At Gallagher, we understand the unique challenges faced by manufacturers. As one of the largest and most trusted insurance brokers in the world, we’re here to help you safeguard your operations, workforce and bottom line.

Try our complimentary insurance review

Our confidential insurance review is designed to provide you with:

• Comprehensive benchmarking: See how your coverage compares to others in the manufacturing industry.

• Gap analysis: Identify potential coverage gaps that could leave your business exposed.

• Policy optimisation: Ensure your values and limits align with your business needs.

• Cost-saving opportunities: With improving market conditions, we’ll explore ways to reduce your insurance costs.

Partner with Gallagher

Our team of specialists is dedicated to delivering tailored solutions that align with your business goals. Let us help you build a resilient risk management strategy that protects what matters most.

For further information, please scan the QR code. CONNECT WITH A SPECIALIST TODAY.

Editor

Paul Attwood editor@mpemagazine.co.uk

Senior Editorial Assistant

Sophie Weir editorial@mpemagazine.co.uk

Features Editor

Harry Peters editorial@mpemagazine.co.uk

Production/Design

Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager

Charlotte Chapman charlotte@mpemagazine.co.uk

Accounts

Richard Lapthorn accounts@lapthornmedia.co.uk

Admin Assistant

Jade Still jade@lapthornmedia.co.uk

Circulation Manager

Leo Phillips subs@mpemagazine.co.uk

Publishing Director

Maria Lapthorn maria@lapthornmedia.co.uk

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB Tel: 01843 808 102

Bodycote Achieves Zero-Emissions Milestone at Derby and Rotherham Plants CBM Warns Downstream Manufacturers Face Soaring Energy Costs

An interview with Albane Dersy, Co-Founder and COO of Inbolt Xylem Flygt pumps selected for London’s Silvertown Tunnel How eSIM Technology Simplifies IoT Device Management - By Sönke Schröder

Welcome to the latest issue of Manufacturing & Production Engineering Magazine.

In this edition, we spotlight the people, projects, and technologies redefining manufacturing. From precision machining to sustainable production, the stories within reflect an industry evolving through innovation and resilience. We hear from leaders driving digital transformation and explore how automation, AI, and data insights are shaping the factories of the future.

This issue includes a preview of the Digital Manufacturing Strategies Summit 2025, a key event uniting Europe’s manufacturing decision-makers to shape the next phase of Industry 4.0.

We hope you enjoy this edition, and if you have news to share, contact editorial@mpemagazine.co.uk

Every

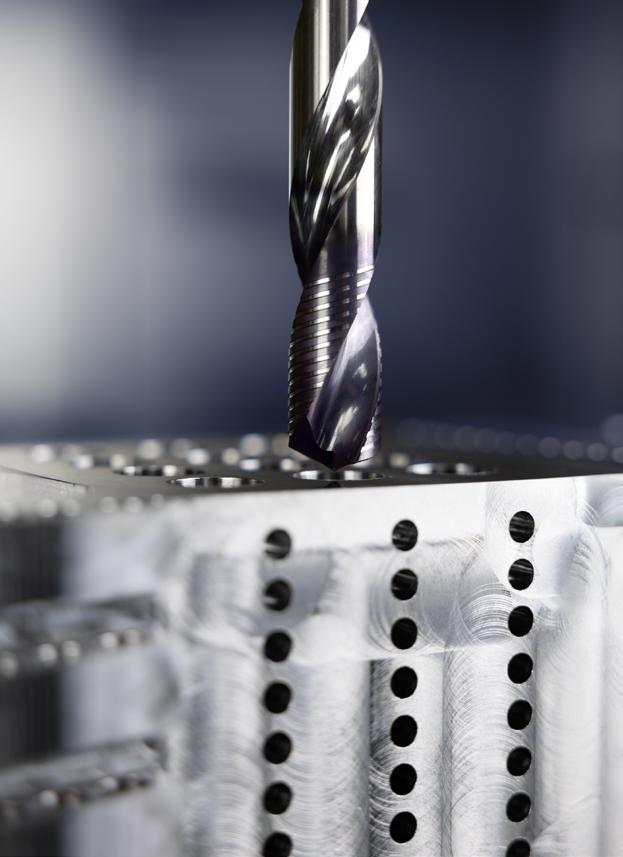

MAPAL is celebrating its 75th anniversary in 2025, marking a journey from a small Swabian toolmaker to a global technology leader in precision machining.

Founded in 1950 by Dr. Georg Kress, MAPAL has been characterised from the outset by entrepreneurial courage, innovation and close customer relationships. The acquisition of a patent for the single-

bladed reamer in 1952 set the course for the company’s future. Subsequent developments – including carbide guide pads and indexable inserts –established MAPAL as a pioneer in fine bore machining.

Under the leadership of the second generation, Dr. Dieter Kress, the company sharpened its focus on reamer technology, building a reputation in the automotive industry

Toyota Gazoo Racing (TGR) has confirmed that it will reproduce key engine components for the iconic AE86 Corolla coupe under its GR Heritage Parts Project. The initiative will see the return of cylinder head and cylinder block sub-assemblies for the celebrated 4A-GE engine, first launched in the 1980s and revered by enthusiasts worldwide.

While retaining the original design and specifications, the parts have been updated using modern simulation technologies, advanced manufacturing methods

and improved materials to enhance performance, durability and ease of use.

The cylinder head sub-assembly features improved machining in the combustion chambers for more consistent compression ratios, a new coating process on intake ports to reduce irregularities, and the inclusion of camshaft cap knock pins throughout for easier assembly.

The cylinder block sub-assembly benefits from precision honing of the cylinder bores, higher-rigidity cast iron, and simulation-based modifications to the crank-cap structure. Intake and exhaust ports

as a partner that delivered not just tools, but solutions. From the 1990s onwards, MAPAL expanded internationally and strategically acquired specialist companies to broaden its product and service portfolio.

Today, under the presidency of Dr. Jochen Kress, the third generation of the founding family, MAPAL continues to transform. The company is responding to industry shifts such as e-mobility, diversifying into aerospace, fluid power and die & mould sectors, and expanding its digital services with c-Com. Sustainability and processdriven organisational development are also central to its strategy.

With operations in 25 countries and more than 100 locations worldwide, MAPAL remains committed to combining innovation with customer proximity – values that have defined the business since its foundation.

Left: Dr Jochen Kress initiated the transformation of MAPAL into a processdriven, global organisation. ©MAPAL

have been thickened in response to customer requests, while added bosses and ribs now allow for transverse mounting – enabling installation not only in rear-wheel drive AE86 models but also in frontwheel drive applications.

The parts were unveiled during celebrations at Fuji Speedway marking the 30th anniversary of Initial D, the cult manga series that helped cement the AE86’s legendary status. Deliveries of the new GR Heritage components are scheduled to begin in spring 2026.

Dicker Precision Components Ltd, based in Hailsham, East Sussex, has strengthened its capacity with the installation of a Dugard 760XP VMC – the company’s sixth Dugard machine.

Founded in 1973, Dicker Precision has built a strong reputation in stainless steel machining, with 90% of its work serving the pump industry. The ISO 9001-certified subcontractor supplies sectors from aerospace and automotive to defence and offshore and is enjoying what Director Mark Love calls its “best year yet.”

The new Dugard 760XP was chosen for its compact footprint, direct drive spindle for demanding stainless steel work, and Siemens Sinumerik

828D control, ensuring consistency across the shopfloor. Probing technology and increased bed capacity further boost accuracy and flexibility.

With Dugard’s Brighton HQ just 25 miles away, the company also benefits from rapid service and local support. As Brandon Love notes: “It’s cost competitive, powerful, and gives us the footprint and work envelope we need to grow.”

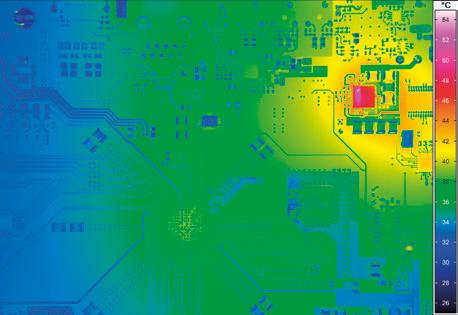

Advanced Rework Technology Ltd. (A.R.T.), the UK’s leading independent IPC-accredited training provider, has announced a series of equipment upgrades at its Witham-based training centre. The investments ensure delegates continue to gain hands-on experience with the same advanced technologies found in modern electronics manufacturing environments.

A key addition is the Purex FumeCube extraction system, supplied by long-standing partner Kaisertech Ltd. Featuring high-grade HEPA and carbon filtration, the unit removes 99.997% of particles down to 0.3 microns. Automatic flow control, low-noise operation and a clear filter warning system further enhance workplace safety and reliability.

The collaboration with Kaisertech is complemented by additional investments from other suppliers, including ASH Inspex HD digital microscopes for PCB inspection and Antistat ESD protection systems to strengthen training in electrostatic discharge control.

With these upgrades, A.R.T. further consolidates its position as the UK’s most comprehensive provider of IPC and bespoke electronics training.

Below: L to R - Adam Sibley, Kaisertech Sales & Marketing Director; John Vickers, Master IPC Trainer, A.R.T. Ltd; Debbie McDade, Managing Director, A.R.T. Ltd; Ben James, IPC Trainer, A.R.T. Ltd and Jon Doggett, Sales Account Manager, Kaisertech.

WERiT, the plastic packaging specialist, has completed an £8m expansion of its Irlam site, increasing its footprint by 40% to over 10,000 m². The project delivers a 3,000 m² warehouse extension, new offices, and advanced blow-moulding machinery, boosting capacity and efficiency while creating nine new jobs.

The investment includes a MAGIC all-electric multi-layer blow-moulding machine, new moulds, and automated packing systems to support customers across food, beverage, chemical and petrochemical sectors, including KTC Edibles, Kerry Ingredients, and Autosmart. Sustainability is central to the upgrade, with solar panels, electric forklifts, EV charging points and a commitment to become paperless by 2028.

Managing Director Sunny Prakash called the project “a pivotal moment” for WERiT, strengthening customer service, jobs and community value. Local leaders including Salford City Mayor Paul Dennett and MIDAS praised the investment as a boost to Greater Manchester’s advanced manufacturing base.

Bodycote, the global leader in precision heat treatment and specialist thermal processing, has announced that two of its UK facilities are now operating with zero carbon emissions –marking a significant step in its decarbonisation journey. The Derby and Rotherham plants, which process turbine blades for Rolls-Royce jet engines, have become the first in the sector to run fully on electricity from renewable sources, eliminating fossil fuel use and achieving the milestone without offsets.

The transformation supports the UK Government’s Industrial Decarbonisation Strategy and underscores the role of industrial

heat electrification in meeting climate targets. At the Derby site, a newly installed closed-circuit adiabatic cooling system has delivered electricity savings of 73% and water use reductions of more than 85%, while avoiding the need for chemical dosing and cleaning.

Operating in a global heat treatment industry worth up to $30bn, Bodycote plays a critical role in ensuring the safety and durability of aircraft engines, automotive gearboxes, surgical tools and joint replacements. Across its more than 100 global sites, the company is rolling out energy-efficiency and electrification programmes, alongside projects exploring hydrogen electrolysers, green methanol and on-site renewable generation.

As the only major heat treatment provider with a nearterm carbon reduction target verified by the Science Based Targets initiative, Bodycote is targeting a 46% reduction in operational emissions by 2030. The Derby and Rotherham plants will now act as blueprints for further global rollouts, with the next zero-emission facility set to be announced shortly.

Above: MP Baggy Shanker on tour of Bodycote’s zero emissions site in Derby

By Kieran Bennett, Business Development Manager – Food & Beverage and Jon Roberts, Account Manager at Bürkert Fluid Control Systems.

Once a waste product, whey is now a profitable source of protein for dairies, fuelling everything from shakes to yoghurts.

Many dairies, which once discarded thousands of tons of whey, now recover it using advanced separation technologies to produce liquid whey, which is then pasteurised, ultra-filtered, and blended into standard whey for later use. With growing demand for protein supplements and highprotein foods, this shift represents a valuable revenue stream and a way to reduce waste.

Traditionally, protein content in whey was determined using Coriolis flow meters, which measure mass and volume separately. Operators would then compare readings to calculate protein content. While widely used, this approach can be time-consuming and prone to inaccuracies, limiting efficiency in protein extraction—a key factor in profitability.

Pictured above:Bürkert’s FLOWave uses surface acoustic waves to precisely measure the mass and volume of liquid whey.

One UK dairy sought a more efficient approach and worked with Bürkert UK to trial the hygienic stainless steel FLOWave flowmeter. Unlike traditional devices, FLOWave uses surface acoustic wave (SAW) technology to measure solids, including protein, directly in liquid whey. The sensor provides instantaneous readings, allowing operators to monitor protein content throughout the production process without relying on multiple devices.

Originally, the dairy expected to use a combination of a flow meter, conductivity sensor, and temperature sensor, but FLOWave combines all of these functions in a single unit. This integration saved space on the line, simplified installation, and reduced costs by at least 40% compared with the Coriolis alternative.

Accurate protein measurement also enables continuous production processes. By providing real-time data, the FLOWave allows dairies to blend thin and concentrated whey efficiently, producing standard whey with minimal storage requirements. Some operators have been able to reduce on-site storage needs by up to two-thirds, storing only the finished product. Instantaneous readings following straining, filtration, and blending help ensure consistency and quality in every batch.

The FLOWave’s precision is such that it can detect even minor solids, ensuring that whey protein content is measured reliably across different specifications, from thin whey to concentrated forms. This capability supports more accurate control of blending and production, which is especially important in large-scale operations where storage capacity and production efficiency are critical.

With recent market pressures challenging UK dairies, protein recovery from whey has become a welcome opportunity. What was once discarded as waste is now a lucrative revenue source, and dairies that adopt precise, responsive equipment like the FLOWave can capitalize on it fully. By streamlining measurement, reducing reliance on multiple sensors, and enabling continuous production, the technology is helping transform whey processing and improve profitability.

In short, the FLOWave offers dairies a modern, efficient, and cost-effective way to measure protein, turning a former by-product into a valuable ingredient for healthfocused food and drink products.

is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

By Gerard Bush, Sales Application Engineer, INMOCO

Optimising servo system performance requires careful management of gain and phase shift to balance speed, accuracy, and stability. While modern intelligent drives can auto-tune motors and control loops, understanding the traditional Bode Plot remains vital for diagnostics, tuning, and system design.

A Bode Plot shows gain—how the system amplifies or reduces an input signal—and phase shift— how output lags or leads input— across a range of frequencies. This allows engineers to predict where a system may become unstable, identify the crossover frequency, and determine optimal gain and phase settings.

Key insights from the Bode Plot include bandwidth, which defines how quickly a system can settle to a commanded position, and phase and gain margins, which indicate stability. It also helps assess resonant frequencies and the load-to-motor inertia ratio,

both crucial for ensuring rapid, precise, and stable motion.

Even with auto-tuning drives like the Kollmorgen AKD2G paired with AKM2G motors, the Bode Plot provides engineers with a visual tool to fine-tune systems, diagnose performance discrepancies, and optimise complex applications. Combining traditional analysis with modern intelligent drives ensures servo systems meet both speed and precision requirements reliably.

Above: Servo Systems, Kollmorgen 2G Motion System significantly enhances torque and responsiveness, improve operator safety, easy installation.

Below: Kollmorgen AKM2G servo motors and AKD2G drives.

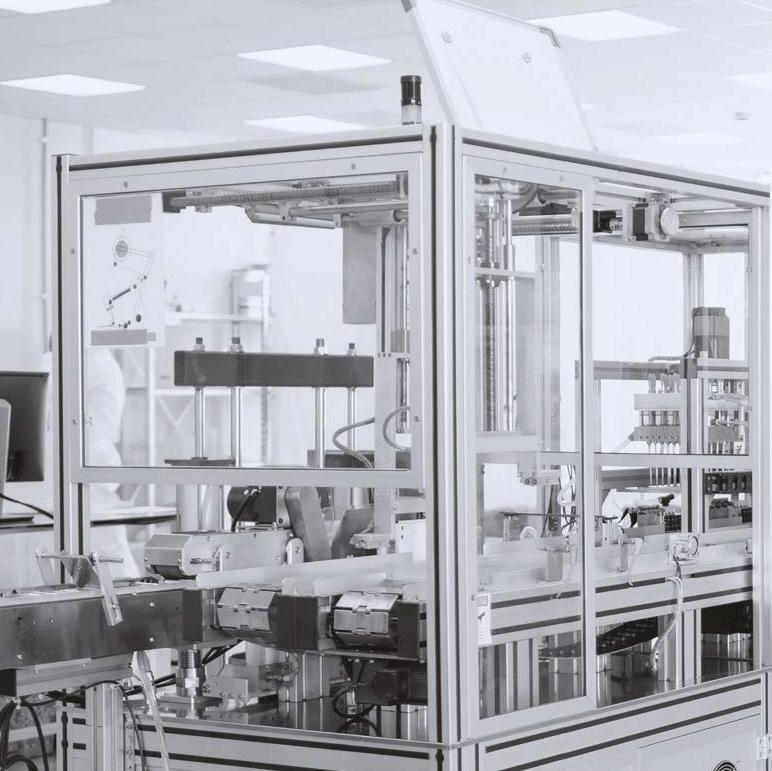

Multipharma, a key player in the Belgian pharmaceutical sector, improves the traceability and efficiency of its logistics operations with ZetesChronos. This solution gives Multipharma optimum visibility on the status of deliveries.

Multipharma has a network of 243 pharmacies all over Belgium, with more than 1800 employees. In handling a multitude of diverse logistics flows, Multipharma was encountering some difficulties with shipment tracking. Manual delivery management was leading to delivery errors.

ZetesChronos facilitates the management of deliveries (POD). The solution provides complete digitalisation of the transport processes, as well as real-time data capture using barcodes. This allows precise tracking of packages travelling between the distribution centre and dispensaries. Multipharma now has greater visibility over each transport unit.

For more information visit: www.zetes.com/en/proof-ofdelivery-software

(+44) 1707

Visit Hamamatsu Photonics at Stand J124 to explore how our extensive portfolio of components, modules, and systems provides innovative, highperformance solutions to the manufacturing industry.

Find out more about our solutions

Light sources

• LEDs (UV – IR)

• Excimer Sources

• Quantum Cascade Lasers (QCLs)

• Deuterium and Xenon Lamps

• Extreme Ultraviolet (EUV) Light Sources

• Laser-Driven Light Sources (LDLS)

• Supercontinuum White Light Lasers

Optical sensors

• Mini-Spectrometers

• Photodiodes and Avalanche Photodiodes (APDs)

• Multi Pixel Photon Counters (MPPCs or SiPMs)

• Infrared Detectors

• X-Ray Flat Panel Sensors

• Photomultiplier Tubes (PMTs)

• VIS/NIR/X-ray Cameras

29th- 30th October 2025

In manufacturing, large-scale construction projects—whether for new facilities, expansions, or retrofits—are vital for driving growth and improving operational efficiency. However, these projects come with risks that require careful management. An Owner Controlled Insurance Program (OCIP) is an effective solution, offering comprehensive coverage for all contractors and subcontractors involved in a project.

While manufacturers often rely on contractors to arrange insurance, taking control of this aspect provides significant advantages. As Tracy Keep, Managing Director of Gallagher’s National Construction Practice Group, UK Retail, explains: “At Gallagher, we believe that tailored insurance solutions are the cornerstone of successful projects. Our goal is to empower manufacturers with the coverage they need to thrive.”

Tracy Keep - Managing Director, National Construction Practice Group, UK Retail

By purchasing an OCIP, manufacturers—referred to as the “Employer”—can unlock several strategic benefits:

• Control Over the Policy: Employers retain full authority over the insurance policy, ensuring alignment with their specific needs.

