FUTURE

MANUFACTURING

FUTURE

MANUFACTURING

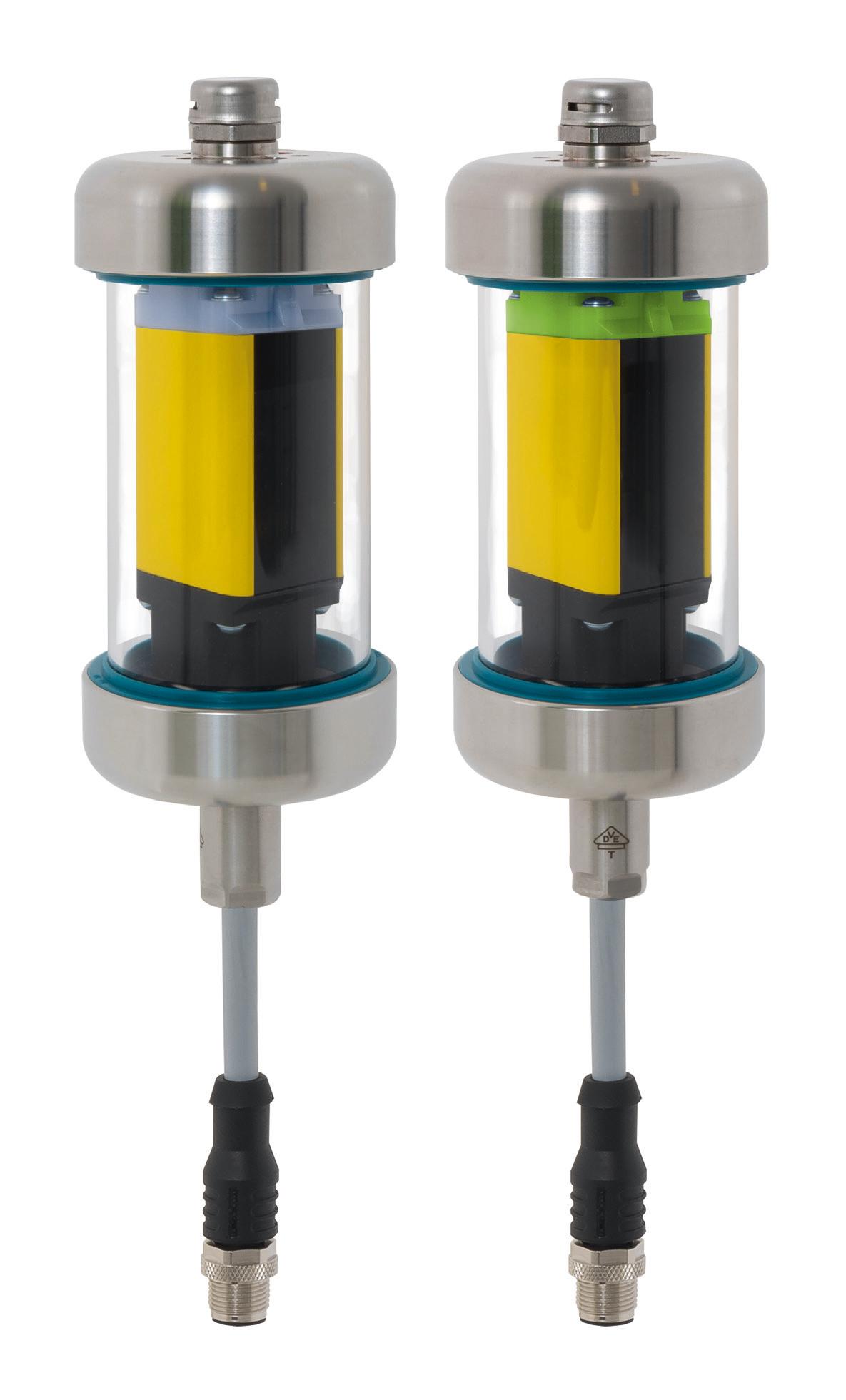

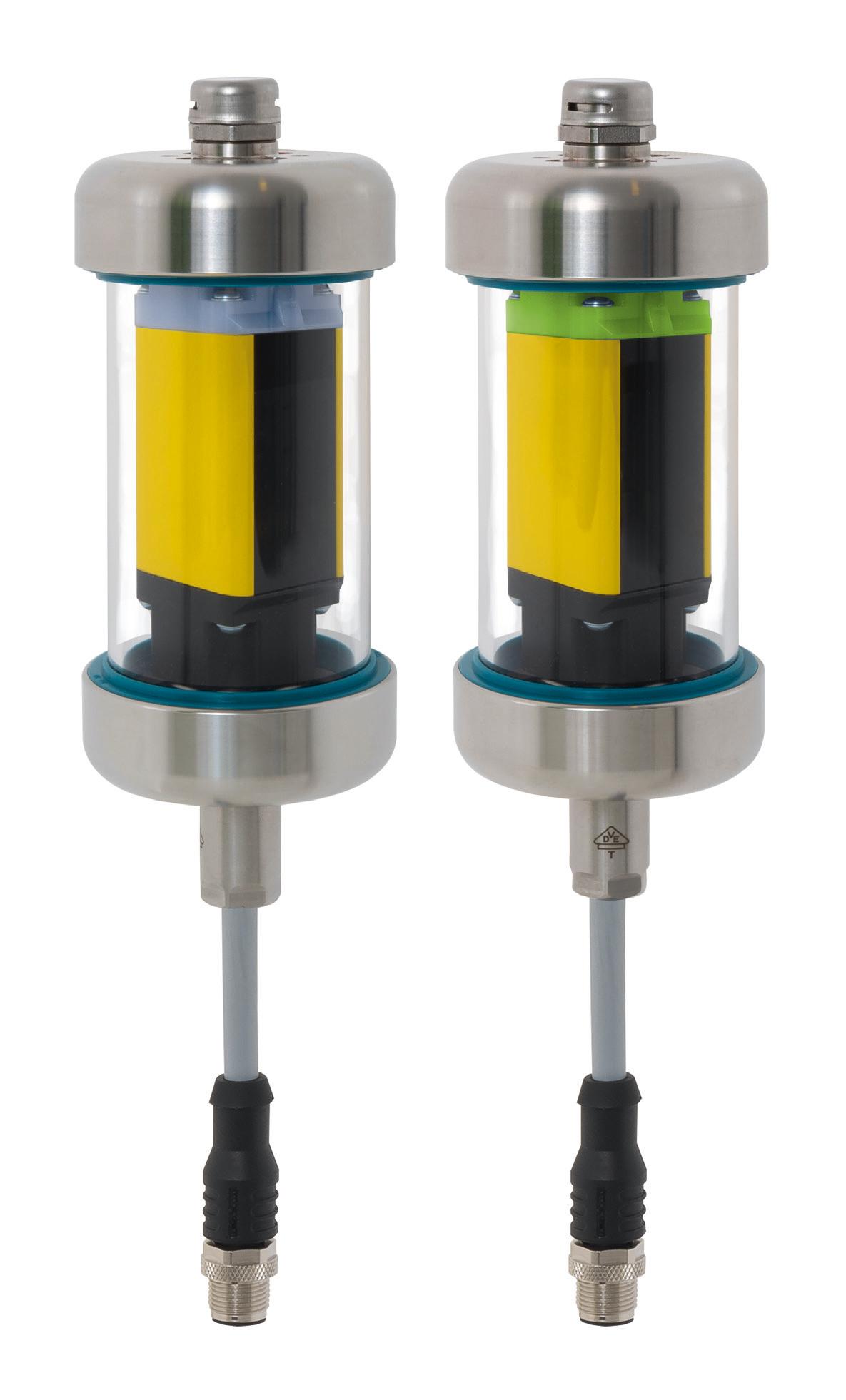

The Schmersal Group has designed a new safety light barrier especially for hygiene-sensitive uses in the food processing industry, such as milk and meat processing.

This version has evolved with the demands of standard cleaning operations in the industry as the sophisticated design helps to ensure IP69 degree of protection (protection against the ingress of water from high-pressure of steam cleaning).

The protective enclosure with external gaskets satisfies stringent standards and is designed to cope with frequent cleaning with water, foam, lyes, high-pressure or hot steam.

SCHMERSAL | Enigma Business Park Malvern, Worcestershire, WR14 1GL

www.schmersal.co.uk

uksupport@schmersal.com

Editor

Paul Attwood editor@mpemagazine.co.uk

Senior Editorial Assistant

Sophie Weir editorial@mpemagazine.co.uk

Features Editor

Harry Peters editorial@mpemagazine.co.uk

Production/Design

Laura Whitehead laura@lapthornmedia.co.uk

Sales Manager

Charlotte Chapman charlotte@mpemagazine.co.uk

Accounts

Richard Lapthorn accounts@lapthornmedia.co.uk

Admin Assistant

Jade Still jade@lapthornmedia.co.uk

Circulation Manager

Leo Phillips subs@mpemagazine.co.uk

Publishing Director

Maria Lapthorn maria@lapthornmedia.co.uk

Welcome to the latest issue of Manufacturing & Production Engineering Magazine.

This edition explores key trends transforming our industry— electrification, automation, sustainability, and supply chain resilience. We cover emerging technologies like humanoid robots, autonomous sewer patrols, and advanced CNC programming, all driving smarter manufacturing.

We also preview Advanced Engineering UK (NEC, 30–31 October), where electrification is reshaping the entire engineering landscape. As Simon Farnfield notes, it’s no longer just a mobility trend—it demands cross-sector collaboration, addressing supply chains and workforce reskilling. With expert speakers from Jaguar Land Rover, Silverstone Technology Cluster and more, the event promises to be a hub for innovation.

We hope you enjoy the issue. If you have news to share, contact us at editorial@mpemagazine.co.uk.

Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB Tel: 01843 808 102 05 12 26 33 48 Company News - Pre-Met on the charge with £500,000 ‘QSP’ relocation Electrification without limits: How electrification is transforming cross-sector engineering Interview - Dr. Paul Rivers, Director of Guidance Automation Events News - Lab Innovations 2025 to tackle sustainability and skills challenges Opinion Piece - The Future of Nuclear: Supporting Industrial Growth and Opportunity

COWI, the international engineering consultancy, has partnered with the University of Strathclyde to trial environmental DNA (eDNA) as a faster, more accurate method of measuring Biodiversity Net Gain (BNG). BNG, becoming mandatory for Nationally Significant Infrastructure Projects in England from May 2026, requires developments to leave natural environments in a measurably better state.

Funded through COWIfonden’s Fast & Furious innovation programme, the pilot focuses on UK railway sites but could apply globally across transport, energy, and urban projects. By analysing soil samples for DNA shed by plants, animals, and microbes, eDNA provides a richer biodiversity picture than traditional surveys, which are labour-intensive, seasonal, and prone to missing protected species.

The technology could help developers meet BNG obligations more efficiently, reducing risks, delays, and costs while providing a clearer understanding of ecosystem health. Trials are underway at multiple sites, with initial findings expected in December 2025.

Below: Andy Sloan, Executive Vice President, COWI UK & International

Ambienta-backed Babcock Wanson Group, Europe’s leading provider of industrial heating solutions, has acquired ACT Andaluces, a Spanish firm specialising in boiler and burner maintenance. Founded by Alfredo Córdoba Toro and now led by his children, ACT enjoys a strong reputation in Andalusia and will act as a regional hub for Babcock Wanson.

The deal strengthens Babcock Wanson’s ability to cross-sell solutions in Southern Spain, part of its strategy to expand direct operations across more than 14 countries. The company, backed by Ambienta and Kartesia, combines organic growth with targeted acquisitions to cement its leadership in sustainable industrial heating.

ACT will continue delivering high-efficiency maintenance and retrofits, while supporting Babcock Wanson’s push into hybrid and fully electrified boilers. This enhances the Group’s capacity to provide turnkey decarbonisation solutions and deepen its local service model.

Below: Left to right - Jamie Young, Eric Dugard and Colin Thomson

Pre-Met has invested £500,000 into relocating the operations and welding technology of Quality Springs & Pressings (QSP) - a business it bought at the start of January.

The leading metal pressings and stamping specialist has upgraded factory-wide electrical supply, freed up 10,000 sq ft of production space and created dedicated welding bays to support new opportunities in defence, aerospace and transportation.

All staff are now operational at the firm’s Studley Road factory in Redditch, with the management team keen to use the acquisition to capitalise on enhanced wire form and spring manufacturing expertise, as well as embedding robotic welding and assemblies into its overall service offer.

Four new jobs have been created so far, and this number could increase with Pre-Met recently securing JOSCAR approval, a global best practice supplier portal used by major OEMs, tier 1s and supply chain companies across the UK and Europe.

James Leng, Managing Director, commented: “Our order book has strengthened quite nicely since the acquisition, and this has given us confidence to re-invest in taking the next steps.

“Many existing clients have extended their order schedules, and this has been combined with securing new work in transportation, electronics, and construction products, alongside some renewals components to extend life of commercial scale recycling bins.”

Operating from Redditch since 1973, Pre-Met originally made high-value pens, cufflinks and telecommunication parts, with today’s company evolving into a critical, quality-assured supplier to aerospace, mobility, med-tech, construction, electronics and transport sectors, shipping its components to customers across the world.

Consistent investment in new technology and workforce development has seen it become

Datalink Electronics has partnered with Altus Group to install the Inertec Cube 460 selective soldering system, strengthening its automation and production capabilities.

Datalink, a contract electronics manufacturer with 40 years’ experience, chose Altus after a detailed evaluation of soldering platforms and robotic options.

The Cube 460 automates complex soldering tasks with

programmable angles, quickchange nozzles, microdrop fluxing, quartz pre-heating, and advanced software for traceability and warpage correction. It supports both leaded and lead-free processes, making it highly versatile for high-mix, low-to-medium volume production.

Business Development Director Aran said the investment will help Datalink scale while maintaining quality. Production Engineer Shane

a metal pressings and assembly specialist, offering a full product lifecycle from concept and design to prototyping and low, medium and high-volume production.

It has also worked tirelessly to achieve the highest levels of manufacturing performance, securing world class ‘right first time’ and quality scores, not to mention gaining ISO 9001, AS9100 (aerospace) and TS16949 (automotive) accreditations.

More recently, Pre-Met has reinforced its commitment to digital transformation by obtaining its Cyber Essentials security certificate.

Nooney praised Altus and Inertec’s technical support, while Altus CEO Joe Booth highlighted the project as evidence of growing momentum: “It’s great to see another Cube 460 in the field and to deepen our trusted partnership with Datalink.”

The collaboration enhances Datalink’s throughput and process control, aligning with its wider growth strategy.

Paint spraying and powder coating specialist Frederick Cooper has partnered with Birmingham agency Pull the Pin (PTP) to transform its digital strategy. Employing 160 people in Small Heath, the business supplies components across automotive, engineering, medical, hospitality, and consumer brands such as Heineken and Strongbow.

The move introduces a multi-channel approach including technical SEO and organic social media to raise awareness and generate new opportunities.

Managing Director Jon Stone said working with PTP marks a major step after years of in-house marketing: “Good isn’t enough anymore. The team at PTP has grabbed the challenge by the scruff of the neck.”

PTP, targeting £1.1m in revenues in 2025, is using its global agency experience and new AI-driven platforms to enhance marketing efficiency.

Head of Client Success Prenam Gill said: “Manufacturers increasingly want a one-stop agency.

“Frederick Cooper has recognised the potential and results are already strong.”

RS Industrial Services (RSIS), backed by Foresight Group, is experiencing major growth following investment in its workforce. Since January 2024, the Teesside-based engineering company has doubled its engineering team, grown its apprenticeship programme to 10, and opened a new training hub.

Metro Mayor Ben Houchen officially opened the facility, describing RSIS as “an absolute success story for the region.” The hub will train employees and address the shortage of skilled engineers, offering industrial training both onsite and at customer premises. RSIS also works with Middlesborough College to provide opportunities for local students.

Recently named Tees Business of the Year, RSIS delivers compliance-led servicing, breakdown support, and crane and lifting equipment installations, while its Industrial Supplies division continues to grow through new contracts.

CEO Mark Cawley said: “We’re investing in people and apprenticeships to tackle sector challenges and secure the next generation of engineering talent.”

Foresight’s Tavia Sparks added: “RSIS exemplifies the exciting businesses driving economic growth in the North East.”

From

As one of the largest and most experienced insurance brokers in the world, Gallagher can offer you a complimentary review of your existing insurance programme. Our team can provide detailed insights on how your business benchmarks against others in the industry, identify potential coverage gaps and recommend the appropriate values and limits for your policies. Additionally, with improving market conditions, we may be able to highlight opportunities where you could save on costs.

CONNECT WITH A SPECIALIST TODAY.

For further information, please scan the QR code.

By Yulin Wang, Senior Technology Analyst at IDTechEx

Historically, the automotive and logistics sectors have led the charge in adopting automation and robotics, ranging from mobile robots and industrial arms to collaborative robots. Now, in a similar trend, automotive OEMs and warehouse operators are once again taking the lead, this time with humanoid robots. Several industry giants, including BYD and Tesla, have announced plans to increase humanoid robot deployment tenfold over the next year. IDTechEx believes that this is a serious commitment and very likely to happen. This aggressive scale-up is expected to drive down costs significantly, accelerating adoption across factory floors.

According to IDTechEx, this momentum will culminate in the deployment of approximately 1.6 million humanoid robots in the automotive sector by 2035. 2025 marks a pivotal year, one in which many automotive manufacturers align on a collective belief: humanoid robots are set to become the physical embodiment of AI in the real world. Industry leaders such as Tesla, BMW, Mercedes-Benz, Hyundai, and Xiaomi are actively

investing in humanoid robotics, either through startups or in-house development.

Supply Chain Synergies: Automotive OEMs already possess robust supply chains that overlap significantly with humanoid robot components, such as motors, sensors (e.g., LiDAR and cameras), and batteries. This overlap enables OEMs to scale production efficiently while leveraging their bargaining power to reduce component costs, making humanoid robots more commercially viable across sectors.

Profitability and New Revenue Streams: While humanoid robots are still early in their development, they are well-suited for deployment on automotive factory floors due to their human-like form, allowing seamless integration without reconfiguring existing layouts. In the long term, OEMs envision humanoids reducing labor costs and generating new revenue streams by selling robots to other industries, helping improve thin automotive profit margins.

Currently, factory use cases are limited to

tasks like material handling, badge labeling, and inspection. However, technical challenges remain, most notably limited battery life (resulting in over 50% downtime), small payload capacity, and high costs.

Following closely behind, the logistics and warehousing industry is projected to be the second-largest adopter of humanoid robots. Facing acute labor shortages and rising operational complexity, warehouses are turning to humanoids as a promising solution. These robots bring precision and consistency to repetitive tasks, improving speed while minimizing human error.

The benefits are multifaceted: humanoid robots help lower labor costs, reduce operational disruptions, and offer unmatched flexibility, capable of adapting to varying tasks throughout the day. Their advanced sensors and AI also facilitate better space utilization, potentially increasing storage density in already-crowded facilities. Moreover, their ability to operate continuously without breaks maximizes productivity and extends operational hours.

Yet, widespread adoption is still in its infancy. As of 2025, humanoid deployment in warehouses remains below 5%, reflecting both technological and commercial barriers. Depending on the workload, each unit typically operates for 2-3 hours before requiring an equally long recharge, resulting in substantial downtime. While fast-charging solutions are emerging, they often come with higher costs and shorter battery lifespans.

Commercial viability is another sticking point. With limited field data on ROI and long testing cycles, Amazon reports an 18-month pilot period before scaling decisions, warehouse operators remain cautious. As with autonomous guided vehicles (AGVs) in their early days, humanoids are undergoing extensive evaluation before seeing widespread use.

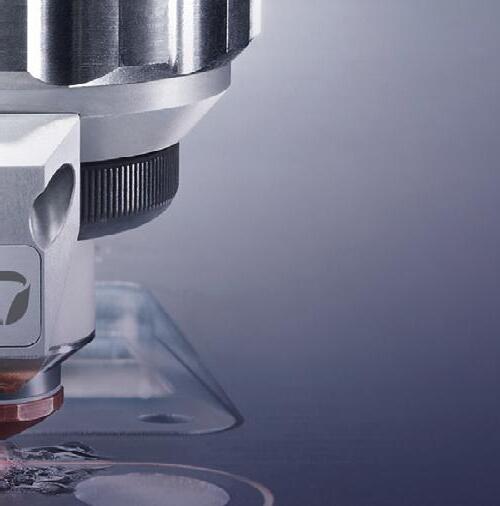

One of Sheffield’s newest manufacturers is helping to revitalise the city’s industrial capabilities with cutting-edge materials processing technology.

Sheffield Technology is winning a growing customer base, with some key projects being attracted back to the UK from overseas. The company is eager to leverage its ability to rapidly laser-cut materials up to 60mm thick— made possible by the company’s investment in a state-of-the-art 24kW Trumpf 5060 TrueDisk laser.

With fully automated material and part handling, this machine boasts a 6-metre by 2-metre plate capacity and can cut: Stainless steel, armour, carbon, and alloy steels – up to 60mm thick, Aluminium – up to 40mm, Copper – up to 16mm and Brass – up to 12.7mm.

Beyond laser cutting, Sheffield Technology’s extensive fabrication and machining capabilities include a

400-tonne, 5.1-metre press brake and automated cobot welding, allowing the company to deliver fully integrated manufacturing solutions.

Darren Mason, Works Director at Sheffield Technology, explained: “The big advantage for us is that we have truly disruptive technology. Our high-power laser operates at a scale and precision that challenges conventional thinking. While most lasers struggle beyond 30mm, we comfortably cut up to 60mm, allowing us to compete on both quality and cost with traditional heavy-duty processes, such as plasma & profile cutting.”

The company’s rapid expansion is reflected in its workforce growth, scaling from just 10 employees last year to 58 today, including four apprentices. With a firm commitment to developing future talent, Sheffield Technology plans to expand its apprenticeship program to pass on engineering skills that have defined the city for generations.

Darren commented: “We’re proud to be back in Sheffield, helping to underpin its metal processing history, and we trust the city will continue to attract work from across the country and beyond. Our capacities and state of the art equipment really do support continued competitiveness within the UK in this important sector, underpinning jobs for our young people in the years ahead.”

Sheffield Technology’s innovation and investment in advanced manufacturing can only support the city remaining at the forefront of British materials processing & manufacturing industry. Visit: www.sheffield-tech.com

Supply chain disruptions, driven by factors like natural disasters, geopolitical conflicts, and economic uncertainties, pose significant challenges for manufacturers. These disruptions highlight the need for robust risk management strategies that protect production timelines, minimise downtime, and ensure access to critical materials.

Proactive supply chain management has evolved from a strategic advantage to a critical necessity. It ensures customer satisfaction, meets delivery commitments, and supports long-term profitability.

“By integrating risk management at every level, manufacturers can achieve consistent performance and resilience across procurement, production, and distribution.” Steve Fletcher, Gallagher’s Joint Head of Office, Birmingham.

Resilient supply chains are essential not just for managing risks but as a driver of business success. Here are strategies to enhance resilience:

1. Reshoring Supply Chains

Relocating operations closer to home improves security and reduces costs associated with long supply chains. Investments in automation, AI tracking, and data-driven risk tools help mitigate higher local labour costs while streamlining processes.

2. Diversifying Suppliers

Overreliance on a single supplier increases vulnerability to disruptions. A comprehensive supplier network analysis helps identify dependencies and alternatives. Building partnerships across geographies ensures flexibility during crises.

3. Investing in Technology

Advanced technologies like IoT and real-time monitoring provide visibility into supply chain operations, enabling proactive risk management. Blockchain systems enhance transparency by tracking product origins and journeys.

4. Adopting Flexible Logistics Strategies

Static logistics frameworks often fail under changing market conditions. Contingency planning for transportation delays and flexible inventory management help businesses respond quickly to disruptions.

5. Strengthening Supplier Relationships

Collaborating with suppliers as strategic partners reduces risks like material shortages. Transparent contracts and open communication foster trust and enable effective crisis collaboration.

Partnering with a specialised risk management firm like Gallagher delivers benefits such as proactive risk identification, tailored mitigation strategies, and greater operational resilience. Gallagher’s Business Continuity Planning (BCP) and Disaster Recovery (DR) processes include Business Impact Assessments (BIAs) to evaluate risks and create effective mitigation plans.

Additionally, Gallagher’s Business Interruption insurance offers financial protection against critical supplier or customer dependencies, providing a safety net during disruptions. Proactive risk management safeguards profitability, supports operational continuity, and unlocks growth opportunities. Partnering with Gallagher equips businesses to build future-proof supply chains that remain resilient and competitive in an everchanging environment.

Scan the QR code to contact us and explore how Gallagher can help secure your supply chain.

Cloud and On-Premise install options

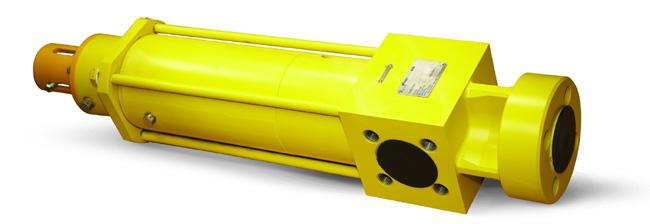

Electrification is gathering pace, moving from a mobility-focused trend into a catalyst for broader engineering and manufacturing change. As manufacturers, systems integrators and designers look beyond combustion and hydraulic technologies, this brings fresh demands on supply chains, productivity and design principles. Here, Simon Farnfield, event director at Advanced Engineering, explores the impact of electrification and the challenges facing the engineering community as we make the transition.

For many engineering and production firms, the most obvious impact of the electrification transition will be the strain it puts on their supply chains. According to a survey by Make UK, increases in cost of raw material, transport and energy are all driving supply chain disruption, with almost half of those surveyed having increased investment in supply chain resilience.

The disruption caused by electrification is almost inevitable: transition requires a shift in components – from hydraulic cylinders

to electric actuators, from internal combustion components to power electronics. These demand new sourcing strategies and supplier relationships. Just to illustrate this, the same survey by Make UK found that four-fifths of companies are diversifying their supply chains by increasing or reducing suppliers, and electrification will only exacerbate this trend.

By 2026, it is estimated that 91,000 engineers — nearly 20 per cent of the UK’s current engineering workforce — will have retired or will be about to. As systems become more electrified and connected, the skills required to design, install and maintain them are shifting.

Today, mechanical engineers are expected to understand electric drives and how they work. Similarly, control engineers must integrate energy monitoring and safety protocols for high-voltage systems.

We must focus on bridging these knowledge gaps, and initiatives such as Advanced Engineering UK’s ongoing #MINDTHEskillsGAP will be crucial. This campaign calls for closer collaboration between industry leaders and policymakers to develop solutions that will secure the next generation of engineering talent.

To harness the benefits of electrification, we must realise that no individual sector has all the answers. For example, battery thermal management techniques used in aerospace could help guide automotive production. Meanwhile, material science advances in robotics could shape EV motor design.

We can expect electrification to continue transforming the UK’s engineering and manufacturing industry, but this also poses several challenges that we must address. The impact on supply chains is one thing, but we must futureproof the skills and knowledge powering our industry, and this means creating a cross-sector collaborative space where ideas can be shared and innovation encouraged.

At Advanced Engineering, the Automotive Forum has been renamed the Automotive, Mobility & Electrification Forum. All three themes will be included in the program, covering the latest developments in commercial and private vehicles as well as motorsport and more. Speakers include representatives from the Engineering Integrity Society, Jaguar Land Rover and Silverstone Technology Cluster and much more.

To see the latest advancements in electrification and more, register your attendance at Advanced Engineering UK today, taking place on October 29 and 30, 2025.

2 days of networking

400+ suppliers

Josh Surga

Engineer

5 free CPD accredited forums 1000s of innovative solutions

10,000+ engineering professionals Scan here to register Association partners

Co-located with

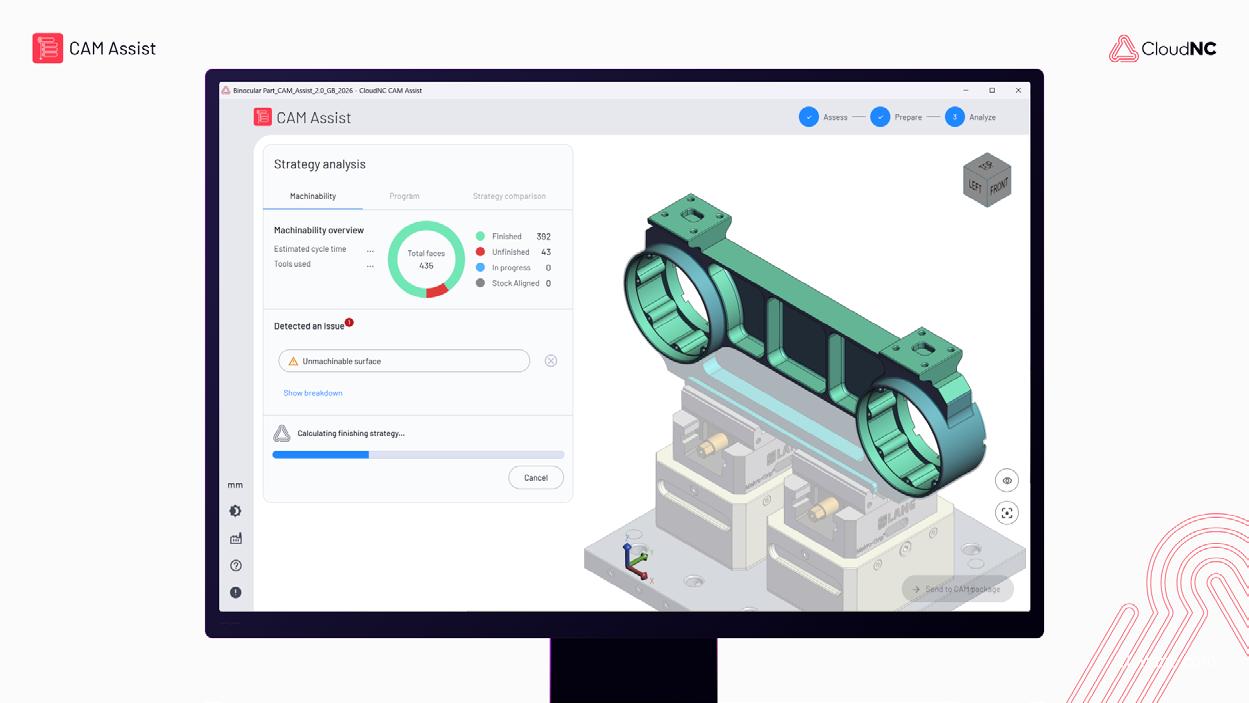

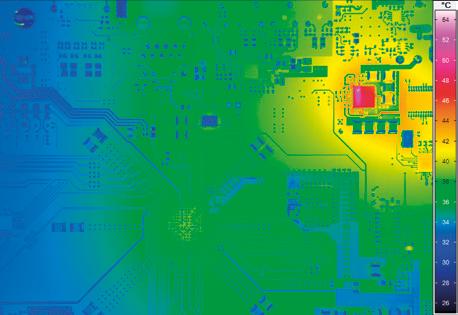

CloudNC has announced that its CAM Assist solution is now used by over 1,000 machine shops and machinists worldwide, who use the solution’s AI to accelerate the programming of CNC machines, making them more efficient.

Now, CloudNC is launching CAM Assist 2.0, a major upgrade to its AI solution that accelerates the CAM programming journey from CAD model to machine ready toolpaths, while giving users more control over each step.

CAM Assist 2.0 is a substantial enhancement to the existing software. It retains the speed of CAM Assist, while adding the oversight, feedback and shared intelligence elements that machine shops need in order to use AI with confidence.

Programmers using CAM Assist can now stay firmly in control of every critical decision, while still saving hours as they turn CAD models into reliable toolpaths.

CAM Assist 2.0 is a web-based CAM automation application that initiates from the user’s CAM package. 3-axis and 3+2 operations are supported.

In the new web UI, the user still generates a working toolpath by pressing the CAM Assist button.

In the new web UI, the user still generates a working toolpath by pressing the CAM Assist button.

Now, CAM Assist 2.0 breaks out the AI stages so that parts can be assessed prior to running. Moreover, as files are being computed, control over strategy editing is passed to the user.

CAM Assist 2.0 also makes machine, material, and tool assembly management easy, as it is tailored to the user’s shop environment and configures itself to the customer. With cloudstorage of these elements, CAM Assist can run faster, utilize more extensive tool libraries and parameters and serve as a common source between CAM programmers.

CloudNC will make CAM Assist 2.0 available to all customers across Autodesk Fusion, Mastercam and Siemens NX platforms, with further integrations to be announced soon.

Farnell powers up with extensive portfolio of new Nexperia products

Each year, Nexperia adds about 800 new product types to its range. In 2024, more than 70 new parts for analogue and power management applications alone were released. To support Nexperia’s product expansion, Farnell has expanded its SKU range in line with the growing portfolio to better serve engineers worldwide.

Nexperia is renowned for its quality and reliability in discrete components, power, and logic ICs and has made a substantial investment in manufacturing. This includes a $200 million commitment to SiC and GaN technology at its Hamburg, Germany facility. The investment is now yielding results, with a rapidly growing portfolio that includes power MOSFETs, wide bandgap semiconductors, IGBTs, as well as analogue and power management ICs.

These manufacturing advancements and new product introductions highlight Nexperia’s commitment to advancing production capabilities and meeting future demands, and Farnell’s expansion of Nexperia power products in stock reflects the desire to meet demand.

The new range of power products from Nexperia is now available and shipping from Farnell in EMEA, Newark in North America and element14 in APAC.

(+44) 1707

Visit Hamamatsu Photonics at Stand J124 to explore how our extensive portfolio of components, modules, and systems provides innovative, highperformance solutions to the manufacturing industry.

Find out more about our solutions

Light sources

• LEDs (UV – IR)

• Excimer Sources

• Quantum Cascade Lasers (QCLs)

• Deuterium and Xenon Lamps

• Extreme Ultraviolet (EUV) Light Sources

• Laser-Driven Light Sources (LDLS)

• Supercontinuum White Light Lasers

Optical sensors

• Mini-Spectrometers

• Photodiodes and Avalanche Photodiodes (APDs)

• Multi Pixel Photon Counters (MPPCs or SiPMs)

• Infrared Detectors

• X-Ray Flat Panel Sensors

• Photomultiplier Tubes (PMTs)

• VIS/NIR/X-ray Cameras

29th- 30th October 2025

Radar has become indispensable in modern sensing systems due to its robustness in challenging environments like fog, rain, snow, and darkness. Its unique ability to provide continuous, long-range, and accurate detection makes it a vital tool across many industries. However, radar alone doesn’t always offer a complete picture, especially in complex scenarios. This is where sensor fusion comes in—integrating radar with cameras and lidar to create a more reliable and comprehensive understanding of the environment.

Doubling Down on Doppler

Radar works by transmitting radio waves and analyzing their reflections, enabling detection of an object’s distance, relative

velocity, and motion. The Doppler effect allows radar to estimate speed and classify targets based on unique micro-Doppler signatures.

Advanced MIMO (Multiple-Input Multiple-Output) radar uses multiple antennas to improve direction, range, and speed accuracy. This is particularly useful in automotive safety and drone navigation, where high-resolution detection in compact systems is crucial.

Despite its advantages, radar has limitations. Its spatial resolution is lower than optical sensors, making it harder to distinguish closely spaced objects. Additionally, radar struggles in cluttered environments due to multipath reflections and may require more complex arrays to measure vertical angles.

To overcome these limitations, radar is often fused with other sensors. Radar and camera integration combines radar’s motion sensing with the camera’s visual data, ideal for applications like autonomous driving. While the camera reads signs and traffic lights, radar detects vehicles even in poor lighting conditions.

Adding lidar to the mix provides detailed 3D spatial information, though lidar can struggle in harsh weather.

As radar and AI continue to evolve, integrated sensing systems will become increasingly capable...

Radar compensates for this by offering reliable long-range detection, making the two technologies complementary. The ultimate sensor fusion involves combining radar, camera, and lidar, leveraging the strengths of all three: radar for range and speed, camera for object recognition, and lidar for spatial precision.

Sensor fusion has its challenges— hardware complexity, power demands, and real-time data processing. However, these are outweighed by the benefits of enhanced safety and performance in mission-critical applications like autonomous vehicles and space exploration. As radar and AI continue to evolve, integrated sensing systems will become increasingly capable, making sensor fusion not just an enhancement, but a necessity for future technologies.

The Lee Company announced the release of the Cryogenic Check Valve – the first product in our extensive lineup to be qualified for operation at temperatures down to -320˚F. This milestone reinforces The Lee Company’s position as a global leader in precision fluid control and marks the start of active and ongoing testing at our in-house cryogenic test facilities.

While the standard acceptance testing is performed at room temperature as a cost and time-saving measure, qualification testing for this innovative check valve was performed with the valve submerged in liquid nitrogen. This testing confirmed leakage results of less than 10 SCCM of helium at -320˚F.

The Cryogenic Check Valve incorporates fitting ends per AS standards, making it easy to integrate into existing systems. The valve’s materials were carefully selected for their compatibility with hydrogen and other fluids used at cryogenic temperatures. In addition, the valve’s adaptable construction supports material changes to suit a wide range of environments.

This product is ideal for use in aerospace and other missioncritical systems that handle ultra-low temperature fluids, such as satellite propulsion systems. Applications include cryogenic propulsion, thrust vector control, and thermal management loops using liquid hydrogen or oxygen, as well as precision fluid control in life support and fuel management systems. Find out more here.

When selecting industrial flow meters, many focus on initial cost and specifications. However, true value comes from considering the Total Cost of Ownership (TCO)—a more comprehensive measure of long-term performance and hidden expenses. Titan Enterprises, a UK leader in flow measurement solutions, emphasizes this oftenoverlooked factor.

As Trevor Forster, Managing Director at Titan, explains, ‘In many industrial applications, the purchase price is just a small part of the full cost. Downtime, maintenance, and recalibration can add up—this is where Titan’s meters stand out.’”

Titan’s flow meters are designed for longevity and minimal maintenance, reducing TCO over time. Key advantages include:

• Rugged Construction: Chemical-resistant materials and solid-state sensors for longer life in harsh conditions.

• Non-invasive Designs: Reduced risk of clogging and wear.Low Calibration Drift: Less frequent recalibration needed.

• Responsive Support: Rapid service to minimize downtime.

As industries become more datadriven, procurement teams are re-evaluating how they choose equipment. Titan advises buyers to consider:

• Long-term reliability

• Downtime and maintenance costs

• Availability of technical support

Forster adds, “When customers factor in the full lifecycle, our meters often deliver better value than cheaper alternatives.” A recent example: a customer’s oval gear flowmeter lasted 15 years in the field before needing repair.

Titan offers a range of meters suited to different applications, all designed with TCO in mind:

• Turbine Flow Meters: Costeffective for clean liquids.

• Ultrasonic Flow Meters: Low-maintenance with high accuracy.

• Oval Gear Meters: Durable for harsh chemicals and viscous fluids.

Water pumping stations are a crucial part of the UK’s water infrastructure and effective flow monitoring is just one of the essential stages in their overall operation. With water resources facing increasing threats from pollution, over extraction and the impact of climate change, it is even more crucial to conserve and manage.

Flow monitoring is a crucial requirement in pumping stations and other similar industrial water handling applications, helping to ensure efficient operation, optimising performance whilst preventing more serious potential problems. By continuously monitoring flow rates, pumping stations can be optimised to prevent issues such as pump failures, blockages, and excessive energy consumption.

Accessing real-time data provides operators with continuous data on flow rates, pump performance and well levels, allowing for immediate assessment and response. Data from flow monitoring helps identify issues such as pump cavitation or rising main problems enabling proactive maintenance and the prevention of expensive breakdowns.

Flow monitoring data can be used for regulatory compliance demonstrating compliance with current regulations, particularly regarding permitted storm and sewage overflows, something very much in the public domain at this time. Cost reductions are always welcomed, and efficient flow management can significantly reduce operational costs and energy consumption.

There are two basic types of flow in water systems and pumping

Over time the ability to measure the volume flow and flow velocity in pipelines, meant magnetic-inductive flow meters with a continuous measuring tube, were the preferred choice.

stations: open channel and closed channel (closed pipe) while the type of monitoring and measuring devices is quite varied. For example, open channel flow measurement, ultrasonic flow meters, bubbler flow meters, submerged pressure transducers, closed channel flow measurement and venturi nozzle devices.

Top of the list are direct flow measurement, sensors, including electromagnetic flowmeters, ultrasonic flowmeters, and Doppler

flowmeters. These are also used to monitor pump performance, measuring pump parameters like power consumption, pressure, and runtime, resulting in valuable insights into pump performance.

A good example is Baumer groups’ PFM43, a compact, yet robust and reliable electromagnetic immersion flow meter developed for handling high-pressure applications up to 100 bar and pipe diameters up to DN2000.

Advantages include simple and quick installation of the sensor, even in existing pipes, leads to considerable time and cost savings, as well as handling water pressures up to 100 bar - an ideal choice for use in pumping stations.

Over time the ability to measure the volume flow and flow velocity in pipelines, meant magnetic-inductive flow meters with a continuous measuring tube, were the preferred choice. However, this meant prohibitive costs for the purchase of standard magnetic inductive flow meters, plus expensive, timeconsuming installation using heavy equipment.

With the compact and easy-toinstall Baumer PFM43 immersion flow meter, it’s now possible to measure volume flow, flow velocity and temperature at high water pressures in the simplest way.

Ross-Shire Engineering (RSE) is trialling an online analysis system to monitor drinking water quality at a Midlands filtration plant. Using micro-mechanical technology, the analysis system fits a highly compact footprint. So far, the trial of the system is achieving accurate and repeatable results, and it is also minimising the need for operator intervention.

In a municipal drinking water treatment facility, CeraMac microfiltration technology can provide an excellent permeate quality, independent of raw water quality, removing pathogens and particles as small as 0.1 µm. This level of filtration is sufficient to provide an absolute barrier to pathogens such as cryptosporidium and clostridium perfringens, replacing the requirement for ultraviolet disinfection. This filtration technique is the basis of RSE’s modular, plug-and-play water treatment plant that can be fully assembled, tested and commissioned within the company’s facility.

Developed to treat poor raw water quality sources and turn it into high quality final water, the modular treatment plants are tested and proven before leaving RSE’s Muir of Ord site near Inverness. In addition to low chemical usage, the plant achieves unmanned operation, supported

A further advantage of the MEMS solid-state technology is its reliability...

by an automated membrane cleaning system. As a result of these advantages, South Staffordshire Water engaged RSE to optimise filtration at a reservoir-fed plant.

To monitor the quality of the drinking water produced by the filtration process and prove the results, RSE wanted to investigate alternative water analysis technology. Key to the plugand-play approach of the modular filtration plant is its compact footprint, enabling the system to be quickly assembled, tested, and transported to the required location – and take up minimal space when installed on site. To maintain these advantages, the water analysis equipment has to fit minimal dimensions.

However, analysis accuracy and repeatability could not be compromised, and RSE also saw advantages in an online system that would provide continuous analysis.

Since its installation, the Type 8906 has performed without any issues.

To fulfil these requirements, RSE invited Bürkert to provide its Type 8906 online water analysis system, which offered the crucial advantage of miniaturisation. Compared to traditional water analysis equipment, such as a steel turbidity sensor that would typically be installed on a metre-wide backboard, the Type 8906 incorporates analysis cubes that measure just 7x7x4cm.

Miniaturisation is achieved thanks to Bürkert’s Micro-Electro-Mechanical Systems (MEMS) technology that involves micrometer-scale mechanical structures integrated with electronics. The pH sensor, for example, is based on an ion-sensitive field effect transistor (ISFET) on chip, that measures pH without the requirement for a traditional glass electrode. For RSE’s trial, the supplied 1m panel included pH, chlorine, conductivity, oxidation-reduction potential (ORP), and turbidity.

In addition to miniaturisation of the sensors, the Type 8906 system also removes the traditional backboard, along with the associated pipework, sensors, electrical connections and wiring. This further reduces footprint, and as well as minimising materials cost, fewer components also reduce the time in design and build.

To answer the required accuracy and repeatability, the MEMS sensors

The MEMS sensors provided the required accuracy and repeatability required by RSE.

could also provide the level that RSE required. For example, the re-agentfree chlorine sensor, based on a high precision membrane covered amperiometric sensor, can measure between 0.01ppm and 5 ppm with a repeatability of +/- 0.02 ppm.

A further advantage of the MEMS solid-state technology is its reliability, largely due to the minimisation of moving parts, plus the resilience of the compact, silicon-chip design. Field use of the chlorine sensor, for example, has reported operation of over two years without any maintenance or intervention, thanks to the reagent-free and electrolytefree design. The silicon chip-based technology also removes the need to recalibrate the sensors, largely thanks to the stability of the material, where instead, traditional probes could require annual, or even quarterly recalibration.

The online capabilities, combined with a system digitised from the sensor chip upwards, also achieves the

generation of analysis and diagnostic data. Water quality results, along with any system issues, can be read from the plant’s SCADA system. The Type 8906 is available with Ethernet-based communications including Profinet, which RSE have sighted as a solution to directly integrate with their PLC and minimise IO cabling requirements.

The trial of the online analysis system started in January this year, and with a flexible time period to review performance, it is set to remain in place for another six months. So far, the system has provided drinking water analysis in line with the specified levels of precision and repeatability. Online diagnostics have also confirmed that the unmanned system has been operating without issue or intervention since its installation.

Several municipal water treatment plants across Europe have already permanently installed Bürkert’s Type 8906 online analysis system and wider

trials are getting underway in the UK this year. Invitations are open to municipal water companies to conduct their own trials.

L ive online , classroom , blended ,

• Gain or renew your 5-year Certificates of Competence*

• Courses f for each career stage based on EEMUA 159

• English, Dutch, German and French language options

• Free or discounted for EEMUA Members and Associates

TankAssessor courses*

6-9 October – in French – Lyon, FR

20-23 October 2025 – in Dutch – live online

3-6 November 2025 – in German

– live online

17-20 November 2025 – in English

– live online

Tank Integrity Manager course

1-5 December 2025 – in English

– Antwerp, BE

In-house courses

By arrangement for your choice of: time, language, location.

TankInspector courses*

13-15 October 2025 – in English – classroom – Manchester, UK

27-29 October 2025 – in Dutch – classroom – Rotterdam, NL

16-18 February 2026 – in English – live online

23-23-25 Februa 2026 – in Dutch – live online

TankBasics courses

6 October - 27 November 2025

– in Dutch – blended, live online

Storage Tanks e-learning

On-demand – in English or Dutch

Also...

Storage Tanks Seminar –Ridderkerk, NL – 27 November 2025

More choices, information and registration at www.eemua.org

Artificial intelligence alone won’t solve the challenges Canadian manufacturers face in today’s global trade environment, says Jayson Myers, CEO of NGen. Ahead of his appearance at the Canadian Manufacturing Technology Show (CMTS 2025), Myers urged businesses to adopt a broader approach that combines AI with advanced materials, robotics, and reliable data systems.

“AI will never achieve flexibility, cost reduction and process improvement on its own,” Myers said, citing research that 70% of digital transformation projects fail in Canada. He pointed to companies like Maple Advanced Robotics, whose AI-enabled sanding system integrates vision and force-sensing technologies to eliminate costly reprogramming, and Carbon Upcycling’s low-carbon cement initiative as examples of innovation with impact.

NGen will showcase 15 advanced manufacturing projects at CMTS 2025 (Sept. 29–Oct. 2, Toronto Congress Centre), part of its $32.3m investment that has already generated $7bn in sales, 55 company launches and 3,500 jobs.

IGD has launched its new allergen risk assessment template and accompanying guidance. This significant initiative is set to bring greater consistency in allergen procedures and support improved food safety for allergy sufferers nationwide.

With food allergies and intolerances rising across all UK demographics, the need for a consistent and effective approach to allergen management has never been greater.

The new template will help to eliminate confusion caused by inconsistent labelling and

A New Era of Intelligent, Agile, and Sustainable

Tech Mahindra, a leading global provider of technology consulting and digital solutions to enterprises across industries, today announced the launch of its latest global research report, ‘The New Era of Adaptive Manufacturing’. The report offers exclusive insights into how manufacturers are reimagining their operations to stay competitive in an era defined by disruption, complexity, and constant change.

Based on a survey of 690 senior manufacturing leaders from organisations with over 1,000 employees across the Americas, Europe, and AsiaPacific, the report highlights how enterprises are prioritising adaptability, sustainability, and intelligence across the

ultimately support a safer shopping experience for consumers.

The new allergen risk assessment template is the result of extensive collaboration through IGD’s Technical Leaders Forum and Network which bring together senior stakeholders throughout the food and consumer goods industry, to discuss common technical issues and strategic opportunities.

IGD was able to facilitate open dialogue in its role as an impartial industry convenor, to coordinate the development of this industrywide solution.

value chain. The report further examines the state of digital manufacturing, AI adoption, workforce skills, and supply chain resilience, revealing critical trends shaping the industry’s future.

Adaptive manufacturing is now a global imperative: 99% of manufacturers confirmed they are adapting to changing market conditions, customer expectations, and demand volatility. This reflects that agility and resilience are fundamental to survival and growth.

The report reinforces Tech Mahindra’s vision of adaptive manufacturing as a blueprint for the industry’s next era, where intelligence, agility, and sustainability define value creation. Tech Mahindra is committed to partnering with enterprises to navigate challenges, embed sustainability into their core operations, and harness AI responsibly to drive measurable impact. By combining advanced technologies with humancentric innovation, Tech Mahindra aims to empower global manufacturers to scale with confidence, transform with purpose, and thrive in a dynamic marketplace.

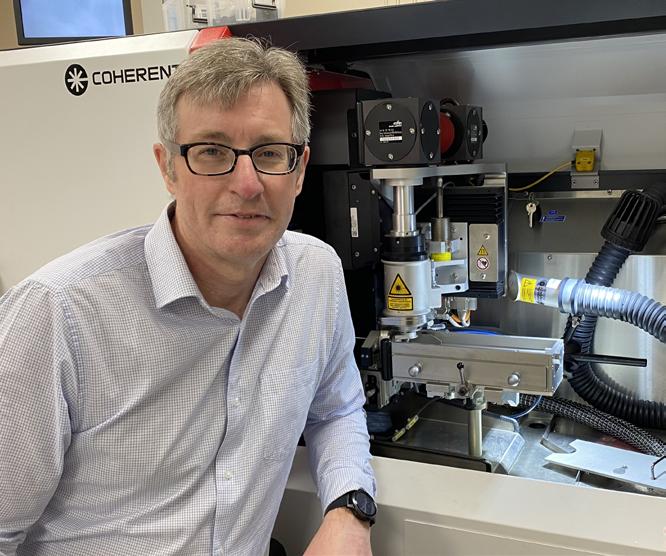

Lincoln-based manufacturing firm Micrometric is continuing to lead the way in laser manufacturing and multi-process services.

The company, which was established over 40 years ago, produces fine parts and precision components for a range of customers in the UK and international markets. It specialises in a range of services including cutting, etching, drilling, and welding as well as tube cutting and precision component machining.

Commercial Director Chris Waters said: “Lasers are at the heart of everything we do, and we have the relevant capabilities and laser equipment to cut, assemble and weld complex manufacturing medical devices including small tubes, injection needles, and endoscopes and intricate parts required for surgical equipment. We have built up a reputation for our personal approach with customers as we want to fully understand our customers’ laser cutting requirements. We’re committed to providing exceptional, customised services that help our customers achieve their goals faster and with greater precision.”

Chris added: “Our laser machines are suited to cutting materials with a

wide range of thicknesses and can cut a range of materials including metal, plastics, and ceramics. We offer micro laser cutting capabilities that allow small parts to be cut to tight tolerances down to +/-0.02mm (material and thickness dependent) across a variety of materials including stainless steel, titanium, copper, brass, and ceramic.

“We are AS9100 qualified and can supply process sheets, certification, first article inspection reports or similar inspection regimes to clients, as required. We use several CO2 and state-of-the-art fibre laser cutting systems which precisely cut materials with minimal heat and excellent edge quality to produce components quickly, efficiently, and cost-effectively.”

Since investing in this equipment, Micrometric’s skilled workforce has used the machines to cut, assemble and weld complex medical and aerospace components for

LEFT: Laser welding

BELOW: Laser cutting examples

LEFT: Chris Waters

companies which produce aerospace filters, automated injection needles, endoscopy components and MRI scanning equipment as well as producing finer, precise parts for other sectors.

Micrometric is equipped with a range of lasers and its experts can weld a wide range of parts to deliver highquality solutions.

Chris added: “Laser welding offers the benefit of welding while minimising heat input which is critical when welding components with temperature-sensitive items inside them or minimising any distortion due to heat. We can also weld autogenously or with wire feed. Depending on the metallurgy of the parts, it is possible to add different alloys as wire to adjust the weldability of the component. The wire feed can be fully automated within the welding machine. For some welds, such as titanium, an inert atmosphere is required, and an enclosed argon welding system is used.”

Micrometric offers a range of inhouse and resourced services to complement its laser machining services and has dedicated equipment for laser drilling, cutting, etching and welding applications. Its extensive work of sub-contracting means that it’s able to offer a single point of contact for manufacturing parts from the initial process through to completion, helping to reduce lead times and production costs.

Micrometric is a member of the Midlands Aerospace Alliance (MAA), The Manufacturers’ Organisation (MAKE UK), Association of Industrial Laser Users (AILU), and Motorsport Industry Association (MIA).

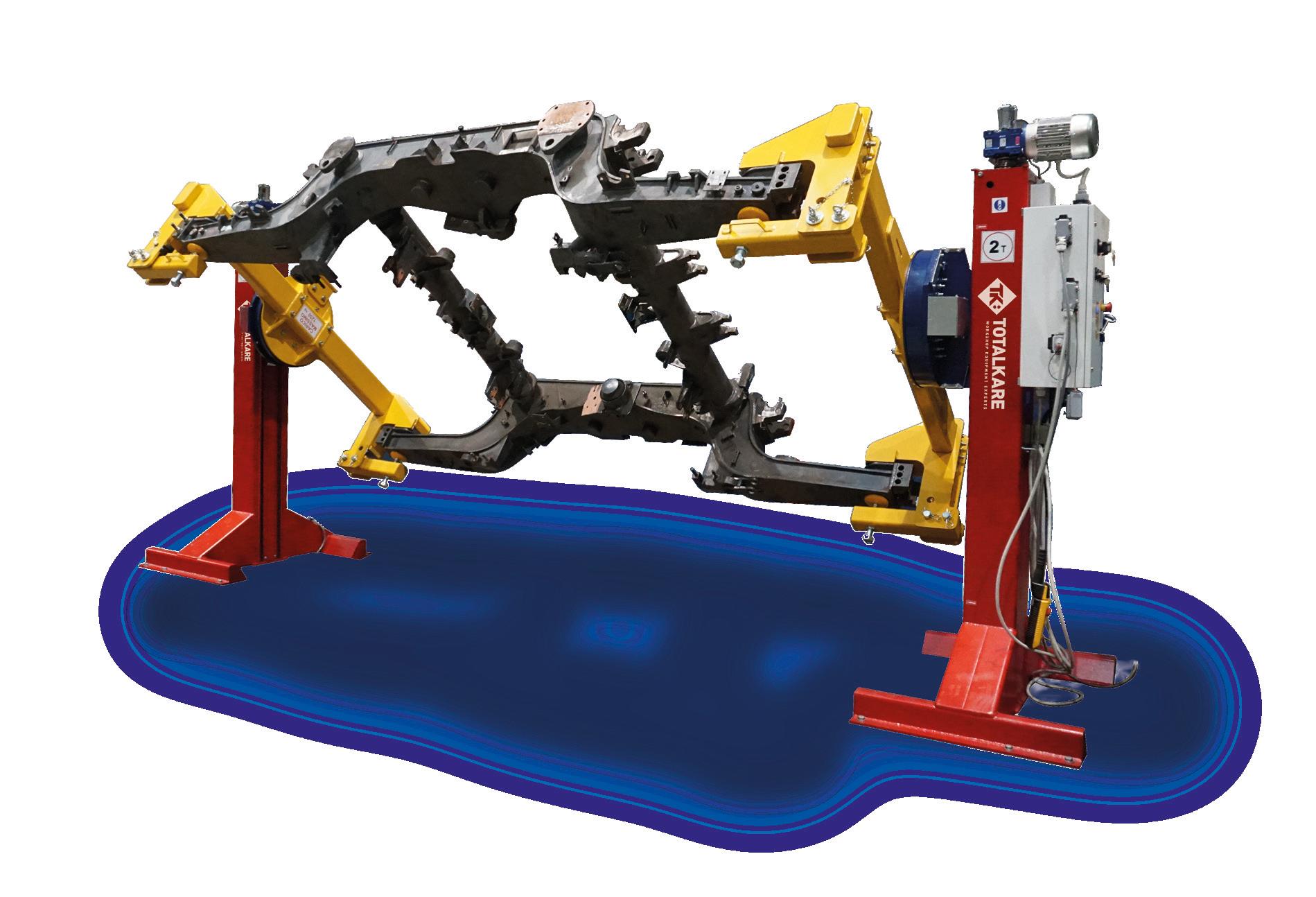

As manufacturing faces increasing pressure to boost productivity and efficiency, automation is often seen as an expensive, high-risk investment — especially for SMEs. Dr. Paul Rivers, Director of Guidance Automation, is challenging that narrative with a bold, low-risk model: automation by the hour.

In this interview, Dr. Rivers shares the inspiration behind this disruptive approach, the misconceptions holding manufacturers back, and how real-world results — from tripling productivity in welding bays to reducing reliance on scarce skilled labour — prove that automation can be both affordable and empowering.

What prompted the creation of the “Automation by the Hour” model?

The price of automation was the trigger! We spent about 10 years helping companies that made electric vehicles, to automate them. We developed the software that manages vehicle control and fleet management which is the key component. The part that always amazed me was that a fork lift truck could be bought for around £40k and we would then add around £10k worth of additional electronics (inc safety) and the new sales price for this upgraded vehicle was £150k. It would make my eyes water.

Was there a particular challenge or customer demand that led to this approach?

After being acquired by an American company we spent a few years selling other people vehicles, combined with other products, to make complete solutions. Effectively we became

an integrator. Again being exposed to these buying prices and combining the products, we didn’t have much wiggle room on price to our customers. Large companies could afford to pay and could justify the return on investment. SME’s struggled to realise the benefits in a reasonable time frame and so would shy away from automation after receiving their quotes.

Recently we did a MBO and made Guidance independent again. We had developed our own vehicles, based on the knowledge we had gained from looking inside so many other people’s vehicles when we were automating them. We learnt so much about the performance, component selection and reliability of various bits of hardware, we could select correctly and quickly. I have a passion to help people solve problems. SME’s have real opportunities for automation, they need it. So I wanted to make it affordable for them. The hardware was designed, the software was developed, I had a very low cost base, so why not help other SME’s automate, at a fair price, no risk to them by trying a solution. So we effectively give the vehicles away, our customer has the robot worker doing the low value tasks (moving goods around) and that frees up the human worker to do the more challenging, much less repetitive tasks. My customer saves an hour of human labour, pays me for an hour of robot labour and by doing this at half the human wage, we share the benefit. We both have skin in the game. ROI from the first hour!

What are the key misconceptions manufacturers – particularly SMEs –have about automation today?

If you see a forked AGV, you recognise it as a pallet mover. You know what it does and if you have fork lift trucks in your facility, you can easily see how paying for an AGV at half the cost of a FLT driver, would be appealing. The challenge with

The UK has suffered from productivity stagnation which causes a vicious cycle: less profit means less money available to invest which in turn limits efficiency gains.

- Dr. Paul Rivers

smaller vehicles is that until they have a “top” on them, they don’t actually have a function. That function and top design is usually what brings together the solution for a specific application. Most SME manufacturers don’t have an automation expert in-house, they are excellent at what they do in terms of improving throughput, cell layout, flow etc, but there is a challenge to find somebody with experience that can advise. If you do take advice from an external source, maybe an integrator wanting to sell you something, there are large CapEx costs, long ROI and so the risk of the unknown will keep SME’s going as they are. Long ROI, the finance company wants a 5-year

lease and you have no idea if the solution will work as intended or gain as much efficiency as first thought.

Pay-by-the-hour, with no long contract, means that we can actually try a solution at a customer’s site, they can see the results in real time. There is no hard sell, if it’s not right for a customer, for whatever reason, we can take it out, no penalty. We would of course only install a system if Guidance believes it will work and add value. Automation isn’t right for every environment and processes. I just believe that with flexible contracts, ease of integration, no CapEx, why wouldn’t you try it? It’s a personal thing, be fair and honest with people, build trust and partnerships, we can grow together.

You mention real productivity gains from projects in sectors like medical and soft furnishings – could you share a specific case study or outcome that stands out?

One of the first projects that we installed was with a medical devices manufacturer. They had 5 welding bays and had recently done an analysis of how many hours the welding machines in these bays were running on average. A time and motion study, who welds the most units per hour and what can be learned from each other to improve performance etc. The welding tools

were actually running for 10 minutes per hour (in each bay). It transpired that the welders would walk the 87 m to stores to collect some parts and wheel them back on a trolley to the bay. The assembly and welding would take place and then removing all of the PPE again, they would take the finished item to the spray shop and hand it over to another department.

Initially we added just one vehicle, the trial. The Robot worker was tasked with moving kitted parts from stores and dropping them at the welding bays. It did that for 9 hours per day, backwards and forwards (actually it collected some machined parts from another area en-route back which needed moving to stores).

It isn’t just the walking time that human workers can save, covering a 180 m distance, you pass many colleagues and exchange pleasantries (sometimes extended), there is a phone to check, toilet breaks, you understand what I am saying.

