DESIGN DIARY

BNV4135-A-S2-2023/4 | SHUI KEI CHEUNG, KIKI | 23141075

BNV4135-A-S2-2023/4 | SHUI KEI CHEUNG, KIKI | 23141075

DESIGN CONCEPT

RESEARCH | SKETCHES | PRECEDENT STUDIES

SUSTAINABLE CONSIDERATIONS

STRUCTURAL ELEMENT | MATERIAL SELECTION | TECHNOLOGY

TECHNICAL DRAWINGS

SITE PLAN | FLOOR PLANS | STRUCTURAL PLAN | ELEVATIONS | SECTIONS

RENDERING

EXTERIOR | INTERIOR

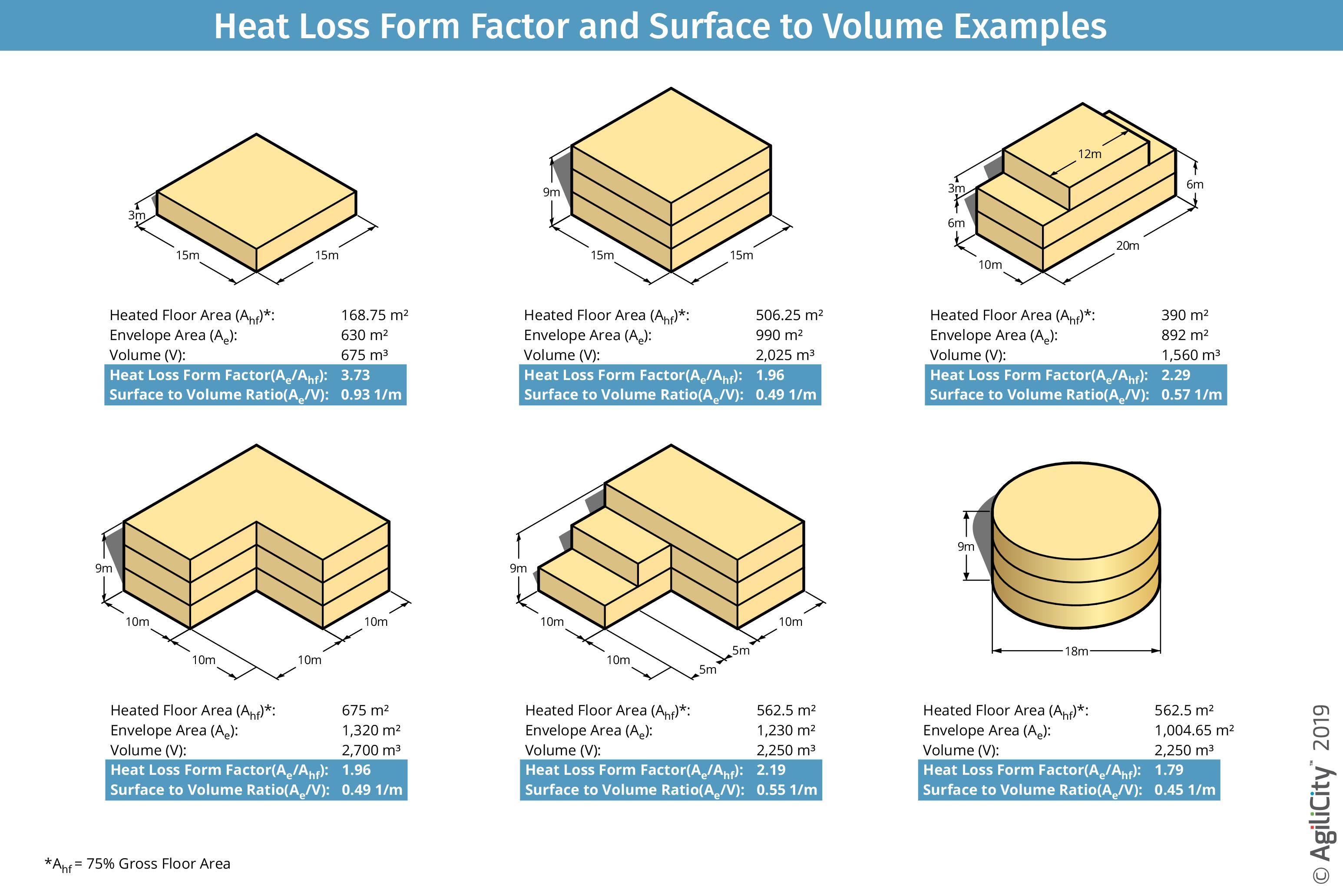

'THE CHALLENGE OF SHAPE AND FORM: UNDERSTANDING THE BENEFITS OF EFFICIENT DESIGN', A REPORT PUBLISHED BY THE BRITISH NATIONAL HOUSE-BUILDING COUNCIL (NHBC) IN 2016, HAS DISCUSSED ABOUT THE ENERGY EFFICIENCY OF DESIGNING A NEW HOME WITH GOOD SHAPE AND FORM PRIOR TO THE DESIGN OF ITS BUILDING FABRIC, INSULATION AND THE NEW TECHNOLOGY.

HEAT LOSS FORM FACTOR (HLFF) IS A USEFUL TOOL MEASURING THE EFFICIENCY OF THE FORM AND SHAPE THAT REFLECTS THE COMPACTNESS OF THE BUILDING.

IT IS THE RATIO BETWEEN THE BUILDING’S ENVELOPE AREA (EA) AND IT’S NET FLOOR AREA (NFA) AND IS CALCULATED AS HLFF = EA / NFA .

THE PASSIVHAUS STANDARD REQUIRES A FABRIC FIRST APPROACH AND A THERMAL ENVELOPE OF HIGH-PERFORMANCE OF WHICH IS THE MAIN AREA THROUGH WHICH A BUILDING CAN LOSE HEAT. HLFF IS AN INDICATION OF HOW MUCH INSULATION IS NEEDED TO ACHEIVE THE PASSIVHAUS STANDARD.

THE EXAMPLE ON THE LEFT DEMONSTRATES THE COMPACTNESS OF DIFFERENT FORMS AND SHAPES. THE LOWER THE HLFF, THE BETTER.

THE CHALLENGE LIES IN THE COMMON CONCERN OF THE LACK OF VIUSAL APPEAL AS A RESULT OF ACHIEVING A LOW HLFF USING INHERENTLY ENERGY EFFICIENT SHAPE AND FORM, SUCH AS A CUBE OR A CYLINDER (NHBC FOUNDATION, 2016). THIS PROJECT WILL EXPLORE ON HOW TO DESIGN USING HLFF TO ACHIEVE INTRIGUING YET PRACTICAL PASSIVHAUS.

PASSIVHAUS STANDARD IS DEVELOPED BY GERMAN PHYSICIST, WOLFGANG FEIST, WHO STRIVES TO DESIGN AND RESEARCH EXCEPTIONALLY COMFORTABLE BUILDINGS WITH MINIMAL CARBON EMISSIONS.

KEY CHARACTERISTICS OF PASSIVHAUS DESIGN:

- EXCELLENT LEVELS OF THERMAL COMFORT ACHEIVED BY:

SUPER INSULATION

AIRTIGHTNESS CONSTRUCTION

THERMAL BRIDGE FREE CONSTRUCTION

HIGH-PERFORMANCE DRAUGHT-FREE WINDOWS

E.G. LOW U-VALUES OF MATERIAL AND BUILDING COMPONENTS (0.08 -0.15 W/M 2 K FOR WALLS, FLOORS AND ROOFS; ≤0.08W/M 2 K FOR WINDOWS); AIR TIGHTNESS WITH AIR CHANGES PER HOUR AT 50 PASCALS ≤0.6 ACH)

- LOW ENERGY DEMANDS RESULTS IN LOW ENERGY COSTS

- VENTILATION STRATEGY PERFORMED BY MECHANICAL VENTILATION AND HEAT RECOVERY SYSTEM (MVHR) THAT MAINTAINS CONSISTENT INDOOR TEMPERATURE AND PROVISION OF FRESH WARM AIR THROUGHOUT THE BUILDING (WALSHAW, 2022).

BUILDINGS ARE CERTIFIED BY THE PASSIVHAUS INSTITUTE OR ANY OTHER ACCREDITED CERTIFIER BASED ON THE CALCULATIONS FROM THE PASSIVHAUS PLANNING PACKAGE (PHPP) TOGETHER WITH SUPPORTING DOCUMENTATION SUCH AS AIRTIGHT TESTING AND COMMISSIONING INFORMATION OF MVHR.