• Tailored Coverage: Gallagher’s expertise allows manufacturers to customise policy wording to suit their unique requirements, rather than relying on a contractor’s preferences.

• Direct Claims Payment: Claims are paid directly to the Employer, avoiding delays caused by contractor involvement.

• Protection Against Contractor Insolvency: Unlike contractorarranged insurance, which ceases if the contractor goes bankrupt, an OCIP remains in force, safeguarding the Employer against risks associated with incomplete projects.

• Inclusion of Additional Stakeholders: OCIPs can incorporate other parties, such as lenders, security agents, and future tenants, ensuring compliance with contractual obligations.

An OCIP is tailored to a specific construction project and typically includes:

• Contract Works: Coverage for physical damage to the works during construction.

• Terrorism: Protection against damages caused by acts of terrorism.

• Property Owners Liability: Safeguards the Employer against third-party claims unrelated to the construction project.

• Public Liability: Covers liability for injury or damage caused to third parties during construction.

• Delay in Start-Up: Protects against financial losses due to project delays caused by insured perils.

• Latent Defects: Long-term protection (up to 10 years) against structural damage caused by hidden defects.

• Non-Negligent Liability (6.5.1): Coverage for damage to neighbouring properties caused by construction activities, even without contractor negligence.

Construction projects are critical to operational growth. By partnering with Gallagher, manufacturers gain access to a specialised practice group that ensures the OCIP is comprehensive, transparent, and tailored to their needs. This partnership protects both the project and the manufacturer’s long-term interests, making Gallagher a strategic investment in the future of your business.

Gallagher’s experienced brokers design OCIPs that provide comprehensive protection and peace of mind.

Scan the QR code above to connect with us.

Cloud and On-Premise install options

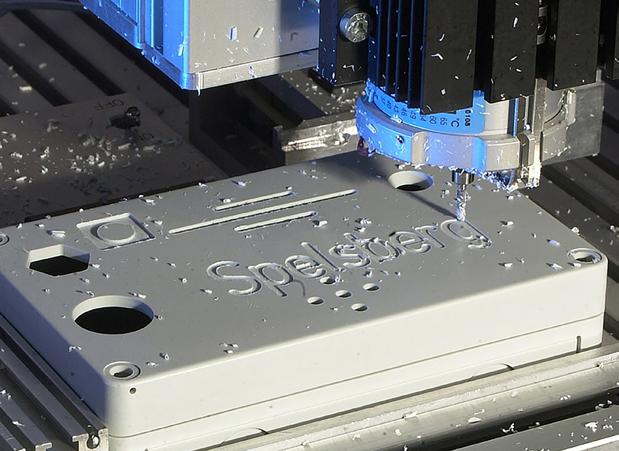

Chris Lloyd, Spelsberg UK’s Managing Director, explains how to approach enclosure customisation.

If a standard enclosure can’t accommodate a component such as a touch screen, or if a cable requires a specific entry point, customisation may be needed. Based on CNC milling and drilling, maintaining structural integrity and ingress protection demands precision techniques and experienced operators. The most effective way to achieve this is to involve an enclosure supplier that provides customisation services in-house.

When engineers need to protect electronic components or electrical terminals, customisation typically adapts the enclosure to integrate external interfaces such as keypads, HMI touch screens, sensors, cameras, or buttons. Non-standard cable entry or exit points are also often required.

Before machining, the first step is to determine whether a standard enclosure meets the requirements. Flexible housings with adjustable dimensions, knock-out holes, and internal fixing options may achieve the goal without cutting. Strategic placement of the enclosure can also reduce the extent of customisation. While online research may help, consulting an enclosure specialist ensures a faster and more reliable solution.

Quality relies on both machine precision and operator expertise.

Above:Spelsberg’s CNC service can also include on-enclosure printing and embossing to add branding or user instructions.

If customisation is needed, selecting an enclosure that can withstand milling or drilling while maintaining its protective function is vital. Appropriate flanges must meet the required IP rating. The manufacturer’s CNC experience often determines the feasible level of customisation. A single-point supplier ensures consistent quality, reducing the risks associated with third-party or in-house adaptations.

Customisation begins with design. CNC machinists can work from CAD drawings or generate designs for customers, saving time for OEMs. Experienced specialists can confirm specifications for milling and drilling while advising on cable routing and other practical considerations.

CNC capabilities include milling slots, holes, contours, 3D shapes, and complex geometries, as well as drilling, countersinking, and tapping threaded holes. Micronlevel precision ensures components fit perfectly, removing unwanted movement, maintaining sealing, and enabling fast installation.

Quality relies on both machine precision and operator expertise. Tool selection, cutting speed, and thermoplastic melting points must be considered alongside cooling techniques to achieve accurate machining.

To prevent strain during CNC machining, enclosures must be secured with vacuum technology or other stabilisation methods to avoid twisting or deformation. Awareness of tolerances is critical, and tempering can help relieve internal stresses.

Speed of production is a key advantage of in-house customisation. Spelsberg’s CNC service can deliver a prototype customised enclosure within 24 hours, reducing the burden on internal engineering teams. Additional services include assembly of components such as PCBs and keypads, as well as onenclosure printing and embossing for branding or user instructions.

Whatever the level of customisation required, relying on an experienced enclosure manufacturer ensures precise, reliable, and timely solutions.

Left: Spelsberg enclosures provides customisation services in-house.

One of Sheffield’s newest manufacturers is helping to revitalise the city’s industrial capabilities with cutting-edge materials processing technology.

Sheffield Technology is winning a growing customer base, with some key projects being attracted back to the UK from overseas. The company is eager to leverage its ability to rapidly laser-cut materials up to 60mm thick— made possible by the company’s investment in a state-of-the-art 24kW Trumpf 5060 TrueDisk laser.

With fully automated material and part handling, this machine boasts a 6-metre by 2-metre plate capacity and can cut: Stainless steel, armour, carbon, and alloy steels – up to 60mm thick, Aluminium – up to 40mm, Copper – up to 16mm and Brass – up to 12.7mm.

Beyond laser cutting, Sheffield Technology’s extensive fabrication and machining capabilities include a

400-tonne, 5.1-metre press brake and automated cobot welding, allowing the company to deliver fully integrated manufacturing solutions.

Darren Mason, Works Director at Sheffield Technology, explained: “The big advantage for us is that we have truly disruptive technology. Our high-power laser operates at a scale and precision that challenges conventional thinking. While most lasers struggle beyond 30mm, we comfortably cut up to 60mm, allowing us to compete on both quality and cost with traditional heavy-duty processes, such as plasma & profile cutting.”

The company’s rapid expansion is reflected in its workforce growth, scaling from just 10 employees last year to 58 today, including four apprentices. With a firm commitment to developing future talent, Sheffield Technology plans to expand its apprenticeship program to pass on engineering skills that have defined the city for generations.

Darren commented: “We’re proud to be back in Sheffield, helping to underpin its metal processing history, and we trust the city will continue to attract work from across the country and beyond. Our capacities and state of the art equipment really do support continued competitiveness within the UK in this important sector, underpinning jobs for our young people in the years ahead.”

Sheffield Technology’s innovation and investment in advanced manufacturing can only support the city remaining at the forefront of British materials processing & manufacturing industry. Visit: www.sheffield-tech.com

A metal forming specialist has been chosen to be part of the Bostin’ Black Country’ Business campaign, designed to boost the economic fortunes of the region.

Bowers & Jones, which received the King’s Award for International Trade earlier this year, is one of the ‘magnificent seven’ selected by the Black Country Chamber of Commerce to showcase the strengths of the area by championing innovation, resilience, creativity and exporting.

The Bilston-based business will tell their story alongside KMB Shipping Group, apprentice training specialist In-Comm Training and health cash plan provider Paycare.

There are also places for creative agency TPSquared, Beacon Centre for the Blind and Dudley Canal & Caverns, which hosted the launch event and photoshoot.

The world leader in the design, manufacture, and refurbishment of rolling mill components has agreed to display the Bostin’ Black Country Business badge and has committed to support Chamber events and media opportunities.

Bostin’ Black Country Business aims to add new companies every quarter, with the view to growing an alumni-type of community.

This will include all the winners of the Black Country Chamber Business Awards in November,

nominations from the Chamber board and possibly even a public vote.

Data from the Economic Intelligence Unit reveals that the Black Country has a total GVA of £25.4bn and a £20,565 GVA per head of population.

In total, nearly 450,000 people are employed across 42,395 enterprises, with strong concentrations of manufacturers, transport and logistics specialists, construction firms and retailers and wholesalers.

There is also a vibrant scientific and technical sector, where bridging the digital skills gap and supporting green job transitions are highlighted as key long-term priorities.

For further information, visit blackcountrychamber.co.uk.

The Confederation of British Metalforming (CBM) has warned that UK downstream manufacturers face a “triple whammy” of non-commodity electricity costs, with new charges set to come into force between October 2025 and April 2026.

The trade association, which represents more than 200 manufacturers of fasteners, forgings, pressings, cold-rolled and sheet metal products, says many companies could see charges double as a result of three changes:

• From October 1st 2025, the Balancing Services Use of System (BSUoS) charge will rise to £1.569p/kWh, up from £1.199p/kWh.

• From November 1st 2025, the government’s Nuclear RAB levy will add 0.345p/kWh to bills, with forecasts suggesting it could increase further.

• On April 1st 2026, Ofgem’s R110ET3 framework will come into effect, with forecasts pointing to a 100% rise to fund transmission network upgrades.

CBM President Stephen Morley warned that many energy-intensive manufacturers fall outside the government’s Energy Intensive Industries (EII) support scheme due to their classification codes.

“We already have the highest energy costs in the G7 – 50% more than Europe and 120% higher than the US. These new charges are a double punch in the gut for

downstream manufacturers,” he said.

Greenfields Energy Group has calculated that the R110-ET3 alone could add £9,305 per year to SME bills and up to £128,000 for larger businesses.

