Choosing and managing PPE workwear

Casey Group Applauded for Leading the Way in Building Safety

Irish construction firm Sisk officially opens new Cork office

Highways UK 2025: Shaping the Future of the Road Infrastructure Sector

Bagged cement in mid-sized construction

Interview with Alex Jones, Director at Walker Morris

London PropTech Show opens Complimentary Visitor Registrations for 2025 Edition

Rob Norton discussses attracting Gen Z to the construction industry

Think Timber Calls for a More Transparent Supply Chain

Farrans Opens Applications for 40 Graduate & Placement Positions

Tel: 01843 808

Editor Maria Lapthorn editor@constructionmaguk.co.uk

Editorial Assistant Sophie Weir editorial@constructionmaguk.co.uk

Sales Manager Hannah Marshall hannah@constructionmaguk.co.uk

Admin Assistant Jade Still jade@constructionmaguk.co.uk

Production/Design Laura Whitehead laura@constructionmaguk.co.uk

Accounts Richard Lapthorn accounts@lapthornmedia.co.uk

Circulation Manager Leo Phillips subs@constructionmaguk.co.uk

Website: constructionmaguk.co.uk

Twitter: @constructionukm

LinkedIn: @constructionmaguk

Winvic Construction Ltd, a leading main contractor that specialises in the design and delivery of private and public sector construction and civil engineering projects, has commenced works on a new state-of-the-art warehouse facility at Coton Park in Rugby, celebrating with an official groundbreaking ceremony.

On behalf of Newlands Developments, Winvic has started the 60-week build programme to deliver a 250,000 sq ft single-storey warehouse at the strategically located industrial park, which sits within the UK Golden Triangle of logistics.

This project sees Winvic’s return to Coton Park, where the company previously delivered two distribution and logistics units on plots 2 and 3, bringing existing knowledge of the site’s infrastructure to support the successful delivery of the latest phase. The new facility will include 15,000 sq ft of office accommodation and will consist of a structural steel, multi-span portal frame with a height of 15 metres and will target a BREEAM Excellent certification and an EPC rating of A/ A+.

The groundbreaking ceremony, attended by representatives from Winvic and Newlands Developments marked a key milestone and highlighted Winvic’s

agility and capability in overcoming complex site challenges early in the programme.

As part of the infrastructure and enabling works, Winvic used a 350-tonne crane to install a 34-metre ex Ministry of Defence tank bridge, to span a 457 mm high-pressure gas main. This was a critical element of the works to enable access onto the site which requires crossing the major utility.

To further progress works, Winvic is constructing a Filcor (polystyrene) road that will wrap around a 54-metre-long 4m x 2m culvert. Traditional construction methods such as cement and compacted fill were not viable due to the loadings imposed onto the gas main.

Winvic and Cadent Gas are working together to develop and implement this solution to ensure the integrity of the gas infrastructure and safety of operatives working on site.

Coton Park is located 3.7 miles from junction 19 of the M1 and fronts the M6, giving direct connectivity to Coventry and Birmingham and other major routes.

£600,000

Work is underway on a project to breathe new life into an iconic Plymouth building, thanks to collaboration between three organisations.

Nudge Community Builders has taken on the Millennium Building, following a £600,000 joint investment from social impact investor Resonance and Esmée Fairbairn Foundation.

Construction has now started on plans to turn the Union Street building into community spaces for young people and the wider community, including a music venue, workshops and a café bar.

The Millennium Building was constructed as a cinema in 1931 and was later turned into a nightclub, before its closure in the early 2000s.

The structure stood empty for 17 years before Nudge purchased 50% of the building, thanks to investments of over £350,000 from the Rank Foundation and 491 community shareholders, and a partnership with Eat Work Art.

The latest phase has seen a joint investment of £600,000 from Resonance and Esmée Fairbairn Foundation, to purchase the remaining 50% of the building, and a £480,000 grant from the Youth Investment Fund to support internal works.

Contractor Clegg Construction has handed over a £37m student accommodation scheme in Leeds ready for the new academic year.

The Fabric Works in Leylands Road is a 402-studio block featuring study space, a cinema lounge and media room, fitness studio and gym, courtyard, bike storage, private dining room, and shared communal space with pool tables and a dry bar area.

The two-year project was handed over on time and ensures that the development is available for students this September.

Delivered in partnership with PPG Leeds Ltd, a joint venture between Primus Property Group

and HIG Capital, The Fabric Works is situated next to Spinners Yard – a 185-apartment build-to-rent development that was completed by Clegg Construction earlier this year for property developer Rise Homes.

The wider project team which delivered The Fabric Works included Tim Groom Architects, Ridge and Partners, Strive, KKA Studio, Quartz Project Services, and Innov8 Development Solutions.

As part of the delivery of The Fabric Works, Clegg Construction undertook a range of commitments to the local community including hosting multiple visits from Leeds College of Building students, significant donations to Blessed of the Father Food Bank, and regular contact with members of the neighbourhood via newsletters, a noticeboard, letter drops and inperson visits from the site team.

Clegg Construction has also worked with Community Wood Recycling for wood waste management and Wren Bakery, which uses baking and coffee as tools to provide disadvantaged women with opportunities towards employment.

The Oxford Trust, an Oxford-based charity with the mission to “encourage the pursuit of science”, has marked the start of construction of its new Aspen Building at the Wood Centre for Innovation in Headington, Oxford with an official groundbreaking ceremony – an important milestone in its 40th anniversary year.

Beard Construction has been appointed the construction partner to deliver a £7 million expansion at the Wood Centre for Innovation.

Central to the development is the Aspen Building, which will sit alongside the existing Linden Building and Science Oxford Centre at the Wood Centre for Innovation.

The new 17,000 sq ft (1,600 sq m) facility will provide high quality CL II level laboratory and office space over two floors and will also feature a STEM resources room to enable the Trust to expand outreach for its STEM education and engagement programmes, delivered by Science Oxford.

The significant investment is in response to the strong demand from start-up and early-stage grow-on science and tech companies seeking laboratory and office space within the Headington Science Cluster.

The project will also boost employment in the area during construction and, once fully operational, is anticipated to create up to 80 new on-site jobs.

Set alongside 15 acres of woodland, the Aspen Building will target BREEAM Excellent and include photovoltaic roof panels, a green wall, rainwater harvesting, cycle parking, shower and locker facilities and a minimum of 10% Biodiversity Net Gain to enhance its surrounding 15 acres of woodlands, ponds, and grassland. The rainwater harvesting will supply grey water for toilets and will provide additional flow to the ponds, minimising the need for sewer discharge.

The Aspen Building is to target practical completion in early summer 2026 and the office and lab spaces are available to pre-let, allowing flexibility of design for incoming tenants.

Demolition contractor Freeley has been appointed to clear the former Offerton High School site in Stockport, Greater Manchester.

Following asbestos removal, Freeley is demolishing two derelict structures - Bridge College in Woodlands Drive, and the Curzon Building in The Fairway, which extends to varying heights and borders Castle Hill High School and Lisburne School.

The smaller building, Bridge College, is being taken down first, with the whole site scheduled to be cleared by mid-December 2025.

As homes, schools and public footpaths are within close proximity, noise, dust and traffic will be carefully managed throughout the project.

As part of the project, Freeley has hired a local resident for the contract, is using local subcontractors and suppliers, and carrying out career advice sessions for people out of work. Continuing its social value commitment, Freeley is also making donations to local charities, including Stockport Foodbank’s Offerton branch, The Wellspring, Stockport Lads Club JFC and St Winifred’s RC Primary School.

VIVID has appointed PMC Construction as the Principal Contractor, and work is now underway to prepare the site at Victory Quay — laying the foundations for a vibrant new community on Portsmouth’s northern waterfront.

Once this essential groundwork is complete, construction of the first phase of new homes can begin — bringing 183 much-needed homes to the area (once complete will bring 835 new homes, a mix of private and affordable tenures including shared ownership, sales and social rent). This marks a major step forward in creating a welcoming new gateway community and neighbourhood for Portsmouth, opening doors for more people to find a place they can truly call home.

PMC Construction brings valuable expertise and a collaborative approach to the project, helping turn this exciting vision into reality—starting with the essential groundwork and site preparation. As a local company, they’ll be

working with many local subcontractors and tradespeople, and they’ve already shown their support for future talent by hosting a skills workshop for aspiring apprentices.

This first phase includes 183 new homes, completing the new sea wall flood defences to help keep the site safe and protect the future community for years to come, raising and preparing the land to make sure it’s safe and ready for building, putting in essential services like water, electricity, and roads to connect the new homes, and creating a scenic coastal path for everyone to enjoy the waterfront.

With works now underway, PMC Construction will continue site preparation through the autumn. Construction will continue to take into consideration seasonal environmental needs and those of the birds and animals who make Victory Quay their home, especially during the winter months. The first homes are expected to be ready for our customers in late 2026.

Fire safety is non-negotiable – but it shouldn’t come at the expense of the environment. With the latest award-winning innovation in fire door technology from Heron Fire Doors, it doesn’t have to. Thermasafe 30™ combines our industry-leading fire door specification with the lowest U-value of any timber door on the market.

Supreme energy efficiency

Industry-leading U-value of 1.2W/m2K, reducing heat loss by up to 30% compared to conventional timber fire doors

Unmatched fire protection

Meets E30Sa test standards, consistently exceeding requirement by 50%

Advanced sustainability

Uncompromising security

PAS24:2022 security rating under attack, impact & mechanical loading

Installer-friendly

British Woodworking Federation Award for Innovation in 2024

Since the Grenfell fire, the industry’s regulatory focus has shifted. With full industry reform underway and new regulatory frameworks being introduced, compliance is now a priority. In response to the tragedy, many papers have been published aiming to improve safety standards across the sector.

Dr Alex Boote, Product and Innovation Manager at ARC Building Solutions, explores how reform proposals in the Construction Product Reform Green Paper are reshaping the built environment, and why accountability, transparency, and continuous improvement must define every move.

Eight years ago a devastating fire broke out at Grenfell Tower in London - one of the worst fires in modern UK history becoming a catalyst for the most significant regulatory reforms in recent times. Alongside the seven-year public inquiry, two key reform papers were published: the 2018 Hackitt Report, discussing building regulations and standards, and the 2024 MorrellDay Review, focusing on testing and certification. Each has significantly contributed to the much-needed industry reform and regulation changes to improve safety standards. These include the Building Safety Act 2022, which banned combustible cladding on high-rise buildings, and amendments to the Building Regulations and Fire Safety Act.

The latest milestone in the Grenfell journey, the Construction Products

Reform Green Paper, published in February 2025, is more than a checklist. It’s a call for action. It challenges businesses to go beyond the minimum and lead the way in building a safer, more transparent, and responsible sector. Though only a recommendation today, it may soon become law. By preparing for these reforms, businesses can get ahead.

The green paper suggests manufacturers undertake detailed risk assessments for each product, considering its lifecycle and foreseeable use. Currently, two-thirds of construction products lack designated standards and fall outside CE or UKCA regulations.

Since Grenfell, two regulators have been created: the National Regulator for Construction Products (NRCP) and the Building Safety Regulator (BSR). Both will soon have the power to enforce sanctions and penalties.

The proposal suggests all products should be clearly labelled with performance and safety-critical information. A new national product library will contain test results,

Dr Alex Boote, Product & Innovation Manager

ARC Building Solutions

certificates of compliance, and relevant academic research, providing full industry visibility. Manufacturers must provide all test data or face penalties. The Code for Construction Product Information (CPPI), a not-for-profit organisation, supports the need for clear, accurate, accessible, and unambiguous product information.

The green paper suggests the UK will likely follow the European Union by introducing digital product passports. These would feature all product information regarding sustainability, performance, and traceability. Digital passports enable end-users to access information digitally and provide complete product traceability from manufacturers to installation.

Third-party accreditation schemes provide confidence that product information is accurate and unbiased. The green paper calls for stronger oversight by national regulators to improve competence and assessment reliability.

The green paper recommends products undergo lifecycle assessments, promoting a circular economy through recycling and reuse. Sustainability should already be a priority within businesses’ frameworks, and this proposal reinforces that approach.

The green paper encourages accountability throughout the supply chain, clearly defining responsibilities for economic operators. Breaches could result in fines, bans from industry work, or criminal charges.

The Grenfell fire showed the deadly risks of unsafe products. To simplify identifying companies that ‘cut corners,’ the paper proposes an easier route for affected parties to recover financial losses from manufacturers.

As the industry moves forward, the Construction Product Reform Green Paper offers a clear vision for reform, urging clearer engagement and regular reviews of regulatory frameworks. Accountability and transparency remain central. Whether you’re a manufacturer, architect, contractor, or regulator, now is the time to help shape a safer future for UK construction.

By Pete Grinbergs, Chief Medical Officer and Co-Founder at EQL.ai

Working in construction is physically demanding in a way few jobs are. Day in, day out, workers face the kind of strain most athletes only endure during training. Pain caused by injury to muscles and joints remains one of the sector’s most persistent, underestimated, and undertreated health threats – more must be done to address this on both an individual and economic scale.

The Health and Safety Executive’s 2024 report shows musculoskeletal (MSK) disorders account for 42% of all workrelated ill health cases in construction, with affected workers losing an average of 21 working days each year. Repetitive strain, awkward postures, and heavy lifting can lead to chronic pain, reduced mobility, and in some cases, people leaving the workforce altogether.

As an ex-Premier League physiotherapist, I’ve seen firsthand how timely, consistent care gets people back to fitness quickly. I’ve also seen the opposite: injuries left to worsen without guidance, workers waiting until the pain becomes unbearable, and sporadic access to a physio affecting recovery.

Within the construction industry, the numbers clearly show that this is something we need to address as a matter of urgency. Left untreated, MSK injuries can have a devastating ripple effect: financial strain from lost work, long-term pain impacting mental health, and lower quality of life.

It shouldn’t only be elite athletes who get the best care. Thousands of construction workers face intense physical pressures every day, and their injuries can often be treated effectively – if the right support is in place. What could that look like?

Access to treatment is one of the biggest challenges. It’s typical to wait weeks or even months for a physiotherapy appointment through the NHS – far too long when early intervention can prevent a small strain from becoming a career-limiting injury.

For many workers moving between sites or working as subcontractors, occupational health provision isn’t always readily available, leaving them to self-manage or push through the pain. Technology can help, and we should leverage it wherever we can to enable the best care. For example, smartphone apps and digital services mean that workers can now have remote contact with a physio within days, or even hours, of injury – so recovery starts sooner. Tech can also enable regular check-ins, which are critical to recovery. Many treatment plans require daily exercises and adjustments; regular touchpoints are far easier to maintain through ongoing digital contact than in-person appointments with a GP or physio.

Another thing we must consider, especially in male-dominated industries like construction, is the social and cultural barriers preventing timely access to healthcare. Asking for help isn’t easy, and research shows men are particularly likely to delay it. Too often, discomfort is ignored or masked with painkillers until the injury can’t be worked through any longer.

Talking openly about pain during work inductions, encouraging symptom reporting, and offering visible support for subcontractors can make a real difference. Providing short, practical training sessions on recognising early signs of musculoskeletal problems can help workers take action sooner. Peer champions or “health advocates” on site could also normalise these conversations and make seeking support feel less like a weakness and more like good practice.

Looking more widely at the sector, MSK injuries have a crippling impact. Workers in pain recover more slowly, are more prone to accidents, and perform less effectively – impacting deadlines, budgets, and safety. In a sector already facing labour shortages, keeping people healthy isn’t just the right thing to do – it’s essential for the industry to prosper.

