Tubing and Fittings Installation Guide.

This guide offers general recommends of how to properly install a central vacuum housekeeping system.

These systems are different from water, steam or dust collection duct system. Follow these few basic principals and your system should provide trouble free operation.

Compression Couplings

Instalok Coupling

Top in Drop (Preferred drop method)

Side in Drops

Labels

Zoned System Design

Elbows

Eliminate Inclines (Horizontal or Vertical Only)

Tubing Supports

lnstalok

IMPORTANTINSTALLATIONINSTRUCTIONS

PREPARINGFORINSTALLATION

■Verifytube and Instaloksizescorrespond with each other ( Figure 1 )

■ Cleanand drytube OD toensure it is freeofdirt and greasewhichcancauseslippage

■ Makesure tubeends are cutsquareandburr-free to avoidmaterialblockages

ASSEMBLINGTUBE&COUPLING

■ Twist Instalokontotubeend ( Figure 2) until tube is centered incoupling ( Figure 3 )

*NOTE: TwistInstalokortubing to facilitate installation

■ Tightenclamp

■ Twisttheconnectingtube intothe Instalok untilbothends butt together ( Figure 3)

■ Tighten remainingclamp

TIGHTENINGTHECOUPLING

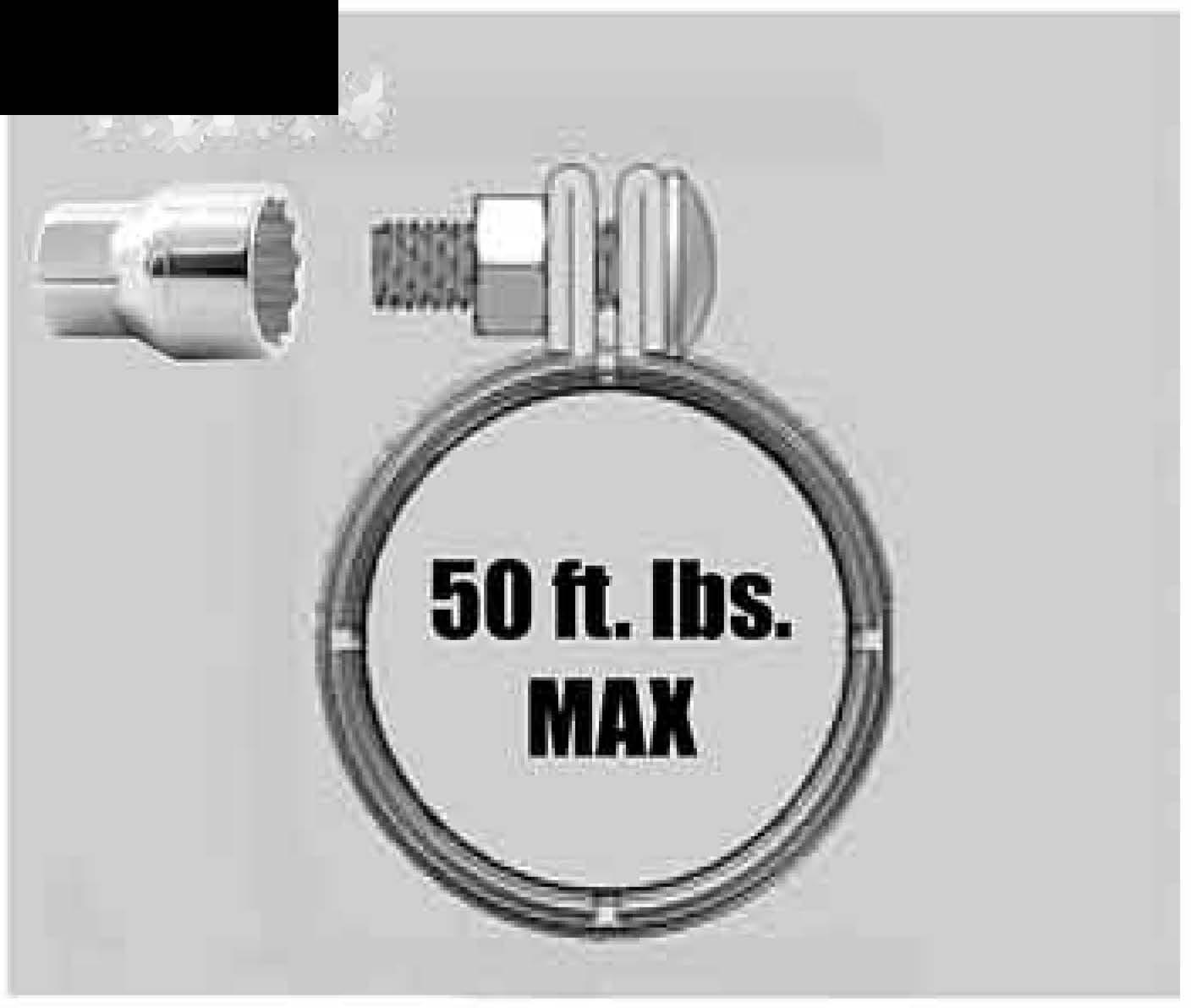

■ Tighten thebolts to 50 foot-pounds oftorque MAXIMUM ( Figure4)

■ Do not over-tighten

4

Figure 1

Figure2

Figure3

Figure

ELBOWS

Provide 10 times the tube diameter of straight tube before and after each elbow.

Example. For 3" Tubing, provide 30" before and after each elbow minimum.

Avoid tight bend elbows (No Street El) Centerline bend radius should be a minimum of 2X the diameter. 3X diameter or larger prefered.

Avoid back to back elbows whenever possible.

Tube Trap to eliminate oversize debris.

The tube trap is an alternative to the standard inlet valve adapter. It provides a system to catch large debris that should not be vacuumed into the central system. Rags, gloves, pieces of skids, shop towels, bolts, and other debris can jam a rotary airlock or get logged into the tubing system. The tube trap captures these items at the inlet valve so the operator can clear these themselves before they enter the system.

When used with the sight glass assembly, the operator can see objects trapped visually to identify whether they need to be cleared quickly.

Tube Trap adapters are 304 stainless steel

Heavy duty construction.

Works with standard inlet valves and can be retrofitted to existing systems with straight drops.

See a video of this product on our YouTube channel.

Tube Trap only works with a straight inlet adapter.

Sight Glass Tube Trap Monitor

Wall Mount Plate. Powder Coated Carbon Steel

Compression Coupling for Quick Installation to 2-1/2” Drops

External Ground Strip

Polycarbonate Sight Glass View Area

Standard 1-1/2” or 2” Inlet Valve

Tube Trap Hose Adapter