The CBM is calling on government to take urgent action, warning that delays until 2027 under the Industrial Strategy will come too late for many firms.

Morley concluded: “Without immediate intervention, these changes risk widespread closures. Industry needs support with extortionate energy costs now, not after it’s too late.”

Asset finance is, for many firms, a form of funding they have used for many years. Yet still, for others, it’s not something they know much about. In this article Close Brothers Asset Finance takes a closer look at the different products and understand why it could be the perfect option when considering your next purchase.

In short, asset finance is an alternative form of funding used by businesses to obtain the equipment they need to grow or access much-needed cash. Asset finance makes the otherwise unaffordable affordable because it gives businesses access to the equipment they need without incurring the cash flow disadvantage of an outright purchase.

Agreements can also be customised to the business’s needs, with flexibility on both the term and repayment schedule.

There are various products that come under the broad umbrella of asset finance with one of the key ones being Refinancing, which is a proven way to make your assets work for you and release cash back into the business.

Asset finance makes the otherwise unaffordable affordable because it gives businesses access to the equipment they need without incurring the cash flow disadvantage of an outright purchase.

Refinancing uses the value of assets you already own to help your business. With Sale and HP Back – a type of refinancing – you sell your equipment to us, and we lend you the money you need to invest in your business.

You pay us back in line with what the equipment earns for you. Once you’re done paying us back, you own the equipment again.

This works whether you own the equipment outright or are already financing it with someone else.

Refinancing is for anyone looking to unlock the value of their existing assets to support their business. Whether you own equipment outright or are financing it elsewhere, refinancing can provide a quick way to access funds for things like new equipment, improving cash flow, or other business needs. It’s a flexible option suitable for businesses of all sizes, including sole traders.

• Get more cash easily - Asset refinancing is a quick and simple way to get extra money for your business needs. You get to keep using the asset you put up as security.

• Pay over a longer time - We can take over your current financing deal with another company and extend the time you have to pay. The costs are fixed, so there won’t be any surprises while you’re repaying the loan.

• Choose what’s best for you - Use the cash injection for your business or buy other things you need. It’s more flexible than some other financing options.

• Decide quickly - Getting cash from your assets helps you make faster decisions when dealing with business contracts. Use the money for hiring people, buying new things, or expanding your workspace.

For more information, please visit: closeassetfinance. co.uk/asset-finance

Why do you believe computer vision in manufacturing has been so widely misunderstood, and what’s changed in recent years to make it more viable?

Computer vision was long seen as unreliable and expensive. Limited by early 2D systems that struggled with lighting, reflections and depth, manufacturers often dismissed the technology, assuming it couldn’t handle the complexity of real-world manufacturing.

The turning point came with a shift to 3D vision. By enabling depth perception and spatial awareness, 3D vision opened automation to previously inaccessible tasks. At first, early 3D vision was primed for tasks like structured light and stereo vision.

Industrial robots are built for precision, but not perception. Even slight misalignments can lead to errors, downtime, and cost overruns.

- Albane Dersy

Today’s systems combine advanced imaging with AI, allowing robots to interpret and adapt in real time. This evolution has made vision not just viable but essential for modern, flexible manufacturing.

Can you explain how vision-guided robotics reduces the need for traditional infrastructure like fixed tooling and precision fixtures?

Industrial robots are built for precision, but not perception. Even slight misalignments can lead to errors, downtime, and cost overruns. Traditionally, manufacturers relied on pricey fixtures and tedious reprogramming to keep robots on track. Vision-guided robotics flips that script.

By giving robots the power to “see” and react in real time, they adapt like a human would. Modern 3D vision systems can be retrained in minutes using CAD data, without the need for retooling or precision fixtures. The vision system also travels with the robot, making it easy to integrate, flexible, and resilient to factory conditions. Now, robots adapt to the environment, not the other way around – unlocking faster changeovers and more agile production.

What are some real-world examples where computer vision has significantly improved reliability and reduced downtime on production lines?

At Stellantis Valenciennes, an advanced computer vision system enhanced production precision and efficiency by addressing two key challenges: inconsistent part positioning and pallet deformation post-heat treatment. Two Universal Robots were equipped with real-time 3D vision, enabling precise handling and eliminating the need for a manual operator to handle 2.7 tonnes of pieces.

Meanwhile, at Stellantis Detroit, a FANUC cell was retrofitted in the Body Side Outer Aperture line, where the age of the racks meant that parts didn’t always fit perfectly

Computer vision acts as both the eyes and the intelligence behind robotic systems, enabling factories to run 24/7 with precision and resilience.

- Albane Dersy

and subsequently led to frequent breakdowns. The vision-guided system eliminated pick errors, reduced downtime by 97%, and achieved ROI in just three months - delivering consistent, collision-free performance without mechanical rework.

How does computer vision technology enable the concept of “dark factories”?

“Dark factories” require more than automation. They demand autonomy. To realise the vision of fully automated factories, capable of operating without human intervention, you need reliability from every system, especially vision. Without human oversight, robots must be able to perceive and respond to even the slightest deviations in their surroundings.

Computer vision provides this capability. It allows robots to detect subtle deviations, such as a misaligned rack, and adapt in real time. Without vision, these errors

could halt production. With it, robots operate continuously and safely.

Computer vision acts as both the eyes and the intelligence behind robotic systems, enabling factories to run 24/7 with precision and resilience. It’s the foundation for lights-out manufacturing that’s not just automated but truly autonomous.

What advice would you give to manufacturers who are hesitant to adopt vision-based automation due to concerns about cost or complexity?

With the introduction of 3D Vision, there is no longer a costly and complex implementation. Engineers don’t need specialised coding skills. They can retrofit existing production cells of robot brands such as ABB and KUKA, training the AI on a part’s CAD file or 3D model within 30 minutes.

This also helps to reduce CapEx and infrastructure costs since production lines don’t need to be ripped out and replaced when manufacturing a new model. Added to that, 3D vision makes the line more reliable and efficient, delivering 80% fewer rejected parts and reducing downtime by up to 97%.

All of this means that manufacturers can see ROI in as little as 3–12 months, demonstrating that the upfront cost pays off quickly.

As European manufacturers accelerate their digital transformation journeys, the Digital Manufacturing Strategies Summit (DMS), held in Berlin on 20–21 November 2025 at The Meliá, stands out as a critical gathering. This summit is designed for senior leaders tasked with integrating advanced technologies, streamlining operations, and building resilient, future-ready enterprises.

Departing from traditional conference structures, DMS prioritises interactivity. Delegates will participate in Think Tank Challenges, workshops, roundtables, and private meetings, each designed to drive collaboration and deliver tangible takeaways. With every agenda personalised to delegates’ priorities, the summit ensures each conversation is targeted, relevant, and actionable.

The agenda, crafted by an advisory committee of industry experts, focuses on four core themes:

• Empowering the Digital Workforce – Building skills, cultures, and strategies to enable adoption of Industry 4.0 technologies.

• Built for Disruption – Preparing manufacturing organisations for resilience against supply chain shocks, emerging technologies, and shifting market demands.

• Smart Factory Innovations –Harnessing AI, automation, and digital twins to optimise production and accelerate efficiency.

• Scaling Digital Operations –Moving beyond pilots to achieve sustainable, enterprise-wide transformation.

The summit features a lineup of distinguished speakers, including:

• Ivan Branco, Volvo Group – SML, sharing insights on BI, analytics, and real-time decision-making across complex operations.

• Gustavo Cabral, VP Digital Customer Supply & Development, Barry Callebaut, exploring supply chain digitalisation and Industry 4.0 applications.

• Ray Ellis, Head AI Security, Philip Morris International, examining cybersecurity imperatives in digitally connected manufacturing systems.

• Carlos Gomes, Sustainable Development & Continuous Improvement Corporate Director, Sodecia, showcasing how AI-based continuous improvement drives operational resilience.

• Simon Levinson, Global Digital Manufacturing Innovation Lead, Danone, highlighting data-driven innovation in FMCG operations.

• Christophe Villain, Global Head of Supply Chain & Procurement Technology, Nestlé, sharing strategies for technology-driven supply chain optimisation.

The summit programme includes headline panels on scaling Industry 4.0, managing disruption, and driving smart factory transformation. Breakout workshops will tackle practical challenges such as AI integration, workforce digital readiness, and aligning IT/OT systems, while the DMS drinks reception and networking sessions provide opportunities to forge meaningful connections.

For sponsors, the summit offers unrivalled opportunities to meet senior decision-makers with active investment projects. Through prearranged one-to-one meetings, targeted roundtables, and peer-led challenges, sponsors can engage with delegates in structured, outcomedriven conversations.

The Digital Manufacturing Strategies Summit 2025 is more than a conference — it is a catalyst for collaboration, innovation, and growth. By fostering knowledge exchange, strategic partnerships, and actionable solutions, the summit empowers Europe’s manufacturing leaders to turn digital ambitions into industrial realities.

For more information or to request an invitation, visit dms-summit.com or email info@intrinsiccommunications.com.

Simon Levinson Head of Digital Manufacturing Innovation, Danone

Christophe Villain Global Head of Supply Chain & Procurement Technology, Nestlé

Adel Emam Chief Operations Officer-MENA, JBS

Simon Levinsons Head of Digital Manufacturing Innovation

‘Think flash fires’ is the message for some manufacturers from commercial insurance broker, McCarron Coates, as it highlights the fire risk wood dust can pose within manufacturing.

Flash fires are not as frequently discussed as flash floods but can be equally devastating. They occur when highly combustible wood dust, comprising fine particles, is suspended in the air and ignited by a nearby source. In the worst cases, an explosion can occur.

Ignition sources include flames, sparks, heat build-up, or static. With little warning, fire can shoot through a building, stirring up more dust and potentially causing a secondary explosion. Even a thin layer of wood dust on a surface can present a hazard, while stacks of contained dust can also build pressure.

The finer the dust, the greater the risk. Particles under 200 microns are usually explosive, with as little as 10% under 80 microns increasing danger. A dust explosion test can verify risk.

Controlling wood dust is essential, not only to save lives but because the law demands it. The UK legal framework is headed by the Health and Safety at Work Act 1974, which requires employers to

ensure employee safety. COSHH Regulations 2002 also apply, as wood dust is a respiratory hazard linked to asthma, COPD, and even cancer. In the USA, it is classed as a Group 1 carcinogen. DSEAR 2002 requires procedures to assess and mitigate explosion risk, while PUWER 1998 demands safe, wellmaintained equipment.

McCarron Coates suggests using the Hierarchy of Controls. At the lowest level is PPE. Director Luigi Maggio says, “Whilst the use of RPE is nowhere near as efficient as eliminating wood dust at source, it will offer some protection. The proviso is that protection depends on having the right particulate filters, correct face-fitting, and specialist RPE for those with facial hair.”

Administrative controls include changing workplace behaviour. For example, wood dust should never be vacuumed with a standard machine, which could trigger an explosion. Instead, ATEX industrial safety vacuums must be used. Wet cleaning prevents dust from circulating, while dry sweeping should be avoided. Special attention should be given to high shelving or hidden areas where dust could accumulate.

At the next level, removing wood dust at source is critical.

above: Luigi Maggio, director at award-winning Leeds insurance brokerage, McCarron Coates

Credit: www.mccarroncoates.com

Local Exhaust Ventilation (LEV) systems capture dust at processes such as cutting, sanding, and shaping, preventing circulation and filtering air safely.

“LEV equipment needs to be fit for the facility, with correct selection part of the risk management process. Under COSHH, it also needs inspecting and testing every 14 months,” says Maggio.

Replacement is another option, as some woods are more hazardous than others. Where possible, switching materials could reduce risk. At the top of the hierarchy is elimination — if wood-based processes are not essential, they should be removed entirely.

“Training staff in all aspects of wood dust control is vital,” says Maggio. “Employees must understand correct cleaning methods, how to wear RPE, and evacuation procedures. Fire drills should be held regularly, hot work strictly controlled, and equipment maintained to avoid overheating, sparking, or static build-up.

“A flash fire can occur seemingly out of nowhere. Manufacturers must ensure they do all they can to prevent this and comply with regulations.

“Over and above that, they should review their sums insured and work with an expert broker, like McCarron Coates, to avoid financial exposure should the worst occur.”

For more help with managing risks like wood dust, visit www.mccarroncoates.com

By Dr. Yavuz Murtezaoglu, Founder & Managing Director – ModuleWorks GmbH

Volvo, renowned for prioritising safety, publicly declared:

“No Volvo car should be involved in a fatal or serious injury crash by 2030.”

Now, imagine transferring this bold vision to CNC machining: eliminating all machine crashes by 2030. It’s an ambitious goal, but as engineers, tackling such challenges is both exciting and necessary.

Ten years ago, a European machine tool builder asked us to develop realtime simulation capable of detecting collisions and stopping the machine to prevent crashes. With support from the CNC control manufacturer, we accessed one second of future machine data. This allowed us to calculate all moving parts and material removal in advance and reliably predict collisions. This system became our Collision Avoidance System (CAS).

While our simulation engine was already fast and capable, deploying it directly on the machine revealed the complexity of the task.

Modern CNC machines operate like a turntable playing an LP, unaware of what is on the record. If the LP has defects, the turntable repeats them blindly—but at least it won’t crash. Similarly, a CNC machine executes

NC programs without understanding their context. It relies entirely on the user or CAM system to provide correct instructions. Tools are defined in tables with parameters like radius and length, which support compensation during machining.

A CAS running on an Industrial PC, linked to the CNC, can calculate the positions of all moving parts and update the in-process workpiece. This distinction is vital to avoid false collision alarms caused by incomplete material data.

Years of collaborative effort with machine tool vendors and control makers allowed us to solve hundreds of detail-level challenges. We achieved a CAS capable of preventing collisions in both manual and automatic modes without generating false alarms.

The quality of a collision avoidance system depends on two factors: it must never miss a real collision, and it must avoid unnecessary stops that could damage workpieces or reduce productivity. Resolving these challenges was a Herculean task—one that could fill a book on its own.

Even a reliable CAS needs accurate job setup data, including tool, holder, and clamping geometries. Each CNC job requires specific configurations. We developed an interactive interface for operators and a standardised import format, evolving into the Manufacturing Data Exchange Specification (MDES). Today, this free, well-documented format is supported by many CAM vendors, machine tool builders, and control makers.

Returning to Volvo’s vision, we now have a pathway for CNC machining. With CAS installed on all machines and MDES-standard job setup data from CAM systems, eliminating crashes by 2030 is achievable. Other providers can develop CAS solutions using the MDES format under a free, open licence.

Even offline simulation solutions can benefit from MDES, enabling NC program verification before machining begins. This intermediate step is already a significant safety improvement.

Schmersal’s innovative DHS door handle system combines the functions of a robust door handle with the signalling of machine status via illuminated handle or push-button.

The door handle system is designed for use with the AZM40 solenoid interlock or with safety sensors from the RSS36 and RSS260 series or as a stand-alone solution. The illuminating handle signals various machine conditions over its area using seven different colours, enabling the user to control the colours individually to signal the machine status.

In addition, a push button is available, which can be individually adapted to customer requirements using the coloured push button caps. The pushbutton can be used for tasks such as a reset function or a request to open the guard door.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

you can cover a wide range of finishing challenges while keeping operations simple and costeffective.

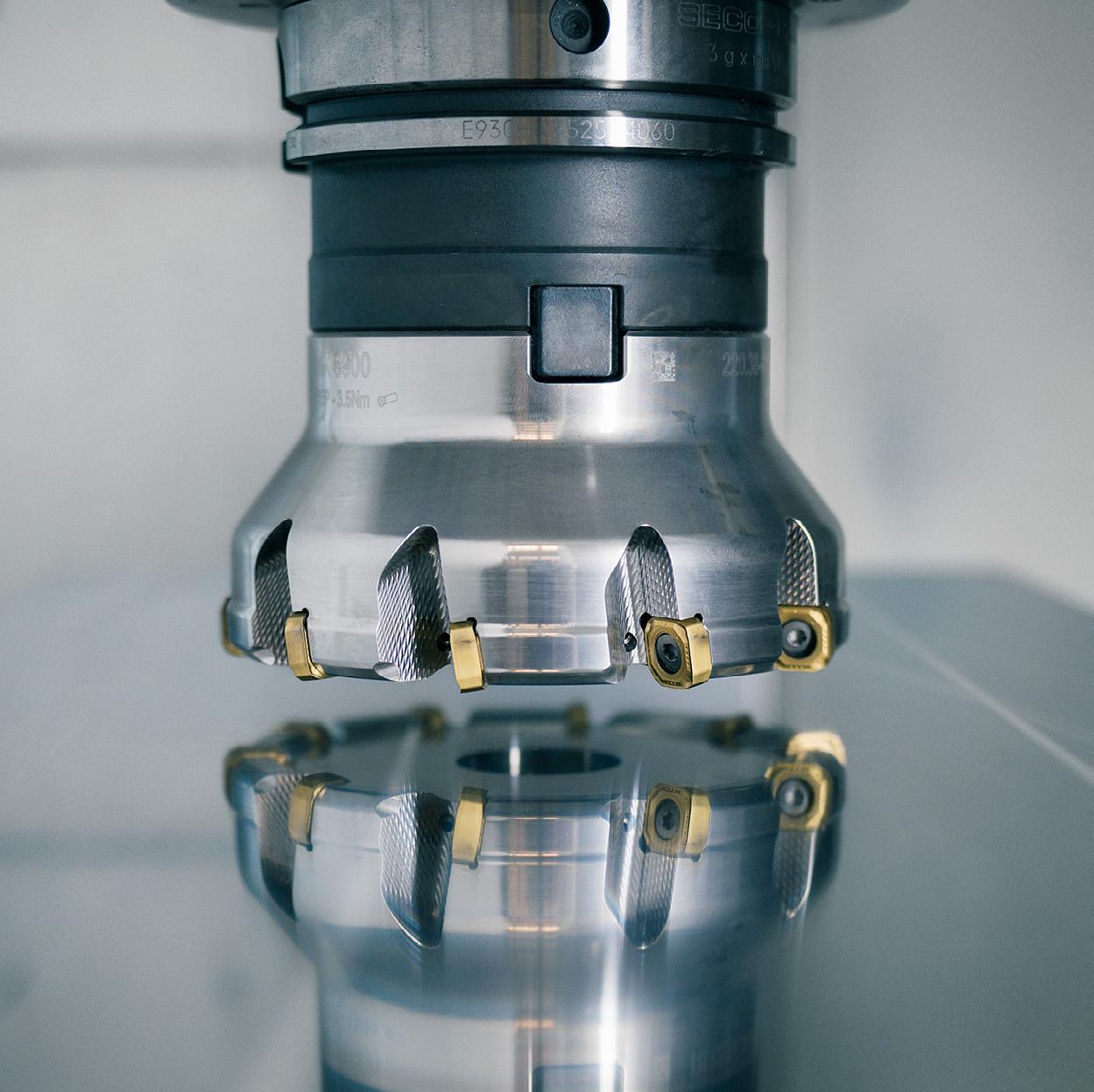

Seco has announced the launch of the .38 Finishing Face Mill system, a selection of cutters engineered for highprecision surface finishing. With ready-to-use simplicity, hybrid flexibility, and ultimate adjustability, this system is designed to meet the full spectrum of finishing needs— efficiently and flawlessly.

The .38 Finishing Face Mill / SNFX1204 system offers three cutter variants—fixed pocket, hybrid, and adjustable—each tailored to different levels of control and performance. Whether your priority is achieving consistent surface finishes or minimizing setup effort, this system offers a practical and flexible solution. Offering two insert types to meet different demands—one with an 88° lead angle for near-wall machining and another with a 27° lead angle for high-feed, open-surface work—

• The Fixed Pocket Cutter (R220.38-….-SN-..SA) is ideal for users seeking effortless handling and setup-free operations. Its tilted screw design ensures perfect insert self-centering and excellent run-out accuracy (4–15 µm), making it a cost-efficient solution that reduces operator error and training needs.

• The Hybrid Cutter (R220.38….-SN-..CSA) combines fixed and adjustable cassettepockets, allowing it to function as a fixed pocket tool by default. The cassette inserts act like dedicated wiper inserts for enhanced surface finish and, while adjustment is possible, it’s not required— offering flexibility without added complexity.

• The Adjustable Cutter (R220.38-….-SN-..HSA) offers ultimate control, with fine-tuning capabilities that achieve run-out as low as 0–2 µm—perfect for demanding applications where surface perfection is non-negotiable.

The .38 Finishing Face Mill system is now avaliable globally.

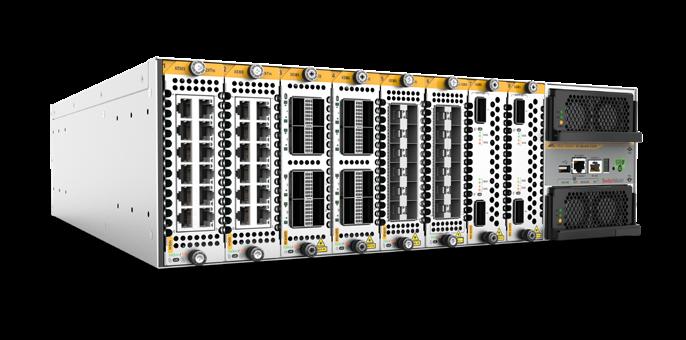

Allied Telesis has unveiled the SwitchBlade x908 Generation 3 (SBx908 GEN3), a compact 3U modular switch designed to address enterprise and data center scalability challenges, including AI, IoT, video, and virtualized workloads.

The SBx908 GEN3 offers capacityon-demand, allowing customers to start with only the ports they need and expand as traffic grows. It supports 1G to 400G interfaces, including copper 10G, fiber 10G, 25G, and 400G, enabling seamless integration with both legacy and modern networks.

Enterprise advantages include a high-density 3U chassis with 8 slots, flexible modular interfaces, and unified operations via AlliedWare Plus™ OS. For data centers, it delivers up to 64x100G ports, 400G support, and optimized server aggregation for virtualized workloads.

Key differentiators:

• Unified platform for enterprise and data center environments

• Compact, high-density 3U design with flexible module selection

• Capacity-on-demand reduces upfront costs

• Intelligent automation with AMF Plus™, NETCONF/RESTCONF, and Ansible

• Integrated security including Active Fiber Monitoring, AAA, and MACsec

The SBx908 GEN3 supports 12.8 Tbps switching fabric and 2,800 Mpps forwarding, with resilient stacking, rapid failover, and AI-powered network assistance, simplifying operations and boosting productivity.

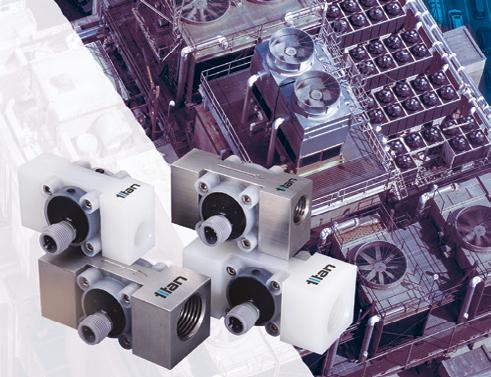

Valves for Hydrogen, Carbon Capture, Topside, Subsea, and Pipeline Applications.

Instrument & DBB Valves

• Manifolds, Needle, Check and DBB Valves to 22.5K psi

• Cryogenic

• Severe Service 650ºC, 10K psi

• Forged & Bolted Construction

Hydrogen & Carbon Capture Valves

• Instrumentation, Ball, Needle and DBB Valves for Hydrogen and Carbon Capture Applications

• Pipeline Ball Valves upto 18”

Pipeline Valves

• 1” to 20” Bore Size

• High Temperature

• High Pressure

• Cryogenic

• API 10K Design

• 10K Ball Valves for Hydrogen Fuelling Stations

Subsea Valves

• Diver & ROV Operated Needle Valves

• Ball Valves Upto 15K

• Manual & Hydraulic Parallel Slide Gate Valves 3/8”, 1/2”, 3/4” and 1”

HMS Networks will host its Automotive TechDay 2025 this October, offering a full day of free live webinars dedicated to the latest advances in in-vehicle communication. Aimed at engineers and technical professionals working in automotive testing, diagnostics, and EV development, the event provides insights into emerging technologies, tools, and real-world applications shaping the industry.

The programme features four expertled sessions. The day begins with Inside CAN XL: Next-Level In-Vehicle Communication, presented by Mark Gerber and Philipp Steil, exploring how higher data rates and flexible data transfer improve automotive systems. This is followed by Automotive Ethernet in 2025 with Kristofer Koch, covering 10BASE-T1S, MACsec, SOME/IP, and TSN. In the afternoon, Markus Demaria leads Mastering Communication Challenges in Automotive Production EOL Tests, offering practical solutions for simulating missing ECUs and integrating high-voltage components. The series concludes with Cybersecurity in Open Linux Embedded Gateways, where Miguel López examines opportunities and security considerations for embedded Linux platforms.

Register Free Here: https://www.hms-networks. com/about-hms/media-center/ webinar/2025/10/21/webinars/VCAutomotive-TechDay2025

LiftEx, the annual flagship event of the Lifting Equipment Engineers Association (LEEA), returns for its 20th edition on 18–19 November 2025 at the Exhibition Centre Liverpool.

Recognised as a leading event for professionals involved in lifting operations across manufacturing, engineering, construction, energy, logistics, defence and entertainment,

LiftEx offers a two-day programme of learning, networking and product discovery.

This year introduces a free Thought Leadership Conference on Day 1, with sessions covering the Digital Product Passport, innovations in subsea load release, tunnel boring machine extraction on HS2, and market insights into vertical construction and trade. Day 2 features an End User Seminar programme, addressing practical challenges such as rope inspection, workforce skills, and safe load securement.

Alongside the conference, the exhibition will host over 100 brands, showcasing lifting equipment, rigging, safety systems, load monitoring technology and digital solutions. Exhibitors include Atlas Winch & Hoist Services, Reid Lifting, RUD Chains, Bekaert, Globestock Safety and RiConnect, the event’s Headline Sponsor.

Networking opportunities will culminate in the LEEA Awards ceremony at Liverpool’s Anfield Stadium, celebrating excellence across the global lifting industry. Register now at liftex25.eventreference.com.

OPEN MIND Technologies AG, a leading provider of CAD/CAM and MES solutions, will be exhibiting at formnext from November 18 to 21, 2025 at Messe Frankfurt, Hall 12.0, Booth B99.

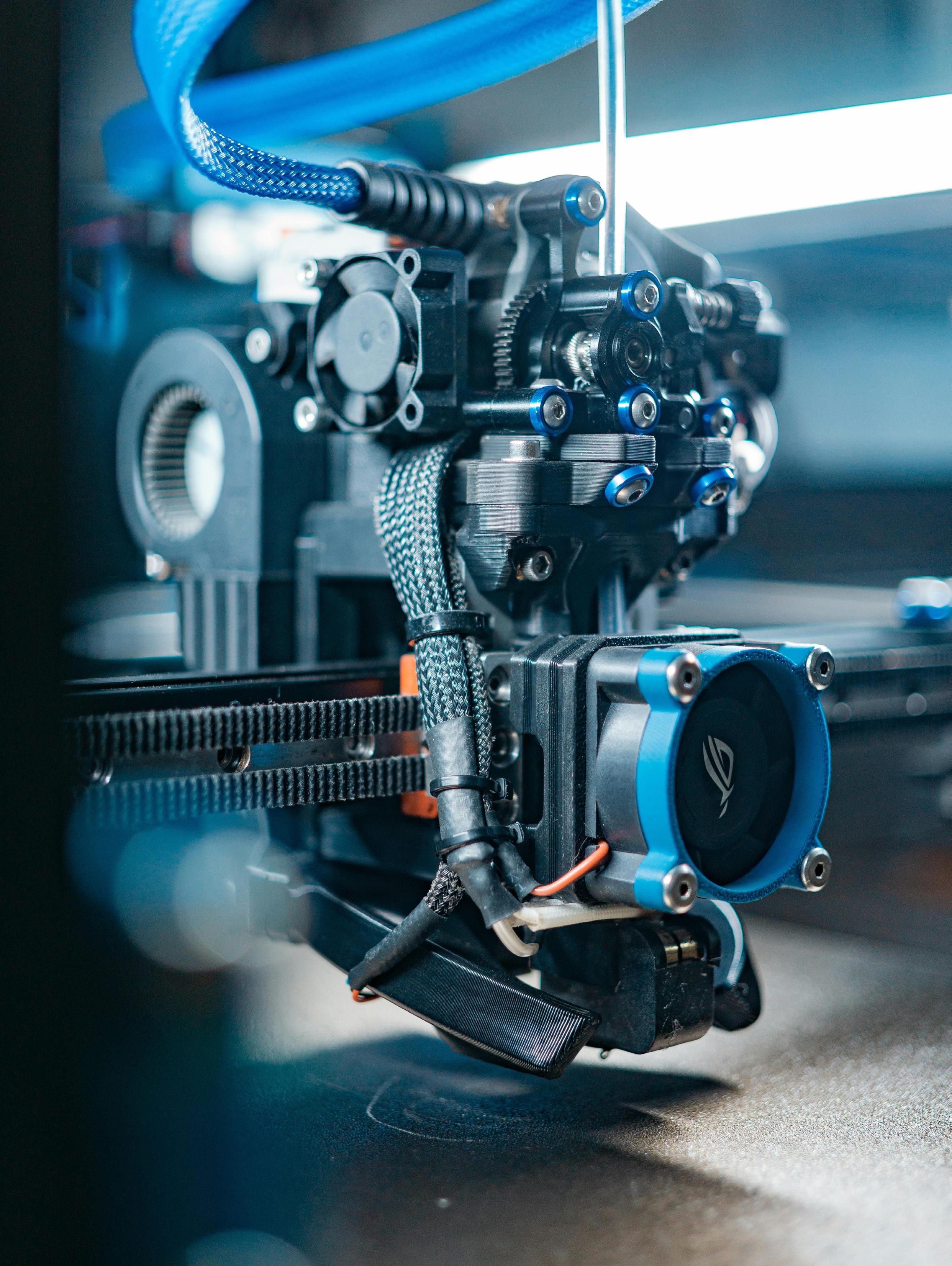

OPEN MIND will present CAD/CAM functions for both additive manufacturing and the precise finishing of additively manufactured parts. hyperMILL® ADDITIVE Manufacturing extends the possibilities of 5-axis simultaneous machining for the Direct Energy Deposition (DED) process and Wire Arc Additive Manufacturing (WAAM).