Construction workers are the backbone of our built environment, and frankly, they deserve better. Giving them the latest digital tools to support health will protect not just individual livelihoods, but the future strength of the sector itself.

Construction insurance tailored to you.

Gallagher offers the strength and positioning of a global insurance group, combined with the personalised care and attention of a local UK broker. With a rich history dating back to 1927, we believe we have the expertise and experience to meet your construction insurance needs.

CONNECT WITH A

For further information, please scan the QR code.

Lung protection is becoming increasingly important on construction sites. Mandatory precautions such as innovative and comfortable respiratory protection systems are therefore a must, especially for longer operating times. The revolutionary swiss air respiratory protection from optrel offers an ideal solution.

Effective protection against pollutants

Moderate to high levels of smoke, gases, vapours, and fine dust are not uncommon. These pollutant emissions can very easily enter the lungs and cause coughing, shortness of breath, bronchitis, and in the long term, even pulmonary fibrosis or silicosis. Employees should definitely be protected from this with comfortable half masks and clever filter technologies.

No (mandatory) breaks and no need for a close shave

The swiss air supplies users with fresh, purified air thanks to its integrated

blower system and highly efficient filters. The positive pressure in its high-tech fabric half mask supports breathing and counteracts fatigue. At the same time, the cooling fresh air allows for increased concentration on the work. And thanks to the overpressure system, the comfortable half mask does not even need to fit tightly, no fit tests are required and even beards do not need to be shaved. The results are: No more forced breaks due to the mask versus conventional dust masks, more performance and more efficiency. For certain tasks in particularly contaminated environments, the useroriented respiratory protection can even be combined with a silicone mask.

To ensure reliable and safe respiratory protection at all times, the control panel of the swiss air shows the filter contamination and the battery capacity. Beside the initial investment, only the filters need to be changed on a regular basis depending on the dust load. By using filters instead of conventional dust masks, waste gets reduced and the sustainability of the company is being increased. Making the swiss air a product, that offers great value for money not only in performance, but also in assisting company goals.

Thanks to its ergonomic harness and low weight construction workers can move freely, hardly noticing their respiratory protection system. The PAPR also works independently from other headgear, hearing protection, or safety goggles. Finally, with the protection cover the swiss air can be used even in the rain.

Welcome to the Swiss Alps –Welcome to optrel swiss air

swiss air is the revolutionary PAPR from optrel and is a testament to everything the company represents. As a swiss manufacturer of respiratory protection and automatic welding helmets, optrel is committed to delivering lasting benefits in its products. That’s why around one quarter of the optrel team is dedicated to continuously researching and developing innovations, that make your everyday work easier and safer. With swiss air, your team lives and breathes real innovation.

Read more about swiss air on the new optrel website or watch a video (product video / instruction video) for more information.

Breath the purest air thanks to the revolutionary swiss air PAPR!

· Eliminates 99.8% of particles, including quartz dust, from the air

· No face shaving and no fit test required

· Ultra easy to use

· Compatible with all common helmets, ear defenders and goggles

The Muck Grit S5 safety boot represents the new pinnacle of our industrial and safety sector portfolio.

A completely new design created on both men’s and women’s specific lasts, the Grit S5 has been created from the ground up, encompassing all of the classic Muck Boot traits of comfort, insulation and is of course 100% waterproof.

The Muck Grit S5 work boot is the culmination of our collaboration with leading Industrial & Safety experts and top European footwear designers/ developers working under the direction of our Global Product team.

The safety boots feature a self-insulating 5mm neoprene bootie construction that is lined with a breathable sandwich mesh layer that effectively wicks moisture away from the body, ensuring a comfortable environment – keeping you warm when inactive and offering effective heat dissipation when active.

The neoprene bootie is protected by extended hand laid rubber overlays that are shaped and contoured for an ideal balance of structure and flexibility.

The Muck Grit S5 is available in a range of colours designed to complement your profession.

The Muck Grit S5 is finished with a versatile “bob” outsole that offers grip in multiple situations.

The upper also features reflective panels to offer 360’ visibility.

The Muck Grit S5 is available in a range of colours designed to complement your profession. So whether you are a man or woman operating on building sites, railways, highways, landscaping or require safety footwear around the farm/stable or at home for DIY, the Muck Grit S5 offers you the 100% Muck Proof protection you need with the comfort you will love.

Browse the Muck Grit collection or Muck Boots safety boots here.

EN ISO 20345:2022+A:2024

S5S FO LG HRO CI HI AN SR

Key features:

• 100% Waterproof

• Key reflective areas

• Composite toe cap

• Comfortable, cushioned and removable PU footbed

• Robust functional heel kick

• Certified to Ankle Protection (AN)

• Energy absorbing heel

• Outsole certified and tested to new maximum Slip Resistance (SR)

• Fuel and oil-resistant outsole

• Performance ladder grip tested to New Ladder Grip Standard (LG)

• Outsole heat resistant to 300°C

• Certified to Cold Insulation (CI) at -17°C

• Certified to Heat Insulation (HI) at 150°C

By Melissa George, Area Sales Manager, Lindström UK

Selecting and managing PPE workwear can be challenging—especially when safety, legal compliance, and a highrisk environment are at stake. With multiple workers, machinery, and hazards in play, how do you choose the right PPE and ensure it’s properly maintained?

Each industry has specific regulations on PPE workwear. Your risk assessment will define the PPE legal requirements, but it’s important to know the requirements of each job, who is doing it, how often and when. Many companies overestimate their PPE needs and buy unnecessary workwear or workwear with too high a specification.

How do I define my company’s specific needs?

If possible, arrange a workwear site visit. Good workwear suppliers will have experts from different fields familiar with the relevant regulations. They will help you find the right workwear for the situations you face.

Do I need to order workwear specifically designed for my industry?

The answer is both yes and no. As a rule, workwear works best when designed specifically for you. But this is also more expensive. A good compromise is to find a supplier that has existing workwear available for the minimum specifications you need.

Do I need fitted garments?

When choosing workwear, make sure it is not too loose and not too tight. It is good when there is some air gap left between the garment and the skin. That way, sparks and spatter stay away from you. You should make sure the jacket overlaps the trouser waist, even

when you are bending down, and check that your wrists and ankles are covered.

Can I share PPE workwear?

Sharing workwear is not recommended. Beyond hygiene and comfort issues, having workwear in your own size makes work safe, and garments will feel more comfortable as well as last longer.

How are garments fitted?

Sometimes companies use a ‘drop pile’ or ‘pool’, where a few standard sizes of PPE workwear are supplied, and an employee takes what best fits / is

available. A more focused alternative is a fitted service where the workwear supplier meets the customer and provides workwear for each user.

How do I take care of workwear PPE?

If PPE garments are not clean and in good condition, they cannot protect you properly. Regular changing, washing and maintenance are essential. If you buy the workwear, then you will have to organise the washing and repair. If you use a renting service, the washing and repair should be done for you.

How can you monitor the use and condition of PPE workwear?

The basic system is simply a manual record, relying on users and management to update workwear use. These days, many companies have technological solutions like an RFID chip which allows workwear use to be recorded, and the information easily presented on an online portal.

Workwear PPE is there to serve a purpose – to protect the user.

It needs to:

• Be up to standard.

• Be comfortable and appropriate.

• Be properly fitted.

• Have its use checked.

• Be regularly cleaned and repaired.

If these factors are not carefully considered, then the workwear will not protect the employee. This puts them, and the company, at risk.

Making durable, functional and ergonomic Trousers that offer great comfort for people who are always on the go has been a constant challenge over the last three millennia.

It is said that the origins of Trousers as a functional, practical, garment can be traced back to the warrior equestrian societies of Eastern Europe and Asia Minor as far back as the sixth century BC. The Scythian and Persian peoples developed Trousers as a practical alternative to wearing robes on horseback. Those more traditional garments were both uncomfortable and impractical while the comfort that Trousers provided for extended periods on horseback made them the practical choice of the time. Loose Trousers tucked into boots were a simple, but effective clothing innovation which increased the comfort, mobility and efficiency of those ancient horse-peoples.

Relics from archaeological finds at Thorsberg (Denmark) and Damendorf (Schleswig-Holstein, Germany) dating from 2nd to 4th Centuries AD show how Trousers had evolved ergonomically to suit practical needs of the time. Made from complex patterns comprising a number of independent pieces of fabric, the Trousers were produced to suit an individual’s body shape with innovations such as waistbands and even integrated foot-pieces.

Despite innovations such as the ZipperFly for Trousers and the basic-styled garments like the Bib ‘n’ Brace and Boilersuit, the workplace had to wait over 100 years, until 1975 in fact, for the next stage in Trouser evolution.

It was the invention by Matti Viio – a Swedish Electrician - of the Holster Trousers with Kneepads that heralded the Snickers Workwear brand and the era of purpose-designed working clothes for modern-day professional tradesmen and women. Since 1975, Snickers Workwear has been inventing and reinventing Work Trousers with Kneepads each with a combination of market-leading design technology, hi-tech fabric innovations for comfort and functionality and more recently a sharp focus on sustainability.

After nearly 50 years of continual innovation, Snickers Workwear now has a range of over 90 styles of Trousers with

8 different types of Kneepad in patented KneeGuard® Systems for individual worker needs in a wide variety of working environments. From professional trades in building and construction, to engineering and maintenance, logistics and warehousing, heavy and light industries as well as hazardous workplaces, Snickers Workwear has a pair of trousers to suit and kneepads for protection - for all shapes and sizes.

In what is probably the most groundbreaking Work Trouser innovation, the brand has now launched the world’s first built-in, certified kneepads which are completely integrated into a pair of Snickers Workwear’s premium stretch Work Trousers - the unique AllroundWork, Stretch Trousers with Capsulized™ Kneepads and Holster Pockets. The result of an intensive research and development process that has spanned the last three years, they deliver low-profile, comfortable impact protection – tested, performance validated and certified to exacting International Standards.

Designed and engineered in partnership with YBC®, the Capsulized™ kneepad components comfortably deliver effective penetration protection and impact absorbtion for the wearer.

A durable CORDURA® stretch covering provides external fabric durability. It integrates with the first performance layer of high-density foam which delivers maximum protection. This combines further with a shield of Ortholite comfort foam technology that’s highly shock absorbent.

Comfort and protection is further enhanced by a foam comfort layer for pressure release when working while kneeling. Finally, there’s an inner polyester fabric which seals the outer protection layers onto the trouser leg and provides a comfortable surface between the wearer’s knee and the kneepad itself.

It’s effectively a Capsulized™ Layer Cake with a number of protection layers that work with each other to dissipate the energy created by the impact of working on your knees or if you accidentally bump them in and around the workplace.

It’s widely accepted that the long-term effects of knee injuries and the impact of working on your knees can cause of a lifetime of discomfort and restricted movement. Yet History has shown that properly designed trousers have an important part to play in delivering comfort, efficiency and well-being in physical activities.

The design technology in Work Trousers has developed considerably since the Thorsberg and Damendorf Trousers as well as Strauss’ first purpose workwear for miners. But while factors like durability and functionality have been the only drivers the design of Work Trousers for the last 170 years, Snickers Workwear’s latest innovation takes the Trouser design and development process to a new level.

Rain, wind or heat. Long days and hard work. When your working conditions change, your workwear needs to keep up. This is where MASCOT® WORKWEAR’s products and the layer-on-layer principle make all the difference.

For the workwear closest to your body, you need a layer that wicks away sweat so you don’t get cold and damp. Our base layers are made from stretchy, moisture-wicking materials that follow your movements and keep your body dry - even during physically demanding jobs.

For a base layer, try the MASCOT® CROSSOVER 20482-786 T-shirt. It is made from 60% organic cotton and 40% recycled polyester and comes in 17 colours, so you are sure to find one to match your business needs or personal style. The fabric dries quickly and retains its colour and shape after every wash. Additionally, the fabric has high wear resistance meaning it made to last longer.

The insulating mid-layer must be able to keep you warm without constricting or restricting your movements. It is crucial that the material is both insulating and breathable. Many of our mid-layers are made with CLIMASCOT® Lightweight Insulation, which is designed to be highly insulating, lightweight, and give you maximum freedom of movement.

2

Try the MASCOT® ACCELERATE 18101511 which comes in 6 colours. The ultimate stretch material makes the jackets elastic in all directions, giving you a unique freedom of movement and comfort as you work. The material is lightweight, water-repellent and is fastened with a zip and internal storm flap, to keep the wind out, making it durable and comfortable to wear in the wetter seasons. It also has reflectors on the arms for visibility at night or in the early mornings.

can choose between waterproof and water-repellent models, all developed with wear resistance, flexibility and functionality in mind.

Try the MASCOT® ACCELERATE 18301231 Outer Shell Jacket. You are still very likely to sweat under your jacket during winter as you work and sweat can get trapped and make you uncomfortable. The 18301-231 jacket is breathable, allowing you to get rid of moisture so you don’t become damp. It is also wind and waterproof to protect you from the elements and includes reflectors for safety. The zip fastener has a double storm flap to provide extra protection against bad weather and a detachable lined hood with adjustable elastic drawstring for you to add or remove as you see fit. A bonus is the ribbed cuffs which stay close to your wrists to keep the cold out. It also follows your movement, so the sleeves don’t hinder your work by getting in the way. Layer 1

Layer 3

The outer layer is your first line of defence against rain, wind, and snow. Many of our jackets are designed to be windproof and waterproof - but still breathable. This is important because moisture from the inside can be just as troublesome as moisture from the outside. Depending on your needs, you

Tested

MASCOT is more than the highest quality products. In addition to the industry’s widest range and high delivery reliability, you get simple and efficient online ordering, customised logo solutions and fast delivery.

Western, one of the UK and Ireland’s most experienced offsite construction specialists, has invested £1m in a fully automated timber panel production line at its Coalisland headquarters.

The investment is part of a multimillion-pound programme to boost innovation, efficiency, and sustainability in construction.

Developed with Modular Building Automation and JJ Smith Woodworking Machinery, the new line combines advanced automation with powerful digital design

tools to deliver higher output, greater precision, improved safety, and energyefficient building systems.

At the heart of Western’s latest initiative is a suite of next-generation machinery to manufacture open and closed timber wall panels with minimal manual handling. Underpinned by hsbcad’s integrated design platform, it enables digital fabrication workflows and rapid designto-manufacture capabilities.

The new system will improve delivery timelines, reduce site disruption, minimise material waste, and ensure tighter building tolerances while supporting Western’s carbon reduction targets. It also enhances the company’s capacity to meet growing demand for faster, greener construction in line with Net Zero ambitions.

“This isn’t just a leap in technology - it’s a statement about where we’re headed,” said Western’s Managing Director, Rory McGuigan. “We’re investing in the future of construction. That means making our operations smarter, faster, and more sustainable.”

For more information visit: westernbuild.com

The Casey Group, a leader in building safety works, has been commended by Dame Judith Hackitt – the architect of the landmark Building a Safer Future report – for its leadership and commitment to culture change following the Grenfell Tower tragedy.

During a recent visit to Casey’s offices and its Building Safety and Skills Academy in Rochdale, Dame Judith met with senior leaders, project teams, and operatives to hear first-hand how the firm is embracing the new responsibilities introduced by the Building Safety Act (BSA).

The visit also included a tour of Avro Hollows in Manchester, where Casey is remediating four 23-storey tower blocks in line with the new safety standards.

Casey Group says her praise highlights a growing sense of optimism across

the sector, as more organisations actively work in partnership with the Building Safety Regulator (BSR) to raise standards and ensure resident safety is prioritised, and the government looks into potential reforms to the building safety processes.

The visit also coincides with Casey achieving six successful Gateway 2 approvals — a key milestone under the Building Safety Act, ensuring projects are reviewed and approved before construction begins.

While the implementation of the new regulatory framework has brought challenges, including complexity and delays, leading contractors like Casey are proving that collaboration and shared learning can turn those challenges into lasting improvements.

The visit comes at a pivotal time, with a new inquiry led by Baroness Taylor of Bolton exploring how the new rules can be more effectively applied. As the UK Government pushes forward with an ambition to deliver 370,000 homes annually, the alignment of safety, efficiency, and delivery remains a key focus.

Raimondi Cranes, the Italian manufacturer of high-performance lifting solutions with a growing footprint in the UK, has announced a definitive agreement to acquire key lifting divisions from US-based Terex Corporation. The deal includes Terex Tower Cranes, SelfErecting Cranes, Rough Terrain Cranes, and the North America Cranes service hub.

This major acquisition expands Raimondi’s product portfolio to include self-erecting and rough terrain cranes, strengthening its offering to contractors across the UK and Europe. It also enhances global support infrastructure and distribution — key for UK firms relying on consistent service and availability.

The acquisition includes manufacturing facilities in Fontanafredda and Crespellano, Italy, and will see around 250 Terex employees join Raimondi. With Terex cranes already widely used on UK construction sites, the move is expected to benefit local customers through broader product choice and improved after-sales service.

The transaction is expected to close in Q3 2025, pending regulatory approvals, and supports Raimondi’s goal of reaching $500 million in annual revenue by 2028.

Ireland’s largest construction firm, Sisk has officially opened its new office at City Gate, Mahon in Cork city centre. Its new Cork office was officially opened today by Michael McGrath, EU Commissioner, Gary McGann, Chairman, Sicon Ltd (Sisk Group) and Paul Brown, CEO, Sisk.

The new office was retrofitted over a four-month period and has capacity for over 50 people. The Sisk – Cork office had previously been based on Kinsale Road since 1967.

The company has recently been announced as main contractor for the extension of Center Parcs Longford Forest having previously completed the Dunkettle Interchange Upgrade Scheme and Pfizer in Ringaskiddy over the past 18 months.

Leading North West property services company, The Momentum Group, has marked a standout year of progress with the release of its second Annual Momentum Contribute Report.

The Momentum Group’s business activities, and the report highlights a string of achievements that demonstrate the business’s commitment to people, places, the planet and professionalism, including delivering 1,178 hours of work placements for local students and individuals facing barriers to work, expanding its apprenticeship programme, alongside strengthened sustainability practices, with 60% of suppliers located within 25 miles and ESG principles embedded in supplier vetting.

Health, safety and well-being also remained a cornerstone of Momentum’s approach. Guided by its ‘Safe First’ principle, the Group reported zero dangerous occurrences, stronger mental health support, including occupational health initiatives, Mental Health First Aider training, and the continuation of its “Time to Talk” programme, and investment above benchmark, with 1.5% of turnover dedicated to health, safety and wellbeing.

Highways UK, in partnership with National Highways, has established itself as the UK’s dedicated highways and roads trade show: bringing together the people responsible for planning, developing, managing, maintaining, and future-proofing the nation’s roads networks.

Join us from October 15th–16th 2025, at the NEC, Birmingham to exchange ideas, build your brand, form new connections and partnerships, grow your professional network and uncover new opportunities alongside us.

With an anticipated 10,000+ attendees, 360+ exhibitors, and 250+ speakers, Highways UK offers you a unique opportunity to connect with a large and exceptionally senior audience. It connects every segment of the highways sector: from local authorities and national agencies to private contractors, consultants, academics, and start-ups.

From policy-level decisions to hands-on infrastructure innovations, this year’s event will foster powerful conversations and showcase transformative technologies aimed at making UK roads smarter and more sustainable.

One of the core reasons for the popularity and success of Highways UK is its holistic approach to addressing challenges and opportunities in the sector. It blends a world-class exhibition with a cutting-

edge multi-theatre conference, all while offering attendees curated networking opportunities.

The event features nine dedicated stages covering a wide array of subjects relevant to the entire highways value chain.

1. Keynote Theatre

2. Big Thinking Stage

3. Strategic Roads Theatre

4. Local Authority Theatre

5. Connected Communities

6. Civils & Materials

7. Digital Roads

8. Network Resilience & Renewal

9. Sustainability Theatre

One of the most dynamic parts of Highways UK is the Start-Ups Zone, where early-stage companies present their game-changing technologies. This dedicated space allows start-ups to pitch

to investors, engage directly with buyers, and gain valuable media exposure.

Highways UK’s commitment to industry development goes beyond innovation, it’s about people and progress. In the Recruitment Zone, jobseekers and employers come together to explore career opportunities, skills gaps, and the future workforce of highways. Adjacent to this, the Professional Development Hub offers bite-sized learning, expertled sessions, and practical guidance to help professionals at every level grow their knowledge and stay ahead in a rapidly evolving sector. Meanwhile, the Vehicle Display Zone puts cuttingedge machinery and fleet technology centre stage, giving visitors the chance to get hands-on with the vehicles and equipment driving the future of highways, maintenance, and traffic management.

The event is designed to facilitate deep connections. Using the official event app, attendees can:

• Set up 1:1 meetings

• Match with potential collaborators

• Create personalised agendas

• Access digital content post-event

In addition, networking lounges, meetups, and hosted roundtables provide intimate settings to engage with peers, prospects, and policymakers.

Highways UK 2025 isn’t just an exhibition and conference - it’s where strategy meets implementation. It brings together the finest minds and most influential decision- makers to shape the roads of the future. As the UK gears up for another transformative decade in infrastructure development, the event will play a pivotal role in delivering smarter, greener, and more resilient road networks. If you’re part of the highways or broader transport sector, this is the one event you can’t afford to miss.

Register for your FREE ticket today: www.terrapinn.com/ huk2025/Constructionukmag

Bringing together the key stakeholders responsible for planning, delivering, and maintaining the UK’s national and local roads, with growing focus on sustainability, climate resilience, and integrated infrastructure that includes water, energy, and transport systems

15th-16th October 2025

Attend? Featuring new solutions and technologies across every stage of the highways supply chain

360+ Global Exhibitors

250+ Expert Speakers

Industry leaders share their views and expertise across 9 specialised theatres & stages.

10,000+ Senior Attendees

Offering you a unique opportunity to connect with a large and exceptionally senior audience.

West Wales contractor Hywel Griffiths Plant Hire and Groundworks has added a bespoke CASE CX210E-S crawler excavator to its growing fleet—built for power, precision, and productivity in tough ground conditions.

The 22.5-tonne machine features a reinforced structure, 800mm low ground pressure tracks, Steelwrist X26 tilt-rotator, Topcon GX90 machine control, and 360° cameras. It’s already delivering strong results on a Morganstone housing site near Haverfordwest, combining Stage V engine performance with impressive fuel economy.

“This machine is a game-changer,” said operator Evan Griffiths. “The Topcon system, combined with the tilt-rotator, allows me to grade without repositioning—it’s incredibly efficient.”

The CX210E-S brings CASE’s E-Series control refinement and was supplied by Riverlea Industrial, a trusted dealer relationship spanning nearly 30 years for Griffiths. All machines are maintained under a CASE service plan, shifting support responsibilities to the dealer.

Built in India but sharing drivetrain components with CASE’s Japanese models, the CX210E-S is tailored for durability and performance.

A final aesthetic touch? Custom grey CASE graphics to match Griffiths’ branded fleet.

With a strong order book, Griffiths is already eyeing additional CASE machinery to meet growing demand.

Commercial Fuel Solutions (CFS), the UK’s leading independent AdBlue supplier, is celebrating 20 years of AdBlue in the UK with a nod to its role as a pioneer in diesel emissions reduction.