After a short period, the welding increased to 30 minutes per hour (across all 5 bays), with just one vehicle. That was a 3-fold increase in welding of 5 people, with the addition of just 1 robot. The vehicle cost half the human minimum wage per hour - the welders are skilled workers and paid higher wages. The second step was to add another vehicle to take the finished goods to the spray shop area, this would add another 10 minutes of welding gain (per cell) and could also take finished goods from the spray area to the assembly cells.

Guidance is looking for investment so that we can roll this out at an even quicker pace.

- Dr. Paul Rivers

The welders didn’t need to walk around, constantly put on and take off PPE. The productivity gain was fantastic.

How do you address concerns around automation displacing skilled workers?

So in this case the automation allowed the skilled workers to use their skills more, welders were welding more, and the spray team were completing more items. There’s a huge number of skills within a manufacturing process that a human does really well. They are not efficient a low value tasks, which the robot workers can therefore do better. A combination of human workers and robot workers means that we can utilise both more efficiently and gain the best from both parties.

Then you can train the humans to be more productive and learn new skills for themselves and the business. Skilled workers are aging and are becoming harder to find, humans like to learn new skills if they are in the right environment with the right employer.

How do you frame automation as a tool for empowerment rather than replacement?

Pushing a trolley (gets harder as the day goes on) or driving a fork lift truck can also be dangerous around humans, the autonomous vehicles are safer. They drive at a defined speed, will always follow rules and always give way to the human workers. Humans are not well designed for repetitive tasks, but they do want to do a good job, use their ability to improve, learn a better way and improve a process if they are empowered to do so.

They are also a little competitive too. Taking away repetitive tasks allows them to shine at what they are good at

Why do you think the UK is still lagging behind other G7 nations in automation adoption – and what needs to change?

As a country we have under invested in technology which helps to drive automation. The UK has suffered from productivity stagnation which causes a vicious cycle: less profit means less money available to invest which in turn limits efficiency gains. We are dominated by SME’s in the UK, which again reduces available capital expenditure for growth. A lack of skills in automation and AI, means that the UK is behind the curve too. Whilst we are trying to buck the trend by manufacturing in the UK ourselves,

generally the UK doesn’t have a thriving automation industry of its own, it relies on imported solutions. Finally UK managers are very risk-averse.

How important are pilot trials and hands-on demos in building confidence in automation solutions?

Pilot trials gain lots of knowledge for the client that is trying it. A client can see a robot worker in their environment; feel confident that it can share the same space as the human work force. Gain knowledge of the real world, how many drops per hour can it do, how can other processes be modified to adapt to the new opportunity to make potential further improvements etc. But most importantly, taking away the risk of investment (other than time), with the

knowledge that there are no penalties if it doesn’t work, you become more confident. If you are a production manager for example and you want to try automation, if you convince your boss to spend £100k on a robot worker and the project doesn’t go to plan, you look as though you failed, but if you spend a few thousand on a trial and it’s a success, you gain a pat on the back for a great idea. Everybody wants to look good to the boss!

From a trial we can see exactly how many robot workers will provide the best return and if you need extras at certain times of the year, we can add vehicles for short periods too, so a very flexible solution for those whose businesses have peaks and quieter periods in their annual cycle.

Larger companies that could afford the CapEx and buy a solution outright, want to do trials and prove concepts with our model and then potentially buy the solution afterwards. So it starts as a concept, we all learn from it, maybe adjust the operation and then we can look for the right way forward. We can be flexible and adapt.

Finally, what’s next for Guidance Automation – are there new innovations or capabilities in the pipeline?

Guidance is looking for investment so that we can roll this out at an even quicker pace. We keep combining different technologies to expand the solutions that we can offer, so by combining our robot vehicles with our pick-to-light software, we can add cobot arms into the mix and go pick the parts too, not just move them around production or warehouse environments. Our aim is to keep humans doing interesting work, in a safer environment. I want to employ apprentices to learn how to build robots, service them, and install them. Guidance is about giving back, upskilling our customers’ workers and training the next generation with the latest technology that becomes available. Treating our customers as partners, we both win. I have confidence in the technology and solutions that we provide and that’s why I don’t mind taking on all of the risk.

To find out more visit: guidanceautomation.com

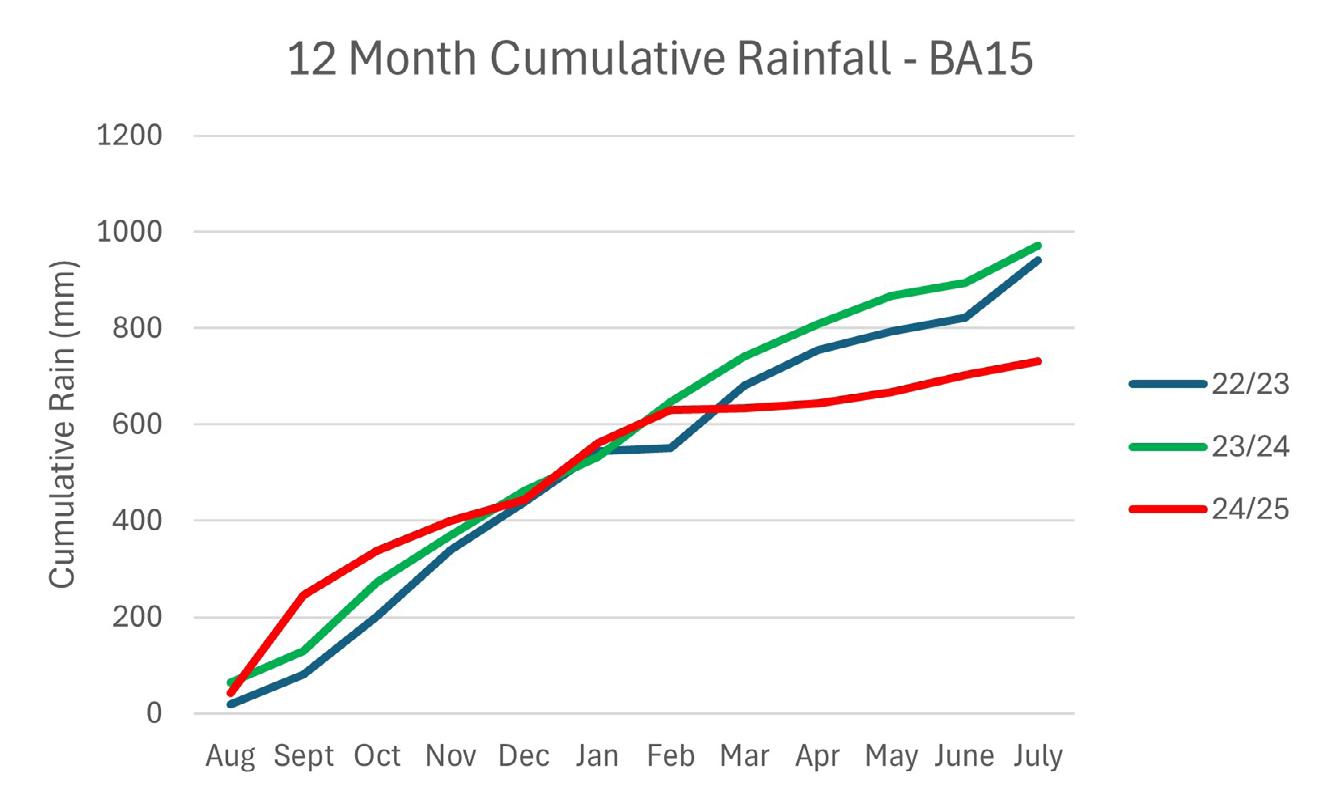

By Lorna Davis, Director, SuDSPlanter

As climate change drives both heavier rainfall and prolonged dry spells, SuDS are increasingly viewed as a tool to address both challenges.

With parts of England facing what the National Drought Group describes as a “nationally significant” water shortfall, water companies are responding in line with their drought plans. This includes stepping up action on leakage and communicating with customers on water efficiency –alongside major long-term projects to ensure future supplies.

Less prominent in drought and resource planning is the implementation of sustainable drainage systems (SuDS). While primarily considered in the context of flood mitigation, SuDS, which are designed to naturally capture, store and release rainwater, can play a meaningful role in tackling water scarcity.

The process of slowing and storing runoff during storms, and encouraging ground infiltration, not only eases pressure on sewer networks, it builds resilience to dry weather in a sustainable way. This forward-looking approach to water stewardship and climate preparedness yields numerous societal and environmental benefits,

in addition to its critical role in reducing flood risk.

The potential role of SuDS in water resource planning is acknowledged by the introduction of National Standards for Sustainable Drainage Systems, which apply to the design of systems for new developments.

Published in July 2025, this governmental guidance from Defra links drought resilience to many of its broader principles - noting that a natural approach to managing water can help meet future resource needs. While not mandatory, the

standards encourage a mindset change among developers – from viewing runoff as waste to be disposed of, to a resource to be collected and reused.

Many SuDS features - like swales, wetlands, rain gardens and detention basins - slow down and store rainwater rather than sending it straight into drains. This stored water can infiltrate into the ground to recharge aquifers or be used later for irrigation, which helps during dry spells.

Infiltration-focused SuDS like soakaways and permeable pavements allow water to seep into the soil. Over time, this supports groundwater levels, which is crucial for ecosystems and water supplies in drought conditions. Vegetated SuDS like green roofs and rain gardens help keep local areas cooler and reduce heat stress for plants and people – important in a heatwave.

The soil and planting design in some SuDS is chosen to retain moisture, supporting vegetation during rain-free weeks. Healthy soil holds more moisture and releases it slowly to plants, reducing the need for extra watering in dry periods.

SuDSPlanter systems incorporate a unique nutrientrich soil mix – made locally to our manufacturing base in Wales - that allows for water infiltration and retention, so plants can thrive in all conditions. The installations, which capture and store rainwater runoff from roofs, were designed to support flood mitigation and drought resilience – a dual functionality that enhances the urban environment in the face of changing weather patterns.

Just as important as the design aspect, SuDS can be an engaging learning tool and promote behaviour change. Installations, like planters in schools, often include visible, educational elements which build awareness of the value of water. Planters are being used to enhance children’s understanding of the water cycle – not just those in ecoclubs, but all pupils – and the pride shown in being part of the project. As climate pressures intensify, society is rethinking how it manages rainwater.

COBA’s ReGen range of ergonomic mats, made from reclaimed PVC, is helping workplaces reduce fatigue and environmental impact.