Unlike many other solutions, the 3D printing module in hyperMILL® ADDITIVE Manufacturing is fully integrated. This advantage becomes particularly clear when seamlessly switching between additive and subtractive machining on hybrid machines. The additive functions of the CAD/CAM suite benefit from OPEN MIND’s leading 5-axis and simulation technologies, ensuring maximum process reliability.

In hyperMILL®’s virtual machine, OPEN MIND has introduced BEST FIT, an innovative alternative to manual alignment of workpieces for further machining. The prerequisite is a 5-axis machining centre with a digital probe. The misaligned raw part billet is probed directly on the machine, and the measurement protocol is transferred to the CAM system. The software adapts the NC code to the real part position. This way, the virtual programming environment is aligned with the actual clamping situation.

Refra’s air-to-water heat pumps, equipped with Siemens’ MVL702 magnetic expansion valve, have demonstrated up to 16% higher COP compared with stepper valve systems, securing the UK National ACR & Heat Pump Award for Best Commercial Heat Pump Product.

Tests on a Refra reversible propane (R290) heat pump showed the valve’s rapid response

© Ilona Brant Pavšukova

– 10 times faster than stepper valves – allows tighter superheat control, reducing energy use by up to 14% and boosting heating capacity by 21%. Crucially, the technology halves defrost cycles, further improving efficiency and operating stability.

The breakthrough offers significant cost savings for commercial and industrial users, especially amid high energy prices. Absolutely Chilled Ltd, Refra’s UK distributor, received the award in Manchester, highlighting growing demand for sustainable heating solutions. With the UK investing £20bn in decarbonisation, Refra’s A2W propane heat pumps with Siemens valve technology are poised for wider adoption across public and private sectors.

Factory automation and robotics leader FANUC UK is set to host The Future of Precision Engineering this January, a new event showcasing the latest developments in automation, digital manufacturing, and robotics. Designed to highlight opportunities in injection moulding and CNC machining, the programme will explore sustainability, energy efficiency, AI, and skills development.

Highlights include the European debut of FANUC’s all-electric S350C ROBOSHOT injection moulding machine, live demonstrations, expert presentations, roundtable discussions, and panel debates. An exhibition area will feature leading organisations such as the Manufacturing

Technologies Association (MTA), Motan Colotronic, and Ultra Polymers.

Each day will focus on a key theme: sustainability (27 Jan), AI-driven innovation (28 Jan), and education and training (29 Jan). Morning sessions will deliver talks and case studies, while afternoons will showcase cutting-edge machinery and partner technologies.

Register today at https://ukopenhouse. fanuc.eu/#whats-on

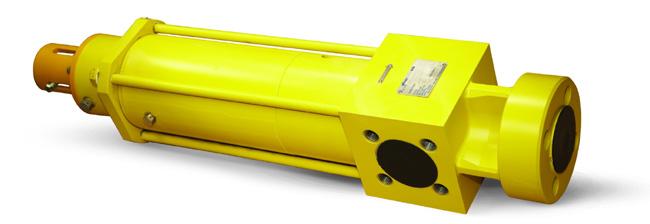

The Silvertown Tunnel’s pumping system is reducing the risk of flooding, delays and costly maintenance, while supporting the long-term resilience of London’s transport network, says Ian Ireland, large pumping projects programme manager, Xylem UK.

Xylem has provided six surface water pumping stations along the route of the 1.4km Silvertown Tunnel, a major piece of new transport infrastructure in London, UK.

The pumping stations, all equipped with Xylem Flygt pumps, prevent surface flooding inside the tunnel by collecting and removing rainwater ingress and water runoff from vehicles. Silvertown Tunnel is a 1.4 km road tunnel constructed under the River Thames to improve cross-river connectivity in east and southeast London.

The project was delivered by Riverlinx CJV, a contractual joint venture, undertaking the design, build, financing and maintenance of the tunnel on behalf of Transport for London (TfL). The tunnel, the first new crossing under the Thames in over 50 years, opened on 7 April 2025.

TfL’s plans to construct a new tunnel under the Thames, from Greenwich to Newham, east London, were announced in 2012. The Silvertown Tunnel, with two lanes in each direction and dedicated bus lanes, was built to provide a new link across the Thames, reduce congestion around the Blackwall Tunnel, offer a crossriver bus route and improve air quality. Around 25,000 vehicles per day are expected to use the tunnel, which took five years to construct.

After opening, London mayor Sadiq Khan said the tunnel was a “great piece of infrastructure” of which London should be “incredibly proud”. Effective surface water drainage and pumping systems are critical. Without them, rainwater entering the tunnel would quickly build up at the lowest points, causing delays and safety risks to drivers and workers.

In May 2023, Xylem was selected to design, supply, install and commission six pumping stations, all related equipment and infrastructure—such as valves, sensors, panels and kiosks—and approximately 1km of 300mm wrapped ductile iron pipework. Xylem’s scope also included pressure testing of the entire system.

Of the six pumping stations, four were constructed at strategic points within the tunnel. The two largest were located at its lowest point— midpoint—serving the northbound and southbound carriageways. The third and fourth were placed at each entrance ramp.

A fifth pumping station was built outside the tunnel on the Greenwich side. The sixth provides drainage services to the tunnel’s fire pump room, in the main operations building, which houses equipment needed to supply high-pressure water in the event of a fire.

In total, 31 Flygt pumps were supplied—24 in operation and seven spares. The pumps operate in a duty/ duty assist configuration to ensure continuous operation in varying weather conditions.

Selected models feature Flygt’s selfcleaning N-impeller, delivering high

efficiency clog-free pumping and reducing unplanned maintenance. The fleet comprises:

• Six Flygt NZ 3301 medium capacity dry well pumps—up to 1320 m³/h with 220 kW combined

• Two Flygt NP 3127 small capacity submersible pumps— up to 260 m³/h, 5 kW

• Six Flygt NP 3171 medium capacity submersible pumps— up to 710 m³/h with 56 kW combined

The two mid-way stations, Low Point Sump—Northbound and Southbound (LPS-NB and LPSSB) house three main pumps each.

Four small sump pumps were sited at each station to help drain the LPS pump rooms. These small units pump any condensation or spillage back into the main drainage system.

Rainwater enters the tunnel’s drainage system through culverts and gully grates. From there, the pipework directs flow to one of the four main pumping stations, via large collection tanks—part of the LPS mid-point systems—and deep wet wells at each end of the tunnel.

The pumps operate automatically when water levels reach a certain point and stop when levels return to low. Automation is directed by bespoke control systems which can be remotely monitored.

Flows are tested for pollutants such as vehicle oil. Non-compliant water is diverted to storage tanks for offsite treatment, while water meeting quality standards is pumped safely into the Thames.

The six pumping systems took Xylem approximately two years to construct. Combined, they handle surface water flows of approximately 2,290 m³/h— enough to empty one Olympic-size pool in about 45 minutes.

L ive online , classroom , blended , e-learning

• Gain or renew your 5-year Certificates of Competence*

• Courses f for each career stage based on EEMUA 159

• English, Dutch, German and French language options

• Free or discounted for EEMUA Members and Associates

TankAssessor courses*

17-20 November 2025 – in English – live online

9-12 February 2026 – in Dutch –live online

27-30 April 2026 – in German –live online

1-4 June 2026 – in French

– Paris, FR

Tank Integrity Manager course

1-5 December 2025 – in English

– Antwerp, BE

In-house courses

By arrangement for your choice of: time, language, location.

TankInspector courses*

16-18 February 2026 – in English – live online

23-25 February 2026 – in Dutch live online

16-18 March 2026 – in French live online.

TankBasics courses

6 October - 27 November 2025 – in Dutch – blended, live online

Storage Tanks e-learning On-demand – in English or Dutch

Also...

Storage Tanks Seminar –Ridderkerk, NL – 27 November 2025

More choices, information and registration at www.eemua.org

As customers, investors, and regulatory bodies mount pressure on businesses to become more sustainable, and with an increased focus on ESG responsibilities, technology can be a valuable partner in achieving these goals.

Did you know? The latest government data shows the UK generated an estimated 40.4 million tonnes of commercial and industrial (C&I) waste in 2020, of which 33.8 million tonnes (84%) was generated in England. The latest estimates for England only indicate that C&I waste generation was around 33.9 million tonnes in 2021.

By taking an insights-driven approach to their waste streams, businesses can create additional revenue streams, reduce waste management costs, and boost their green credentials.

Sadly, the amount of commercial and industrial waste generated by businesses is having a massive impact on the environment. Most of this waste ends up in landfills, generating greenhouse gas emissions 25 times more effective at trapping heat than carbon dioxide.

This is terrible news for our planet. And consumers are not ignoring the facts.

