Our drum kit is a truly a passive solution that is designed to contain the effects from an explosion in a properly vented or suppressed dust collector or cyclone.

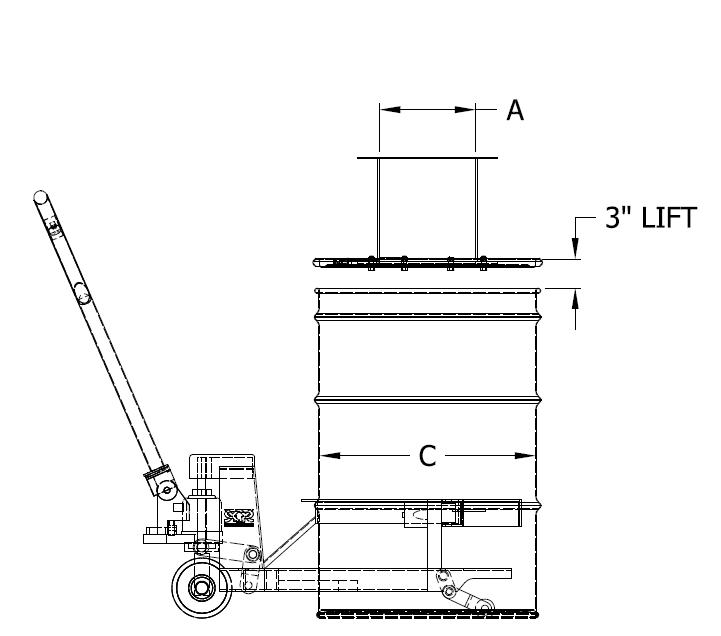

The ergonomic design of our drum kit makes changing barrels a breeze. The quick clamp design requires no tools for change out and the included hydraulic lift reduces the risk of injury or spills.

ECONOMICAL Installation of the drum kit is as simple as bolting our paten pending spool to the discharge flange of your collector. Requires no leg extension, no electric and no air. The low installation and maintenance cost combined with the time saving from a quick drum change out equates to more money in your pocket when compared to alternatives when you choose our drum kit.

Legends Equipment has partnered with XP Products to offer their drum kit solution.

Our drum kit is an innovative alternative to traditional rotary valves that can bind or jam when used in an vacuum system seeing various dust and debris. This design allows all collected materials to pass into the drum and still be a rated passive collection devices f for handling combustible dust.

Our drum kit acts as a strengthened extension of the dust collector. It is designed to withstand the reduced pressure (Pred) that develops during a properly vented deflagration event and is not limited by a Kst value.

If the explosion relief vent is sized properly and can accommodate the added volume of the drum kit, no modifications are required to the vent panel or isolation device on the inlet ducting.

• Stainless Steel (Food Grade)

• Proximity Sensor

• Level Sensing Instrumentation

• Custom Spool Size

• Rated to 0.7 bar

• 660 lbs lift capacity

• Standard models are painted carbon steel

• NFPA Compliant

A. HYDRAULIC DRUM TRUCK/LIFTER:

Drum truck designed for use with 55-gallon steel drums with a lifting capacity of 800 lbs. The drum truck provides a safe and easy way to maneuver drums with a single operator. The drum hydraulic drum truck weighs 117 lbs

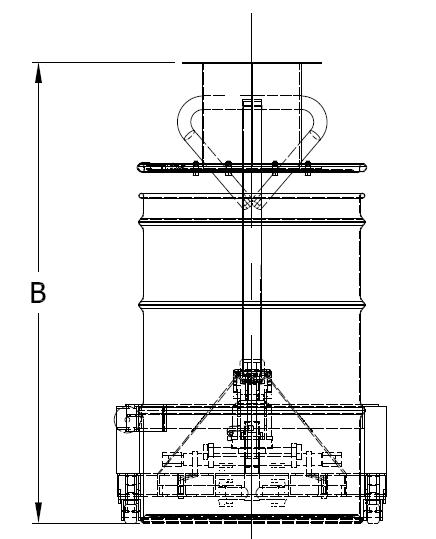

B. HEAVY DUTY FLANGED SPOOL:

12-gauge square or round bolted flange to match dust collector outlet flange. 12-gauge square or round spool bolted and reinforced to drum lid.

C. DRUM COVER CLAMP AND DRUM LID:

Reinforced drum cover clamp with manual lever. EPDM rubber gasket seal around drum top perimeter.

D. HEAVY DUTY 55 GALLON STEEL DRUM:

Steel drum, exterior black painted.

Provides indication drum is full and needs changed.

Confirm the drum is in position and can be interlocked to stop the airlock during drum changes for safety of operators.

When used without an airlock, it will shut the system down as the drum is changed.

Company Name: Address:

E-Mail:

Material Name:

Combustible Dust: Yes No

Temperature: Kst: Pmax:

Moisture Content:

Additional details:

General Design

Materials of Construction: Carbon Steel (standard) Stainless Steel

Drum Size (C): 55-Gallon (standard) 30-Gallon

Connection Size (A): Round Square Specify connection size

Clearance Under Flange to Floor (48” Standard) Dimension B

Level Sensor: Yes No

Drum In Place Sensor: Yes No

Additional Notes: