Respirator Fit Test Training

Learner Guide

In completing this course you will learn how to perform respirator fit testing and know the correct use of equipment.

1.

Learner Guide

In completing this course you will learn how to perform respirator fit testing and know the correct use of equipment.

1.

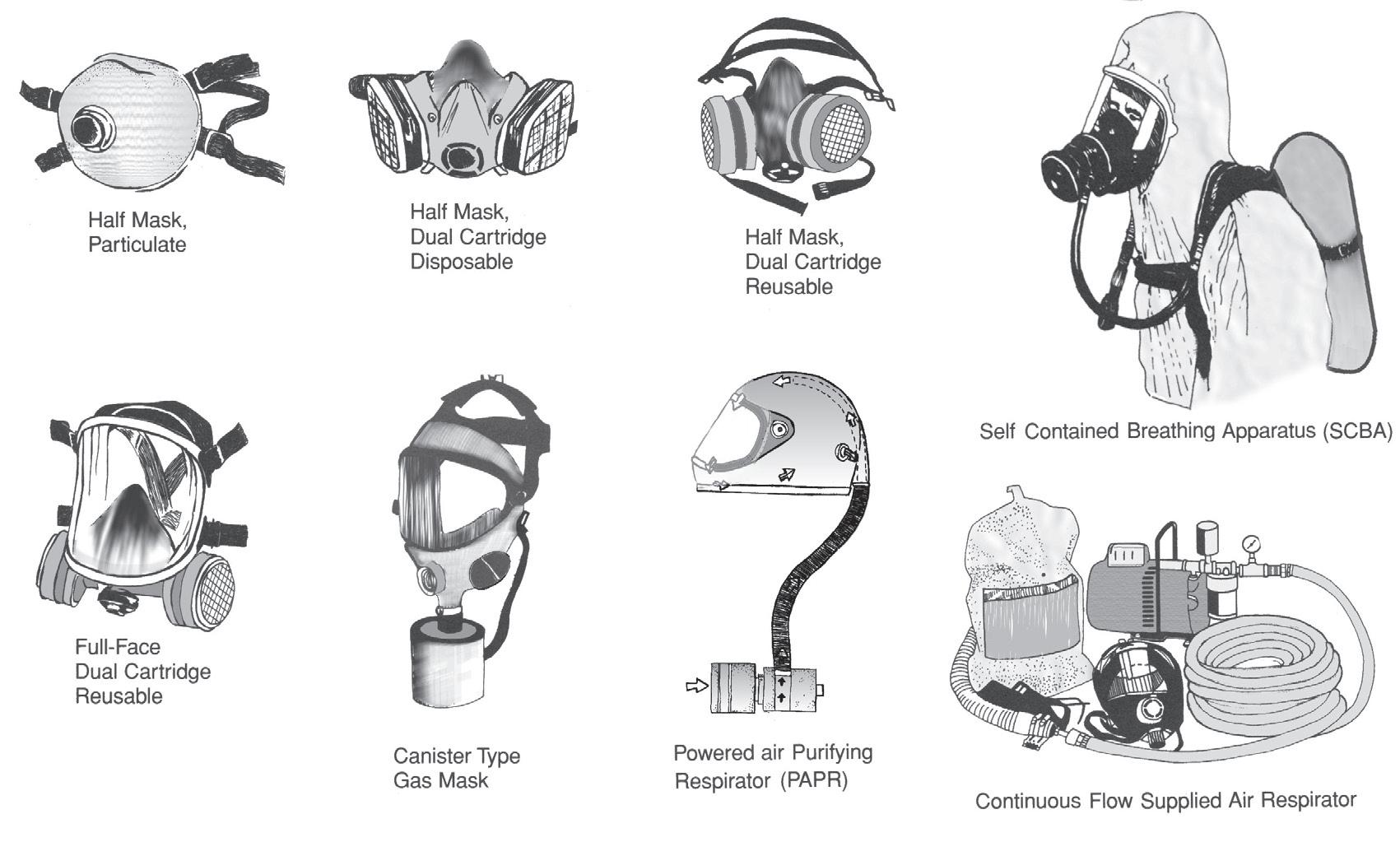

Respirators are worn by persons who must work in environments where the air is unfit to breathe and either have the function of filtering the air before the user is exposed or they supply a separate source of clean air.

The purpose of a respirator fit test is to protect an individual by ensuring that the respirator creates an effective seal on the face of the user thereby reducing the level of inhaled hazardous particles. The degree of protection can vary depending on the filtration of a particular make and model of respirator. In addition, it is very important that an individual knows how to properly put on (don) and wear a respirator.

A fit test is a validated method of matching a respirator to an individual, and checking the effectiveness of the seal, between the wearer and the outside environment.

The purpose of a respirator fit test is to protect an individual by ensuring that the respirator creates an effective seal on the face of the user thereby reducing the level of inhaled hazardous particles. The degree of protection can vary depending on the filtration of a particular make and model of respirator. In addition, it is very important that an individual knows how to properly put on (don) and wear a respirator.

Respirator fit testing is required for all tight-fitting respirators, including:

• half-face disposable

• half-face reusable

• full-face reusable

• tight-fitting powered air purifying respirators (PAPR)

• self-contained breathing apparatus (SCBA).

Positive-pressure respirators are a special subclass available in both APR (air-purifying respirator) and SAR (supplied-air respirator) versions, which can, in turn, be either tight- or loose-fitting. They provide high levels of protection by pumping air into the mask at all times rather than relying on the wearer’s lung power to draw air in (as do negative-pressure respirators). Tight-fitting positive-pressure respirators are fit tested in “negative-pressure mode” by temporarily converting them with an adapter. This is done because the effectiveness of the seal by itself cannot be evaluated properly while the power is creating positive pressure inside the mask.

There are two types of tests— qualitative and quantitative . A business may choose either method, according to their needs. The use of one or the other type of tests depends on the type of test will depend on the level of respiratory protection required and the resources available. The use of one or the other type of test will depend on the type of respiratory protective equipment (RPE) to be fit tested, the extent of RPE usage, and the resources available.

Qualitative tests are fast, and are easily performed. However, these tests rely on the wearer’s subjective response , and so are not entirely reliable. There are two available tests, QLFT-ATT, which is Qualitative Fit Testing- Aerosol Taste Test, and QLTF- IAA/Isoamyl acetate (banana smell); only for testing respirators with organic vapor cartridges. For the purposes of this course, we will be focusing on QLFT-ATT.

They use a test atmosphere which may be an enclosure into which:

a) The user can enter wearing the equipment

b) A ‘test’ contaminant (of low toxicity) can be placed.

Isoamyl acetate is a low toxicity substance with a banana-like odour. This test is only used on respirators equipped with an organic vapour cartridge. The substance is applied to the cotton wad inside the enclosure. The prospective user should put on the RPE in an area away from the test enclosure so that there is no prior contamination of the filters by ‘pre- exposure’ to the isoamyl acetate. The user enters the chamber and performs each of the following activities for 30 seconds:

a) Normal breathing .

b) Deep breathing , to simulate heavy exertion. This should not be done long enough to cause hyperventilation.

c) Side-to-side and up-and-down head movements . These movements should be exaggerated, but should approximate those that take place on the job.

d) Talking . This is most easily accomplished by reading a prepared text loudly enough to be understood by someone standing nearby.

e) Other exercises may be added depending upon the situation. For example, if the wearer is going to spend a significant time bent over at some task, it may be desirable to include an exercise approximating this bending.

f) Break face-piece seal and expose the wearer to test agent to verify the wearer’s sensitivity.

This test is suitable for respirators incorporating any particulate filter. It relies upon the wearer’s ability to detect a safe aerosol by taste. Individuals vary in their taste threshold; therefore a screening procedure is performed to establish suitability. Saccharin is sweet and Bitrex is bitter.

First, test subjects are tested for sensitivity to the taste of the aerosols. They are tested by wearing the hood, and keeping their mouth open, while the aerosol is sprayed into the hood, in “spray groups” of ten puffs each. If the subject tastes the flavour at any time during the first 10 puffs, they are given a score of 10. If they taste it at any time in the second group of ten puffs, they are given a score of 20. If they taste it in the third group of puffs, (21-30) they are given a score of 30. You stop puffing at any point when they taste the aerosol. If a subject does not taste the aerosol within 30 puffs, they cannot be tested using this method.

A period of at least several minutes should elapse after the sensitivity test before re-testing the subject wearing the RPE. Subjects may rinse their mouths with water at this time.

The test subject, having passed the sensitivity test, is fitted with the appropriate RPE. Since the flavoured mist is an airborne particulate, gas filter RPE should be fitted with a particulate filter for the test. The subject must keep their mouth open and tongue out inside the respirator. The subject places the hood over their head, and the aerosol solution is puffed through the test hole . The test subject will start to do a series of seven exercises (a protocol) similar to the ones outlined in the test above. Each “exercise” takes one full minute. The protocol below is from OSHA:

1) Normal Breathing

2) Heavy Breathing

3) Turn head side to side (stopping for two breaths at each turn)

4) Tilt head up and down, (stopping for two breaths at each apex)

5) Read a written passage (The Rainbow Passage)

6) Bending over

7) Normal breathing

Initially, the tester will deliver the same number of puffs as the subject’s score (10, 20 or 30) Then, the tester will deliver a half set of puffs every 30 seconds, (5, 10 or 15) The timer runs continuously, so, the aerosol gets delivered twice a minute. Since each exercise will be done for one minute, the aerosol should be delivered twice during each exercise in the protocol.

If at any time during the test, the subject can taste the aerosol solution, the test is considered a fail, and should be stopped. At the end of a successful (passed) test, the subject must remove the respirator, and the aerosol is delivered into the hood again, to confirm that the subject can still taste the aerosol.

These tests are relatively easy to perform and the equipment is inexpensive. There are disadvantages to qualitative testing. The test is subjective, and if a person has poor taste sensitivity, or is at risk for an allergic reaction, they cannot be tested this way. It can be time-consuming to perform education and assessment depending on protocols, and the test itself takes no less time than a quantitative test.

Because all qualitative tests rely on recognition of a taste or smell, test subjects should have no food or flavoured drink, no smoking or vaping, for 30 minutes prior to testing.

Quantitative test methods use equipment to measure the efficiency of a respirator in preventing materials in the atmosphere from entering a user’s breathing zone:

• Ambient Aerosol Condensation Nuclei Counting (CNC) using a PortaCount machine.

• Controlled Negative Pressure (CNP) uses a test that creates a vacuum by temporarily cutting off air.

• Generated aerosol uses a non-hazardous aerosol such as corn oil generated in a test chamber.

For the purposes of this course, we will only be discussing Ambient Aerosol Condensation Nuclei Counting (CNC) using a PortaCount machine.

This test measures the particle count found within the respirator and compares it to the particle count outside the mask, (ambient particle count). To do this, you must have an ambient particle count to measure against. You can use naturally occurring or artificially generated atmospheric particles.

The test subject will perform a series of exercises during the test, to challenge the seal of the mask. The machine will continually assess the particle count within the respirator and outside the respirator and compare them.

There will be more discussion of this method further in the course.

Selecting the best fit test method can only be done after considering the pros and cons of each method. For certain respirators, and certain levels of required protection, you will not have the choice, as qualitative testing can only be done up to a required protection level of 10. The table below provides a comparison of qualitative vs. quantitative methods.

Qualitative fit testing (QLFT)

Quantitative fit testing (QNFT)

Suitability for type of RPD

Suitable for disposable and reusable half masks; not suitable for full-face masks.

QNFT-CNC is suitable for disposable and reusable half masks and full-face masks.

QNFT-CNP is suitable for reusable masks only.

Vulnerability/ Objective Outcome

Exposure Limits

Advantages

Based on subjective detection and response by the wearer of the RPD. Fit factor is a “given score” with no numeric measure.

May be used to fit test negative pressure air-purifying respirators if they will only be used in atmospheres less than ten times the WEL, since existing evidence only validates the QLFT protocols to identify respirators that achieve a fit factor of 100.

• Low equipment cost

• Simple pass/fail results

Disadvantages

• Chance of employee deception

• Limited protection-factor verification (maximum fit factor of 100)

• Subjective results may be unreliable

Objective test; provides a numerical measure of how well a face piece seals against a wearer’s face; this is called a fit factor.

Can be used for concentrations higher than ten times the Workplace Exposure Limit.

• High protection factor test, up to 2000 for a full face-piece.

• No chance of employee deception

• Highly reliable

• Documentation of numerical results

• Expensive up-front equipment costs

• QNFT-CNC requires probed face piece or probed adapters, specific to the mask

• QNFT-CNP requires special leak-tight test adapters, specific to the mask

• Annual recalibration of equipment is required.

Trained Staff Fit tester should be trained in the delivery of the test, but interpreting results relies on the ability of the wearer to sense a test agent

Testing Methods

Specialized Equipment

Simple but test results are totally dependent on the user ability to detect the agent, and give an honest response. Unable to achieve a fit factor above 100.

Equipment is relatively inexpensive, but a test agent, either taste or smell, must be obtained. Test hoods are effective, but “homemade” versions will also work.

Requires a highly trained operator who understands how to set up and use the equipment, perform preventive equipment maintenance, and troubleshoot issues.

Both QNFT-CNC and QNFT-CNP are highly sensitive and accurate methods of testing.

QNFT-CNC: Requires a PortaCount machine or similar, and particle generator,

QNFT-CNP: Requires The OHD Quantifit instrument or similar,

Both are expensive up-front investments.

Accuracy of Result

Only Pass/Fail is detected. If a test subject is uncooperative, they may not provide truthful responses.

QNFT-CNC: Extremely accurate, detecting particle leakage of very low amounts

QNFT-CNP: Extremely accurate at measuring the leak rate inside the mask.

Atmospheric Sensitivity

Totally dependent on the subject

A calibrated machine is required, but should reliably detect particles or pressure change, depending on the method used.

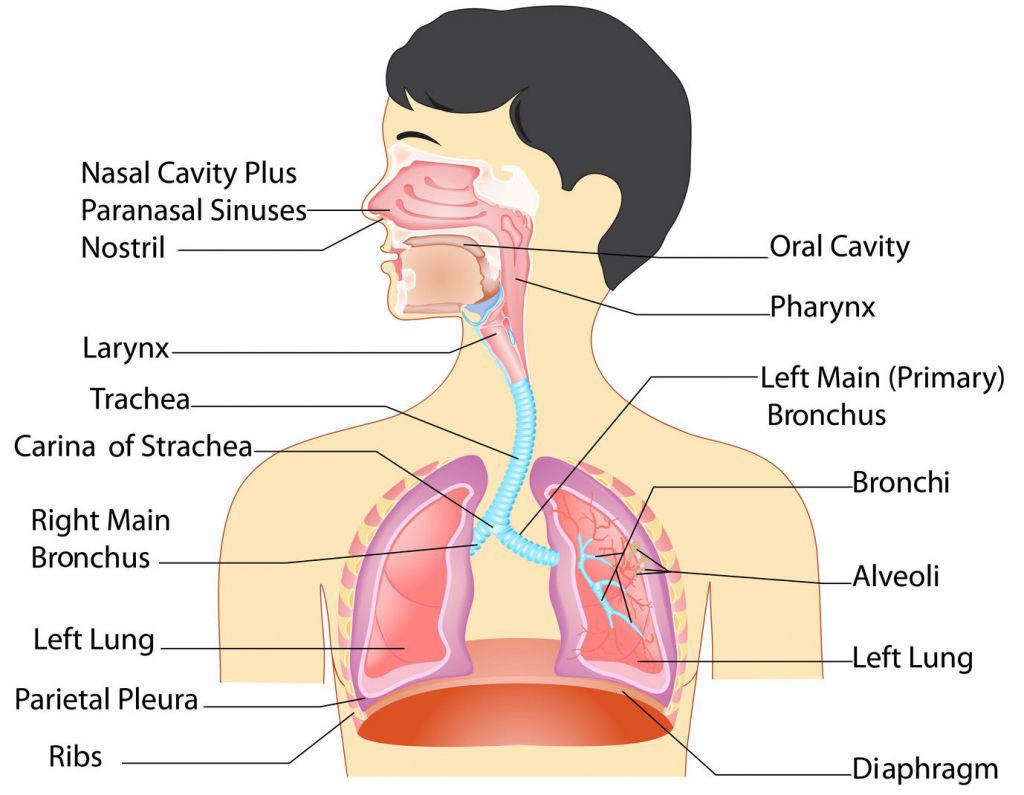

The major function of the respiratory system is gas exchanged between the external environment and the circulatory system. This involves taking in oxygen from the air to the blood and releasing carbon dioxide (and other gaseous waste products) from the blood back into the air.

Upon inhalation, gas exchange occurs at the alveoli, the tiny sacs which are the basic functional component of the lungs. The alveolar walls are extremely thin (approx. 0.2 micrometres). These walls are composed of a single layer of epithelial cells in close proximity to the blood capillaries which in turn are composed of a single layer of endothelial cells. The close proximity of these two cell types allows permeability to gases and, hence, gas exchange. Oxygen is taken into the blood whilst excess carbon dioxide is released.

The average person who is moderately active during the daytime breathes about 20,000 litres of air every 24 hours. Inevitably, this air contains potentially harmful particles and gases. Particles, such as dust and soot, mould, fungi, bacteria, and viruses deposit on airway and alveolar surfaces. Fortunately, the respiratory system has defence mechanisms to clean and protect itself. Only extremely small particles, less than 3 to 5 microns in diameter, penetrate to the deep lung.

Cilia, tiny muscular, hair-like projections on the cells that line the airway, are one of the respiratory system’s defence mechanisms. Cilia propel a liquid layer of mucus that covers the airways. This mucus layer traps pathogens (potentially infectious microorganisms) and other particles, preventing them from reaching the lungs. Cilia beat more than 1,000 times a minute, moving the mucus that lines the trachea upwards about 0.5 to 1 centimetre per minute (0.197 to 0.4 inch per minute). Pathogens and particles that are trapped on the mucus layer are coughed out or moved to the mouth and swallowed.

Alveolar macrophages, a type of white blood cell on the surface of alveoli, are another defence mechanism for the lungs. Because of the requirements of gas exchange, alveoli are not protected by mucus and cilia— mucus is too thick and would slow movement of oxygen and carbon dioxide. Instead, alveolar macrophages seek out deposited particles, bind to them, ingest them, kill any that are living, and digest them. When the lungs are exposed to serious threats, additional white blood cells in the circulation, especially neutrophils, can be recruited to help ingest and kill pathogens. For example, when the person inhales a great deal of dust or is fighting a respiratory infection, more macrophages are produced, and neutrophils are recruited.

Rebecca Dezube , MD, MHS, Johns Hopkins University

Coughing is a natural defense mechanism that protects the respiratory tract from inhaling foreign bodies and by clearing excessive bronchial secretions. Sneezing is simply an involuntary release of air that helps the body to get rid of irritants in our nose and throat, like allergens, dirt, and dust.

The four main routes of entry of toxins into the body are via inhalation, ingestion, absorption and injection. With regards to understanding respiratory protection, airborne particulate can only enter the body via inhalation, absorption through skin and eyes, or ingestion (swallowed particulate). Of these, inhalation is the route that poses the greatest threat to health.

1) Ingestion :

Humans have evolved mechanisms in the gut to regulate the uptake of essential elements. Toxic elements may have to compete so that generally only a fraction of any ingested dose is absorbed into the body (often 10% or less). Possible causes of ingestion in industry are mouth pipetting in laboratories, swallowing dust which has been inhaled and cleared by the mucociliary escalator, smoking and eating at the workstation or simply having dirty hands where the hand later comes in contact with the mouth.

2) Inhalation :

In the lung there are no similar mechanisms for selective uptake. Particles less than 10 micron in diameter may reach the alveoli. If soluble, approximately 40% are then absorbed. Insoluble chemicals are relatively safer, for example lead sulphide, whereas lead carbonate is highly soluble and causes poisoning quickly. Larger inhaled particles are less of a risk as absorption higher up the respiratory tract is less efficient. It is important to remember that not only is the lung responsible for the uptake of substances into the body it is also acted on as a target organ. Materials which are not absorbed into the body can remain in the lungs and cause physical and / or chemical damage to them. Inhalation accounts for approximately 90% of industrial poisoning.

3) Absorption :

In the skin there is again no selective uptake. Fat-soluble compounds are absorbed readily as are organic solvents. Percutaneous absorption through healthy intact skin can occur with nitrobenzene, phenol, mercury, and aniline. Absorption of phenol through just a few square inches of intact skin can be lethal. Impervious protective clothing like gloves will increase the rate of absorption if accidental contamination occurs on the inside. Damaged skin also facilitates absorption of toxins.

Once substances have entered the body they can be distributed around the body through the blood supply bound to plasma proteins or to red cells. They may concentrate differentially in the organs. Other toxic materials may be in solution or bound to lipids. Only lipid-soluble substances can pass the blood-brain barrier. (Basic Principles Occ Hyg - 3.3.3)

Airborne contaminants are potentially harmful substances that are either not naturally in the air or are present in an unnaturally high concentration and to which workers may be exposed in their working environment.

Airborne contaminants come in various forms:

• Dust : solid particles generated and dispersed into the air, for example, handling, crushing, grinding of organic or inorganic materials such rock, ore, coal, wood and grain.

• Fibres : Respirable fibres are considered responsible for adverse health effects caused by asbestos. To be respirable, a fibre needs to have a diameter of less than three micrometres and a length of greater than five micrometres; and a length to width ratio of greater than 3:1. These fibres are capable of penetrating to the terminal bronchioles of the gas exchange region of the lung and represent the most significant hazard to human health as they have the potential to cause asbestosis and mesothelioma with only minimal exposure.

• Mists : are suspended liquid droplets generated by condensation of vapour back to the liquid state or by breaking up as a liquid into a dispersed state, such as by splashing or atomising. Mist is the term applied to a finely divided liquid suspended in the atmosphere. Examples are an oil mist produced during cutting and grinding operations, acid mists from electroplating, acid or alkali mists from pickling operations, paint spray mist in painting operations and the condensation of water vapour to form a fog.

• Gases : are formless fluids that expand to occupy the space or enclosure in which they are confined. Examples are nitrogen, oxygen and formaldehyde.

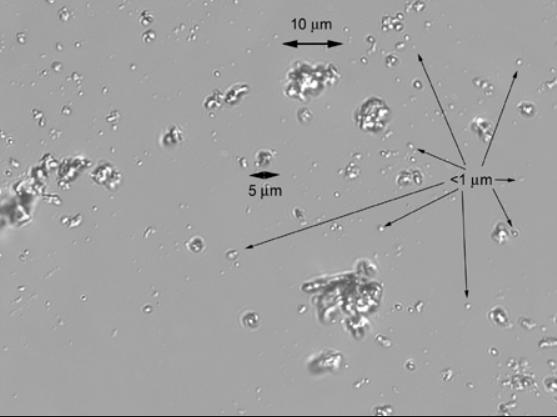

• Fumes : are extremely fine - usually less than 1.0 micrometer in diameter. Fumes are formed when the material from a volatilised solid condenses in cool air. In most cases the hot vapour reacts with the air to form an oxide. Fumes are often associated with molten metals, especially in processes like welding.

• Vapour : is the gaseous form of a substance which is normally in the solid or liquid state at room temperature and pressure.

• Biohazard Aerosols : illnesses spread by tiny pathogens (eg. bacteria, fungi, or viruses) in the air transmitted through airborne contact. In most cases contracted when someone breathes in infected air.

Particles is a generic term used to describe airborne solid or liquid substances in the finely divided state ie, particulate aerosols such as dusts, mists, fumes, fibres and fog as well as microorganisms.

What size dust is a respiratory hazard?

Inhalable dust particles are under 100 microns in diameter.

Thoracic dust particles are under 25 microns and can penetrate the head airways and enter the airways of the lung.

Respirable (breathable) dust fragments are measured in microns. This is the smallest size dust fraction. Respirable dust particles are under 10 microns in diameter.

• Determined by having an upper (max) aerodynamic diameter of 10μm (micron)

• Very small respirable 0.5 to 2μm

• Hazardous when deposited in the gas exchange area of the lung (bronchioles and alveoli).

Like the skin and the eye, the lungs are affected by irritants and allergens. They also respond in the forms of fibrotic pneumoconiosis and malignant disease to a variety of industrial agents.

Particles greater than 10 μm in diameter are filtered by the nose. The branching structure of the airways encourages deposition of 2-10 μm particles which can then be cleared by the mucociliary escalator. In the alveoli remaining particles either pass back up the bronchial tree freely or are phagocytosed (a process by which certain living cells called phagocytes ingest or engulf other cells or particles) by macrophages and taken to the mucociliary escalator or to the surrounding lymphatic system. Despite their efficiency, large volumes of particles can overwhelm these defence mechanisms.

Irritation caused by gases and fumes produces inflammation of the respiratory tract and the symptoms tend to be acute (sudden and severe) or delayed, depending on the solubility of the toxic agent. There can also be chronic (ongoing and recurring) effects. Chronic effects from prolonged exposure may be chronic bronchitis or COPD.

Allergic reactions to substances can cause occupational asthma. Symptoms include severe shortness of breath as well as wheezing, coughing and chest tightness. Certain substances such as isocyanates (used in paints), flour dust and various fumes can cause asthma. These substances are called ‘respiratory 20 sensitizers’ or asthmagens. They can cause a change in people’s airways, creating what is known as the ‘hypersensitive state’.

Not everyone who becomes sensitized goes on to get asthma. But once the lungs become hypersensitive, further exposure to the substance, even at quite low levels, may trigger an attack.

Occupational lung diseases are conditions of the respiratory system that have occupational exposure as a risk factor for developing the disease. These diseases may be acute, sub-acute or chronic, and either malignant, non-malignant or infectious in nature.

Pneumoconiosis

The pneumoconioses are a group of interstitial lung diseases caused by the inhalation of certain dusts and the lung tissue’s reaction to the dust. The principal cause of pneumoconiosis is work-place exposure.

Pneumoconiosis diseases may not produce any symptoms for years. However, as the lungs become less flexible and porous their function is greatly reduced. Initially, symptoms include shortness of breath, cough, and general ill feeling. As the diseases progress, shortness of breath, coughing up blood and poor blood oxygenation may occur.

Occupational lung diseases include:

• Aluminosis – pneumoconiosis caused by the presence of dust containing aluminium in the lung tissue.

• Asbestosis, asbestosis induced carcinoma, mesothelioma –diseases caused by inhalation of asbestos.

• Asthma – a condition in which a person’s airways become inflamed, narrow and swell and produce extra mucus, which makes it difficult to breathe.

• Berylliosis (chronic beryllium disease) – pneumoconiosis caused by inhalation of dusts (or vapours) containing beryllium.

• Byssinosis – a pneumoconiosis caused by inhalation of cotton dust.

• Coal workers’ pneumoconiosis (CWP) – pneumoconiosis caused by exposure to respirable coal dust.

• Hard metal pneumoconiosis (hard metal lung disease or HMLD) – fibrotic pneumoconiosis caused by respirable dusts of hard metals such as tungsten, tungsten carbide and cobalt.

• Silicosis – pneumoconiosis caused by exposure to respirable crystalline silica, may lead to lung cancer.

• Talcosis – pneumoconiosis caused by exposure to respirable talc dust.

Safework Australia

Commonly referred to as COPD, this is a group of progressive lung diseases. The most common of these diseases are emphysema and chronic bronchitis. Many people with COPD have both conditions.

Emphysema slowly destroys air sacs in your lungs, which interferes with outward air flow. Bronchitis causes inflammation and narrowing of the bronchial tubes, which allows mucus to build up.

COPD makes it harder to breathe. Symptoms may be mild at first, beginning with intermittent coughing and shortness of breath. As it progresses, symptoms can become more constant to where it can become increasingly difficult to breathe.

Malignant tumours of industrial origin can affect the lungs and surrounding tissues. Lung cancer has been discovered in people working with asbestos (miners, insulators) and this risk is increased by cigarette smoking, arsenic (pesticides), chromium (pigment manufacturers), polycyclic aromatic hydrocarbons (coal gas manufacture, tar workers) and ionising radiation (uranium miners). Wood dust (hardwood furniture makers), leather dust and nickel dust have been directly tied to nasal sinus cancer.

Any person or worker that is required to wear RPE to limit their exposure to workplace airborne contaminants:

• Cuts or drills manufactured stone such as kitchen benchtops

• Blasts, excavates or tunnels into sandstone, clay or granite

• Drills, cuts or chases into concrete and brickwork

• Cuts bricks or tiles dryangle grinds on concrete or masonry

• Jackhammers, scabbles or chisels concrete

• Cleans up the dust and debris created by the above activities, including dried concrete slurry dismantles equipment covered in dust

• Demolishes buildings.

Any person in the health industry that may be exposed to airborne infections includes:

• Medical Staff (doctors, nurses, specialists)

○ Particularly Anaesthetics, Emergency/Trauma, Theatre, Dental, Opthalmology

• Allied Health Staff

• Cleaning and janitorial staff

Two categories of respirators:

1) Air Purifying Respirator (APR) – Removes contaminants before they reach the breathing zone

2) Supplied Air Respirator (SAR) – Provides a source of respirable air which is independent of the working environment.

Air Purifying (APR) Variations:

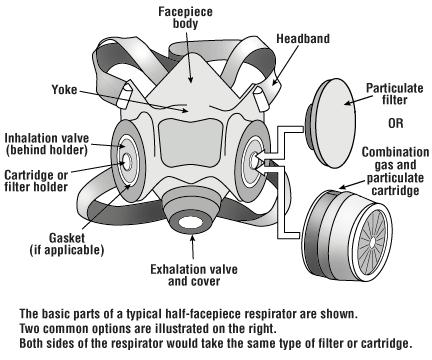

APR’s work by removing gases, vapors, aerosols (airborne droplets and solid particles) or a combination of contaminants from the air through the use of filters, cartridges, or canisters. These respirators do not supply oxygen from other than the working atmosphere, and therefore cannot be used in an atmosphere that is oxygen-deficient or immediately dangerous to life or health.

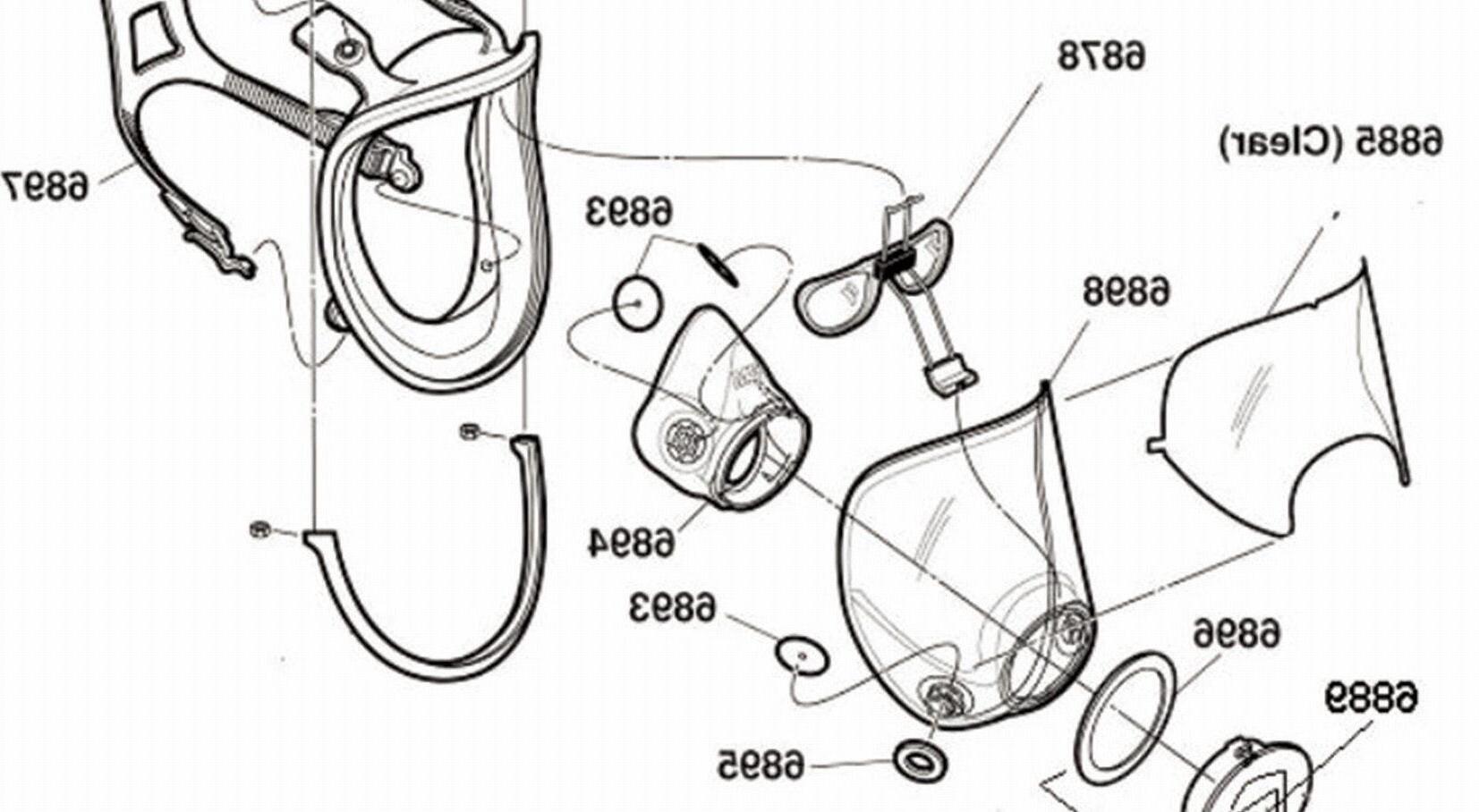

• Disposable (filtering facepiece)

• Half face: with filters P1, P2, or P3

• Full face: with filter P3

• Powered Air–Purifying Respirator (PAPR): battery-powered devices that use a blower to pull air through attached filters (for particles) or cartridges (for gases or vapors) to clean it before delivering it to the breathing zone of the wearer. Highefficiency (HE) filters are the only class of particulate filters available for powered airpurifying respirators. The benefits of PAPRs include a low breathing resistance with a high level of protection.

Supplied Air (SAR) Variations:

• Self–Contained Breathing Apparatus (SCBA) For use in situations where the ambient environment is deadly, i.e. under water or highly toxic atmosphere. Provides up to 2 hours of air but can be very heavy to carry.

• Continuous Supplied Air Respirator (airlines or hoses): These are usually long hoses, and air supply is unlimited. The length of the air hose may present issues in certain work environments, where users need to move from one area to another.

• Escape Breathing Apparatus: short term, for emergency evacuations that will not take longer than 15 minutes.

*Air Purifying Respirators (APR)

*Supplied Air Respirators (SAR)

There are two types of filters for air-purifying filters:

1) Particulate Filters that filter out thermally and mechanically generated particulates. The particulate filter is rated according to its efficiency; P1 the lowest efficiency to P3 the highest efficiency. NOTE: Respirator users are advised that an additional gas filter or filters will be required where the process responsible for generating particulates also liberates toxic gases.

a) Class P1 filters : used against mechanically generated particulates, e.g. silica and chrysotile. Three types of Class P1 filter RPE are generally available, i.e. powered type, replaceable filter type and disposable type.

b) Class P2 filters : used for protection against mechanically or thermally generated particulates or both, e.g. metal fumes. Three types of Class P2 RPE are generally available, i.e. powered type, replaceable filter type and disposable type.

c) Class P3 filters : used for protection against highly toxic or highly irritant particulates, such as beryllium. Two types of Class P3 RPE are generally available, e.g. powered type and replaceable filter type. For P3 filter classification, a full facepiece is required for non-powered RPE, and a head covering or full facepiece for a PAPR. When a P3 filter is used in a half facepiece, a protection factor equivalent to a P2 filter is achieved.

2) Gas Filters are used to protect against specific gases and vapours. These filters are coded with letters to indicate the contaminant for which the filter provides protection. See the below table.

Type A – organic vapours

Type B AUS or B1 – acid gases

Type B2 and B3 – acid gases and hydrogen cyanide (HCN)

Type E – sulphur dioxide (SO 2 )

Type G – agriculture chemicals

Type K – Ammonia (NH 3 )

Type AX - Low boiling point organic compounds (below 65°C)

Type NO - Oxides of nitrogen

Type Hg – Mercury

Solvents (with boiling point above 65°C)

Chlorine / sterilization of water, chemical manufacture, hydrogen chloride / chlorinated organic chemical manufacture, steel pickling

Plastics manufacture, gold ore refining, HCN fumigation

SO 2 /casting of metals, bleach manufacture, manufacture of sulphuric acid, fertilizer manufacture, metal cleaning, petroleum refining

Low vapour pressure (below 1.3 Pa at 25°C) organic vapours, pesticide spraying, mixing, manufacture

NH 3 /refrigeration, manufacture of fertilizers, explosives, plastics, low boiling point amines/chemical manufacture

As specified by the manufacturer (e.g. dimethyl ether, vinyl chloride)

Oxides of nitrogen

Metallic mercury/chemical industry, inorganic mercury compounds

Type MB - Methyl bromide Fumigation

Other types

For use against specific chemicals not falling in the above type description as specified by the manufacturer (e.g. hydrogen fluoride)

The mode of air delivery may be either one or a combination of the following:

1) Non-powered : air is drawn through the filter or filters by wearer inhalation. The respirator may consist of a half facepiece with one or more replaceable filters, a filtering (disposable type) facepiece, a full facepiece or head covering with one or more replaceable filters, or a mouthpiece and nose clip, with integral filter.

2) Powered : the contaminated air is drawn through a filter by means of a fan and delivered to the space enclosed by the head covering. This respirator may be a half facepiece, full facepiece or head covering with one or more replaceable filters and an electrically operated blower unit. The air delivery to a wearer may be continuous or on-demand. This is referred to a positive pressure respirator. A low-flow warning device may be fitted to indicate a reduced air supply.

Positive-pressure respirators are special subclass available in both APR and SAR versions, which can in-turn, be either tight- or loose-fitting. They provide high levels of protection by pumping air into the mask at all times rather than relying on the wearer’s lung power to draw air in (as do negative-pressure respirators). Tight-fitting positive-pressure respirators are fit tested in “negative-pressure mode” by temporarily converting them to an APR with appropriate filters. This is done because the effectiveness of the face seal by itself cannot be evaluated properly while the air supply is turned on.

APR and SAR can both be further separated into tight-fitting and loose-fitting styles. Tight-fitting respirators form a tight seal to the wearer’s face and will not provide protection if they do not adequately match the individual’s facial features. Loose-fitting respirators are typically hoods that fit over the entire head and have a neck seal that is not dependent on the wearer’s features.

All tight-fitting respirators must be fit tested .

In order to select appropriate RPE for your workplace, you need to learn how to calculate the level of protection that is required. Let’s look at some of the terminology we will use.

Regulatory agencies set the limits to which workers can be exposed to particular hazards. These are known as “Exposure Standards “. They are numerical values (e.g. milligrams per cubic metre) which represent the exposure levels to which workers may be repeatedly exposed and are regarded as an “acceptable risk”. There are three exposure standards to consider.

1) 8-hour time-weighted average (TWA)

2) Short term exposure limit (STEL)

3) Peak limitation (PEL)

reflects the maximum average exposure a worker can be subjected to without experiencing significant adverse health effects. This may be measured as TWA, STEL, or PEL.

• Time-weighted average (TWA) is a method of calculating a worker’s daily exposure to hazardous substances such as dust, fumes, chemicals, gases, or vapors. It is averaged to an 8-hour workday or 40-hour week, along with the average levels of exposure to the hazardous substance and the time spent in that area.

• Short term exposure limit (STEL) means the time-weighted average maximum airborne concentration of a substance calculated over a 15-minute period. This is the maximum average exposure a worker can be subjected to in a 15-minute period without experiencing significant adverse health effects. Exposures at the STEL must not be longer than 15 minutes and must not be repeated more than four times per day. There must be at least 60 minutes between successive exposures at the STEL.

• Peak Exposure Limit (PEL) means a maximum airborne concentration of a substance determined over the shortest analytically practicable period of time (under 15 minutes)

Note that not all substances are given an STEL or a PEL. Not all chemical substances affect the body in the same way and therefore, some present higher risks to workers than others. The table on the next page gives an example of this. If a substance has a STEL, it must be observed along with the TWA limits.

Where workers have a working day longer than eight hours or work more than 40 hours a week, the person conducting the business or undertaking must determine whether the TWA exposure standard needs to be adjusted to compensate for the greater exposure during the longer work shift, and decreased recovery time between shifts.

Peak limitation or short term exposure limit exposure standards must not be adjusted. TWA exposure standards must not be adjusted (increased) for shorter work shifts.

The following examples are taken from the Safework Australia publication, Workpalce Exposure Standards for Airborne Contaminants

The selection of an appropriate respirator must be done so that the exposure level to the contaminant is reduced to an acceptable level. To understand the contaminant level in the atmosphere an assessment must be undertaken, often by an occupational hygienist. This is called environmental sampling. Once you know the contaminant type and level, you can select RPE.

A protection factor is a measure of how well a mask will filter contaminants. There are several protection factors we must consider when choosing a respirator.

• The Required Minimum Protection Factor (RMPF): is the level of protection required by the respirator to reduce the exposure to an ‘acceptable level’. It is calculated as ambient airborne particle concentration / acceptable exposure level

• Assigned Protection Factor (APF): is the level of protection a respirator will provide that can be expected by 95% of all clean shaven, fit tested and trained wearers on the job. This number is given by the manufacturer of the respirator, and it is used to assist in selecting an appropriate respirator. We multiply the APF by 10 to get the fit factor we wish to achieve. In other words, a respirator with an APF of 10 should have a fit factor of 100 in a fit test. A respirator with an APF of 50 should have a fit factor of 500 in a fit test.

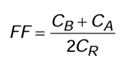

• Fit Factor: is the numerical result produced by a fit test. It is calculated as the number of particles in the ambient atmosphere outside the mask divided by the number of particles inside the mask during a specific set of exercises. It is a score given to determine if a respirator provides a good seal on a user, and is used to match a respirator to an individual. Fit Factor is related to Assigned protection factor in that the required fit factor to pass a mask will be 10x the assigned protection factor.*

• Workplace Protection Factor (WPF): this is the level of protection actually experienced by an individual while working in a hazardous environment. It is expressed as the concentration of REAL ambient hazard outside the respirator divided by the concentration of REAL ambient hazard that leaks into the respirator. WPF’s are usually measured by attaching personal sampling pumps to individuals while they go about their normal work activities. This technique is often used for conducting respirator research.

* This is based on combining filters and masks appropriately, for example, a P3 filter will an APF of 50 will not achieve a fit factor of 500 because it is only a half mask.

Workplace Protection Factor = ambient airborne particle concentration outside the mask divided by particle concentration inside the respirator while working. Requires real-time sampling of respirator in the workplace.

Fit Factor= ambient airborne particle concentration outside the mask divided by the number of particles inside the mask during a specific set of exercises; the result of a Fit Test

The Required Minimum Protection Factor= ambient airborne particle concentration divided by workplace exposure limit.

Remember a passing fit factor is generally 10 times the Assigned Protection Factor of the respirator or filter being tested.

The Workplace Exposure Standard limit for respirable crystalline silica is a Time Weighted Average of 0.05mg/m3

In Workplace X, the current exposure level is 0.45mg/m3.

We calculate the Required Minimum Protection (RMP) by dividing the Current Exposure Level (CEL) by the Workplace Exposure Standard’s limit (WES).

0.45/0.05 = 9

Required minimum protection for this workshop is 9. Therefore, a P2 mask, which has an Assigned Protection Factor of 10, will provide adequate protection. The fit factor we would need to achieve on a fit test is 100.

When looking at protection against micro-organisms such as viruses and bacteria, it is difficult to provide a protection factor as it may not be known what level of exposure is harmful for an individual. Different microorganisms may have a different level of risk, the infectious dose and the individual susceptibility may be varied. In general, N95 masks (P2) are considered to provide adequate protection against microorganisms. This is supported by recent research.

The filtration efficiencies against aerosols containing two different types influenza virus particles (H1N1 and H5N1) were measured for five different models of 3M filtering facepiece respirators. Testing was conducted at the University of Nebraska Medical Center in collaboration with 3M.3638 The results indicate filtering efficiency above 95%, but just below 99%, against an aerosol containing H1N1 virus particles.

The products tested included respirators with NIOSH N95 approval (US) and with EN149 FFP2 and FFP3 approvals (Europe).

36. Lore, M.B., Sambol, A.R., Japuntich, D.A., Franklin, L.M. and S.H. Hinrichs, Inter-laboratory performance between two nanoparticle air filtration systems using scanning mobility particle analyzers. Journal of Nanoparticle Research. 13:15811591; 2011.

37. Lore, M.B., Sebastian, J.M., Brown, T.L., Viner, A.S., McCullough, N.V. and S.H. Hinrichs, Performance of Convential and Antimicrobial-Treated Filtering Facepiece Respirators Challenged with Biological Aerosols. Journal of Occupational and Environmental Hygiene. 9(2):69-80, 2011.

38. Hinrichs, S.H., Lore, M.B. and Brown, T.L. Filtration Peformance of Five Respirator Models when Challenged with H1N1 and H5N1 Influenza Virus Aerosols. 20 October 2010 Report from University of Nebraska Medical Center to 3M Company. 2010.

Several factors need to be considered when selecting RPE as noted within the Australian Standards.

A respiratory protection program includes the following components:

1) Contaminant: level of toxicity, physical form, concentration. Generally, you protect against particulate hazards with a filter and against gas and vapours with a cartridge. If both types of hazards are present, combination cartridges are an option that can filter out both particles and gas or vapours. Also consider flammability of contaminant, whether the contaminant is an eye or skin irritant, or if device failure would be immediately life-threatening.

2) Worker: physical and psychological factors, which will be identified in a medical screen.

3) Work Task: physical aspects, i.e. effort causes faster breathing, or sudden body movements which could affect fit; need for other PPE; vision or communication requirements

4) Work Environment: temperature of environment, or being near flammable substances

5) Equipment Limitations: Does it protect skin, eyes? Is there an air hose or a tank with a limited amount of air? Is it too heavy to wear for any length of time?

6) Special Response to HAZMAT Incidents: These may require further risk assessment and specialized equipment as hazards may include radiation or deadly toxins. It is likely that the respiratory equipment is just one part of the PPE that may be required.

Below is a summary of the information required to make decisions about RPE:

1) Understand the hazard

a) Particulate?

b) Gas or Vapour?

c) Biological?

d) Combination?

2) Understand the exposure

a) Are you certain of the exposure levels?

b) Are they outside the Workplace Exposure Standards?

c) Do you need to assess the environment?

3) Know the level of protection required

a) What level of protection is needed to bring the exposure to below the acceptable level?

4) Select the appropriate respirator

a) Does it meet Australian Standards?

b) Can it be used with the other PPE required?

c) Can one model be used for all individuals?

Whether you work in industry or healthcare, your business is responsible for creating and ensuring a safe workplace, as much as is practicable.

There is extensive legislation in Australia to guide businesses as they manage WHS in the workplace.

The below is a list of the legislation, standards, codes and guidance documents that are in place to manage and outline workplace health risks.

• Work Health and Safety Act 2011

• Work Health and Safety Regulation 2011 (particularly Chapter 3 – General risk and workplace management and 7.1 – Hazardous Chemicals)

• AS/NZS 1715:2009 Selection, use and maintenance of respiratory protective equipment

• Silica and the lung—fact sheet

• Safe Work Australia Managing Risks of Hazardous Chemicals in the Workplace Code of Practice 2012

• Managing risks of hazardous chemicals in the workplace Code of Practice 2013

• Foundry Code of Practice 2004

• Abrasive blasting Code of Practice 2013

• Excavation work Code of Practice 2013

• Silica – Technical guide to managing exposure in the workplace – Work-related Disease Strategy 2012 – 2022

Clinical guidelines provide information on general principles of respiratory protection for healthcare workers and are formally aligned with following legislation and standards.

Australian/New Zealand Standards:

• Standards Australia AS 4381:2015 - Single-use face masks for use in healthcare

• Standards Australia AS/NZS 1715:2009 - Selection, use and maintenance of respiratory protective equipment

• Standards Australia AS/NZS 1716:2012 - Respiratory protective devices

National Safety and Quality Health Service Standards:

• Standard 3 - Preventing and Controlling Healthcare Associated Infections Criterion 3.7.1requires infection prevention and control consultation regarding policies and procedures that address personal protective equipment.

Australian Guidelines for the Prevention & Control of Infection in Healthcare (2019):

• Recommends that where there is a high probability of airborne transmission due to the nature of the infectious agent or procedure then a correctly fitted P2/N95 respirator should be worn

Principles for the Management of Tuberculosis in New South Wales PD 2014:

• Tuberculosis (TB) Services are required to operate in accordance with this policy in conjunction with the current relevant guidelines for the prevention and control of tuberculosis in NSW, which reflect best practice for the clinical and public health management of TB.

Note

Each state and territory will have its specific legislation that must be read in conjunction with the AS and ISO standard.

AS/NZS 1715:2009 & ISO 16975-3

These two Standards are referred to regularly in Australia as guidance for the development of a Respiratory Protection Program in a workplace.

• AS/NZS 1715:2009 Selection, Use and Maintenance of Respiratory Protective Equipment

• International Standard ISO 16975-3, Respiratory protective devices – Selection, use, and maintenance – Part 3: Fit- testing procedures

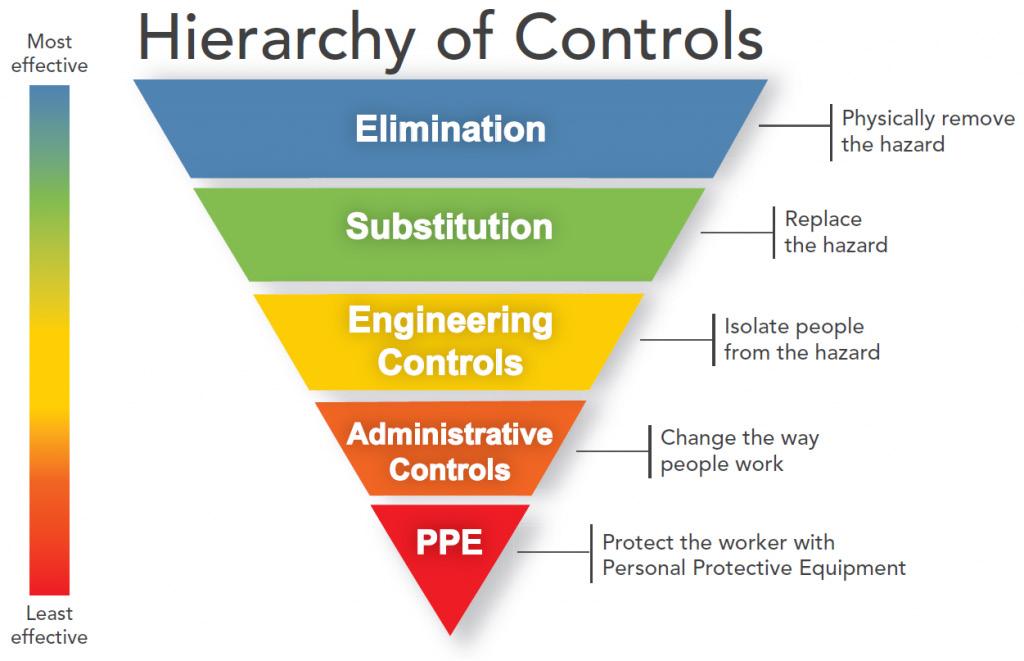

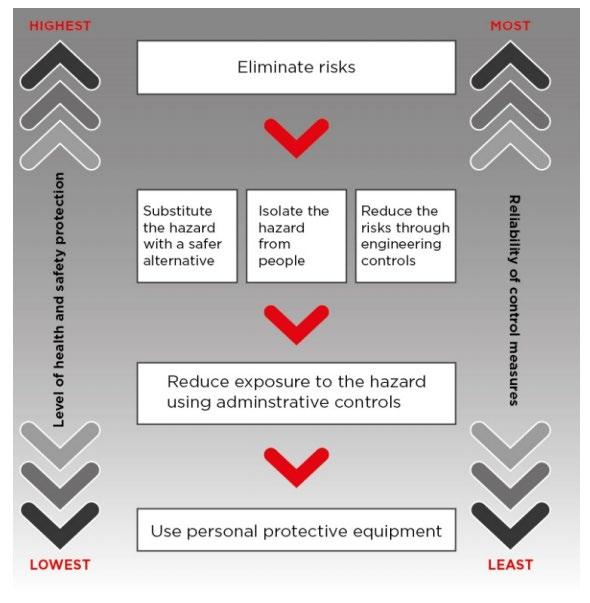

Risk management refers to the steps that a business and its employees should take to reduce or eliminate safety risks in their workplace.

The hierarchy of control is a system for controlling risks in the workplace. It is a step-by-step approach to eliminating or reducing risks and it ranks risk controls from the highest level of protection and reliability through to the lowest and least reliable protection. The hierarchy consists of hazard control measures broadly grouped into five categories.

Eliminating the hazard and risk is the highest level of control in the hierarchy, followed by reducing the risk through substitution, isolation and engineering controls, then reducing the risk through administrative controls. Reducing the risk through the use of protective personal equipment (PPE) is the lowest level of control and is also considered the least reliable.

Elimination

• Ensure well-designed work premises and processes. Adopt production processes that generate less dust.

• Treat the dust at its point of generation.

• Have plant equipment that is automated / remote controlled if possible. Substitution

• Substitute with a less hazardous substance, such as the use of pellets rather than powders, or replace sand with garnet as abrasive blasting agent.

• Substitute chemicals and other hazardous substances for less hazardous types, where practicable.

Engineering controls

Administrative controls

• Install effective local exhaust ventilation

• Provide plant with enclosed cabins that filter out air contaminants and are air-conditioned

• Place a physical barrier between the dust-generating task and the worker, such as the use of enclosed cabins to isolate workers.

• Use remotely operated machinery, such as remotely controlled conveyors.

• Install effective local exhaust ventilation

• Provide plant with enclosed cabins that filter out air contaminants and are air-conditioned

• Housekeeping and signage

• Restricting time of exposure, rotation of staff away from dusty areas

• Air quality monitoring

• Safe work procedures and inspections

• Limit eating and drinking

• Vaccination programs and health checks

• Employee training in identifying and managing the risk

Respiratory Protective Equipment

• Select the most appropriate RPE. Available in range from simple P1 or P2 disposable half-face respirator to powered air purifying respirator (PAPR) and air supplied positive pressure demand respirator.

• Minimum required protection factors may need to be determined for correct respirator selection. See AS/NZS 1715 or WHSQ’s silica documentation for further assistance.

• Ensure training, comfort and fit testing are provided before use. Respirators should not be shared. Maintain and store respiratory protective equipment properly.

• Applicable for short term applications. Suitable for all emergency applications, useful when higher order controls cannot fully control the risk.

With regards to the development of a Respiratory Protection Program in a workplace, a significant guide is found in Standards Australia AS/NZS 1715:2009. Selection, use, and maintenance of respiratory protective equipment . This Standard outlines the requirements for fit testing and the creation of a Respiratory Protection Program for a workplace.

One of the best ways to prevent occupational exposure to airborne contaminants is to use a respirator. However, a respirator is only as effective as its seal. Users of respirators must be medically assessed, trained, and fitted to a respirator, as well as taught how to maintain one. In order to ensure that respirators are used correctly in a workplace, a business should have a documented Respiratory Protection Program. A Respiratory Protection Program is a core component of ensuring respiratory safety in a workplace.

Standard AS/NZS 1715:2009 provides a clear outline of the requirements for a proper Respiratory Protection Program. While following this guideline is not required by legislation, Industrial Standards are considered to be “best practice” and a strong indication of a business’s commitment to creating a safe work environment.

According to AS/NZS 1715:2009, a Respiratory Protection Program must include the following components:

1) Appointment of a Program Administrator : This person should have the background and training to enable them to make sound decisions based on an understanding of workplace hazards. Ideally, they should be a WHS professional.

2) Selection of RPE : This process will include considerations of contaminants, operator task requirements, including use of other PPE, communication, vision and comfort.

3) Medical screening of users of RPE : All users of RPE should be screened for conditions that preclude the safe use of RPE.

4) Training : Training must be provided in the safe use and limitations of RPE and should be conducted at least annually.

5) Issue of RPE : Where practicable, RPE shall be for a wearer’s exclusive use. RPE should bear identifying marks.

6) Fitting of equipment : Facial fit tests are required to establish proper fit of RPE.

7) Wearing of RPE (where required) : The RPP shall require that RPE is used properly and worn at all times when required.

8) Maintenance of RPE : Maintenance shall include cleaning and disinfection, inspection, repair, and storage or disposal. All should be done according to manufacturer instructions.

9) Disposal of equipment : Where legislative requirements exist or there are relevant manufacturer guidelines for appropriate disposal, these should be followed.

10) Records for a respiratory protection program : These should include user records, issue of RPE, maintenance and procedural records.

11) Program evaluation : Annual audits are recommended, including a review of the risk assessment, and the results of any biological or atmospheric monitoring.

Using a respirator may place a physiological or psychological burden on employees. The impact of that burden varies with the type of respirator worn, the job and workplace conditions in which the respirator is used, and the medical status of the employee. It is recommended that an initial medical assessment is undertaken to establish if a person is able to wear a respirator. Some factors will preclude the use of RPE entirely.

Physiological considerations

• Chronic lung conditions, i.e. emphysema or asthma

• Circulatory diseases

• Seizure disorders

• Ability to support the weight of the respirator

Psychological considerations

• Claustrophobia

• Isolation

• Anxiety Example Medical Screen https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.134AppC

Factors which can affect the quality of the seal on a respirator:

• Facial hair

• Scars

• Dental issues, i.e. dentures, missing teeth

• Piercings

• Facial characteristics such as high cheekbones, broken nose, hollow cheeks.

• Wearing Glasses

• Other PPE requirements

AS/NZS 1715:2009 Selection, Use and Maintenance of Respiratory Protective Equipment

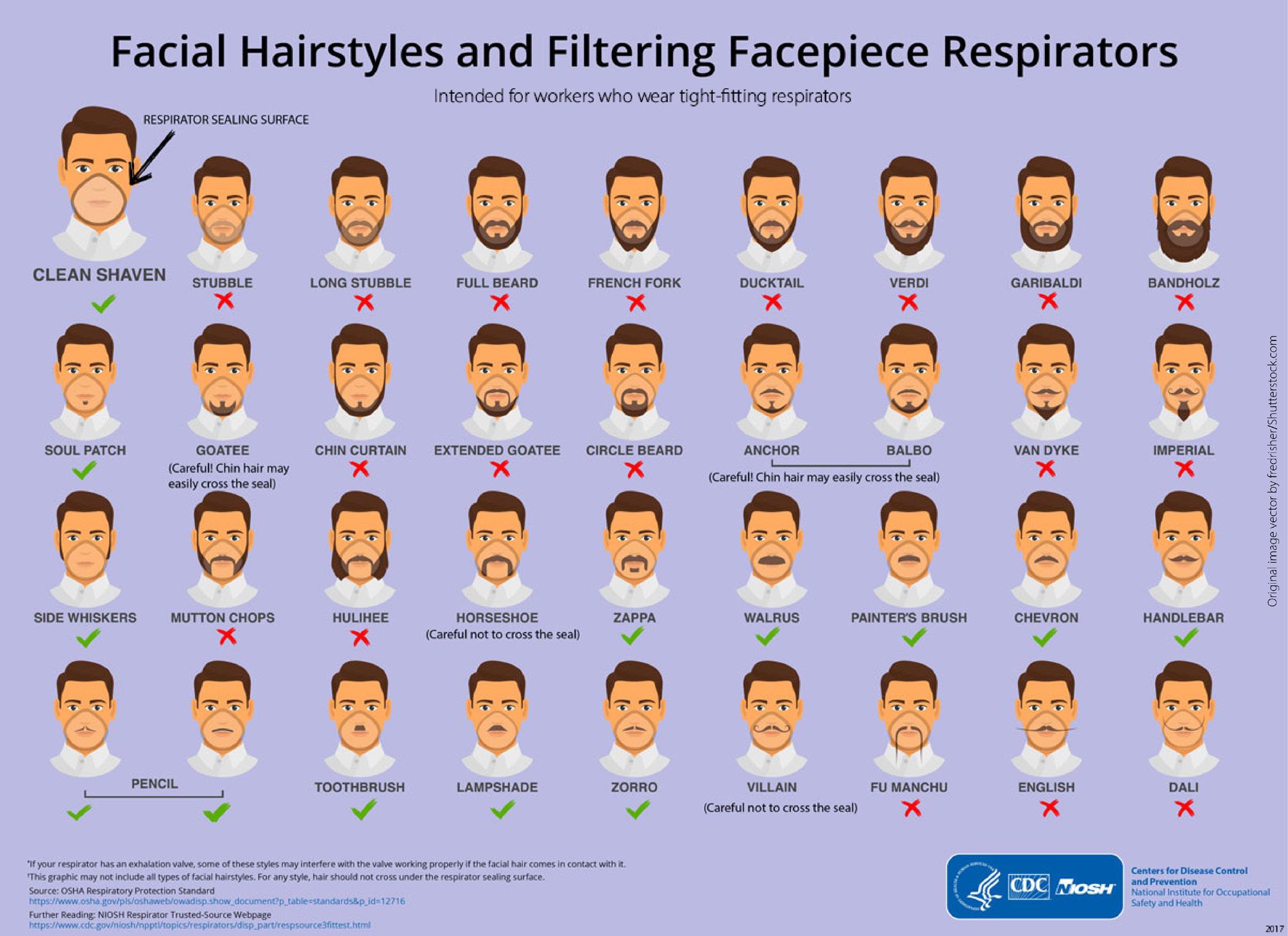

Tight-fitting respirators need to seal securely to the face to create a reliable barrier. Gaps in this face seal let contaminated air inside the respirator. Even a day or two’s growth of stubble can be enough to significantly interfere with respirator fit and create gaps that reduce the protection a respirator can provide. Face seal leakage has been shown to increase from 20 times to 1000 times in the presence of facial hair. Facial hair that does not come between the respirator surface and the skin is not a problem, i.e. a trimmed moustache.

Acceptable Facial Hair Styles

Other PPE such as safety or prescription glasses, hair nets, hard hats and hearing protection are often required to be worn concurrently with a respirator. This can affect the effectiveness of RPE in the following ways:

• Interference with the respirator seal

• Augmentation of physiological factors like body temperature

• Increase in psychological factors such as feelings of claustrophobia

It is important that ALL required PPE be worn during fit testing in order to assess the respirator properly, considering their job role and working environment.

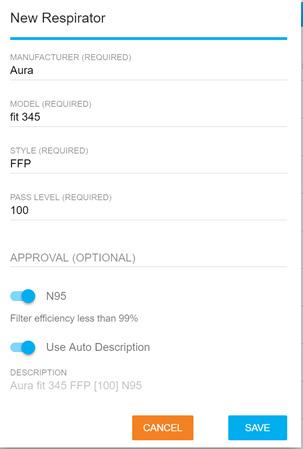

Select RPE for testing that is representative of the RPE used in the workplace. Test subjects may bring their own respirators to be tested, if needed. Ensure proper adapters are available when this is the case.

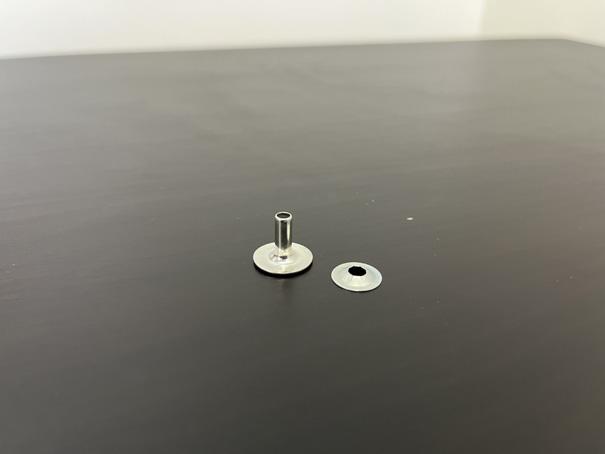

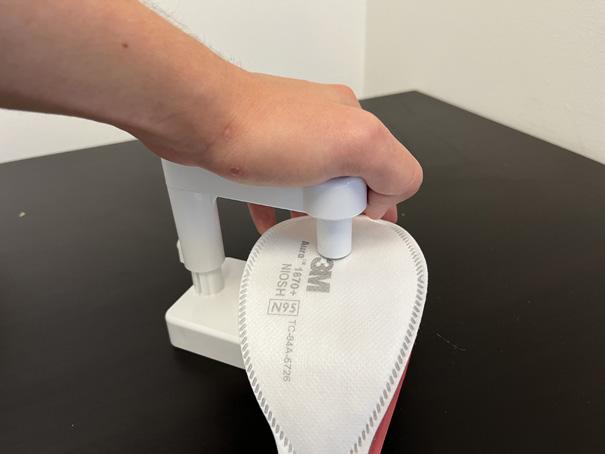

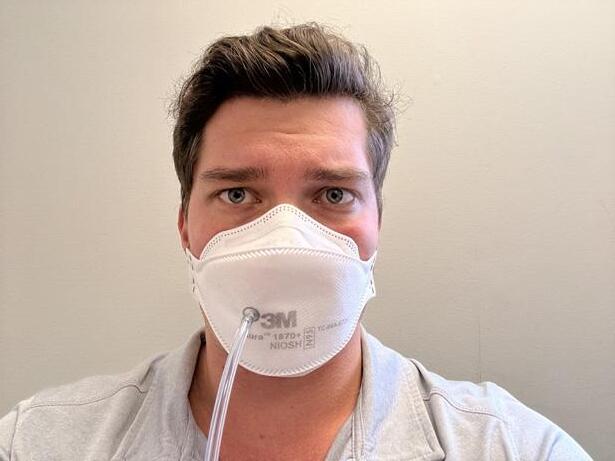

When using quantitative fit test methods, you must adapt the RPE to be attached to a sample hose. Reusable respirators must be fitted with adapters, before attaching the filter. The filters used for fit testing may be different than the ones used in the workplace. Be aware that the weight of filters and adaptors can affect the fit. Ensure that probes or adapter hoses are placed directly in the breathing zone between nose and mouth.

The RPE user must first be trained in donning and doffing a respirator. After training, they must be given opportunities to practice. They must be able to demonstrate that they can competently don the selected RPE, in accordance with the manufacturer’s instructions.

Prior to the fit test, the last donning must be done unassisted by the wearer. This is very important, as it ensures that the wearer will be able to properly don the respirator unassisted in the work environment.

a filtering face piece

Donning a reusable half-face respirator

The following RPE are suitable for using the negative pressure fit check:

a) Disposable respirators

b) Reusable face-piece

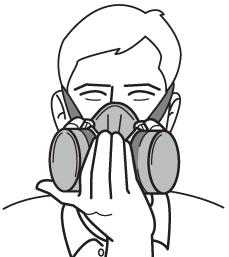

For a disposable face-piece, the wearer completely covers the filter with both hands or a non-permeable substance, e.g. a polythene bag, and inhales sharply. The face pieces should sink onto the face with a very vigorous breath indicating an adequate seal. If an unsatisfactory face seal is indicated by the feel of an airstream channelling through the leak, re-adjust the RPE until a satisfactory seal is indicated.

On reusable masks, the user should cover both filters and inhale gently so that the face piece collapses slightly. If the face piece remains slightly collapsed and no inward leakage is detected, the RPE is probably well fitted.

Wear must block the exhalation valve on a half or full face-piece respirator or fully cover the respirator surface on a filtering face-piece, usually by using your hands, and trying to breathe out. If slight pressure builds up, that means air isn’t leaking around the edges of the respirator.

The negative pressure check and the positive pressure fit check should be used each time a respirator is worn but should not be considered reliable fit-tests. They cannot be used in place of a fit test . The wearer should use these fit checks every time, just before entering the hazardous atmosphere. These tests are only suitable for respirators with tight-fitting facepieces.

Although these tests are simple, they have significant drawbacks, the main one being that the wearer may touch the RPE after it has been positioned on the face, possibly modifying the facial seal. Remember, the quality of a user fit check depends on the skill and effort of the user.

According to AS/NZS 1715:2009, fit testing should be conducted annually (recommended minimum) and at additional times when required:

• Before the respirator is issued

• User reports discomfort or suspects poor fit

• When there is a change in the wearer’s facial characteristics:

○ Weight loss or gain;

○ Substantial dental work;

○ Any facial changes (scars, moles, effects of aging, etc.) around the face seal area;

○ Facial piercings;

○ Introduction or change in other head-worn personal protective equipment (PPE);

○ There is a newly identified health issue related to exposure, i.e. a blood test that indicated excess exposure.

There are safety considerations to take into account when conducting fit tests. Awareness of these issues will help you anticipate and prevent any unnecessary risk.

• Test subjects may experience unexpected distress wearing a respirator

• Test subject may experience an allergic reaction to test aerosols.

• A fit-test hood will elevate inhaled carbon dioxide levels and decrease inspired oxygen levels. Ensure test subjects are not experiencing dizziness or headache.

• Test subjects may feel too hot or experience other distress, such as claustrophobia.

Review safety data sheet (SDS), depending on the chemical being used. Understand how to recognise potential reactions to the chemical. If you suspect a subject is having a reaction or is experiencing dizziness or distress, stop the test and remove the hood and RPE.

• Test subjects may experience unexpected distress wearing a respirator

• Risk of tripping over cords

• Alcohol is flammable

• Risk of electric shock

• Placing probes must be done with care to avoid pinches or cuts

• Equipment should be placed with ergonomic considerations in mind, so testers are not leaning over a low desk while conducting tests.

Ensure your initial setup considers ergonomics and limits trip hazards. After refreshing the wick, close and remove sources of alcohol. Conduct regular equipment checks for frayed or damaged electrical cords. Ensure operator is familiar with operations of probe setter tool.

It is imperative that relevant infection control procedures are followed throughout the fit testing process. This includes minimising contact between staff, appropriate donning/doffing procedures, cleaning and disposal protocols for equipment.

The program administrator should ensure that current infection control protocols are observed in maintaining any reusable RPE and testing equipment.

Disinfection may be achieved by using a broad-spectrum disinfectant. The choice of preparation should be made based on recommendations of the RPE manufacturer and medical authorities. Such information should also assist where protection against the transmission of a specific pathogen is required.

With all disinfectants, particular attention should be paid to the manufacturer’s instructions regarding their use, e.g. dilution, temperature, exposure time.

Benchtops and desks:

• All surfaces where the fit testing equipment and RPE will be placed such as benchtops, desks, and tables must be clean and sanitised before commencing a fit test.

• Fitting of a disposable absorbent cloth that covers the table may also be required if the surface is damaged or shows signs of absorbed contamination i.e., stains, etc.

Washing Hands:

• Both fit testers and participants should wash their hands properly prior to engaging in fit testing. Participants should be asked to avoid touching their face during testing. Testers should wash or disinfect hands every time they touch the wearer or their facepiece. Disposable gloves should be worn by the fit tester during the tests and when disinfecting the masks after a test has been completed.

• Disposable gloves must be changed for each test being conducted.

Fit testing hood (QLFT-ATT Only):

• A visual inspection of the hood must be conducted when setting up for fit testing and between fit tests to check for any contaminants and defects.

• Wipe down the hood with a disposable sanitising wipe when preparing for a fit test, between fit tests, and at the end of the day.

• On completion of fit testing, the hood should be adequately cleaned and stored in a sealed bag or container to minimise contamination when stored.

Twin tubing, (QNFT-CNC only):

• A visual inspection of the twin tubing must be conducted when setting up for fit testing and between fit tests to check for any contaminants and defects.

• Wipe down with a disposable sanitising wipe or other suitable cleaning equipment when preparing for a fit test and between fit tests.

• During fit testing, condensation can build up in the twin tubes. If condensation build-up becomes an issue, it may require changing with another clean tube assembly.

• On completion of fit testing, the twin tube should be adequately cleaned and stored in a sealed bag or container to minimise contamination when stored. Do not store twin tubing with moisture inside. TSI, manufacturer of the PortaCount, does not recommend disinfecting of the interior of the tubes between use, however, if you choose to disinfect the tubing, you should rinse the tubing with distilled water.

Adaptors and sample tubes for re-usable masks (QNFT-CNC only):

• A visual inspection of the adaptor must be conducted when setting up for fit testing and between fit tests to check for any contaminants and defects.

• The adaptor and sample tube (the tube from the adaptor to the breathing zone) must be cleaned and sanitised when preparing for a fit test.

• Between fit tests, the adaptor and sample tube must be inspected and sanitised before connecting it to another mask. This includes cleaning and sanitising the suction cap used to hold the sample tube in place during the testing process, if applicable.

Use only clean and disinfected reusable RPE when fit testing. No test subject should don a reusable mask that has not been cleaned and disinfected.

Practice good hand and cough hygiene as per Covid 19 protocols. Fit tests should never be conducted on users who are feeling unwell or appear symptomatic of any respiratory or other illness.

A Fit Test Protocol is the term used to describe the specifics of fit test requirements as per each region’s industrial Standard. These fit test protocols set the fit test frequency, minimum fit factor (pass level) for both half and full-face masks, and they state whether a fit test would be acceptable on a positive pressure mask (converted to negative pressure mode for testing).

Each Standard will have its own test protocol, including what exercises must be completed during the test. These exercises are designed to assure scientifically valid results, when testing the seal on a respirator. The exercise protocols are designed to be used with either fit test method, qualitative or quantitative. All fit tests must be conducted in negative pressure mode, regardless of the type of (tight-fitting) respirator. Businesses should chose the best protocol based on their industry and work task requirements.

In Australia, businesses will commonly refer to these international Standards:

• OSHA 9CFR1910.134 Respiratory Protection Standard

• ISO 16975-3 - Respiratory Protective Devices - Selection, Use And Maintenance - Part 3: Fit Testing Procedures

• ANSI Z88.2-1992 Respiratory Protection with ANSI Z88.10-2001 Respirator Fit Test Methods

• AS/NZS 1715:2009 Selection, use and maintenance of respiratory protective devices

Each protocol’s variations make that protocol more or less appropriate for a business to use when fit testing. For example, if a fit test is performed using the OSHA1910.134 – Appendix A, all exercises are to be performed with the wearer standing on their feet (or jogging). This is a good choice where the worker spends most of their time at work on their feet.

The exercises in each protocol are designed to challenge the seal of the respirator by mimicking the actions that a worker may be required to do while carrying out their normal work tasks. One protocol allows the test to be conducted under higher physical demand (on a treadmill or exercise bike), while another allows a tester to add in elective exercises which may be more job specific. This allows the respirator to be tested dynamically, and to get results that can be assumed to be closely representative of using the respirator in the workplace.

It is important to follow the chosen protocol accurately. If there is a deviation away from instructions contained within the protocol, a tester is unable to consider fit test results to be reliable – irrespective of the method chosen (QLFT – ATT, QNFT – CNC, QNFT – CNP).

See the table below to compare each of the protocols and their test exercises.

Standard/Regulation Test Exercises

OSHA 9CFR1910.134

1) Normal breathing (1min)

2) Deep breathing (1min)

3) Turning head side to side (1min)

4) Moving head up and down (1min)

5) Talking (Rainbow Passage) (1min)

6) Grimace (15s)

7) Bending over (1min)

8) Normal breathing (1min)

OSHA 9CFR1910.134 FAST Half/Full Face:

1) Bending over (50s)

2) Jogging In Place (30s)

3) Turning head side to side (30s)

4) Moving head up and down (39s) FAST Filtering Facepiece:

1) Bending over (50s)

2) Talking (Rainbow Passage) (30s)

3) Turning head side to side (30s)

4) Moving head up and down (39s)

QNFT-CNP QNFT-CNP Redon Exercises:

1) Facing forward (30s)

2) Bending Over (30s)

3) Head shaking (3s several times)

4) Redon 1

5) Redon 2

Bonus Exercises

None

None

Standard/Regulation Test Exercises

ISO 16975-3

QLFT:

1) Normal breathing (1min)

2) Deep breathing (1min)

3) Turning head side to side (Sitting or standing, 1min)

4) Moving head up and down (1min)

5) Talking (Rainbow Passage) (1min)

6) Jogging In Place (1min)

7) Normal breathing (1min)

QNFT:

1) Normal breathing (1min)

2) Deep breathing (1min)

3) Turning head side to side (Sitting or standing, 1min)

4) Moving head up and down (1min)

5) Talking (Rainbow Passage) (1min)

6) Bending over (1min)

7) Normal breathing (1min)

Bonus Exercises

None

Standard/Regulation Test Exercises

ANSI Z88.10-2010

QLFT – ATT

1) Normal breathing (30s)

2) Deep breathing (30s)

3) Turning head side to side (30s)

4) Moving head up and down (30s)

5) Talking (30s)

Elective exercises: Bending over (30s), Jogging in place (30s), Stepping (30s), Vigorous head shake (30s)

QNFT – CNC

1) Normal breathing (30s)

2) Deep breathing (30s)

3) Turning head side to side (30s)

4) Moving head up and down (30s)

5) Bending over (30s)

6) Talking (30s)

Elective exercises: Re-don + normal breathing (30s), Jogging in place (30s), Stepping (30s), Grimace + normal breathing (30s), Vigorous head shake (30s)

QNFT – CNP

1) Normal breathing (30s)

2) Re-don + normal breathing (30s)

3) Bending over (30s)

4) Vigorous head shake (30s)

Elective exercises: Deep breathing (30s), Turning head side to side (30s), Moving head up and down (30s), Stepping (30s), Grimace + normal breathing (30s)

Bonus Exercises

Yes (electives + job specific exercises)

Standard/Regulation Test Exercises

INDG479

1) Normal breathing (1min)

2) Deep breathing (1min)

3) Turning head side to side (Sitting or standing, 1min)

4) Moving head up and down (1min)

5) Talking (Rainbow Passage) (1min)

6) Bending over (1min)

7) Normal breathing (1min)

QLFT: fit test exercises should be performed with the wearer standing.

QNFT: fit test exercises (except for the bending exercise) should be performed while the wearer is:

1) cycling on an exercise bike;

2) walking on a treadmill; or

3) carrying out a stepping exercise.

Bonus Exercises

None

In addition to providing specific test protocols, each Standard also has specified the fit factor that must be achieved for a respirator to pass a fit test. The reason that qualitative fit test methods are limited to a fit factor of 100 is because 100 is the pass level these methods were designed for in the laboratory. This is based on the difference in the concentration of the sensititivity solution to the test solution All legitimate qualitative methods were carefully developed in a laboratory and validated against quantitative method instrumentation.

Full-face masks should not be tested using the Qualitative method, as that method cannot provide a fit factor above 100.

The accepted Standards also state that 100 is the maximum fit factor for all half-masks, (disposable or reusable) when using Quantitative testing. These Standards diverge on the fit factor required to pass a full-face mask(see table above). Some will require a fit factor of 500 while others set the pass level at 2000.

Why doesn’t somebody develop and validate a qualitative fit test method for higher pass levels?

The reason is related to human sensitivity to the chemical stimulants used in this method. For a qualitative fit test method to be validated for 100, the test subjects must be able to detect reliably a challenge agent concentration inside the respirator that is 100 times less than the challenge agent concentration outside the respirator.

Properly designed qualitative protocols include a threshold sensitivity test that each person must pass prior to being fit tested to ensure that he or she can detect the very low in-mask concentration that results when the fit factor is just below 100. If a person cannot pass the threshold test, that qualitative fit test method cannot be used.

Most people have the ability to sense 1/100 concentrations, but the percentage of people who can reliably sense lower concentrations such as 1/500 or less drops off quickly.

Because of this, it is unlikely that a qualitative fit test method will ever be developed for a pass level of 500 or higher.

Remember, disposable filters and filtering face pieces will have an Assigned Protection Factor (APF): which is the level of protection a respirator will provide that can be expected by 95% of all clean shaven, fit tested and trained wearers on the job. If the APF on a filtering face piece is 10, the highest fit factor you can achieve is 100, if the APF is 50, the minimum fit factor you would test for would be 500.

However, no Standard will recognise a fit factor above 100 for anything less than a full-face mask. Even though a half-mask may have a P3 filter with an APF of 50 or 100, the fit factor achieved will never be higher than 100.

Standard/Regulation Issuing organization Fit test frequency

OSHA 9CFR1910.134

Respiratory Protection Standard

ISO 16975-3 - Respiratory Protective Devices - Selection, Use And Maintenance - Part 3: Fit Testing Procedures

ANSI Z88.2-1992

Respiratory Protection with ANSI Z88.10-2001 Respirator Fit Test Methods

NFPA 1500-2007 Fire Department Occupational Safety and Health Program

Safety and Health Administration (USA)

(the International Organization for Standardization)

National Standards Institute (USA)

Fire Protection Association (USA)

NFPA 1404-2006 Standard for a Fire Department SelfContained Breathing Apparatus Program National Fire Protection Association (USA)

CSA Z94.4-02 Selection, Use, and Care of Respirators

INDG479 Guidance on Respiratory Protective Equipment Fit Testing

AS/NZS 1715:2009

Selection, use and maintenance of respiratory protective devices

Standards Association (Canada)

Executive (UK)

EN529:2005 Respiratory protective devicesRecommendations for selection, use, care and maintenance - Guidance document European Committee For Standardization, 36 B-1050 Brussels

fit factor for halfface masks

fit factor for fullface masks QLFT allowed for positivepressure masks

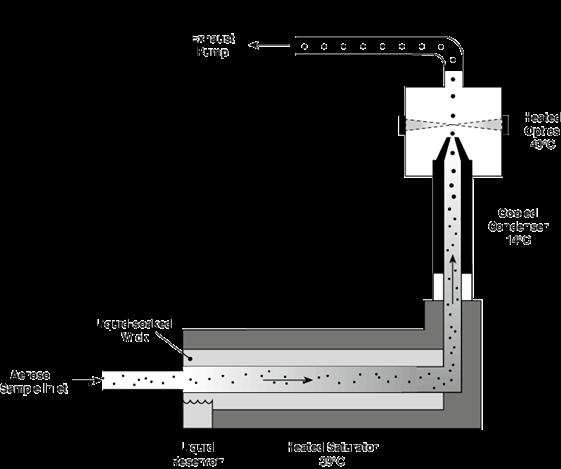

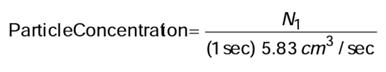

A quantitative fit test is done using very precise measuring equipment. The TSI PortaCount Fit Tester is one such piece of equipment and will be the unit we refer to in this course, although other Condensed Nuclei Counter units are available. This machine can sample the air outside a respirator, (the ambient atmosphere), and the air inside a respirator, which the user is breathing, and compare the number of particles in each. Before we go any further, we need to understand how particles are counted by the PortaCount Fit Tester.

Particle is a generic term used to describe airborne solid or liquid substances in the finely divided state ie, particulate aerosols such as dusts, mists, fumes, fibres and fog as well as microorganisms.

The PortaCount Fit Tester is a condensation particle counter. That means it can count the particulate in the atmosphere both inside and outside a respirator. The working principle of a particle counter is to expose aerosol particles to supersaturated vapor, in this case, reagent-grade isopropyl alcohol, which condenses onto the particles, allowing them to grow to sizes at which they can be optically detected. The alcohol in the PortaCount Fit Tester is delivered by a wick inside an alcohol cartridge. Do not substitute any other alcohol in the PortaCount Fit Tester. Do not use isopropyl alcohol that is less than 99.5% pure.

TSI, the manufacturer of the PortaCount Fit Tester, specifies that a minimum ambient concentration of 1000 particles (pt)/cm 3 is needed to properly conduct a fit test. However, when testing with a filter that is <99% efficient, such as P2, or N-95 series masks, the ideal ambient particle concentrations is 100 to 800 pt/cm 3 . The PortaCount Fit Tester has an accessory that can be used to view only a certain size range of particles, called the N95-Companion. This accessory is especially important when working with a particle generator, because the particles have such a wide size range. It is activated in the software when fit testing.

The N95-Companion is an aerosol pre-conditioner that selects particles in a specific size range and passes them on to the PortaCount Fit Tester. Any particles that are not in that size range are discarded, (not counted) because they could incorrectly be counted as seal leakage. Some generated particles are so small, they can penetrate a filter that is <99% efficient, , so we want to screen them out of the actual test. The ambient particle count range you should see when working with the N-95 Companion is therefore much lower.

Ideal ambient particle concentrations is ~100 to 800 pt/cm 3 with N95 Companion running or ~2,000 to 8,000 pt/cm 3 without N95 Companion running. If ambient particle count is too high, it can affect the fit factor results, skewing them towards false positive test results.

In some testing environments, the ambient particle count is very low, because of excellent air filtration, or it is a naturally clean environment. In this case, a particle generator can be used to create an artificial atmosphere. When using a particle generator, testing should be conducted in a room no larger than 7m x 7 m. Placement of the particle generator should be no closer than 2 metres to the PortaCount Fit Tester.