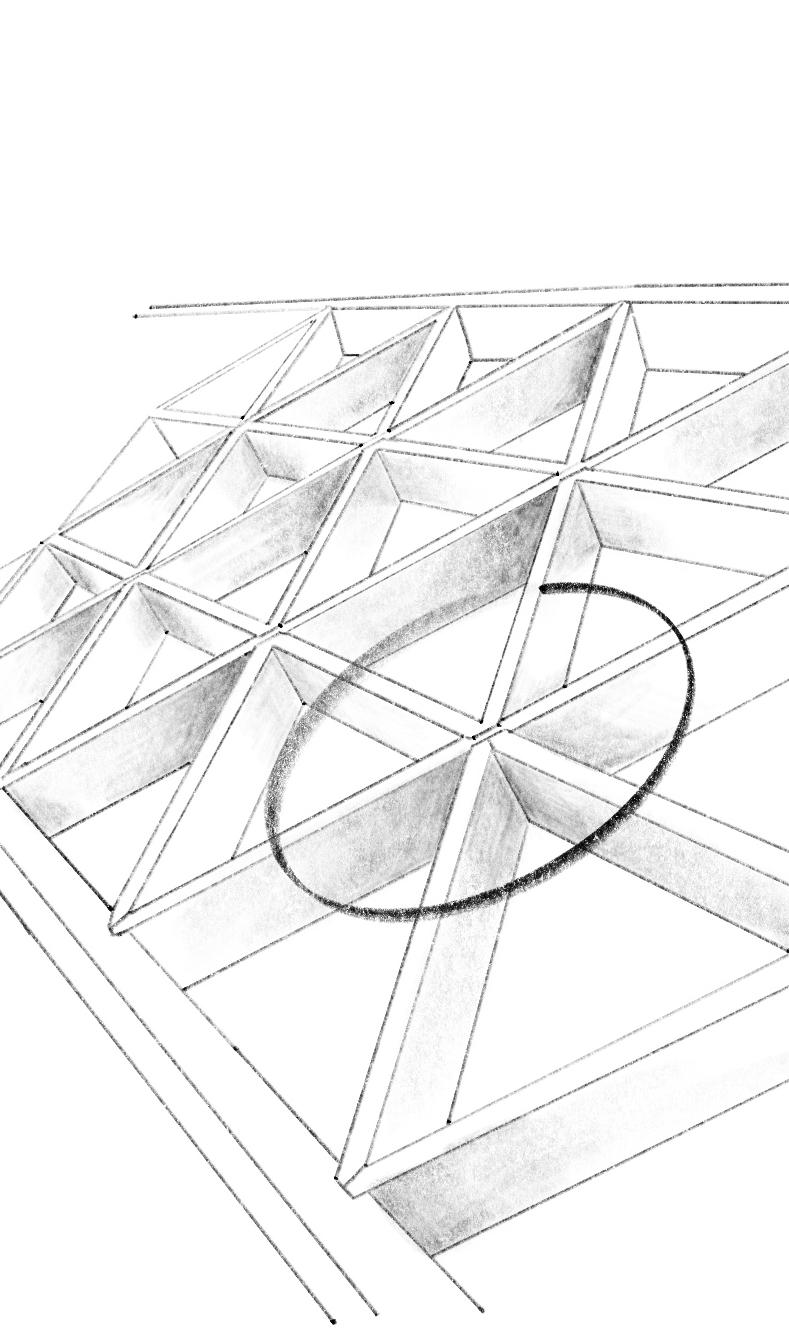

U VALUE OF CARPET TILE Where average thickness of a carpet tile is 6-8mm. R thickness of material / lamda Synthetic Carpet thermal conductivity 0.060 (W/mK) Thickness = 500mm 0.5/0.060 = 8.333333333 W/m.K. U 1/ans = 0.12 W/m² K LUCY LEES (MMU ID: 21439197) // MANCHESTER SCHOOL OF ARCHITECTURE BA3 TECHNOLOGIES 3 PART A: BUILDING CASE STUDY (BCS) // DETAILED FRAGMENT. ENVIRONMENT MATERIALS & CONSTRUCTION: STRUCTURE: ENERGY: RAW MATERIALS PRIMARILY IMPACT EMBODIED ENERGY ELECTRICITY GRID MIX IMPACTS EMBODIED ENERGY PRODUCING MATERIALS MANUFACTURING TRANSIT CONSTRUCTION END OF LIFE TRANSIT USE RE-PURPOSED RECYCLED NYLON RECYCLED CARPET RECYCLED PLASTICS BIO BASED MATERIALS CARPET TILE EMBODIED CARBON LIFE-CYCLE: EMBODIED CARBON: Carbon kg CO²/kg Carpet tiles, nylon (Polyamide), pile weight 770g/m2 = 13.7/ m² Steel Pipe 1.37 CO²/kg Concrete (eg in-situ floor slabs) with 25% PFA RC40 = 0.132 CO²/kg Timber (general - excludes sequestration)= 0.72 CO²/kg Plywood 1.07 CO²/kg Wood stain varnish= 5.35 CO²/kg - Nylon Production from Crude Oil: This process yields a significant carbon footprint due to crude oil's contribution to greenhouse gas emissions. - Nylon's Carbon Footprint: In carpet tile manufacturing, nylon derived from crude oil can make up over 50% of the total carbon footprint. - Recycled Nylon Yarns: Interface utilizes highly recycled nylon yarns, reducing the carbon footprint of their tiles by up to 80% by minimizing the need for new nylon production. - Pre-Solution Dyed Yarns: This innovation reduces carbon emissions compared to traditional dyeing methods by adding colourants to the yarn solution before extrusion. - Recycled Plastics in Backing: Incorporating recycled plastics in the backing helps mitigate CO2 emissions by preventing their release into the atmosphere. LOCATION: Masons Bend, Alabama, USA Analysis of key elemental features that effected the deign of my chosen fragment of Lucy carpet house SEISMIC & TORNADO MAPPING - ALABAMA: The extreme climate conditions of the site have lead to design changes such as the reinforced concrete foundations which are strong enough to resist earthquakes and tornadoes. The addition of a reinforced concrete basement creates safe space in the eventuality of an tornado. However, the timber roofs would likely not withstand tornado. MICRO MAPPING:HOW THE CLIMATE DIRECTLY EFFECTS THE CUR- CLIMATE: Interface's Process Regular Process Tornadoes by county 19502020 81+ 0-20 0 140 40 60 80 100 120 20 PRECIPITATION (mm) J F M A M J J A S O N D 0 5 10 15 20 25 30 35 40 TEMPERATURE ( C ) High Low This graph gives quantitative and a more location specific data on the climatic zone. The area experiences a wide range of temperatures and precipitation. FRAGMENT CONSTRUCTION: Gravel foundations and drainage are laid before reinforcement steel is laid and concrete is poured to create the exposed concrete floor finish. Steel plate is laid which the steel frame is bolted to followed by a layer of timber to distribute weighting of the carpet layer. Carpet tiles are placed in layers of 5 tiles followed by an overlapping 5 tiles to create rigidity and distribute weight. Carpets continue to be laid around and on top of the window exterior holding it in place through the weight.& downward force. Compression beam added and bolted into place creating downward force and solidifying the carpet. This removes any air gaps and creates water tightness. An exterior timber finish is added. Atimber roof frame is attached to the compression beam by an timber frame which is clad with painted timber. SOIL COURSE GRAVEL 110mm DRAIN PIPE REINFORCEMENT STEEL BARS POURED CONCRETE STEEL PLATE TIMBER PLATE Rigid insulation, Sheeting, breather membrane and roof membrane fixed to the structure. Metal joists attached. Corrugated metal cladding attached to joists. Final constructed fragment PROTOTYPING & SPECULATION: RIGID INSULATION VAPOUR CONTROL LAYER PLYWOOD DECKING PLYWOOD SHEETING BREATHABLE MEMBRANE WATERPROOF ROVING MEMBRANE METAL FIXINGS AIR GAP CORRUGATED METAL ROOF TIMBER ROOF STRUCTURE PLYWOOD FASCIA This is simple roof build up which would be easy to assemble for the students without expertise in construction. This speculated roof build up that would reach an estimated U value of 0.11 W/M2K necessary to reduce energy released through the roof essential when temperatures hit minimums. Foundation to wall prototyping: Roof overhang: The roof overhang, chosen to prevent solar gain during months where the sun is higher. Essential to preventing overheating in the bedrooms. insulation between wooden frame timber structure (attatched to wall structure) timber structure timber cladding PROTOTYPE 1: The wall to foundation connection is through a timber board that evens out weighting from the carpet tile and can create an attachment for the steel pole structure. However, this attachment may not be secure and the timber may not be able to withstand the load from the steel structure and roof structure. PROTOTYPE 2: This wall to foundation connection has more layers including the addition of damp proof course(DPC), a steel plate and insulation. The DPC prevents damp rising up the walls. The steel plate is better fixing for the structure as it will have better load bearing properties and a more secure joint connection. The insulation would prevent potential thermal bridging from the steel plate. The timber distributes the weight of the carpet tile evenly. PROTOTYPE 3: This detail build up is what speculate to have been used in the building. It is the same build up as prototype without a layer of insulation. Insulation exposed to exterior elements would damage quickly and would become inefficient. Moreover, most insulation wouldn't hold shape under the pressure from the carpet tiles and compression beam. The layer of timber has insulating properties and, as shown, there is timber skirting on the interior which acts as an insulator instead. Build Up: 1. Carpet tiles 2. Timber board 3. Concrete foundation Build Up: 1. Carpet tiles 2. Timber board 3. Insulation 4. Steel plate 5. Damp proof course 6. Concrete foundation Build Up: 1. Carpet tiles 2. Timber board 3. Steel plate 4. Damp proof course 5. Concrete foundation 2 3 1 4 2 3 4 5 INTERFACE DONATED CARPET TILES. Made from recycled pre died Nylon Yarn & CQuest Bio backing (made from 90% recycled material). Claimed to be carbon sequestration & circular economy & loop manufacturing. CFA is a humid subtropical climate. C Mild temperatures F No distinct dry season A = Hot summer. CLIMATIC ZONE: FCBS CARBON CALCULATOR: STEEL REINFORCEMENT BARS (REBAR). Used in the concrete foundations and the tornado shelter of the building. Roughly 3% of the reinforced concrete. POURING CONCRETE. BLACK WARRIOR CONCRETE. Used for the foundations of the building. Once set it is one of the safest and most durable materials against earthquakes. Concrete releases heat slowly keeping the building cooler in summer months. PLYWOOD. Discounted scotch plywood. CARPET TILE UNDER COMPRESSION TIMBER WINDOW PANE LINTEL TIMBER WINDOW FRAME STEEL FRAME POLES

MEMBRANE

INSULATION METAL

CORRUGATED

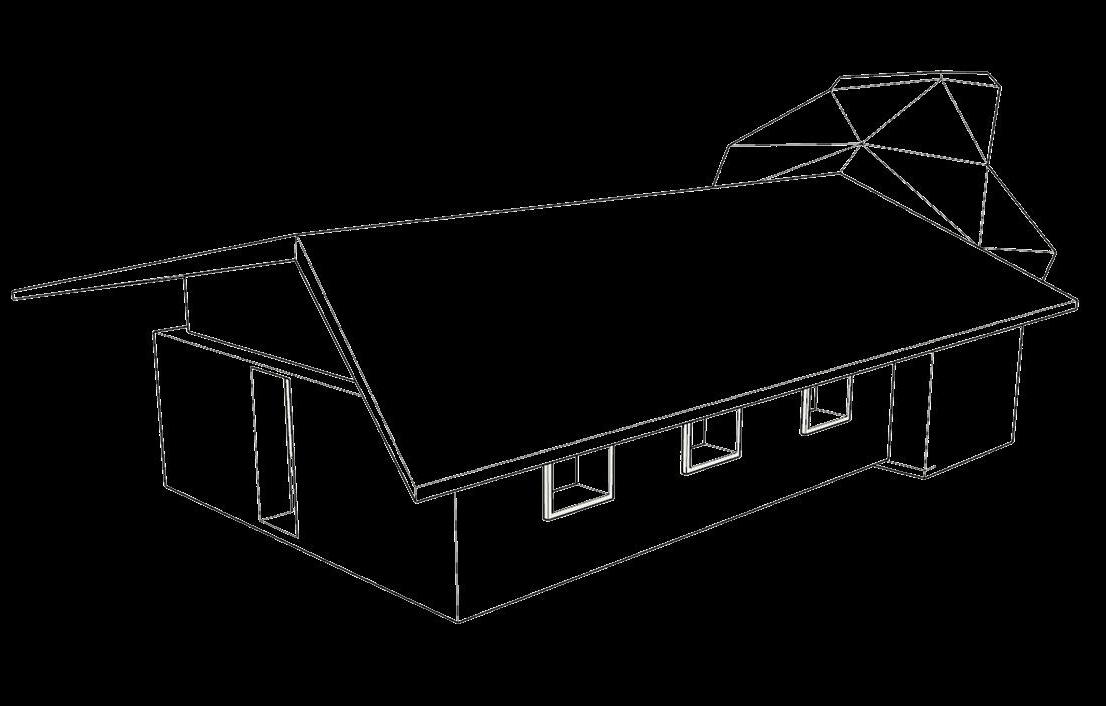

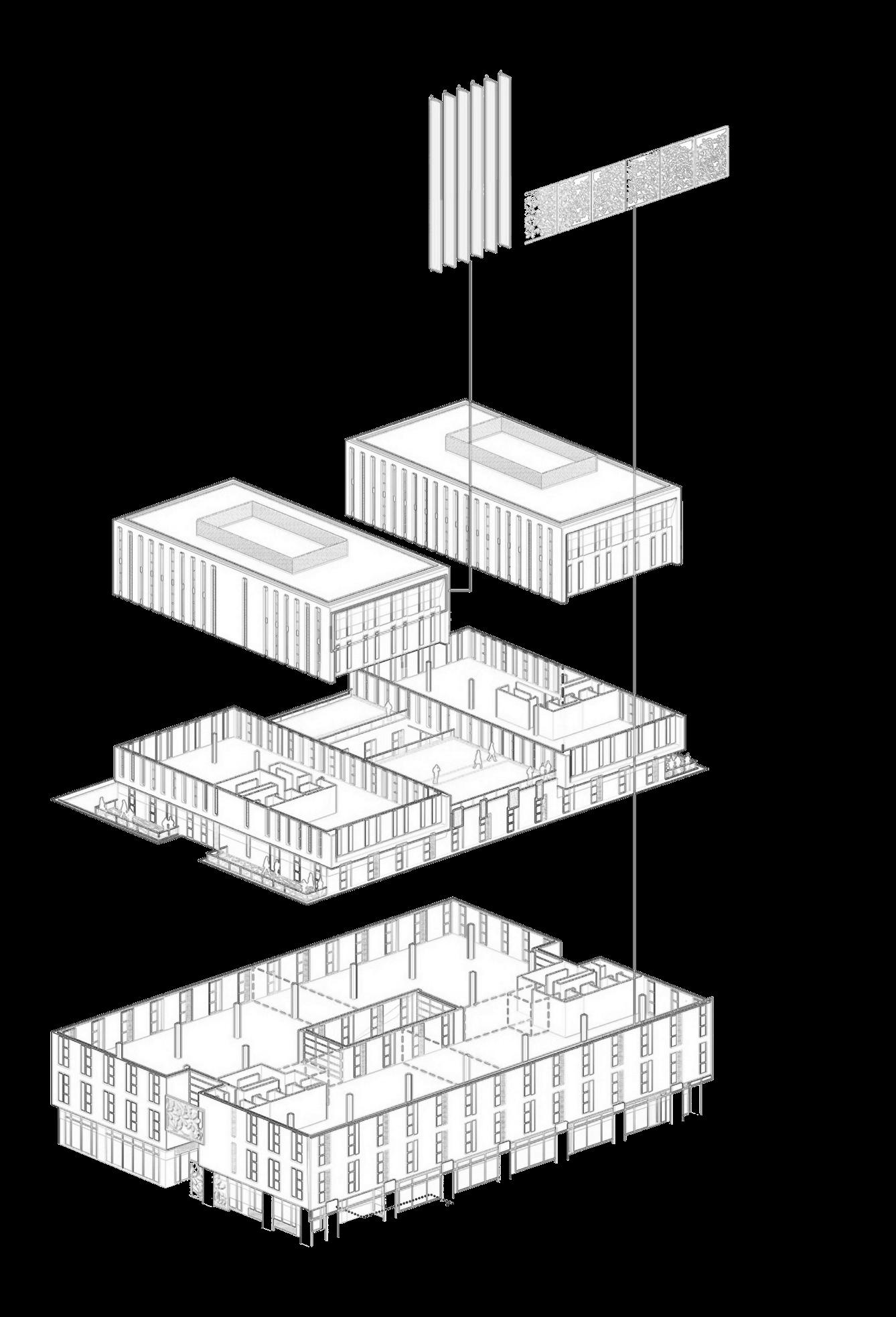

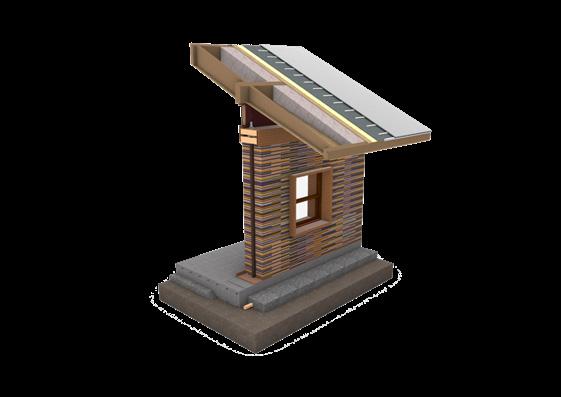

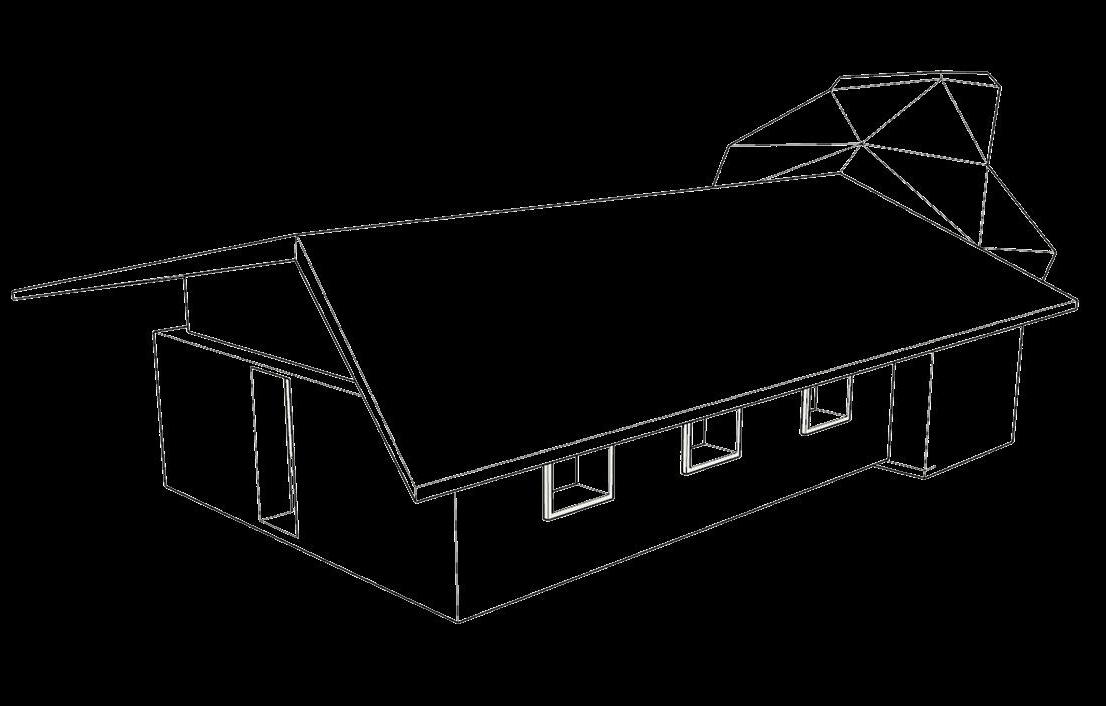

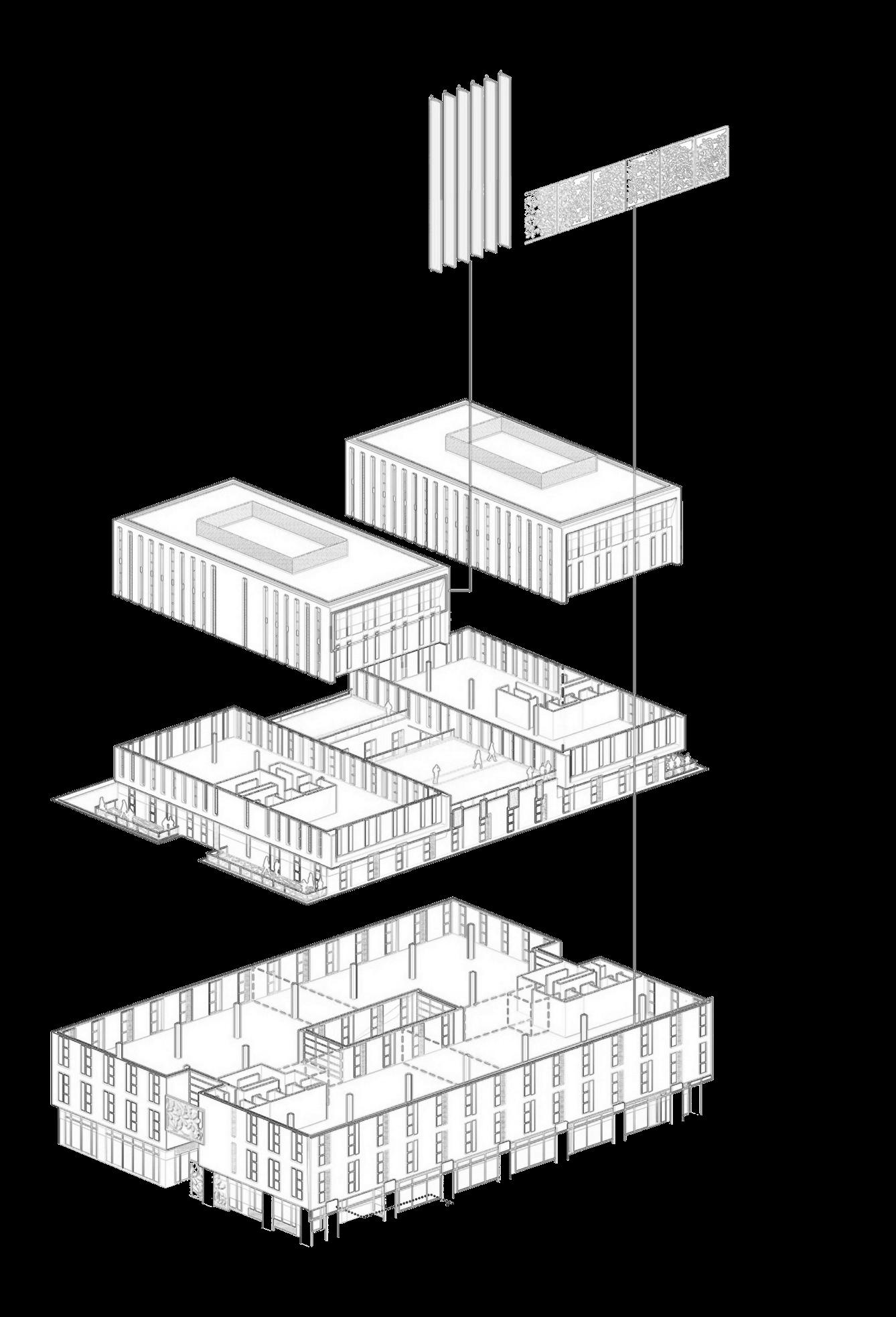

FRAGMENT SELECTION: The chosen fragment is the environmental barrier between Alabama's climate and one of the childrens bedrooms. How does it compare to UK regulations for bedrooms: - Ventilation and air quality system from the window creating adequate air quality - Insulation and soundproofing are both qualities that are inherent to the stacked carpet tiles. - In PART L new buildings have to achieve a U value of 0.18 W/m²K. and this achieves 0.12 W/m²K. - Regulations address solar gain which is addressed by the roof overhang and window depth. LUCY CARPET HOUSE: FRAGMENT: All content highlighted or associated with a dashed orange line should be read as speculative. The carpet tile acts as a wall structure whilst providing insulating qualities, water & fire resistance. CARPET TILES: The carpet tiles are stacked in similar way to a standard brick bond, overlapping to increase overall strength and load bearing qualities ELASTOMETRIC EXTERIOR COATING. Donated hydro stop. MINWAX LIGHTING: discounted Tuscaloosa electric. Used to protect exposed timber and to create an aesthetic finish. CORRUGATED METAL SHEETING. Is the outermost layer, serving as the protective and visually defining 'skin' enveloping the roof structure. The incorporation of donated carpet tiles from Interface presents a strategic cost-saving measure for the project. These tiles are typically donated due to defects or overproduction, offering a sustainable sourcing solution. To ensure safety and quality, the carpet is stored for seven years to allow any fumes or chemicals to dissipate before installation. Upon arrival at the site, the carpet undergoes several treatments to enhance its durability and resilience. Anti-pest and anti-microbial properties are applied, along with fire-retardant liquids as a precautionary measure. The carpet tiles exhibit low flammability under compression, attributed to the oxygen-depleted environment within the wall assembly. Furthermore, the waterproofing of the tiles involves coating them with an elastomeric substance. This coating not only renders the carpet impermeable to moisture from rain and wind but also serves to prevent dampness within the wall structure. RIBA SUSTAINABLE GOALS: TIMBER RING BEAM. Used for compression of carpet tiles and also supported by steel frame The FCBS carbon Calculater gives a representation of where the most embodied carbon is found in my fragment. As expected the most embodied energy is found in the foundations of reinforced concrete. Due to the materiality of the external walls being recycled sequestering carbon carpet tiles and steel frame there is very little embodied energy in the walls. Timber frame roof structure Timber frame roof structure clad in corrugated metal Timber structure interior walls Timber structure with polycarbonate sheeting Compression Beam Steel frame Double glazed windows with timber lintel and frame Reinforced concrete basement Skylight window Carpet tile wall build up Concrete foundations SUN PATH: The sun path Has effected the orientation of the building where there is less glazing facing south to prevent