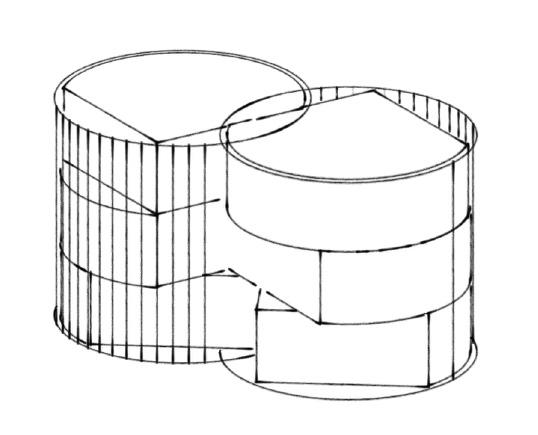

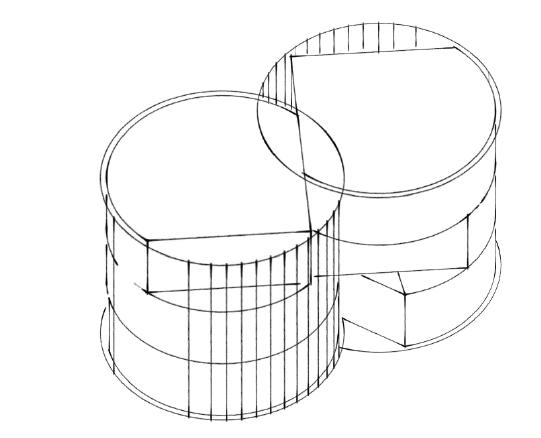

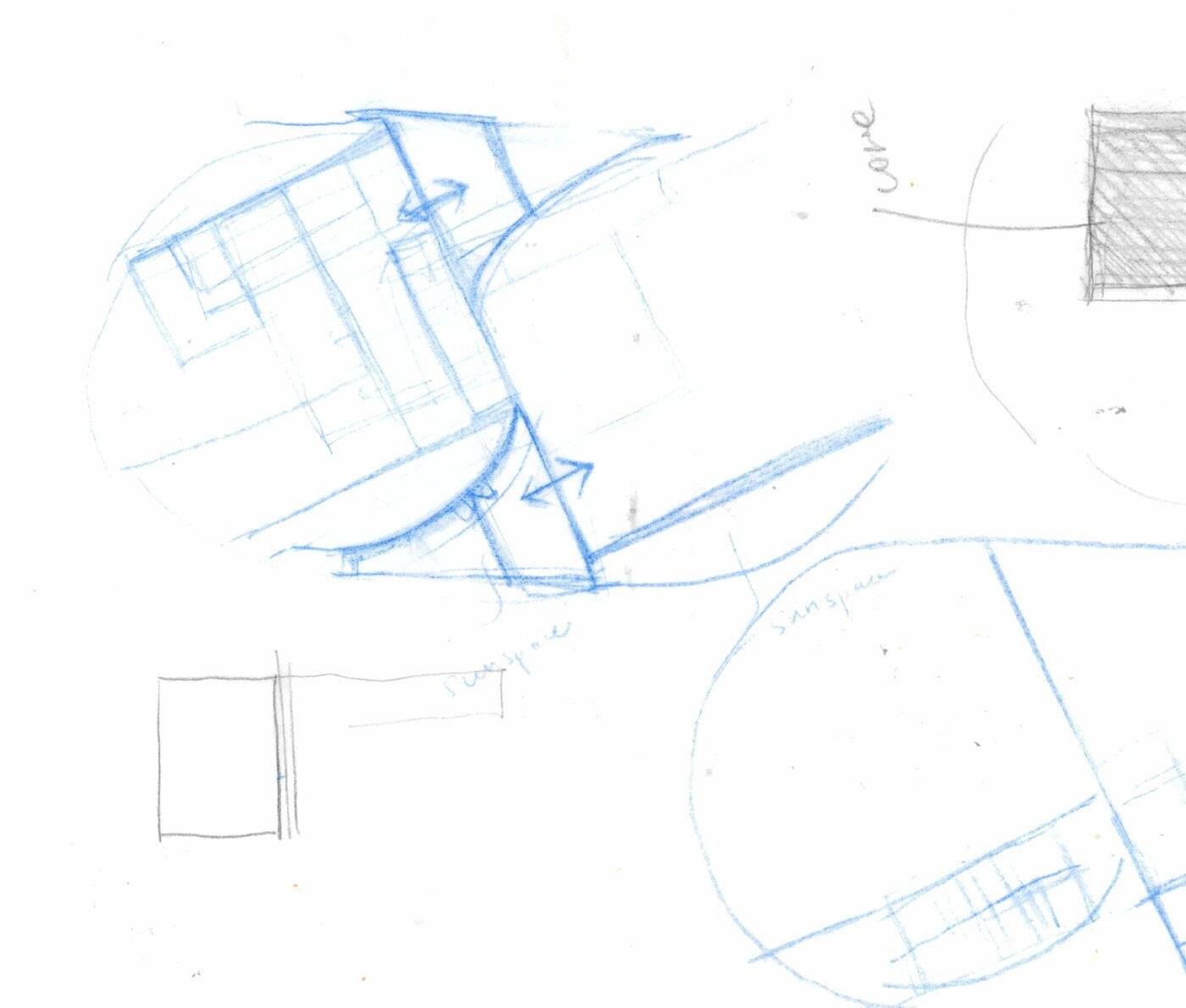

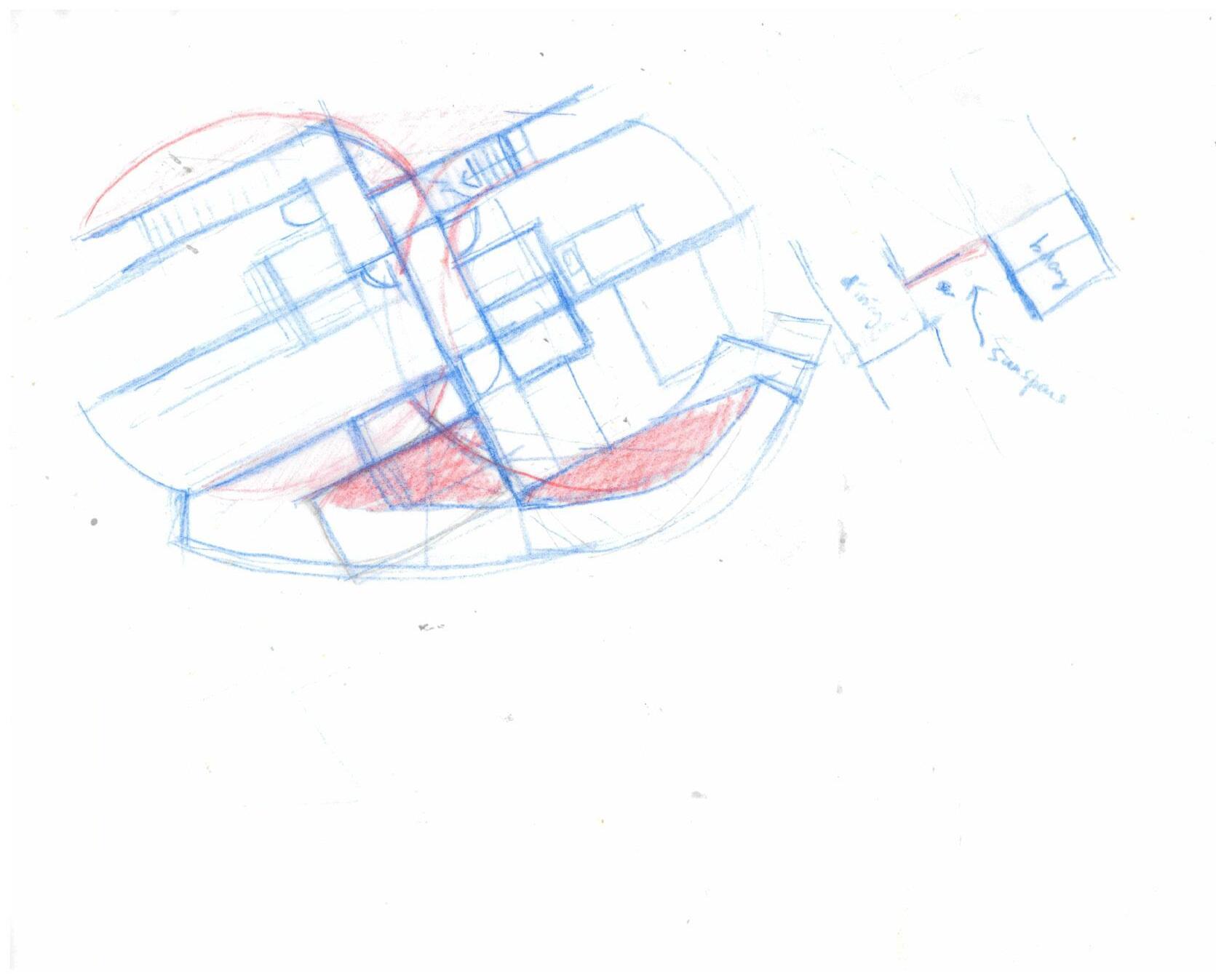

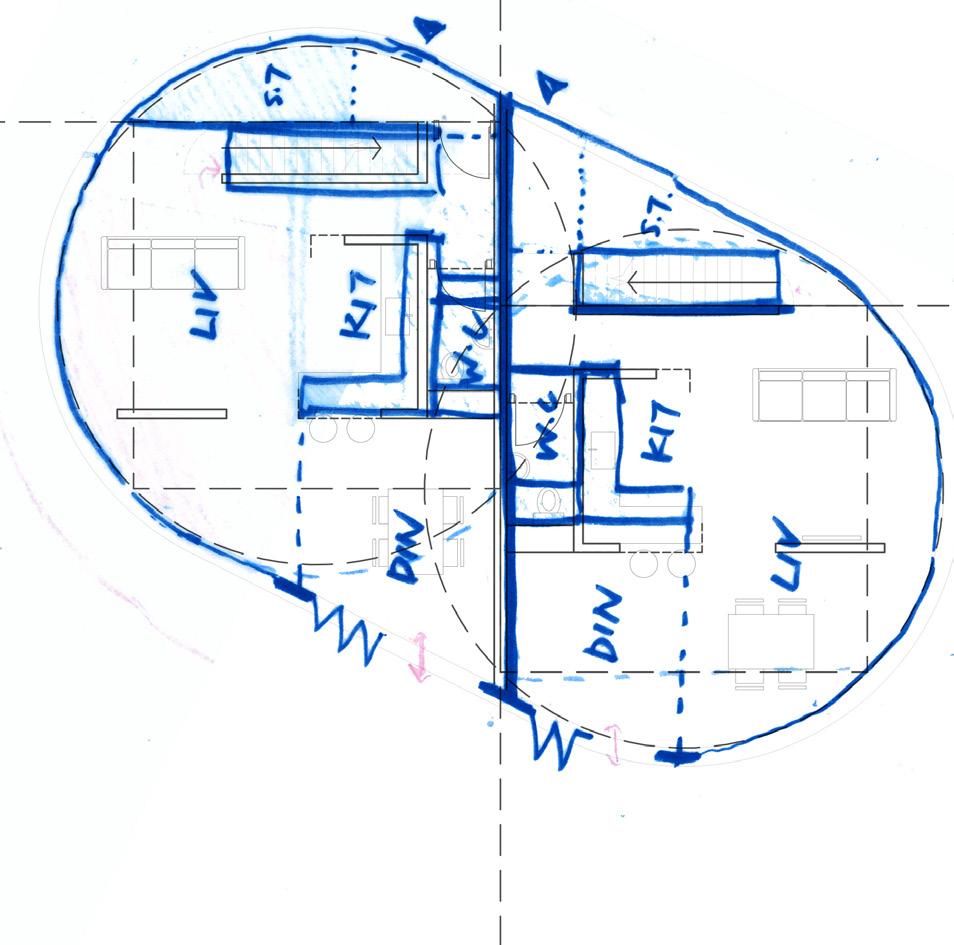

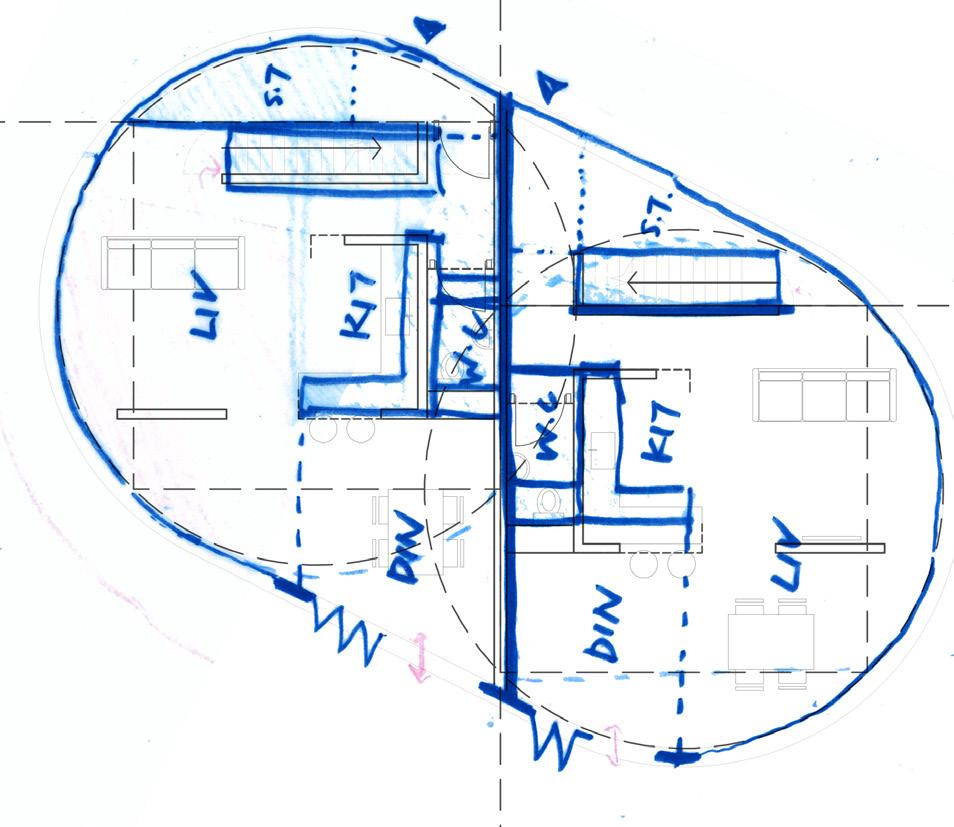

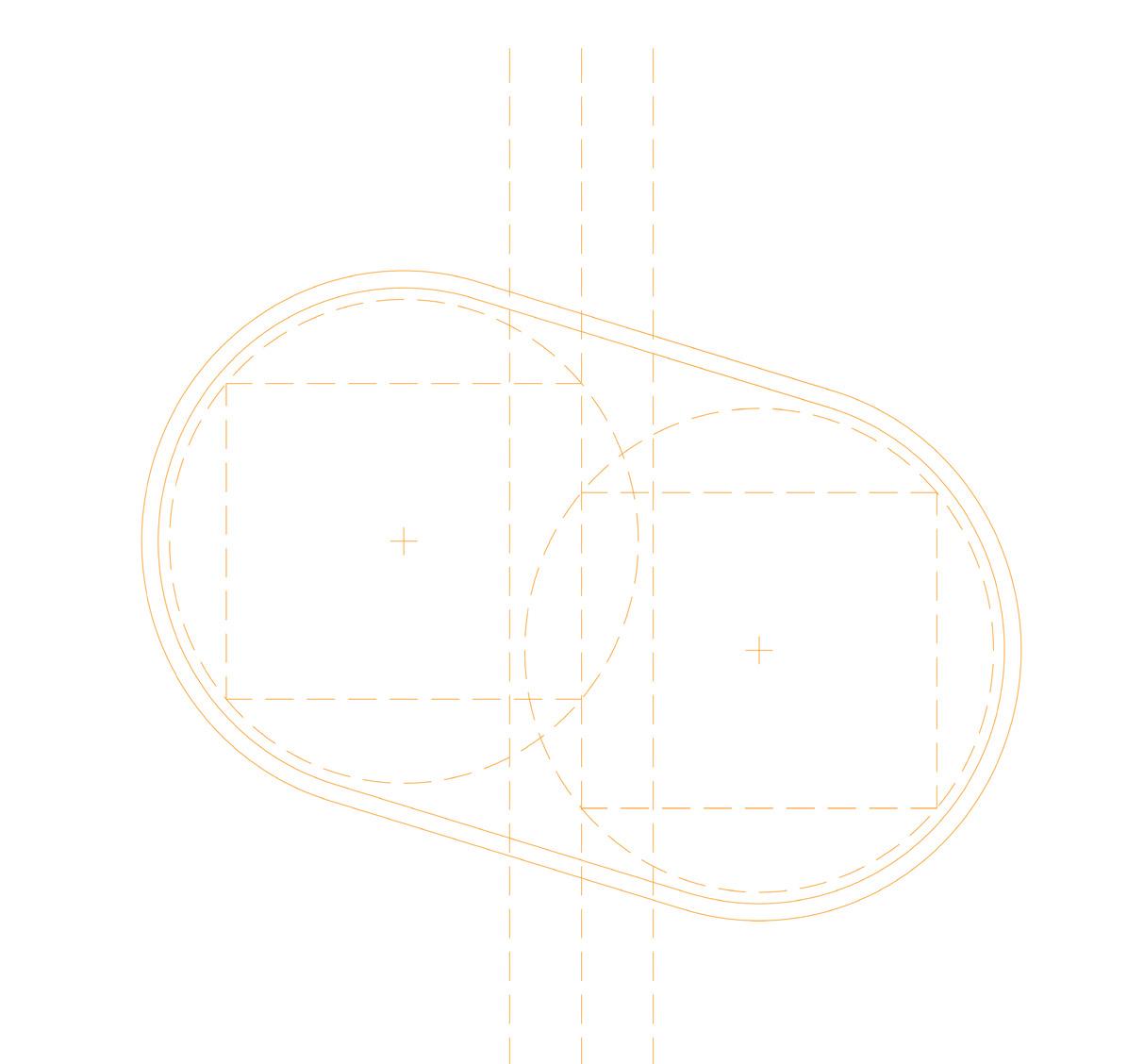

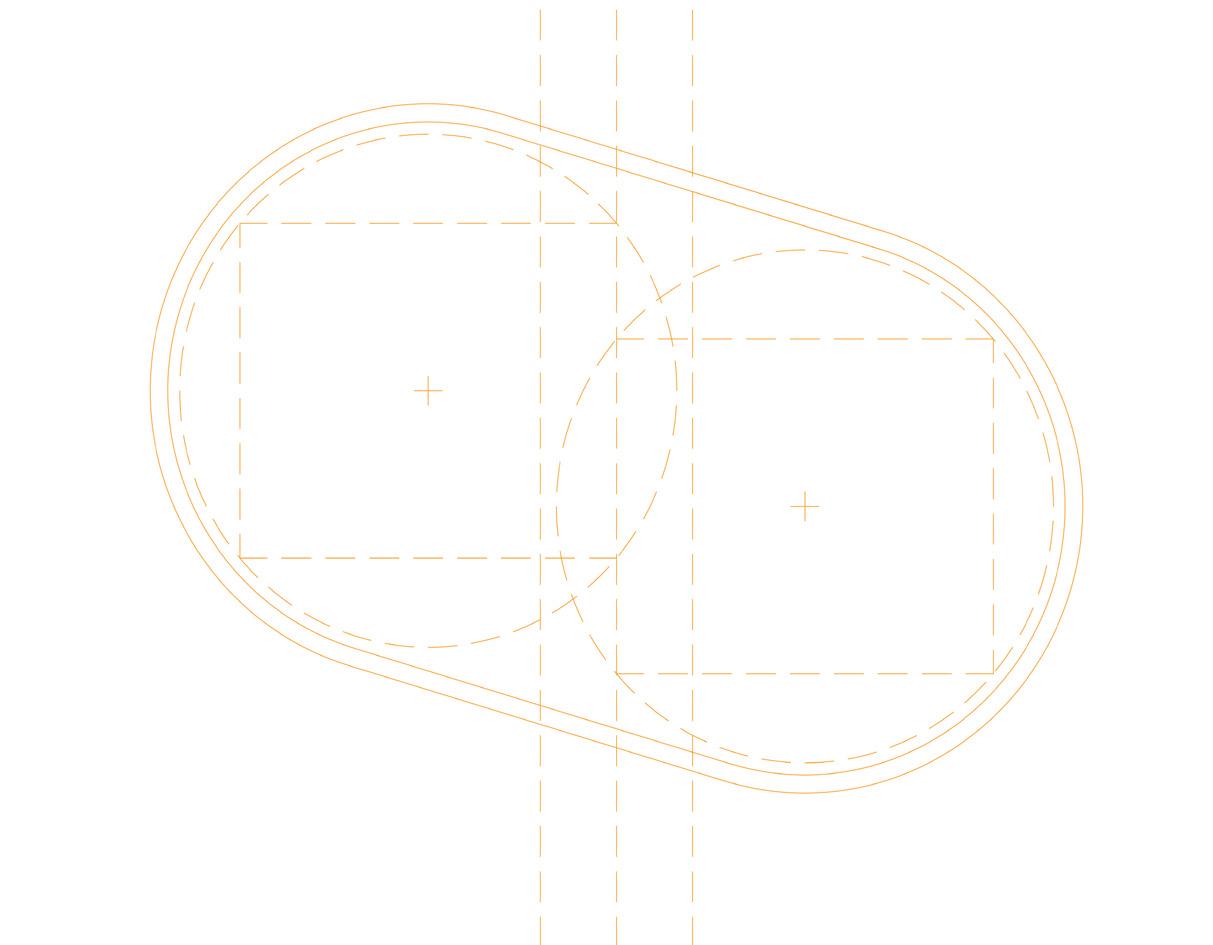

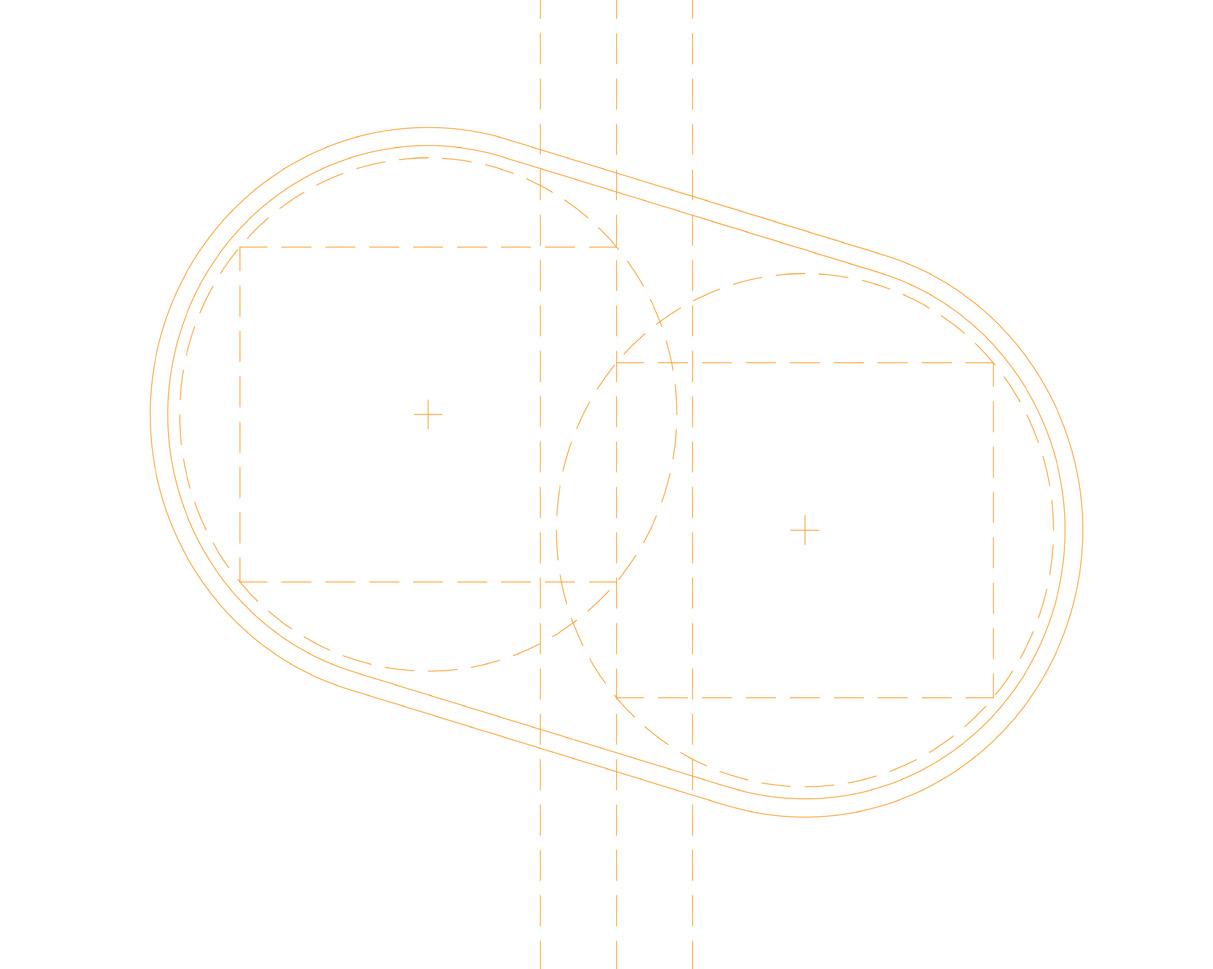

