THE NECESSITY OF TESTING LM&M // JANUARY 2024 // THE NECES SIT Y OF TESTING

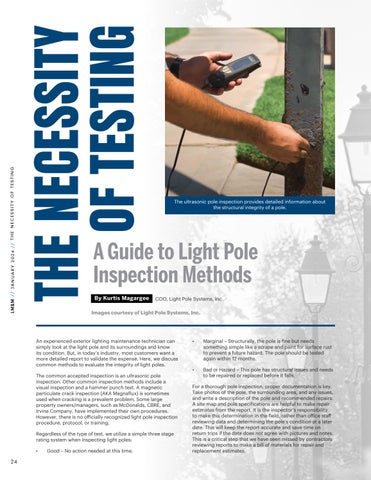

The ultrasonic pole inspection provides detailed information about the structural integrity of a pole.

A Guide to Light Pole Inspection Methods By Kurtis Magargee

COO, Light Pole Systems, Inc.

Images courtesy of Light Pole Systems, Inc.

An experienced exterior lighting maintenance technician can simply look at the light pole and its surroundings and know its condition. But, in today’s industry, most customers want a more detailed report to validate the expense. Here, we discuss common methods to evaluate the integrity of light poles. The common accepted inspection is an ultrasonic pole inspection. Other common inspection methods include a visual inspection and a hammer punch test. A magnetic particulate crack inspection (AKA Magnaflux) is sometimes used when cracking is a prevalent problem. Some large property owners/managers, such as McDonalds, CBRE, and Irvine Company, have implemented their own procedures. However, there is no officially recognized light pole inspection procedure, protocol, or training. Regardless of the type of test, we utilize a simple three stage rating system when inspecting light poles: •

24

Good – No action needed at this time.

•

Marginal – Structurally, the pole is fine but needs something simple like a scrape and paint for surface rust to prevent a future hazard. The pole should be tested again within 12 months.

•

Bad or Hazard – This pole has structural issues and needs to be repaired or replaced before it falls.

For a thorough pole inspection, proper documentation is key. Take photos of the pole, the surrounding area, and any issues, and write a description of the pole and recommended repairs. A site map and pole specifications are helpful to make repair estimates from the report. It is the inspector’s responsibility to make this determination in the field, rather than office staff reviewing data and determining the pole’s condition at a later date. This will keep the report accurate and save time on return trips if the data does not agree with pictures and notes. This is a critical step that we have seen missed by contractors reviewing reports to make a bill of materials for repair and replacement estimates.