solar gain and there is a roof overhang and deep window lintels to prevent direct solar gain during months of summer solstice. WIND DIRECTION: The prominent wind direction is from the South West. The building is sheltered by trees on its SW so there is little need for design alteration for wind. SW Winds A diagram depicting the prevention of solar gain and water run off and cooling through concrete foundation. Rain Sun Ray Cooling DESIGN METHODOLOGIES: FIRE RESISTANCE CONSTRUCTIBILITY ENVIRONMENTAL TECHNIQUES With a constrained budget, it's reasonable to expect limited resources for prototyping. In order to construct the carpet tile wall effectively, the carpets would have needed to be stacked higher than the intended height, anticipating compression during installation. To grasp this concept, conducted prototyping test, akin to what students might have undertaken, to estimate the height change of carpet under compression but on a smaller scale. Using four stacked carpet tiles, measured the height before and after compressing them with the weight of a person. Through this experimentation, we discovered that the primary compression and height alteration occur in the yarn, while the backing experiences relatively minimal change in height under compression. This insight also sheds light on how the tiles achieve fire resistance, as there is no space for oxygen, and clarifies how the wall build-up enhances weather resistance, effectively becoming wall primarily comprised of backing with thin layers of insulation interspersed. With principles adjacent to the "&" Atelier, this design prioritizes material selection as its foundational aspect. It's this approach that enables it to significantly address five of the RIBA & UN Sustainable Design Goals Outcomes. The project exemplifies a building that received materials first, compelling the team to find innovative ways to utilize them efficiently. Since the tiles are reused, their carbon footprint is already enclosed within them, making them a superior choice compared to traditional wall constructions. This approach underscores a sophisticated understanding of sustainable practices and demonstrates a commitment to minimizing environmental impact. Highlighted are the principles that this building addresses: 7. Affordable and clean energy operational energy 9. Industry, innovation & infrastructure 11. Sustainable cities and communities social value 12. Responsible consumption and production - embodied energy 13. Climate action. This building also addresses issues on equality as it is designed for the community and was a project that was constructed with community engagement. Analysing the integrity of the wall build up against the UK building regulations provides a better understanding of the efficiency of the building. Part B of the fire regulations goes into depth on information about fire regulations. It is important to note that Lucy carpet house was built in Alabama and may have been built under different regulations but have chosen too evaluate in comparison to UK regulations to understand the precedent in better depth. The wall build up doesn't have any combustible materials in the external wall system and are fire resistant preventing spread to other sections of the building or external building (in this case there aren't any close enough to spread to) The