In every sector, from logistics to manufacturing, the pressure is on to find ways of working that are not only efficient and safe but also environmentally responsible. While attention often falls on headlinegrabbing changes like renewable energy or carbon offsetting, the quieter shifts—those that focus on materials and everyday workplace essentials—are just as crucial.

One of these shifts is happening in the world beneath our feet. Floor coverings such as anti-fatigue mats may seem like a small detail, but in factories, workshops, and warehouses they play an essential role: protecting workers from fatigue and insulating against cold or hard flooring.

For employers, procurement managers, and health & safety officers, mats are rarely top of the agenda. Yet the choice of everyday products— whether packaging, cleaning supplies, or floor coverings—adds up. Shifting to options that incorporate recycled content is a practical way to reduce a company’s environmental footprint without disrupting operations or demanding additional investment in training or infrastructure.

COBA, a manufacturer with decades of experience in workplace safety and wellbeing solutions, has introduced its ReGen range of ergonomic antifatigue mats, made with reclaimed PVC. This initiative challenges the traditional reliance on virgin plastics by reclaiming post-industrial PVC waste— by-products that would otherwise be discarded—and transforming it into high-performance workplace mats. The process reduces demand for new raw material, diverts waste from disposal, and creates a product that is both practical and circular in origin.

What does “post-industrial waste” mean?

Every manufacturing process generates scrap material. In the case of PVC, trimming, offcuts, or excess compound often end up unused. Instead of treating this as landfill waste, the ReGen process softens and reworks it into new material, ready for use in fresh applications. The result: a reduction in waste streams and a step towards closing the loop in PVC manufacturing.

Balancing sustainability with performance

There is always a challenge in ensuring that recycled content doesn’t compromise safety or durability. The ReGen range demonstrates that balance:

• Orthomat® ReGen 100 is made with 100% regenerated material, designed for lighter industrial use where workers are largely stationary.

• Deckplate ReGen 70 combines 70% regenerated content with a dual-layer construction, offering extra resilience for tougher environments.

Both provide the same ergonomic and safety benefits as conventional anti-

fatigue mats, proving that sustainable design doesn’t require compromise.

The bigger picture

No single product will solve the sustainability challenge facing industry. But initiatives like COBA’s ReGen anti-fatigue mats illustrate how incremental changes can add up to significant progress. By rethinking materials, manufacturers can help reduce resource use, extend the life of what’s already produced, and contribute to cleaner supply chains.

Sometimes, the most meaningful changes are the ones we barely notice—like standing on a mat that helps reduce waste as well as fatigue.

Regal Rexnord will present its braking and drivetrain solutions at HUSUM WIND 2025 (Hall 3, Stand 3C33; outdoor Stand 0F10), showcasing tools and certified spare parts designed to improve safety, reduce downtime, and extend turbine life.

The company’s Roadshow Truck will feature interactive demonstrations of its Lifting & Installation Tool (LBS 120) and yaw disc resurfacing tool (DRTGen.2), which enable faster brake replacement and on-site machining – halving downtime and reducing crane costs.

Regal Rexnord’s portfolio spans trusted brands including Svendborg Brakes, Stromag, and Warner Electric, supporting a global fleet of more than 200,000 turbines. With more assets reaching maturity, the company stresses the importance of predictive servicing, IIoT-enabled monitoring, and using certified parts to preserve turbine safety and performance.

Global Aftermarket Manager Wind Dierk Sternberg said: “Preventive maintenance isn’t just cost-effective, it’s vital. We support customers with approved parts, expert technicians, and reliable tools that maximize return on investment.”

We support customers with approved parts, expert technicians, and reliable tools that maximize return on investment.

Made in Britain to ‘champion UK manufacturing’ on national events tour

Made in Britain is standing up for excellence in British manufacturing this Autumn at some of the UK’s most influential industry, political, and trade events.

From party conferences to rail and engineering exhibitions, the not-for-profit organisation will use each stage to amplify the voices and impact of its 2,200+ members – and show just how far the Made in Britain mark can take a UK business.

With product examples ranging from prize seed potatoes to toilet cisterns, traffic bollards to manhole covers, and cooling caps to wheelie bins, Made in Britain’s mission is clear: to promote British-made products while driving sustainable growth for UK manufacturing and the broader economy.

From globally recognised firms like Polypipe, Vauxhall, Forterra and Tigerplay, to niche innovators like Lockabox, British Drum Co., and Forbes & Lomax, Made in Britain members represent the diversity and dynamism of UK manufacturing.

Showcased products will range from invisible light switches and picnic benches to neon signage, NHS hairnets, and the iconic Thomas Crapper toilet systemall certified to carry the Made in Britain mark.

With political, industrial and consumer interest in provenance and sustainability at an all-time high, Made in Britain is using its autumn tour to make one thing clear: when it’s made in Britain, it matters.

Visitor registration is now open for Lab Innovations 2025 (October 29–30, NEC Birmingham), the UK’s largest exhibition for the lab community. With over 200 exhibitors and thousands of attendees, this year’s theme “co-LAB-orate” will focus on sustainability, collaboration, and skills.

Laboratories, which consume up to ten times more energy than offices, face growing pressure to reduce environmental impact. The event will showcase solutions through the Sustainable Laboratory feature and Sustainability Pitches, highlighting low-impact products.

To break down silos, attendees will access CPD-accredited talks, networking spaces like the Lab Square, and interactive workshops on robotics, biotech, and accreditation. Exhibitors include AstraZeneca, Bronkhorst UK, and Innovate UK, with experts on hand to answer technical queries.

Returning speakers praised the event’s role in driving collaboration. Journalist Tom Whipple described it as vital for “building community and making contacts,” while Department for Business and Trade’s Ajay Desai noted its value for exposing businesses to new opportunities across the supply chain.

The Engineering Construction Industry Training Board (ECITB) has revealed the 26 finalists for its 13th annual Training & Development Awards, taking place at Glaziers Hall, London, on November 6. The event will celebrate excellence in training, bringing together leaders and rising talent from across the industry.

Finalists, chosen from more than 100 nominations, represent individuals, companies, and training providers across nine categories. Judges include senior figures from BCECA, ECIA, Phillips 66, Altrad Integrity Services, and EDF Energy. Hosted by Dr Maggie AderinPocock, with Skills Minister Baroness Smith of Malvern in attendance, the ceremony will also

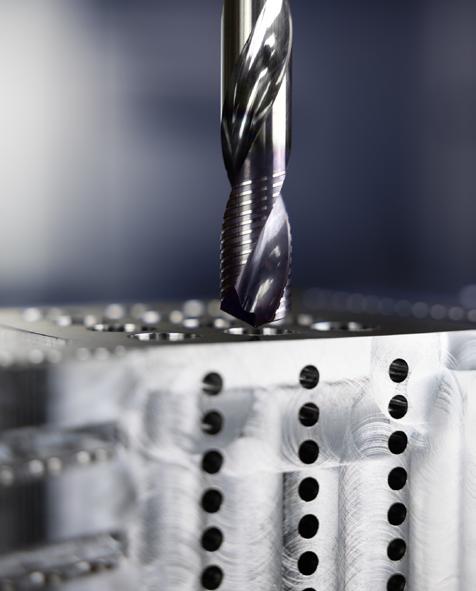

On stand N182 at Advanced Engineering leading tooling experts

MAPAL will be presenting a range of their latest innovative tooling solutions with a focus on Aerospace, Automotive, and Fluid Power sectors.

Key highlights include: The UNIQ DReaM Chuck 4.5° - Now available in new lengths and interfaces. The OptiMill-Tro-Inox trochoidal milling cutter - Specially designed for applications with problematic chip removal, and the OptiMill-Uni-HPC-Pocket - Developed to optimise time-consuming ramping processes when machining pockets.

MAPAL will also showcase its latest Aerospace spotfacing tool with an integrated micro stop cage, replacing the previously used brushes and offering numerous advantages to ensure precise machining. Highly versatile, this tool also supports countersinking, chamfering, and deburring operations.

highlight ECITB’s new strategy to grow industry entrants, boost diversity, and enhance workforce competence. Chief Executive Andrew Hockey (above) said: “While we look ahead to future challenges, the awards provide an important moment to celebrate success stories from across the ECI.”

A sewer robot that inspects pipework and raises blockage alerts before flooding occurs is to be deployed in a live network for the first time.

Pipebot Patrol is a £1.8 million project, funded by the Ofwat Water Breakthrough Challenge, with Spring Innovation as the knowledgesharing partner.

As the first autonomous sewer robot of its kind in the world, Pipebot Patrol is designed to navigate and inspect miles of pipeline continuously over a 30-day period, pinpointing the precise location of blockages as they are beginning to form.

The project is managed by Northumbrian Water with partners Environmental Monitoring Solutions, Gateshead Council, Jet Aire, Minicam Group, Newcastle City Council, Southern Water, Sunderland City Council, Thames Water and the University of Sheffield’s School of Mechanical, Aerospace & Civil Engineering, leading on robot development.

Since the project launched in July 2024, the development team

After the fantastic progress already made, our team of technical specialists is approaching a key phase - deploying the Pipebot in a live sewer zone.

- Clive Surman-Wells

has designed, built and successfully tested the Pipebot in laboratory conditions. The next step is a sewer zone field trial, which will build understanding of how the robot operates under real conditions.

There are 40,000 incidents of sewer flooding each year in the UK, a high proportion of which are a consequence of blockages.

Historically, mitigating actions taken by utilities have been reactive, prompted by alerts to rising water levels in the network. This approach means it is often too late for a crew to be dispatched to clear the blockage before flooding occurs.

Pipebot Patrol enables proactive inspection and maintenance of networks through an array of advanced mobile sensors and realtime sewer data, captured as the robot moves through pipelines.

The data is analysed and presented in a user-friendly dashboard, which flags up potential blockages early, giving utilities time to take action before the sewer backs up and overflows.

As well as offering greater environmental protection, Pipebot Patrol aims to improve health and safety by minimising human exposure to sewers, deliver cost savings through fewer emergency callouts, support mapping of sewers for asset records and pave the way for future innovations in robotics.

Clive Surman-Wells, innovation partnerships manager for Northumbrian Water Group, said: “Pipebot Patrol is a game-changer for sewer management, presenting three completely new concepts in flooding avoidance - the mobile sensor array, continual patrolling and near real-time alerts on impending blockages, including location data.

“After the fantastic progress already made, our team of technical specialists is approaching a key phase - deploying the Pipebot in a live sewer zone.