Deloitte’s 2023 Sustainable Consumer survey revealed that 30% of consumers had stopped buying products due to ethical or

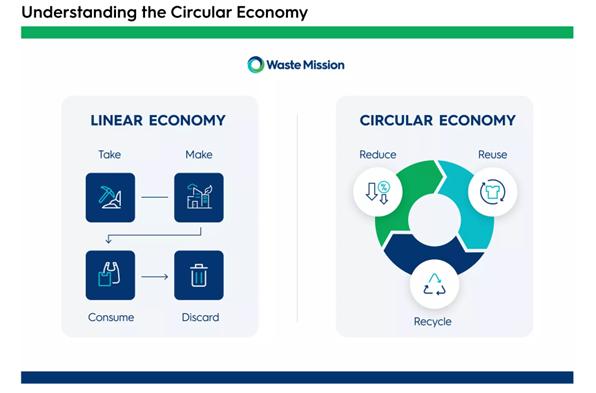

sustainability-related concerns. And almost 50% see circularity (explained in more detail later) as essential for buying a product.

If those aren’t reasons enough to reconsider waste management within your business, then how about this statistic: Every year, UK businesses can spend between 4–10% of their average annual turnover on waste disposal.

That’s a significant chunk of profit.

For actionable strategies check out our recent waste management blog.

Instead of collecting, transporting and disposing of waste, sustainable waste management looks for solutions that won’t harm the environment or human health and instead focus on reducing natural resource consumption.

Sustainable waste management revolves around a hierarchy:

• Reduce the initial amount of waste generated

• Reuse where possible

• Recycle what can’t be reused

• Sell what we can

• Only then, dispose of what’s left

From helping to reduce carbon emissions to improving air and water quality to commoditising waste streams that may be currently running at a financial loss – sustainable

waste management has incredible environmental, economic and social benefits.

This type of model, where everything is reused, repaired or recycled, can also be understood as the circular economy.

From groaning landfill sites to ecosavvy consumers and wasted profit, there are multiple reasons to embrace a sustainable waste management strategy and reduce the amount of waste your company produces.

Plus, let’s not forget how there are growing concerns around securing supply chains in an ever more volatile world. But, the great news is that sustainable waste management practices can help manufacturers ride the fluctuation in raw material prices.

“We already work with a range of major electricity network operators, offering them unique services for their transformer and switchgear recycling, ensuring that nasty elements like PCBs and F Gases are safely recycled. Additionally, we are developing some unique technologies in the WEEE waste sector, allowing us to extract precious metals from WEEE waste.”

- Nicola Guest, Waste Mission’s Group Marketing Manager

We believe that to achieve a more innovative and sustainable future, manufacturers in the UK need to prioritise long-term sustainable waste management goals.

And that’s where our team at Waste Mission can help.

Recently Waste Mission unveiled our custom-built Waste Management Portal. This innovative platform is designed specifically for contracted customers, enabling them to manage their waste more effectively and sustainably than ever before, staying up to date with waste streams, compliance and ESG targets.

At Waste Mission, we are driven by our unwavering commitment to doing what’s right – for our clients, staff, and the planet. No matter the complexity of the task, we want to simplify waste solutions for UK industries and

manufacturers. We aim to educate, encourage and uncomplicate waste management by offering a bespoke, tailored service, all from a single point of contact.

Our responsive team of experts becomes an extension of your business, taking care of waste so you can stay focused on your core operations. We promise to:

1. Guide you to reduce waste and increase your profitability

2. Help turn your waste into solutions, reducing reliance on new materials

3. Navigate complex regulations for you, ensuring you meet environmental and legal requirements

4. Provide a waste portal so you can easily access data on your waste production, recycling levels, and carbon footprint.

“These features are groundbreaking for our clients,” says Nicola Guest, “People have been blown away by the simplicity of use and the ease of understanding the data. Everything you need is at your fingertips and simplifies what has historically been a complex processmaking sustainability simple.”

See the portal in action

If you care about your environmental impact and are looking for a reliable partner to help navigate the complexities of your waste management, then we’d love to talk.

To book a waste review or learn more, visit our website wastemission.com, call us at 01438 745307 or email control@wastemission.com

In-Comm Training, one of the UK’s leading engineering and manufacturing apprenticeship providers, is calling on employers in the Black Country, Birmingham and Shropshire to tap into its biggest-ever talent pool.

Following record outreach with schools and community groups, the provider now has 200 young people seeking placements—with 125 already

placed and 75 more ready for October/November starts in roles ranging from engineering and design to welding and manufacturing.

Backed by over £225,000 in donations, including £25,000 from the Orlik family, In-Comm has expanded its STEM engagement to 15 new schools, sparking unprecedented demand for apprenticeships.

Scottish green chemical producer Celtic Renewables has welcomed four apprentices through a Modern Apprenticeship scheme in collaboration with Forth Valley College in Falkirk, Scotland.

The new apprentices met with Gillian Martin, Cabinet Secretary for Climate Action and Energy, at Forth Valley College to discuss their future career aspirations. The meet and greet came as part of a wider visit to the institution, where the MSP for Aberdeenshire East met with a host of lecturers and apprentices to learn more about their contribution to the future of a low-carbon Scotland.

Each of the four college students will garner experience as an apprentice Electrical Engineer, Process Operator and Mechanical Engineer while studying for their Scottish

As climate change accelerates, empowering young professionals to shape a sustainable future has never been more important. The building controls and automation sector (BEMS) provides rewarding apprenticeships and career paths that allow the next generation to reduce the built environment’s carbon footprint—a crucial opportunity, given commercial buildings account for around 40% of the UK’s total energy consumption.

Recent UNICEF research highlights the drive among young people: 72% believe there is still time to tackle the climate crisis, 60% say green skills unlock new careers, and 65% are eager to work in environmentally focused roles. Yet only 66% feel they currently possess the skills needed—an opportunity the BEMS sector is addressing.

The BCIA’s BEMS Controls Engineer Level 4 Apprenticeship offers a specialised pathway,

blending technical training and hands-on experience in controls hardware, communication protocols, supervisor software, and networking over 36 months. Over 250 learners from more than 100 employers have joined the programme, developing future-ready skills in a growing, sustainability-driven sector.

Career opportunities now include Building Automation Engineers, HVAC Engineers, Smart Building Consultants, EMS Specialists, and

Vocational Qualification at Forth Valley College.

This is the first year Celtic Renewables has participated in a Modern Apprenticeship scheme. It aims to expand its participation and take on more apprentices in the coming years as the company scales up its operations producing green chemicals using waste and by-products from food, drink and agricultural industries.

There are currently over 25,000 apprentices across Scotland, with close to two thirds (63.9 percent) training in the science, technology, engineering or maths (STEM) fields. This uptake is a result of the £100M investment from the Scottish Government to encourage school leavers into apprenticeships, with the aim of creating a new generation of qualified workers to work in Scotland’s burgeoning green economy.

Left: Celtic Renewables biorefinery at Grangemouth near Falkirk. © Celtic Renewables.

Below: Kerry Johnson, Chief People Officer at Celtic Renewables. © Celtic Renewables.

Sustainability Consultants—roles critical to designing, installing, and optimising smart building systems that enhance energy efficiency, indoor environments, and air quality while reducing emissions.

Through the Young Engineers Network (YEN), participants gain a platform to collaborate across the industry, influence innovation, and contribute to the UK’s net zero ambitions. For climate-conscious young professionals, a career in BEMS isn’t just a job—it’s a chance to drive real, impactful change.

Find out more about the Young Engineers Network

Made Smarter North West, the government-backed technology adoption programme, is celebrating the success of its Leading Change for Digital Champions (LCDC) initiative, which has empowered over 50 manufacturers to embrace digital transformation.

Since launch, nine cohorts of 84 participants from 53 companies have completed the fully funded programme, creating a regional peer network of digital champions. Designed for personnel at all levels— from production operatives to aspiring managers—LCDC provides workshops, coaching, and industry site visits, including Amazon’s fulfilment centre, while fostering peer-to-peer learning. Graduates join the Digital Champions Network,

meeting twice yearly to share insights and collaborate.

Participants reflect the diversity of North West manufacturing, including food producers Carrs Pasties and Firstplay Dietary Foods, engineering firms Hilton Docker and Newland Engineering, and electronics and packaging specialists Fylde Electronic Laboratories and Precision Pallets.

Ruth Hailwood, Head of Organisation and Workforce Development at Made Smarter, said: “Digital change works best when embraced at every level. Champions bridge leadership and shopfloor, helping businesses embed technology, improve communication, and deliver lasting benefits.”

LCDC complements the Leading Digital Transformation programme for senior leaders, equipping the wider workforce to put strategy into practice. The next cohort begins in November, with limited spaces available.

Manufacturers can register interest here.

The Engineering Construction Industry Training Board (ECITB) has launched its new five-year strategy, Leading Industry Learning 2026–2030, aimed at tackling skills shortages and supporting growth across the engineering construction industry (ECI).

Shaped through consultation with employers, training providers, asset owners, trade unions, and government, the strategy focuses on developing the workforce needed for critical infrastructure, energy security, and net zero projects. ECITB Chair Lynda Armstrong OBE highlighted the sector’s role in delivering vital infrastructure across

the UK, noting the importance of long-term planning to meet evolving challenges.

The ECITB forecasts that 40,000 additional workers will be needed by 2030 to support major projects, including nuclear, renewables, oil and gas, water treatment, hydrogen, and carbon capture initiatives. The strategy addresses these challenges through three key pillars:

1. Supporting Employers: Delivering high-quality training, qualifications, and labour market intelligence for effective workforce planning.

2. Growing Talent: Increasing new entrants, diversifying the talent pool, and supporting workforce retention through upskilling and reskilling.

3. Transforming Skills: Investing in regional hubs, leveraging technology, and promoting modular and blended learning approaches.

ECITB CEO Andrew Hockey emphasised that achieving the strategy’s goals requires collaboration across the sector. The strategy follows extensive consultation over 12 months, including workshops, roundtables, and surveys across the UK. Further details and levy proposals for 2026–29 will be presented at Regional Forums in October 2025, inviting all levy-paying employers to participate.