building has internal walls that close of living and sleeping spaces to create barriers to limit fire spread. Although the wall build up is fire resistant under compression due to the lack of oxygen, it may be an option to consider drywall (gypsum board) as an interior lining due to its fire resistance (burns up to 60min). In this instance there would need to be a breather membrane in-between the two materials. Carpet tile Breather membrane Gypsum board Part of the UK building regulations prioritizes the conservation of fuel and power within buildings, with stringent requirements for energy efficiency. The energy performance of Lucy Carpet House exemplifies compliance with these regulations, notably with the carpet wall achieving an impressive U-value of 0.12W/m² K, surpassing insulation and thermal performance standards set by the UK. Additionally, Part addresses cooling and ventilation, exemplified by the bedroom window design. This innovative feature allows for top and bottom opening, maximizing ventilation while minimizing energy consumption and heat loss when closed. Furthermore, Part promotes the use of renewable energy sources. While Lucy Carpet House boasts low embodied energy, consideration for operational energy suggests the placement of solar panels on the south-facing roof. A standard domestic solar panel system comprising 16 panels, each producing 265W on an ideal day like the summer solstice, can generate approximately 4,224W/day across 25m². Given the average American home's daily electricity consumption of 29,130 watt-hours, solar panels could substantially reduce operational energy needs, improving sustainability and compliance with Part regulations. The building is surrounded by trees on its SW which provides partial solar shading and wind shade. It is on flat land preventing the need to landscape. Lucy Carpet House minimizes reliance on professional expertise by leveraging student-led construction under close supervision, reducing costs significantly. The project capitalizes on students' deep understanding of the design, particularly the innovative stacked carpet wall system they developed, which simplifies assembly. While the stacked carpet wall system is straightforward, challenges arise in intricate construction areas, such as joint connections in wooden roof frames and technical aspects of reinforced concrete floors and basements. These require meticulous planning and execution. Despite complexities, the building's basic structure boasts robust integrity, with the master bedroom's timber frame roof adding complexity due to its support requirements. Adherence to regulatory standards ensures compliance with building codes, emphasizing structural integrity, fire safety, and energy efficiency. Stringent supervision and thorough documentation uphold safety and quality. Lucy Carpet House showcases student-driven construction navigating complex challenges. Strategic design and oversight strike a balance between innovation and regulatory compliance, reflecting both ingenuity and craftsmanship. (RURAL STUDIO, NO DATE) STUDIO, R. (NO DATE) RURAL STUDIO, WWW. T8PROJECTS.COM. AVAILABLE AT: HTTPS://WWW. T8PROJECTS.COM/LUCY.PHP. (RURAL STUDIO, NO DATE) (RURAL STUDIO, NO DATE) FINANCIAL The financial implications of constructing Lucy Carpet House were significant, considering the project's