Founded 18 years ago, CFS’s involvement in the sector predates even its retail launch—former CEO Robin Futcher helped deliver the UK’s first depot dispensing systems for Yara’s initial AdBlue trials with DHL and Next.

Today, CFS supports around 1 in 50 HGVs on British roads and continues to lead with innovative AdBlue handling and storage systems for logistics and heavy plant.

Recent developments include a groundlevel AdBlue filling solution for plant equipment and the BlueBox—a lowercarbon packaging innovation from parent company New Era Energy. The company also authored EI3426, the UK’s first AdBlue forecourt safety standard.

“From those early trials to nationwide supply, we’ve remained committed to solving real-world emissions challenges,” said Paul Norman, Commercial Director.

As the commercial vehicle industry evolves toward cleaner technologies, AdBlue remains a critical bridge—and CFS remains at the forefront of nextgeneration fuelling solutions.

Garry Gregory, Packed Products Director at Tarmac, explores

why bagged cement remains a preferred choice for mid-sized projects.

When it comes to mid-sized construction projects, the selection between bagged and bulk cement plays a pivotal role in influencing logistics, cost-efficiency, and environmental sustainability. While bulk cement often presents cost advantages for large-scale operations, bagged cement offers distinct benefits that align with the nuanced demands of smaller, phased projects.

logistics

The conventional 25 kg bag cement size, while heavy, continues to remain the industry standard for regular site labour and facilitate traditional mix ratios. This is for good reason. It’s a format that avoids the complexities associated with smaller sacks that can complicate batching and ratio consistency.

Moreover, when sites operate in phases, such as mortaring, rendering, patching, or localised slab pours, ordering bagged cement enables delivery matched to daily or weekly consumption without committing to large upfront volumes. This reduces the risk of over-ordering, spoilage, or storage issues, especially in urban or space-constrained environments.

While bulk or ready-mix cement often offers lower per-tonne costs, eliminates manual lifting and packaging waste, this cost equation shifts for mid-sized multi-phase work. Minimum order thresholds, short-load fees, and the possibility of unused material erode savings. In these cases, bagged cement parcels keep the project lean, both financially and operationally.

Waste reduction is a significant consideration when using bagged cement in mid-sized construction

projects. Because the material is supplied in pre-measured bags, it can be used incrementally and precisely according to each phase of the build. This phased approach helps sites avoid the common problem of surplus cement being left unused, often stored in damp or unsuitable conditions that can compromise quality.

By minimising leftover cement, projects generate less environmental impact from both unused product and packaging waste. Ultimately, the precise control afforded by bagged cement supports more sustainable construction practices in a way that works for mid-sized projects.

Bagged deliveries avoid the need for silos or tanker access, which is particularly advantageous in tight city environments or refurbishment projects where deliveries must suit narrow windows, limited space, or staged reuse of site areas. Delivery flexibility reduces the risk of missed bulk loads derailing phase timing.

Rather than being a fallback when bulk supply isn’t practical, bagged cement in this context is a deliberate delivery model rooted in operational nuance and quality assurance. It embeds control directly into how construction progresses, batch by batch.

As we celebrate 125 years of Blue Circle at Tarmac, we proudly reaffirm our commitment to mid-sized construction projects. As the industry evolves, we’ll continue to adapt to modern building needs and changing standards.

Our goal is to support builders with reliable solutions, helping mid-sized projects thrive and make a lasting impact in the built environment.

In conclusion, while bulk cement may be advantageous for largescale operations, bagged cement offers distinct benefits that align with the specific needs of mid-sized construction projects. By prioritising quality control, logistical flexibility, and cost-effectiveness, bagged cement proves to be a strategic choice for many construction professionals working on mid-sized projects.

CT1, the UK’s Number 1 Sealant and Adhesive, has partnered with Toolstation, one of Britain’s fastest growing suppliers of tools, accessories and building supplies to the trade, to launch an exclusive competition giving customers the chance to win a brand new Ford Transit Custom (280 L1 2.0 TDCi 136ps EcoBlue) in a striking Magnetic Metallic Grey.

Open to all members of the Toolstation Club, the competition invites customers to sign up and spend £50 or more on CT1 branded products to be entered into the draw.

CT1 with revolutionary TRIBRID® technology has become the product of choice for tradespeople nationwide, while Toolstation continues to support professionals with quality tools, trade essentials and top brands at great value. This collaboration reflects a shared commitment in recognising the vital role of tradespeople across the UK.

The Ford Transit Custom is a trusted favourite among the trade because it offers a blend of reliability, versatility, and practicality, with a good payload capacity and flexible load space for tools and materials. Its comfort and user friendly features, such as wide opening doors and a load through bulkhead, improve daily usability. With EcoBlue technology, it delivers efficiency and reliability, making it the ideal vehicle for professionals on the move.

“At CT1 we understand the everyday needs of tradespeople - having the best products and the best tools for the job. Our partnership with Toolstation highlights both brands dedication to the community - we are always here to back the trade. And what better way to do that than by giving one lucky customer the keys to a brand new Ford Transit Custom!” said Nicola Walsh (pictured left), Director of Sales and Marketing at CT1.

The competition runs from Monday 8th September - Sunday 30th November 2025 (inclusive). Customers must be signed up to the Toolstation Club and spend at least £50 on CT1 branded products in a single transaction to qualify. The Prize draw will take place on 2nd December 2025. Full terms and conditions can be found at www.toolstation.com/promotions-terms-and-conditions#ct1-win-van

This year, the brick colour of the year is silver city, a very pale silver-grey that ‘pulls in design cues from its natural surroundings.’

Brick has long reflected the colours and textures of their natural environment. Before infrastructure allowed us to transport raw materials across the country (and the globe), brickmakers used clay from local quarries and builders used local bricks. Due to variations in regional clay, buildings across the country would display colour differences that harmonised with surrounding nature.

Returning to the brick colour of the year, a silver-grey would look most at home in slate and stone-dominant environments such as Cumbria or Lancashire, or the dramatic granite and schist landscapes of much of Scotland. It can also help soften steel and concrete-heavy surroundings in cities like Manchester, Leeds and Bristol.

Blockleys offers the impactful cool-toned greys Synthesis S09 and Sterling Grey and Floren.be provides delicate pale greys with depth in its Polaris and Alpha facing bricks.

Pastel colour bricks

The prevalence of pastels might feel like a distinctly millennial trend, but we can trace their popularity back to the 18th century when pastel portraits became highly sought after.

Pastel colours have a cyclical presence in design trends. After the Second World

War, the surge of soft, bright hues in decor, cars and fashion reflected postwar optimism. In the 1980s, the global influence of TV show Miami Vice and the vibrant namesake city it portrayed made pastels popular once more. The 2010s boost sprung from cultural shifts and was accelerated by consumer goods branding that favoured openness and softness.

Fast forward to today and pastels are on the rise again in our built environment. You’re unlikely to see ‘millennial pink’ clay bricks but you might see more pale reds and yellows that evoke a soothing and hopeful atmosphere. Floren’s

Alaska Rustic and Warboys Cream and Blockleys’ Penine Buff Wirecut and Park Royal are examples of pastel bricks from the Michelmersh portfolio.

Bold brick colours

While pastels will be a favourite for specifiers, bold brick colours are also likely to see a surge in popularity. Dezeen has reported that a retreat from the minimalism trend will see more ‘dynamic and emotionally engaging designs’ from a ‘collective yearning for authenticity’ which puts vibrant orange and red clay bricks firmly in the picture.

The strengths of clay brick are consistent regardless of colour, but bricks like Michelmersh’s Hampshire Stock Farnham Red and Hampshire Stock Henley Orange can offer a charm reminiscent of classic British buildings. The versatility of bold reds and oranges for both contemporary and heritage designs can be seen in our Design District and Wolverton Hall Folly.

Not sure how to go about finding the best brick colours for your design? We have multiple resources to make your selection:

• Try our free Façade Designer which lets you visualise any combination of our products, in your specified ratios, in just a few clicks.