RECREATE CIRCLE USING SUBTRACTED SHAPES THROUGH WHICH TO INTRODUCE ORTHOGONAL WALL ELEMENTS INTO A CIRCULAR PLAN A SQAURE WITHIN A CIRCLE PUT TOGETHER TWIN SQUARES-CIRCLES TO SIMULATE TWIN UNITS (SEMI-DETACHED HOUSE) AND TEST WITH ROTATIONS AND MIRRORING 3D SKETCHES OF A 3-STOREY HOUSE HEAT LOSS FORM FACTOR CALCULATIONS FOR DIFFERENT SHAPES OF THE SAME AREA SIZE TO EXPLORE A LOWEST HEAT LOSS ENVELOPE FORM. IT SHOWS THAT ANY SHAPES DEVIATE FROM CIRCLES WILL RESULT AN INCREASE IN THE PERIMETERS THUS THE FACTOR PROPORTIONATELY. THE IDEA IS TO IMPROVE THE TRADITIONAL REACTILINEAR FORM OF HOUSES TO ACHEIVE AN ENERGY EFFICIENT FORM. AN OBROUND ENVELOPE OUTWEIGHS A CIRCULAR ENVELOPE BY ALLOWING STRAIGHT WALLS FOR OFF-THE-SHELF HOME FURNITURE TO PUT AGAINST WITH. DEVELOPING GEOMETRIC GUIDES FOR SPATIAL DEVELOPMENT

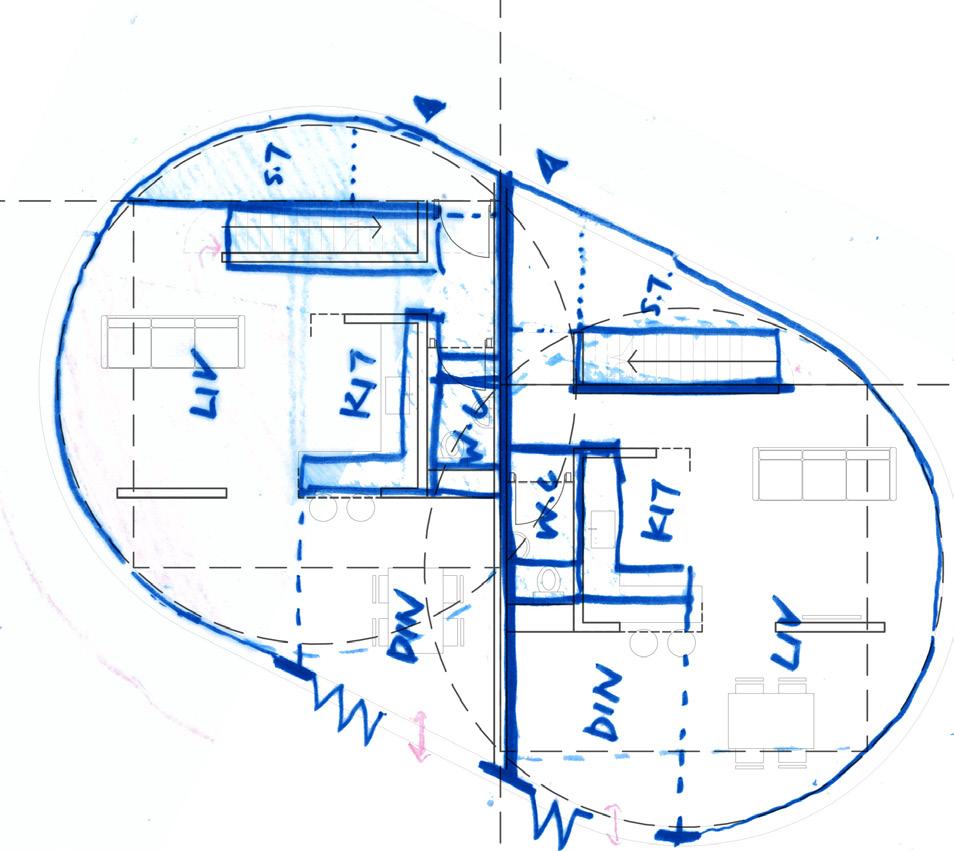

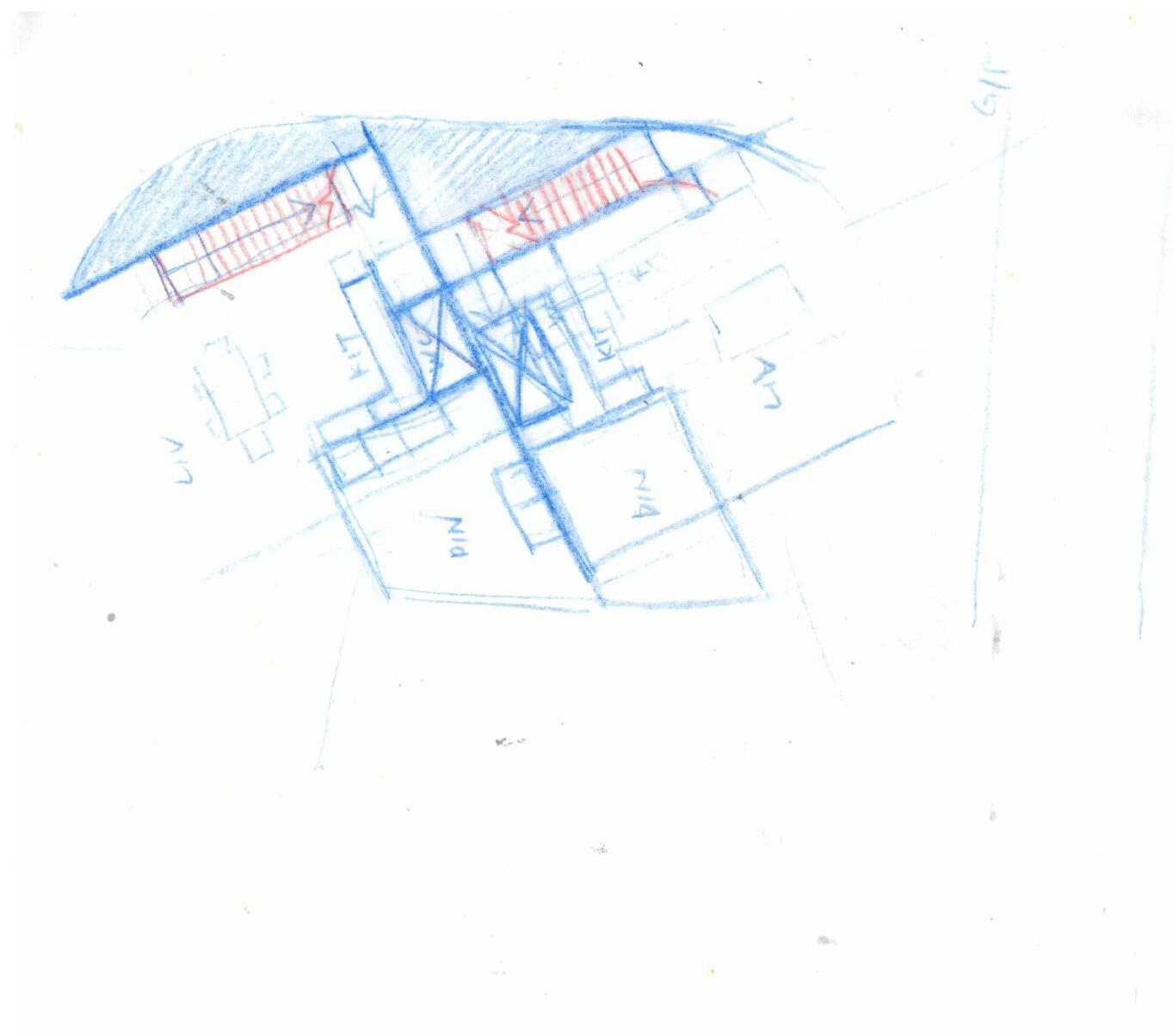

EXTERNAL RELATIONSHIP OF THE ENVELOPE WITH THE SITE BOUNDARY

REFINEMENT OF OBROUND ENVELOPE BY ONCE AGAIN REFERRING TO HEAT LOSS FORM FACTOR THE SHAPE OF AN OBROUND ALLEVIATES THE RESTRICTED ORIENTATION OF THE HOUSE WITHIN A COMMONLY NARROW SITE, UNLIKE A RECTILINEAR ENVELOPE WHERE THE EDGE CONDITION BETWEEN THE HOUSE AND THE BOUNDARIES ARE BEING INTENSIFIED BY ITS POINTY CORNERS. THE OBROUND CREATES A PROTOTYPE THAT CAN ADJUST TO MAXIMIZE THE SOUTH FACING PORTION OF THE HOUSE. ACCESS TO THE TWO UNITS THE AXIS IS ADJUSTED WITHIN THE SOUTH-FACING RANGE TO IMPROVE THE PROPORTION OF SPACE STUDY OF ROOM LAYOUTS AND LOCATION OF STAIRCASES UNDER THE CONSIDERATION OF STANDARDIZED PREFABRICATION. THE IDEA IS ALSO ABOUT POSSIBLE CHANGE OF LAYOUT SUCH AS CONVERSION INTO G/F BEDROOM TO ADAPT FUTURE NEEDS.

RECREATE CIRCLE USING SUBTRACTED SHAPES THROUGH WHICH TO INTRODUCE ORTHOGONAL WALL ELEMENTS INTO A CIRCULAR PLAN A SQAURE WITHIN A CIRCLE PUT TOGETHER TWIN SQUARES-CIRCLES TO SIMULATE TWIN UNITS (SEMI-DETACHED HOUSE) AND TEST WITH ROTATIONS AND MIRRORING 3D SKETCHES OF A 3-STOREY HOUSE HEAT LOSS FORM FACTOR CALCULATIONS FOR DIFFERENT SHAPES OF THE SAME AREA SIZE TO EXPLORE A LOWEST HEAT LOSS ENVELOPE FORM. IT SHOWS THAT ANY SHAPES DEVIATE FROM CIRCLES WILL RESULT AN INCREASE IN THE PERIMETERS THUS THE FACTOR PROPORTIONATELY. THE IDEA IS TO IMPROVE THE TRADITIONAL REACTILINEAR FORM OF HOUSES TO ACHEIVE AN ENERGY EFFICIENT FORM. AN OBROUND ENVELOPE OUTWEIGHS A CIRCULAR ENVELOPE BY ALLOWING STRAIGHT WALLS FOR OFF-THE-SHELF HOME FURNITURE TO PUT AGAINST WITH. DEVELOPING GEOMETRIC GUIDES FOR

EXTERNAL RELATIONSHIP OF THE ENVELOPE

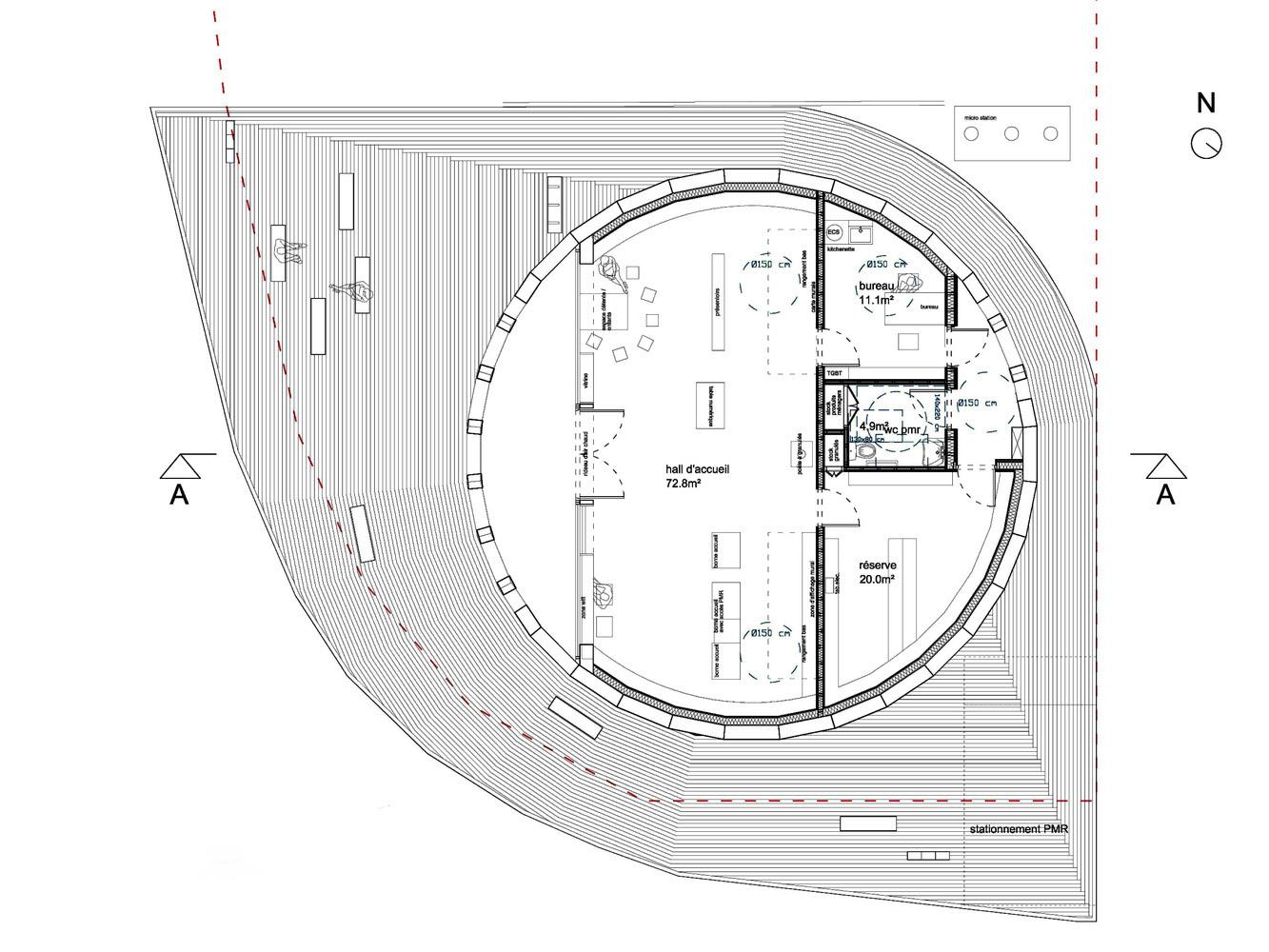

PLAINFAING TOURIST OFFICE (88) IN FRANCE BY STUDIOLADA

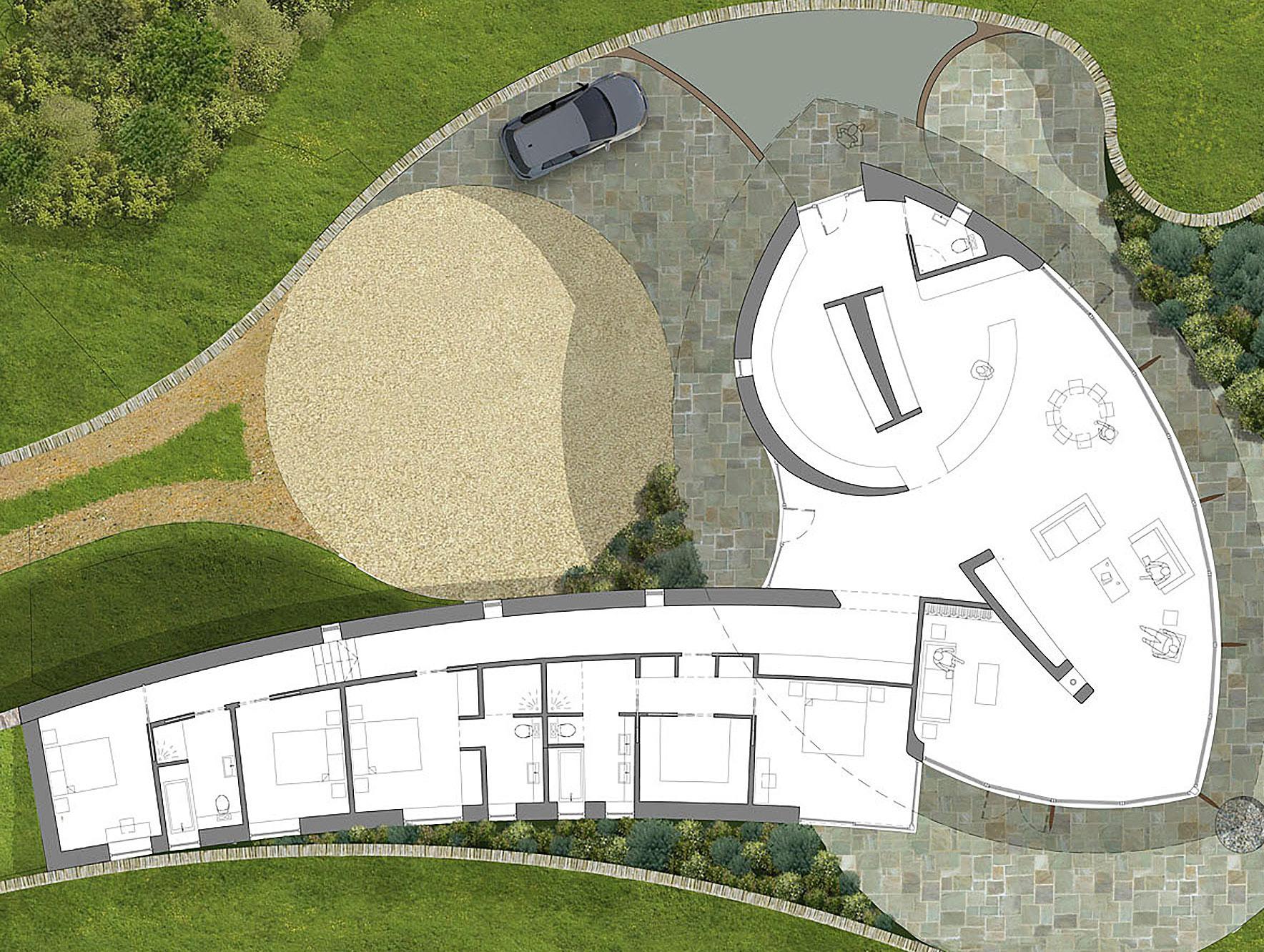

PARAGRAPH 84 (FORMERLY PARA 55) DWELLING IN COTSWOLD BY HAWKES ARCHITECTURE

INTERIOR OF CIRCULAR PLAN IS GUIDED NOT BY A RADIAL GEOMETRY BUT BY ORTHOGONAL BISECTING WALLS AND FURNITURE OR OTHERWISE MORE FREELY ARRANGED SPATIAL CONFIGURATIONS.

OSTRO PASSIVHAUS - PAPER IGLOO IN KIPPEN, CENTRAL SCOTLAND

PASSIVHAUS CERTIFICATION TECHNICAL STANDARDS SECTION 7: SUSTAINABILITY ‘GOLD’ LEVEL.

FEATURES:

• TREATED FLOOR AREA: 170M 2

• SPACE HEATING DEMAND: 15KWH/(M 2A)

• HEATING LOAD: 11 W/M 2

• PRIMARY ENERGY DEMAND: 37KWH/(M 2A)

• FINAL AIR PRESSURE TEST RESULT: 0.20 ACH @50PA

U-VALUES:

• 245MM STUD WALLS: 0.09 W/M 2K

• 145MM STUD WALLS: 0.10 W/M 2K

• WINDOWS & DOORS (AVERAGE): 0.82 W/M 2K

• ROOF: 0.07 W/M 2K

• FLOOR: 0.12 W/M 2K

EXTERIOR :

NARROW BOARDED RAINSCREEN OF NATURALLY WEATHERED LARCH CLADDING FITTED ON A 30 DEGREE ANGLE, WITH VERTICALLY ORIENTATED, PUNCHED OUT TRIPLE GLAZED OPENINGS

INTERIOR :

CENTRAL SERVICE BLOCK CLADDED IN STAINED OAK CONTAINS WET SERVICES, BATHROOM AND CIRCULATION

CONSTRUCTION:

TWIN-WALL TIMBER FRAME, STICK-BUILT ON SITE SITTING ON AN EPS INSULATED RAFT FOUNDATION SYSTEM (BY ISOQUICK), THE WALL ARE FILLED WITH HAND PLACED STEICO WOOD FIBRE INSULATION, AND EXTERNALLY COVERED IN A CONTINUOUS 100MM THICK LAYER OF T&G GUTEX WOOD FIBRE INSULATION BOARDS BEHIND THE RAINSCREEN CLADDING THE INTERNAL PARTITIONS ARE FERMACELL AND THE STRUCTURAL SLAB IS EXPOSED ON THE GROUND FLOOR AS THE INTERNAL FINISH CONTRIBUTE TO THE DECREMENT DELAY KEEPING THE SPACE THERMALLY COMFORTABLE WITHOUT EXTREME TEMPERATURE SWINGS.

TECHNOLOGY / FEATURES:

- 6 X 250W PV PANELS FOR ELECTRICITY GENERATION, - 2 X 12 TUBE EVACUATED-TUBE SOLAR THERMAL PANELS FOR HOT WATER CREATION

- WASTE WATER HEAT RECOVERY UNIT (WWHR) BELOW THE MOST USED SHOWER

- INFRA-RED (IR) PANELS FOR MINIMAL HEATING

- SEDUM TO ROOF (WALSHAW, 2022)

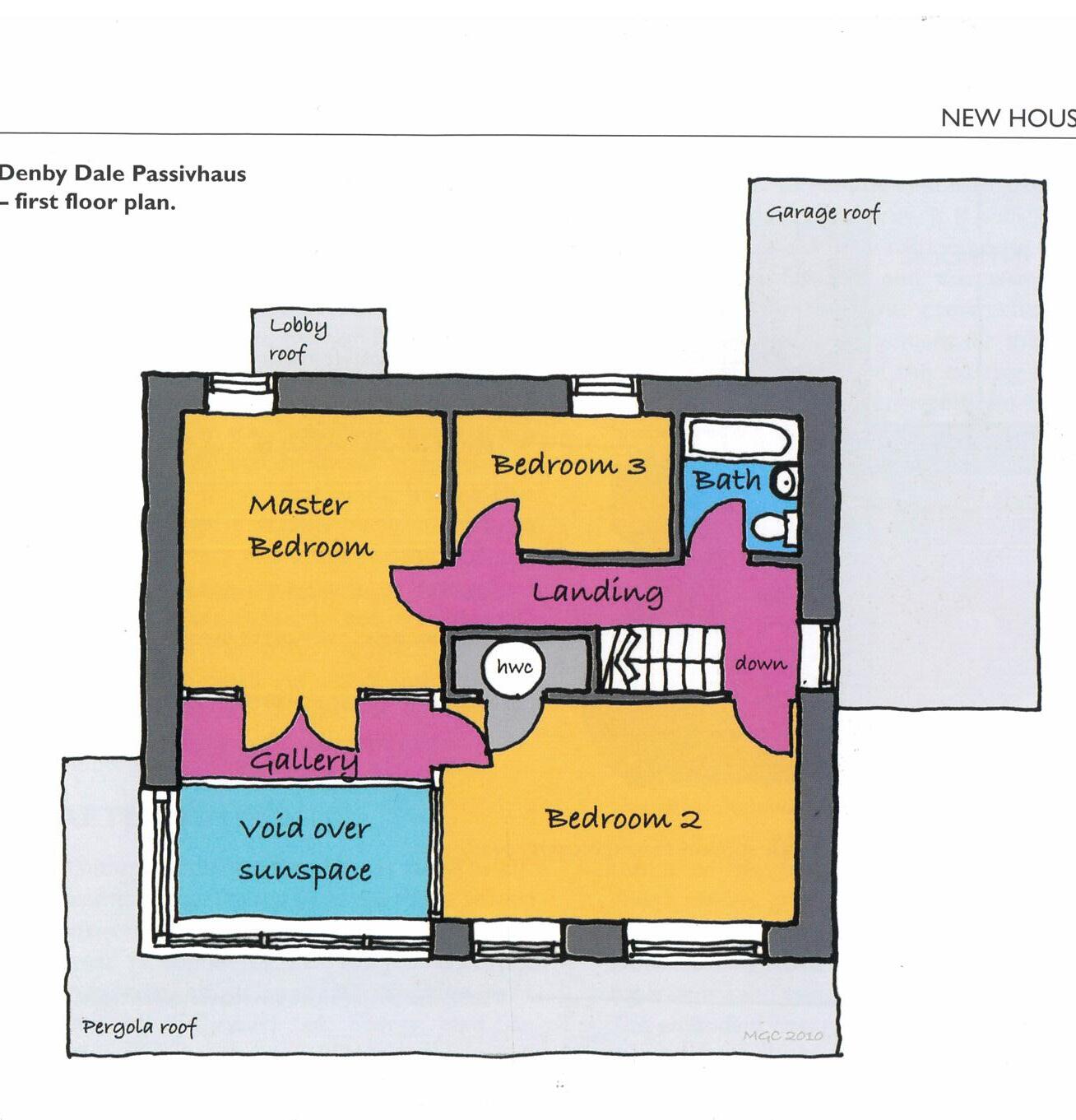

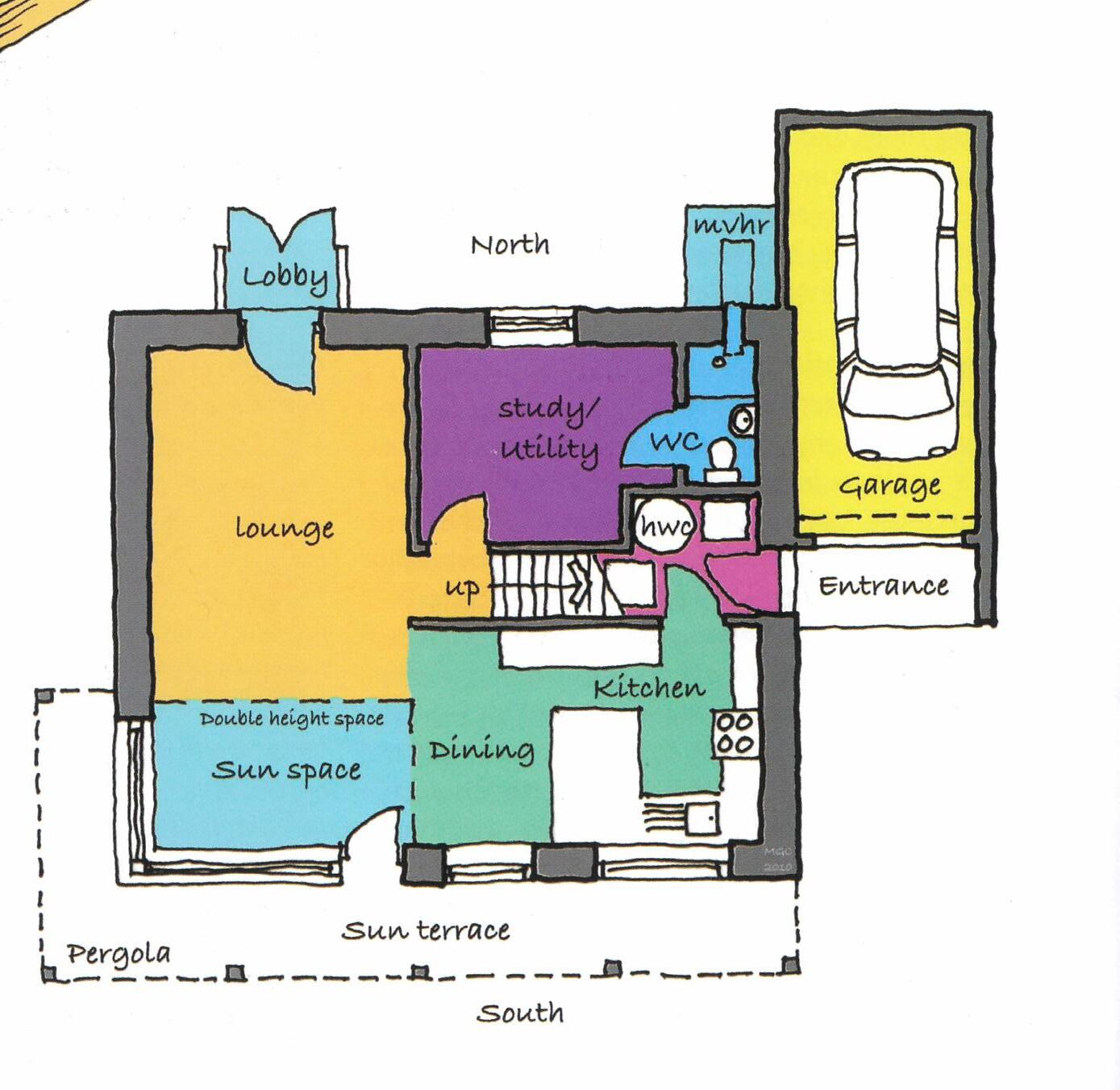

THE DENBY DALE PASSIVHAUS IN WEST YORKSHIRE, UK BY GREEN BUILDING STORE & ARCHITECT DERRIE O’SULLIVAN

IT IS ONE OF THE FIRST CERTIFIED PASSIVHAUS HOMES IN THE UK RECEIVED PASSIVHAUS CERTIFICATION IN 2010

FEATURES:

• TREATED FLOOR AREA: 104.4M2

• SPACE HEATING DEMAND: 15 KWH/M2/YEAR

• HEATING LOAD: 10 W/M2

• PRIMARY ENERGY REQUIREMENT: 87 KWH/M2/YEAR

• AIR PRESSURE TEST RESULT: 0.33 ACH @ 50 PA (TO PASSIVHAUS AND EURONORM STANDARD)

U-VALUES:

• EXTERIOR WALL: 0.113W/M2K

• ROOF: 0.096 W/M2K

• GROUND FLOOR: 0.104 W/M2K

• WINDOWS/ AVERAGE: 0.8 W/M2K (WALSHAW, 2022)

• ALMOST SQUARE PLAN FOOTPRINT PROVED ECONOMIC AND ENERGY EFFICIENT, MEET 15KWH/M2/YEAR SPACE HEATING REQUIREMENTS

• INTEGRATED CONSERVATORY AS SUN SPACE ON THE SOUTH ELEVATION WITH EXTERNAL SHADING TO EXCLUDE HIGH-SUMMER SUN ANGLES

• SUPER INSULATION - WALLS: 300MM FIBREGLASS BATTS; UNDER GROUNDFLOOR: 225MM POLYFOAM INSULATION; ROOF VOID: 500MM FIBREGLASS QUILT; WINDOWS AND DOORS: TRIPLE GLAZING WITH INSULATED THERMAL BREAK IN FRAME

• MINIMISING THERMAL BRIDGING

• MAXIMISING AIRTIGHTNESS WITH GREAT DETAILING AND USE OF AIRTIGHTNESS MEMBRANES AND TAPES.

• MECHANICAL VENTILATION SYSTEM WITH HEAT RECOVERY

• THERMAL MASS HELPS TO KEEP INTERNAL TEMPERATURE STABLE IN WINTER AND SUMMER

• MECHANICAL VENTILATION WITH HEAT RECOVERY (MVHR) SYSTEM (COOK, 2011)

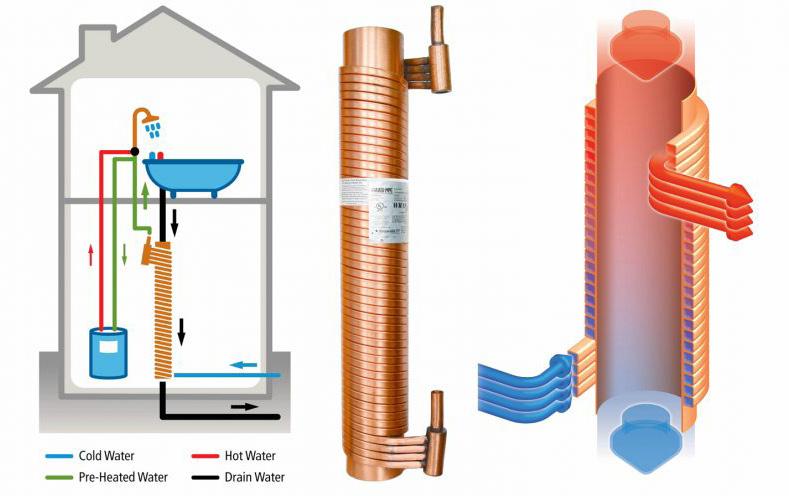

WHAT IS CLT CONSTRUCTION?

CLT PANELS ARE THE LOW BEARING STRUCTURE THAT CAN FORM WALLS, FLOORS AND ROOFS. THEY ARE ALL CUT TO SIZE IN THE FACTORY AND DELIVERED TO SITE ON FLATBED LORRIES. ERECTION OF CLT STRUCTURE IS BY CRANE AND IS FIXED TOGETHER WITH LARGE SCREWS AT REGULAR CENTRES ALONG THE JOINTS. NEW DOOR OPENINGS AND WINDOWS ARE SIMPLY CUT IN THE CLT IN THE FACTORY WITHOUT ANY ADDITIONAL LINTELS REQUIRED.

CLADDING OPTIONS AND THE REQUIREMENT FOR BREATHER AND VAPOUR CONTROLLING ARE ALL THE SAME AS THOSE FOR LOAD BEARING STUD WORK (HETREED ET AL., 2023).

WHY CHOOSING CLT?

+ LIGHTER STRUCTURES SAVE ON FOUNDATIONS

+ SUITABLE FOR EXTENDING EXISTING BUILDINGS WITHIN MINIMAL MODIFICATION

+ SMALLER CARBON FOOTPRINT THAN STEEL OR CONCRETE

+ CARBON SEQUESTRATION

+ STRUCTURAL PERFORMANCE IS INCREASINGLY PREDICTABLE

+ EASILY PREFABRICATED AND WELL-SUITED TO MODULAR CONSTRUCTION

+ BUILDING WITH CLT IS TYPICALLY NOT DEPENDANT ON WEATHER CONDITIONS, APART FROM STRONG WIND. IT CAN BE INSTALLED IN COLD AND WET WEATHER, SNOW AND FROST

+ VERY SHORT SITE ERECTION TIME

+ WARM AND APPEALING NATURAL TEXTURE AND COLOUR (WHITEHEAD, 2019)

ANY DISADVANTAGES?

– IT NEEDS ADDITIONAL THERMAL MASS TO HELP WITH THERMAL PERFORMANCE DUE TO ITS LIGHTWEIGHT CONSTRUCTION

– SAME FOR ITS ACOUSTIC PERFORMANCE

– REQUIRES A RELIABLE AND SUSTAINABLE SOURCE AND MIGHT BE RARE OUTSIDE EUROPE AND NORTH AMERICA

– THE STRUCTURE MUST BE KEPT DRY TO PREVENT ROT

– CLIENTS ARE SCEPTICAL OF PERFORMANCE IN FIRE

– SHORTAGE OF DESIGN AND CONSTRUCTION EXPERTISE (WHITEHEAD, 2019)

EXTERIOR MATERIAL

CLT STRUCTURE CLADDED WITH REPURPOSED AGRICULTURAL ROOFING SHEETS

INTERIOR MATERIAL

ALL PRIMARY CLT STRUCTURES EXPOSED THROUGHOUT WITHOUT ANY ADDITIONAL CARBON-HEAVY AND COSTLY PLASTERBOARD LININGS OR PAINT FINISHES. MINIMAL MATERIAL PALETT TO GIVE WARMTH AND TEXTURE TO THE INTERIOR.

WINDOWS & DOORS

TRIPLE GLAZED TILT AND TURN WINDOWS THE PRESENCE OF MULTIPLE CHAMBERS WILL SERVE AS A BARRIER THAT SIGNIFICANTLY REDUCES HEAT LOSS AND ALSO PREVENTING COLD AIR FROM ENTERING.

SEDUM ROOF COVERING

CREATE BIODIVERSE ENVIRONMENT FOR LOCAL WILDLIFE AND HELP ATTENUATE THE RAINWATER. RAINWATER TO BE DEALT WITH RAISE RAIN GARDEN

RAINWATER HARVESTING

PV PANELS ON ROOF

- 35-40 DEGREE

HOT WATER CYLINDER (HWC)

LOCATED NEAR THE CENTRAL OF THE HOUSE TO ALLOW SMALLER PIPE DIAMETER AND SHORTER ROUTE THAT REDUCE HEAT LOSS

MINIMAL HEATING SYSTEM VIA INFRARED PANELS

CLOSE TO EXTERIOR WALL TO SHORTEN COLD AIR PIPE AND PREVENT HEA T LOSS. IT SHOULD BE INSTALLED AT A CONVENIENT LOCATION FOR EASE OF REGULAR FILTER REPLACEMENT TO MAINTAIN INDOOR AIR QUALITY

RAINWATERHARVESTING TANK

UNHEATED STAIRCASE SHOULD BE PLACED ON THE NORTH SIDE CLOSE TO OUTSIDE WALLS ACTS AS BUFFER TO THE EXTERNAL ENVIORNMENT

SUPER INSULATION & AIR TIGHTNESS

TRIPLE GLAZED TIMBER INWARD OPENING

SOUTH FACING

NATURAL LIGHTING

SUNSPACE

SUN-SHADING TO EXCLUDE HIGH SUMMER SUN ANGLES (E.G. BALCONY, ROOFOVERHANGS, WINDOW REVEALS)

OPERABLE WINDOW TO VENT EXCESS HEAT

THERMAL MASS

TO MODERATE TEMPERATURE SWING OF TYPICAL LIGHT-WEIGHT TIMBER CONSTRUCTION BY USING INCREASED DENSITY WALL LININGS AND EXPOSED

CONCRETE FLOOR SLABS ON GROUND FLOOR

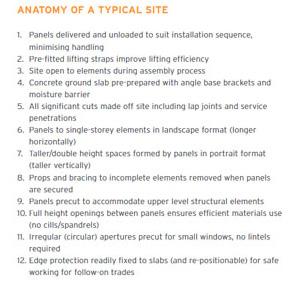

MINIMAL HEATING SYSTEM VIA INFRARED PANELS

INFRARED PANELS TRANSMIT HEAT EMITTING LOADS OF INFRARED RAYS AND WARM THE SURROUNDINGS THROUGH HEAT RADIATION. THE SURROUNDING OBJECTS ABSORB THE HEAT WITHOUT ENERGY BEING WASTED IN HEATING UP THE AIR LIKE THE TRADITIONAL HEATER DOES THROUGH CONVECTION.

SEDUM ROOF COVERING

CREATE BIODIVERSE ENVIRONMENT FOR LOCAL WILDLIFE AND HELP ATTENUATE THE RAINWATER

RAINWATER TO BE HARVESTED AND STORED FOR USE

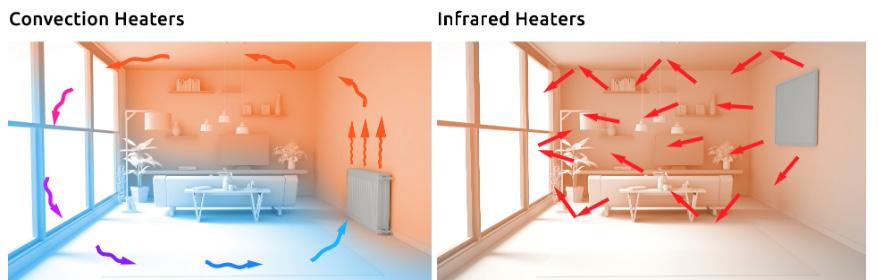

WASTE WATER HEAT RECOVERY

RECOVERING HEAT FROM OUTGOING WARM WASTE WATER, SUCH AS SHOWER WATER TO PRE-HEAT INCOMING COLD FRESH WATER THAT HELPS TO SAVE ENERGY AND LOWER HEATING COST.

IT IS ONE OF THE METHODS RECOGNISED BY THE NATIONAL HOUSE BUILDING COUNCIL (NHBC) TO PASS BUILDING REGULATIONS PART L. IT IS ALSO THE MOST COST-EFFECTIVE WAY OF INCREASING A STANDARD ASSESSMENT PROCEDURE (SAP) SCORE.

A VIDMAR, P. BY JERNEJ AND VIDMAR, P. BY J. (2021) HOW CAN USING FORM FACTOR R EDUCE ENERGY CONSUMPTION OF BUILDINGS?, MODELUR. AVAILABLE AT: HTTPS:// MODELUR.COM/USE-FORM-FACTOR-TO-REDUCE-ENERGY-CONSUMPTION-OF-BUI LDINGS/ (ACCESSED: 01 APRIL 2024).

B NHBC FOUNDATION (2016) ‘THE CHALLENGE OF SHAPE AND FORM: UNDERS TANDING THE BENEFITS OF EFFICIENT DESIGN’. MILTON KEYNES: NHBC FOUNDATION.

C WALSHAW, E. (2022) UNDERSTANDING PASSIVHAUS: A SIMPLE GUIDE TO PASSIVHAUS DETAILING AND DESIGN. FIRST IN ARCHITECTURE.

D COOK, M.G. (2011) THE ZERO-CARBON HOUSE. MARLBOROUGH, UK: CROWO OD.

E HETREED, J., ROSS, A. AND BADEN-POWELL, C. (2023) ARCHITECT’S P OCKET BOOK. LONDON ; NEW YORK, UK; US: ROUTLEDGE, TAYLOR ET FRANCIS GROUP.

F CRAWLEY, N. (2021) CROSS LAMINATED TIMBER: A DESIGN-STAGE PRIME R. LONDON, UK: RIBA PUBLISHING.

G WHITEHEAD, T. (2019) THE PROS AND CONS OF TIMBER STRUCTURES, WS P RETHINK OFFSITE. AVAILABLE AT: HTTPS://RETHINKOFFSITE.WSP.COM /INSIGHTS/TIMBERSTRUCTURES-DOES-WOOD-CUT-IT/ (ACCESSED: 07 APRIL 2024).