limited budget of $30,000. Typically, such a budget would severely restrict the functionality and quality of the building. However, smart material selection and collaboration with Rural Studios allowed for cost-effective construction without compromising functionality. Due to the budget one could speculate to achieve the builds materials such as concrete and wood would have had to be sourced from local areas,which would play a large part in reducing cost. While these materials may incur higher initial costs compared to the recycled materials, their proximity to the construction site could minimize transportation expenses and carbon emissions. For instance, ALLCAPS concrete, located approximately 29.5 miles from the site, could have provided an accessible and environmentally conscious option for sourcing concrete, whilst promoting supporting local business. Moreover, Rural Studios' provision of labour further mitigated expenses, as their involvement eliminated the need for hiring professional contractors. Their expertise and dedication ensured efficient construction within the budgetary constraints, maximizing the value of each dollar spent. By leveraging local resources and expertise, Lucy Carpet House demonstrates how strategic decision-making can optimize financial resources while maintaining the functionality and integrity of the building. The project serves as a testament to the importance of thoughtful planning and collaboration in achieving cost-effective and sustainable construction outcomes. S Concept of south facing solar panels to provide the family with renewable energy. Interface carpet, after 7 years of storage to remove toxins, assuming they are from the head office have significant distance to travel 244.2 miles (3hrs 51 min drive which adds to the embodied carbon of the tile through emissions cased by transportation. (GILLARD, 2014) GILLARD, J. (2014) MOREXLESS: LUCY’S CARPET HOUSE_RURAL STUDIO, MOREXLESS. AVAILABLE AT: HTTPS://MOREMOREXLESS.BLOGSPOT.COM/2014/03/LUCYS-CARPET-HOUSERURAL-STUDIO.HTML (ACCESSED: MARCH 2024).. LOAD BEARING WALLS : FRAGMENT STRUCTURE: The carpet tile walls act as the main load bearing walls and the load is transferred into the reinforced concrete foundations. The majority of the load is dead loads from the roof structure. Live loads are from environmental elements (wind/rain) and from people & furniture in the build. DEAD LOADS DEAD LOADS SW WIND LOADS RAIN LOAD LUCY CARPET HOUSE: RESOLUTION IMAGES OF LUCY CARPET HOUSE ONCE CONSTRUCTED Left Image: image shows my chosen fragment from its exterior. Right image: Lucy Carpet house from its driveway. (Hursley, 2002) (The Lucy House onSITE architecture, no date) THE LUCY HOUSE ONSITE ARCHITECTURE (NO DATE) ON SITE ARCHITECTURE. AVAILABLE AT: HTTP://WWW.ONSITEARCHITECTURE.COM/PROJECTS/THE-LUCY-HOUSE/ (ACCESSED: 5 MARCH 2024). HURSLEY, T. (2002B) LUCY’S HOUSE IN ALABAMA BY RURAL STUDIO, ARCHITECTURAL REVIEW. AVAILABLE AT: HTTPS://WWW.ARCHITECTURAL-REVIEW.COM/ARCHIVE/ STACKS-OF-REDUNDANT-CARPET-TILES-ARE-USED-TO-CONSTRUCT-WALLS. The most interesting structural build up within my fragment is the connections between the floor structure and the carpet wall / the roof structures connection to the carpet wall. WALL - ROOF: The roof is connected to the compression beam through a wooden frame that is clad in treated plywood.