• Order our swatchbook, containing every product in our portfolio, to see our full range of colours as well as the most relevant technical information.

• Download building information modelling (BIM) files, available for all our clay brick products, which allow you to see the aesthetic you can achieve with specific colours. Visit: www.mbhplc.co.uk

Chosen by leading architects, our award-winning bricks unite timeless beauty and proven durability. Whether you are seeking a rich palette of colours, a variety of textures, or refined finishes, Michelmersh’s clay products deliver design freedom and lasting performance. Inspired by precision craftsmanship and quality, each brick contributes to creating projects that inspire and captivate clients.

Website: www.mbhplc.co.uk

Email: sales@mbhplc.co.uk

Telephone: 0844 931 0022

Following a successful debut, Digital Construction North returns to Manchester Central on 19 November 2025, uniting 1,000+ AECO professionals for a full day dedicated to innovation in the built environment.

Free to attend, the event will feature 50+ exhibitors, 75+ expert speakers, five content theatres, and eight hours of CPD-certified content. Key themes include AI, BIM, digital twins, automation, asset management, and sustainability — all critical to advancing digital transformation in construction.

Visitors can expect interactive sessions, tech demos, live product launches, and podcast recordings. Leading names like Elecosoft UK, Glider Technology, IFS UK, Revizto,

and Trimble UK will showcase the latest solutions designed to boost efficiency and profitability.

“Last year proved there’s real appetite in the North for a dedicated showcase of AECO innovation,” says Event Director Karolina Orecchini. “This year, we’re going even bigger.”

Networking remains at the heart of the event, with space for Northern AECO meetups and community events.

Spaces are limited and registration is now open. Attendance is vetted and prioritised for AECO professionals in the North directly involved in project delivery.

Register here to be part of the North’s essential industry event.

FOR 10TH ANNIVERSARY EDITION

A host of industry leaders, government figures, and innovators will take the stage at the 10th anniversary of UK Construction Week Birmingham, held at the NEC from 30 September to 2 October 2025.

Confirmed speakers include Richard Parker, Mayor of the West Midlands, David Atkinson of Willmott Dixon, and Emma Whigham, Director of the NHS New Hospital Programme, among a line-up of 200+ thought leaders tackling the UK’s most pressing built environment challenges.

This year’s programme explores how the construction sector can meet ambitious housing and infrastructure targets through policy reform, digital transformation, decarbonisation, workforce development, and innovation. Sessions will also address safety, regulation, mental health, and funding. Key sessions include:

• “Midlands United”, with Mayor Richard Parker on regional growth and green transition.

• “Turning Policy into Progress”, with Willmott Dixon, Kier Construction and others on whether the sector is ready to meet UK infrastructure targets.

• “Partnering for Health”, on the NHS’s Hospital 2.0 delivery model.

Other highlights cover AI in construction, procurement strategies, affordable housing, and safety at height.

With over 300 exhibitors, face-to-face networking, the Build Connect Lounge, and a show app to pre-book meetings, UKCW Birmingham 2025 is set to be the industry’s most influential event of the year.

To register for UKCW Birmingham for free, visit https://forms.reg.buzz/ukcwbirmingham-2025/cab-pr

We provide your construction office!

Fast availability in different sizes

Easy to dismantle and relocate

Adaptable and expandable at any time www.containex.com

Single Units are designed for drills, ladders & other tools using our simple peg-in pegout system it has never been easier to identify who is in possession of the asset. Our Mechanical Key Systems use the same concept on a larger scale to identify who has any key at a glance.

The Keytracker Smart Locker systems have unique and state-of-the-art RFID technology, smart charging facilities and provide secure storage for any type of device or equipment. Keytracker electronic cabinets ensure all keys are organised, secure, and quickly accessible to authorised users.

Alex Jones is a Director at Walker Morris, specialising in regulatory and construction law. With extensive experience advising developers, housing associations, and contractors on the evolving building safety landscape, Alex brings a practical and insightful perspective to the industry’s most pressing challenges.

In this interview, Alex shares his views on the UK government’s latest Building Safety Regulator (BSR) reforms — from the fast-track approval process to the implications of a single construction regulator — and what they mean for developers navigating a post-Grenfell regulatory environment.

The UK government’s recent BSR reforms aim to accelerate housing delivery. What’s your take on how these changes will practically impact the speed of new-build approvals?

Without specific details on what these reforms will mean, we’re very much in a “watch this space” position. That said, the government’s proposed changes can only be a welcome change to what is generally seen as a stalled process of progress.

Focusing on unlocking delays in the approval process (which have steadily worsened since coming into force in October 2023), the new Fast Track Process, together with additional reinforcements (including plans to recruit a further 100 new staff), should help unlock the delays, clear the backlog, and get approvals moving faster. The added impetus of new leadership to drive this should see that these reforms are successfully implemented sooner rather than later.

However, ultimately, how quickly this works in practice will depend on what

is rolled out and how smoothly the new system is rolled out.

One of the headline announcements was the introduction of a fast-track process. How can developers best position themselves to take advantage of this accelerated pathway?

Whilst it depends on the specifics of the reforms proposed, the most effective course of action for stakeholders is to maintain current best practice for progressing an application through the process and apply those same best practices to the new fast-track process when it becomes live.

Developers (and contractors) should be looking to:

• Get involved with the BSR and engage their multi-disciplinary team as early as possible in the process to mitigate the risk of hold-ups arising later down the line.

• Consider specialist building safety/ gateway advice to support the applications from commencement and through the process;

• Submit clear, complete, and compliant applications and detailed plans which serve to demonstrate realistic compliance with applicable safety requirements.

• Keep an eye out for new guidance from the BSR and industry bodies. For example, the Construction Leadership Council (CLC) revealed during recent Parliamentary discussions that the body has led a process to develop a set of guidance notes to support stakeholders. This, and similar guidance, will undoubtedly serve as an invaluable resource for developers travelling through the process.

With over 100 new staff and a leadership overhaul at the BSR, what challenges or opportunities do you foresee in adapting to this revamped regulatory structure?

The new leadership will bring fresh impetus for progress. Noting their serious fire safety backgrounds, it is clear that safety will remain enshrined as the core focus. However, the material benefit of these reforms is that having more people means applications should move faster. The potential for faster processing times is great news for developers stuck waiting in long approval queues where the changes will likely lead to improved engagement (where better resourced) and quicker turnaround times.

Yet with these changes, comes challenges. Bringing in so many new staff is no small feat and will require a lot of training and coordination to ensure consistency. That is not an easy task to effectively implement.

Overall, it’s a big shift, but if the BSR can manage the transition well, it could lead to a more responsive, consistent, and safety-focused regulator.

Continued >>>

The bar has already been raised by the changes brought by the Building Safety Act. Those changes have already been hard to adjust to from a compliance perspective, with a short window of transition afforded to developers and housing associations and a new, faster process will no doubt bring about further challenges.

The recent changes, and the House of Lords Industry and Regulators Committee inquiry into the success of the BSR suggest that the UK Government is alive to ensuring the right balance is struck.

You’ve advised developers and housing associations on regulatory reform — what are the immediate compliance challenges they should be preparing for under the new system?

The bar has already been raised by the changes brought by the Building Safety Act. Those changes have already been hard to adjust to from a compliance perspective, with a short window of transition afforded to developers and housing associations and a new, faster process will no doubt bring about further challenges.

However, the difficulty with the new regime is that we don’t yet know what it will fully entail and what developers/ housing associations will need to consider for and under the new process.

To date, there has not been much in the way of guidance provided to stakeholders on successfully navigating the approval process since it has come into force. That has presented challenges for developers/ housing associations who have no clear idea as to expectations and that will remain the case without better access to information and greater engagement by the BSR.