- FLOOR: The steel pole is bolted to a steel plate that sits on top of and is bolted to the reinforced concrete floor system. The steel plate is topped with timber board and timber skirting to prevent thermal bridging.

RIGID

FIXINGS

WALL

DATE:29/01/2024

SPEAKER: Rhodri Evans

POSITION: Architect and Facade Consultant.

ORGANISATION: BDA (Building Design Assistants)

LECTURE 1:ADVANCED FACADE SYSTEMS

CRITICAL REFLECTION:

DESIGN METHODOLOGY & TECHNICAL STRATEGY:

DATE:31/01/2024

SPEAKER: Kevin P.Flanagan

POSITION: Architect and Partner

ORGANISATION: PLP Architecture London

CRITICAL REFLECTION: DESIGN METHODOLOGY & TECHNICAL STRATEGY:

STRUCTURAL ANALYSIS OF A TIMBER HIGH RISE

This lecture discusses the importance of developing a technological environmental Envelope design with glass. Including, the importance of understanding the choice of Material and how that affects both the sustainability performances and the visual Appearance of the interior and exterior spaces. The use of a glass facade creates a sense of place by manipulating light and temperature. Its use is a key factor in the evolution of Architecture. Adopting the prefabrication of facade components to a 1:1 scale can improve quality Control and safety in construction. Further to this, a cost-effective approach involves utilizing free facade samples to create a colour reflection analysis to fine-tune aesthetic solutions both of which streamline construction processes and contribute processes and contribute to a more aesthetic resolution. Further, exemplary practice is the use of fritting in glass panels, aimed at reducing the U-value while simultaneously preserving or enhancing the proportion of glazing. This practice is crucial for advancing building methodologies and constructing structures geared towards a more sustainable future.

RESPONSIBILITIES:

It is the role of the Architect and M&E engineer to work together to provide the most aesthetic facade whilst prioritizing energy efficiency, maximum safety, daylight control, sufficient testing, and performance monitoring during the existence of a building. For instance, architects must consider comprehensive testing on various types of laminated glass (single silver/double silver/triple silver) to ascertain the most cost-effective, secure, and aesthetic facade solution. This affects the overall aesthetic and performance of a build. Rhodri Evans talked through a range of high-rise curtain wall buildings, which used similar technologies to what intend to use in my design project. The majority of my design project is glazed on the lower floors therefore the use of fritting could lower the UWC and increase the glazing percentage. For the larger panes of glass, I intend to use a triple silver solar control coating to minimise solar factor and maximize the percent of light, implementing a shaft box methodology as a secondary skin serves a dual purpose: facilitating ventilation and regulating heating, especially important in my current design project that hosts studio spaces with curtain walls

COMPLIANCE:

Environmental Impact Assessments (EIA) and Building Control Bodies assess the impact of proposed developments using energy models, physical models and simulations, provided by architects and M&E engineers in RIBA stages 3&4, to ensure the design complies with Part L building regulations (energy efficiency & carbon emissions).