However, with a faster turnaround process expected, we can anticipate that stakeholders will be expected to buy into a quicker approach (meaning quicker turnaround times for application responses, and shorter deadlines). If that is the case, what is needed is better guidance for developers to align with the new processes where better guidance to support stakeholders through the process will enable them to understand the process and comply with the requirements and timescales of the BSR which will no doubt become quicker with the new, fast track process.

The reforms move toward a single construction regulator, as recommended by the Grenfell Inquiry. What are the implications of this shift, both for the industry and for public trust in building safety?

This change simplifies things. Instead of dealing with multiple bodies, there’s now one clear authority and one clear, centralised expectation as to requirements.

For developers, that means fewer mixed messages and more consistency. You’ll know exactly who to deal with and what’s expected.

For the public, it could help rebuild trust. After the Grenfell tragedy, confidence in the system was shaken. The changes, led by experienced fire safety figures like Andy Roe and Charlie Pugsley sends a strong message that there is a clear desire to create a clearer, more accountable system.

Of course, the real test will be in how this new structure performs. But if it delivers on its promise, it could mark a turning point for both the industry and the people who live in these buildings.

How do you see the balance playing out between faster housing delivery and maintaining the rigorous safety standards demanded post-Grenfell?

This is the material challenge of these changes, and the right balance has to be struck. However, what cannot be compromised is the safety of the buildings being constructed and any changes need to enshrine this mantra, whilst enabling effective and expedient delivery. With the leadership team now in place, I expect that safety will be the foundation of the regime, with enhancements to promote delivery only introduced where they complement, rather than compromise safety. The Fast Track Process feeds into this approach,

Looking ahead, these reforms are likely to shape construction law and policy in some fundamental ways, especially regarding accountability and enforcement.

where it is meant to boost capacity, not at the expense of lowering standards. Keeping that balance will take strong and regular oversight, good training, and clear performance tracking of what is working and what isn’t. The recent changes, and the House of Lords Industry and Regulators Committee inquiry into the success of the BSR suggest that the UK Government is alive to ensuring the right balance is struck.

Considering these changes, what should legal and compliance teams within construction firms be doing differently right now?

As and when more detail materialises, legal and compliance teams should look to shift into a proactive role to be ready. With a view to hitting the ground running for when the reforms come into play, now’s the time to:

• Consider the current state of play with your existing applications – what’s working, and what isn’t

• Review your current processes and best practices.

• Ensure your teams are trained up and knowledgeable about current regulatory requirements so that they can move fast when new changes arise

• Keep tabs on how the BSR plans to enforce the new standards.

• Be ready to provide more detailed, and potentially different documentation when needed.

With Andy Roe and Charlie Pugsley leading the reformed BSR, what signals do you think their appointments send about the future direction of the regulator?

Both have deep experience in fire safety and enforcement. Given their backgrounds, their leadership suggests the UK Government and the BSR are serious about putting safety and accountability at the heart of the construction industry.

Andy Roe’s comments on appointment confirm as much where he said: “I look forward to working with colleagues both in industry and the BSR to tackle the current issues and delays head on and help get those homes built safely.”

Their appointments confirm that safety isn’t just about ticking boxes anymore. It’s about making sure buildings are genuinely safe, and that those responsible for delivering them are accountable with a safety-first culture central.

Do you expect these reforms to have a noticeable impact on investor and developer confidence in the UK housing market?

In simple terms, they absolutely should improve confidence in the sector.

The changes brought by the Building Safety Act, whilst welcome, have created uncertainty around planning for and delivering projects. That uncertainty has been compounded by ever increasing delays in the system since the Gateway Regime became fully effective in October 2023.

Of course, confidence will depend on how well the new system works in practice.

If the BSR can deliver faster approvals from the get-go with appropriate and

better engagement with stakeholders (whilst not compromising safety), then we’re likely to see a real boost in sentiment across the board.

Looking ahead, how might these changes influence longer-term trends in construction law and policy — particularly around accountability and enforcement?

Looking ahead, these reforms are likely to shape construction law and policy in some fundamental ways, especially regarding accountability and enforcement.

We’ve now moved into (and continue to move deeper into) an era where compliance isn’t just a box-ticking exercise. The new system, which is being enhanced by these reforms, puts a

much stronger emphasis on proving that buildings are safe right from the design stage through to completion. That’s influencing and will continue to influence how contracts are written, how risk is managed, and how responsibilities are shared across project teams.

We’ll also likely see tougher enforcement. With a single, central regulator and a new leadership team who have serious fire safety and enforcement backgrounds, there’s a clear signal that non-compliance will be treated seriously. That could mean more investigations, more penalties, and a greater focus on holding individuals (not just companies) accountable when things go wrong.

Further, the regulatory regime only covers Higher Risk Buildings. However, if the enhanced and updated regime can be successfully implemented such that the process is significantly improved with better process times, greater awareness of requirements all whilst maintaining safety; the success of these reforms could lay the groundwork for the wider implementation of the regulatory regime across the construction industry more broadly. If that happens, legal teams and businesses across the industry will need to have greater awareness of the changes and the process generally.

Ecoblend is an advanced range of innovatively blended construction aggregates, building a better, more environmentally conscious future.

Ecoblend is the most comprehensive range of manufactured and recycled sub-base and capping aggregates on the market - providing the construction industry with cost-efficient, sustainable solutions meeting the highest standards of quality and performance.

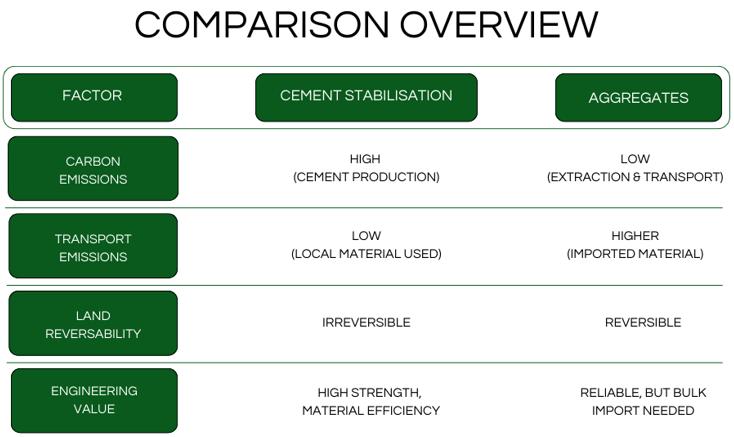

Carbon and Land-Use Impacts: Cement-Stabilised Ground vs. Aggregates

Choosing between in-situ ground stabilisation using cement and cementbased binders and the use of imported aggregates is often seen as a cost or technical performance decision. Increasingly though, carbon footprint and land-use consequences are becoming just as critical.

Carbon Emissions: Cement-Based Stabilisation

In-situ cement-based ground stabilisation improves ground strength by mixing existing soils with cement or proprietary binders. The challenge? Cement’s significant carbon footprint.

Manufacturing 1 tonne of cement emits around 0.8–1 tonne of CO₂ due to chemical reactions in limestone calcination and energy-intensive kiln firing. In stabilisation applications, emissions can be estimated at around 80 kg CO₂ per m³, depending on mix and binder ratio and this number excludes the CO2 used by the heavy plant needed to carry out the process.

Although using in-situ material reduces haulage emissions, cement’s embodied carbon outweighs these savings, making it a carbon-intensive method overall.

Natural, secondary, and recycled aggregates have a much lower inherent carbon footprint. Their extraction, processing, and transport typically emits less than 20-40 kg CO₂ per m³. Even with transportation factored in, total emissions remain far below those of cement-stabilised material.

However, aggregates can bring other environmental considerations. Quarrying and transporting materials consume fuel and contribute to traffic-related emissions. Moreover, excessive extraction of primary can lead to significant local environmental consequences, including habitat loss, increased dust levels, and noise pollution, so recycled or manufactured aggregates are generally the preferred environmental option.

Despite this, their overall carbon impact is considerably lower than cement-based stabilisation.