RESPONSIBILITIES:

DATE:13/02/24

SPEAKER:Laura Stafford POSITION: Architect ORGANISATION: 5 Plus Architects

LECTURE 5: DESIGN FOR HIGH ENVIRONMENTAL PERFORMANCES STANDARDS

CRITICAL REFLECTION:

DESIGN METHODOLOGY & TECHNICAL STRATEGY:

This lecture underscores the necessity of integrating environmental considerations into office space design. This seems to be driven by tenants and companies who want younger generations entering the workforce. There is an understanding that these staff advocate for a push towards sustainability. A holistic approach is advocated, balancing factors such as human comfort, productivity, and flexibility with environmental consciousness. Modern architecture now assigns equal importance to both embodied and operational energy in buildings, shaping a path towards a more sustainable future. A prime example is "The Hive," where a reduction in floor-to-floor height is a response to natural ventilation, where the need for mechanical ventilation is reduced by the use of double-opening windows either side of the open atrium. This innovation reduces the building s height offering space-saving benefits that can lead to the extension of an extra floor, it also cuts carbon emissions and energy usage. Overall, the discourse on office design is evolving to embrace sustainable practices, promising a future where environmental stewardship and architectural innovation converge to create inspiring, resilient built environments.

In striving to achieve net-zero targets, architects must leverage a diverse array of resources to inform their design processes. While there's no one-size-fits-all template, guidance extending beyond building regulations can be gleaned from authoritative sources such as the RIBA Climate Challenge, RICS, UKGBC's UK Green Building Standards, and the London Energy Transformation Initiative (LETI). LETI's targets, for instance, advocate for improved U-values (>0.12W/m²K), enhanced insulation thickness, airtightness (target >1), and minimized thermal bridging (Y value to 0.04). Adhering to these benchmarks serves as a practical guideline towards designing for a more sustainable future, with new constructions poised to meet net-zero objectives. Architects bear responsibility for mitigating embodied carbon emissions where prioritizing retrofitting

COMPLIANCE:

As mentioned architects have a responsibility to comply with LETI, RIBA, RICS, and UKGBC standards. 'The Climate Change Act 2008' mandates an 80% reduction in greenhouse gas emissions by 2050, with carbon budgets regulating emissions. 'The proposed Future Homes Standard' targets all new homes in England to be "zero carbon ready" by 2025. Compliance is crucial to meet emissions reduction goals and enhance building resilience against climate change. Through adherence to these regulations, architects play a vital role in fostering sustainable design practices and mitigating the environmental impact of construction, ensuring a greener, more resilient built environment for future generations.

This lecture emphasizes the pressing need for transformative shifts in architectural practice to champion a more sustainable future, underscored by alarming statistics such as the built environment's contribution of approximately 53% of carbon emissions, with the cement industry alone responsible for 23% of greenhouse gas emissions. Highlighting Cross Laminated Timber (CLT) as a viable alternative to concrete exemplifies the direction towards greener design principles. This is particularly pertinent to my ongoing design intervention focused on sustainable art, where the choice of materials, such as timber over concrete, can serve as a tangible example of environmentally conscious construction. Furthermore, advocating for a paradigm shift in architectural design, such as utilizing external walls as primary structural elements, while eliminating traditional cores, introduces innovative approaches that redefine architectural programs. It is imperative to challenge conventional practices that have remained largely unchanged since the 1980s and to establish firm deadlines for climate action. By pushing for these changes, we can instigate a fundamental transformation in the built environment, essential for the well-being of our planet and future generations.

RESPONSIBILITIES:

The architect and structural engineer must meticulously assess the impacts of loads and environmental factors on new materials before implementation. For Cross-Laminated Timber (CLT), critical attention must be given to load-bearing points to avoid structural failure due to excessive strain. Additionally, rigorous testing against site conditions is imperative. For instance, the Oakwood Timber Tower employs a perimeter structure to evenly distribute loads through diagonals, a strategy distinct from concrete buildings due to their disparate properties. Regulatory measures for CLT also contribute to expedited construction, diminishing costs, labor, and environmental footprint.

COMPLIANCE:

High-rise timber structure buildings must adhere to a plethora of regulatory standards, including the Building Regulations 2010, guidelines set by the Institution of Structural Engineers, and Timber Construction Standards (BS), which encompass health, safety, and fire regulations. Contrary to misconceptions, the number of regulations for timber structures is not greater than those for concrete structures.

RESPONSIBILITIES:

DATE:05/02/24

SPEAKER:Les Postawa POSITION: Structural Engineer

ORGANISATION: Director at Les Postawa Associates

LECTURE 3: STEEL V CONCRETE V TIMBER

CRITICAL REFLECTION:

DESIGN METHODOLOGY & TECHNICAL STRATEGY:

This lecture examines optimal materials for building applications, questioning the assumption of timber's superiority without justification. It stresses aligning structural choices with environmental requirements and functionality. Scrutinizing embodied carbon is essential for material selection. Comprehensive material knowledge empowers architecture students to drive sustainable change. Early comprehension of material impacts can elevate architectural practice, improving building performance and fostering a greener environment. &rchitecture's principles align with the idea of material first therefore through depth of knowledge of material the best choice can be made to achieve common good through practice.

RESPONSIBILITIES:

HIT & MISS BLOCK

DATE:13/02/24

SPEAKER:Andrea Cooley

POSITION: Technical & design support manager

ORGANISATION: Wienerberger UK

LECTURE 4: BRICK:THE PAST AND FUTURE OF MASONRY BUILDINGS

CRITICAL REFLECTION: DESIGN METHODOLOGY & TECHNICAL STRATEGY:

This lecture delves into the rich history of brickwork, exploring its durability, details, and the trajectory of its future applications. In modern architectural practice, fired brick primarily serves as the outer layer, or "skin," of buildings, rather than fulfilling structural functions Notably, when correctly designed, brickwork can have a lifespan of 150 years. In contemplating designs for a more sustainable and adaptable future, it becomes imperative to envision buildings capable of transcending multiple lifetimes and serving a range of purposes. Leveraging brick as a building's outer layer allows for a multitude of interventions and modifications over its lifespan. A hallmark of exemplary brickwork practice lies in viewing it as a versatile and creative material, encouraging experimentation with patterns and mortar colours prior to construction. This approach not only ensures the development of a high-quality exterior facade but also fosters an engaging aesthetic that enriches the architectural landscape.

RESPONSIBILITIES:

Selecting suitable structural material involves assessing its embodied carbon across various Modules: Production, Use, End of Life, and Beyond Life. Timber evaluation necessitates Consideration of sustainable forestry, biodiversity, and adhesive carbon. PostDemolition carbon release complicates timber assessment, influencing material and building Properties selection. Architects bear responsibility for justifying timber's use structurally. Windmill Hill by Stephen Marshall Architects exemplifies oak as a structural material, prompting design adjustments and yielding high-quality finishes, highlighted in the 'reading room' eaves. Materiality selection responsibility enhances aesthetics by showcasing structure. The process of selecting the correct material can lead to better design.

COMPLIANCE:

RIBA's professional standards and codes of practice provide architects with invaluable guidance on material selection, sustainability, and ethical considerations in architecture. These standards ensure that architects make informed decisions prioritizing environmental responsibility and ethical practices. However, architects encounter constraints imposed by building regulations. These limitations may stem from safety regulations, zoning laws, or conservation requirements, restricting the range of materials available for use.

Architects must meticulously decide the most suitable brick for each specific location, understanding intimately how the material will interact with its, environment. Brick, being susceptible to freeze-thaw cycles, poses a risk of breakage, meaning architects must gauge the extent of exposure to rainfall influenced by both micro and macro climate dynamics. A critical consideration lies in the "F & S" factor of the brick—where "F" denotes frost resistance to frost and "S" indicates solubility of salt content. Architects must adeptly weigh these factors to determine the most efficient and resilient option for the given area, thereby mitigating the need for frequent replacement of bricks due to environmental stressors. Further discourse delves into the comparative merits of engineered brick versus moulded clay-fired brick, with a keen focus on their suitability for the prevailing climate conditions while also accounting for the architectural aesthetic of the building. This nuanced examination underscores the architect's pivotal role in ensuring both functional resilience and visual appeal in brick selection for construction projects.

COMPLIANCE:

In the UK standard brickwork must comply with the BSI publication of 'specification for masonry units' & 'recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 18996-2 (PD 6697-2019)' where the '6697' document is the UK document. These documents provide regulations for standard brickwork but at current day there is no issue for modern brickwork such as textured brickwork seen in the precedent 'Severn acres - Cambridge' and hit and miss brickwork that can be seen in the precedent 'London school of economics'. In these cases they building must comply with BSI (British standards institution) standards such as BS EN 771 (Specification for masonry units) and BS 5628 (Code of practice for the use of masonry).

LUCY LEES (MMU ID: 21439197) // MANCHESTER SCHOOL OF ARCHITECTURE BA3 TECHNOLOGIES 3 PART B: TECHNOLOGICAL DISCOURSE // LECTURE COMMENTARY

PREFABRICATED FACADE COMPONENT

TIMBER BUILD UP OF WINDMILL HILL CREATING AN INTERESTING CEILING DETAIL VIEW FROM INTERIOR JOINT DETAIL ROOF CONSTRUCTION LECTURE 2: FUTURE VISION FOR A HEALTHIER GREENER CITY Structural design that allows timber frame buildings to exceed building regulations that usually limit height to 4 stories. Structure would have to continue around the build for the best support. Carbon sequestering due to the timber but just because of this doesn t mean it is necessarily the best material choice. This modular component tests multiple factors of a building design including - Glass - Structure - Scale - Aesthetics Used in larger scaled buildings which use lot of glass cladding to test light shade and reflectiveness This modular element can also be used for technological testing for daylight factors, energy and loads Exposed structure making for an interesting aesthetic detailing Although the detail is specific to this design its simple concept so it should be simple to remake meaning it can be recreated by non-specialists. Circled is the Joint detail which can be seen in the next drawing. Wood slots into its space and is secured with screws.

Multi textured brickwork can create an interesting aesthetic but it can also cause the bricks to erode quicker because there is more exposure to freeze thaw SEVERN ACRES, CAMBRIDGE THE HIVE: MANCHESTER Central atrium that allows for natural ventilation to flow through the office building. Cladding for aesthetics Window openings operated by individual workers allowing individual mediation of temperature. Primary ventilation on 1st floor upwards to prevent air pollution in the building. MATERIAL CHOICE X CONSTRUCTION OFFICES MATERIALITY EXTERNAL FACTORS CLIMATE WEATHERING AESTHETICS TESTING MOCK-UPS REGULATIONS REQUIREMENTS TO MAKE THE ''CORRECT'' MATERIAL CHOICE THERE ARE PRIMARY FACTORS THAT THE ARCHITECT MUST CONSIDER (REGULATIONS /TESTING / AESTHETIC / EXTERNAL FACTORS(CLIMATE)/ MATERIALITY SPECIALIST ASSEMBLY PRECEDENTS MATERIAL PRECEDENTS BUILDING PRECEDENTS FACADE MANIPULATION EXTERNAL INTERNAL SOLAR WIND PRECIPITATION TEMPERATURE POLLUTION NOISE MATERIAL DAMAGE FREEZE THAW TEMPERATURE VENTILATION COMFORT HUMIDITY LIGHT ACOUSTICS LOAD ACTIVE DEAD CLIMATIC PEOPLE FURNITURE STRUCTURE WALLS ROOF BUILDING TYPE RESIDENTIAL HIGH RISE SINGLE - 4 STORIES MORE DIVERSE CHOICE OF MATERIAL AIM FOR INNOVATION EMBODIED CARBON AIM TO LIMIT EMBODIED CARBON ALUMINIUM POLYSTYRENE BRICK PLYWOOD BRICK STRAW BAIL MOST - LEAST EMBODIED CARBON LEAST CARBON MOST EFFICIENT MATERIAL CHOICE NEW SYSTEMS FOR HIGH RISE TIMBER HIGH RISE TEST WITH SAMPLES TESTING WITH 1:1 FACADE SYSTEMS LARGER BUILDINGS ENERGY LESSER COST SINGLE - 4 STORY PRECEDENTS FOR TESTING DIGITAL SIMULATION AESTHETICS CLIMATIC SIMULATION CLIMATE TARGETS RIBA SUSTAINABLE OUTCOMES UK BUILDING REGS A-R EMPHASIS ON: PART AStructure PART BSafety PART L& PART MAccess & use BSI LETI RIBA UKGBC CARBON READY BY 2025 NET 0 BY 2050 78% REDUCTION IN GREENHOUSE GASSES BY 2030