German architect with international experience across Jordan, Italy, Germany, and Austria. My background spans award-winning competitions in Amman, computational design research in Milan, and hands-on project delivery of industrial and office buildings in Germany and Austria. Skilled in BIM (Revit), parametric design (Rhino/Grasshopper). I’ve developed a practice grounded in both design clarity and technical responsibility. With BIM expertise and ongoing training in construction project management, I bring not just ideas, but the ability to coordinate, lead, and deliver. I bring both the curiosity to explore and the discipline to follow through.

CONTACT INFORMATION

Khalidalabdulh@gmail.com

004915906170381

www.linkedin.com/in/khalid-alabdula

M.Sc. Politecnico di Milano Building Architecture

M.A. Architecture School of Anhalt Bauhaus Architectural and Cultural Heritage

B.Sc. Applied Science University Architectural Engineering

https://issuu.com/khalidalabdulh/docs/architektur-computational_design_portfolio_2023

• Certified practice training in construction project management, contracts, cost-risk- conflict and quality management. 19.05.2025 - 29.07.2025

• Online Workshop / Rhino, Grasshopper, Rhino Inside Revit Design Workflow, By Dusan Cvetkovic. 04-14.05.2025

• Construction Cost Estimation & Project Management (HOAI & AVA), Dessau. 17.07.2023 - 11.08.2023

• Technical & Leadership Communication (German Professional Training), Dessau. 22.05.2023 - 14.07.2023

• Gerrit Rietveld Military table, Bauhaus Holzmöbel-Workshop. 01.10.2021 - 30.11.2021

• Heritage Restoration Summercamp Workshop, Quedlinburg, Germany. 27.09.2021 - 03.10.2021

• PRINT in PRINT: Advanced Robotic 3D Printing Workshop. 26-27.06.2021

Alfatraining Bildungszentrum

Rhnio

Alfatraining Bildungszentrum

Alfatraining Bildungszentrum

Anhalt HS Bauhaus

Sommercamps Exkursion Digitalfurtures

• Revit – Expert in regulatory-driven modeling and detailed documentation for industrial and office buildings

• Rhino + Grasshopper – Used for early design concept development prototyping, parametric façade studies, and optimization of geometries

• INDEXLAB, Politecnico di Milano – Research on modular, recyclable systems and discrete geometry

PROJECT ARCHITECT - ARCHITECTURAL DESIGNER

Planungsbüro Baumert & Peschos GmbH

• Led architectural design and technical coordination for mid-sized industrial, commercial, and office buildings, including warehouse and archive facilities with integrated parking and bicycle storage.

• Produced detailed technical drawings for tender and construction phases, including roof plans with drainage solutions, foundation sections (1:25), facade detailing, and structural cross-sections (1:50).

• Managed site inspections, client and contractor meetings, and project coordination.

• Handled building permit applications (Baugenehmigung), ensuring compliance with national building codes, accessibility regulations, fire protection, and sustainability standards.

• Developed design variations, cost assessments, and contract amendments.

• Quality, cost, and schedule control.

• Integrated BIM methodology using Revit for project coordination and 3D visualization.

ARCHITECTURAL ASSISTANT (6 MONTHNS PROBEPERIOD)

Planungsbüro Baumert & Peschos GmbH

• Assisted in detailed design and documentation of a multi-use project in Austria (govermental, residential, commercial).

• Supported lead architects in design modification, technical detailing, and coordination with consultants.

INTERN AND JOINT THESIS RESEARCH – ARCHITECTURE AND TECHNOLOGY

Indexlab - Creativity And Technology

• Developed robotic fabrication techniques for architectural applications.

• Designed complex parametric structures integrating computational design and advanced material research.

• Researched sustainable digital fabrication strategies to optimize material efficiency and reduce environmental impact.

• Produced physical and digital 3D models using innovative manufacturing technologies.

• Software used: Rhino 3D, Grasshopper, Revit, C#, 3D Printers, ABB Robots.

STUDENT RESEARCH ASSISTANT – DOCUMENTATION

Anhalt Architecture School of the BAUHAUS

• Assisted in architectural documentation and visualization for academic BAUHAUS projects.

ARCHITECTURAL INTERN

Wael Al-Masri Planners And Architects

• Supported design development and documentation for various architectural projects.

• Assisted in 3D modeling and concept visualization using BIM tools.

INTERNSHIP IN CONSTRUCTION DRAWING

Nazeeh Al-Qarim Office

• Developed architectural drawings and technical documentation for various project types.

MARCH,2024 - MARCH, 2025 MAGDEBURG, GERMANY

SEP,2023 - MARCH,2024

MAGDEBURG, GERMANY

DEC,2021 - MAI, 2022 LECCO, ITALY

JAN, 2021 - FEB, 2021 DESSAU, GERMANY NOV, 2017 - FEB, 2018 AMMAN, JORDAN JUL, 2017 - OKT, 2017 AMMAN, JORDAN

00. Addaptive Reuse

THE RECLAIMED GARDEN OF CASCINA SAN FEDELE - ARCHITECTURAL PRESERVATION STUDIO

POLITECNICO DI MILANO UNIVERSITY

01 Offices and Research-Oriented Industrial Facility

CASCINA SAN FEDELE - ARCHITECTURAL HERITAGE CONSERVATION

POLITECNICO DI MILANO UNIVERSITY

02. Multi-Use Building

TUNNEL OF THE ARTISTS ADAPTIVE REUSE

ARCHITECTURE SCHOOL OF ANHALT BAUHAUS

03. Performance - Driven Design

SMART PAVILION 21 - DIGITAL SCALE-UP

POLITECNICO DI MILANO UNIVERSITY

04. Digital Fabrication and Computaoinal Design in Architecture

RETHINKING ORNAMENT

POLITECNICO DI MILANO UNIVERSITY

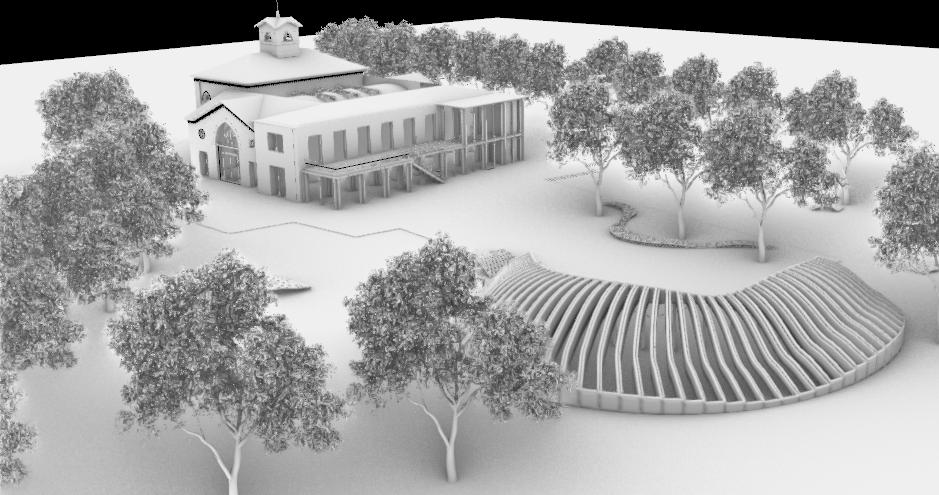

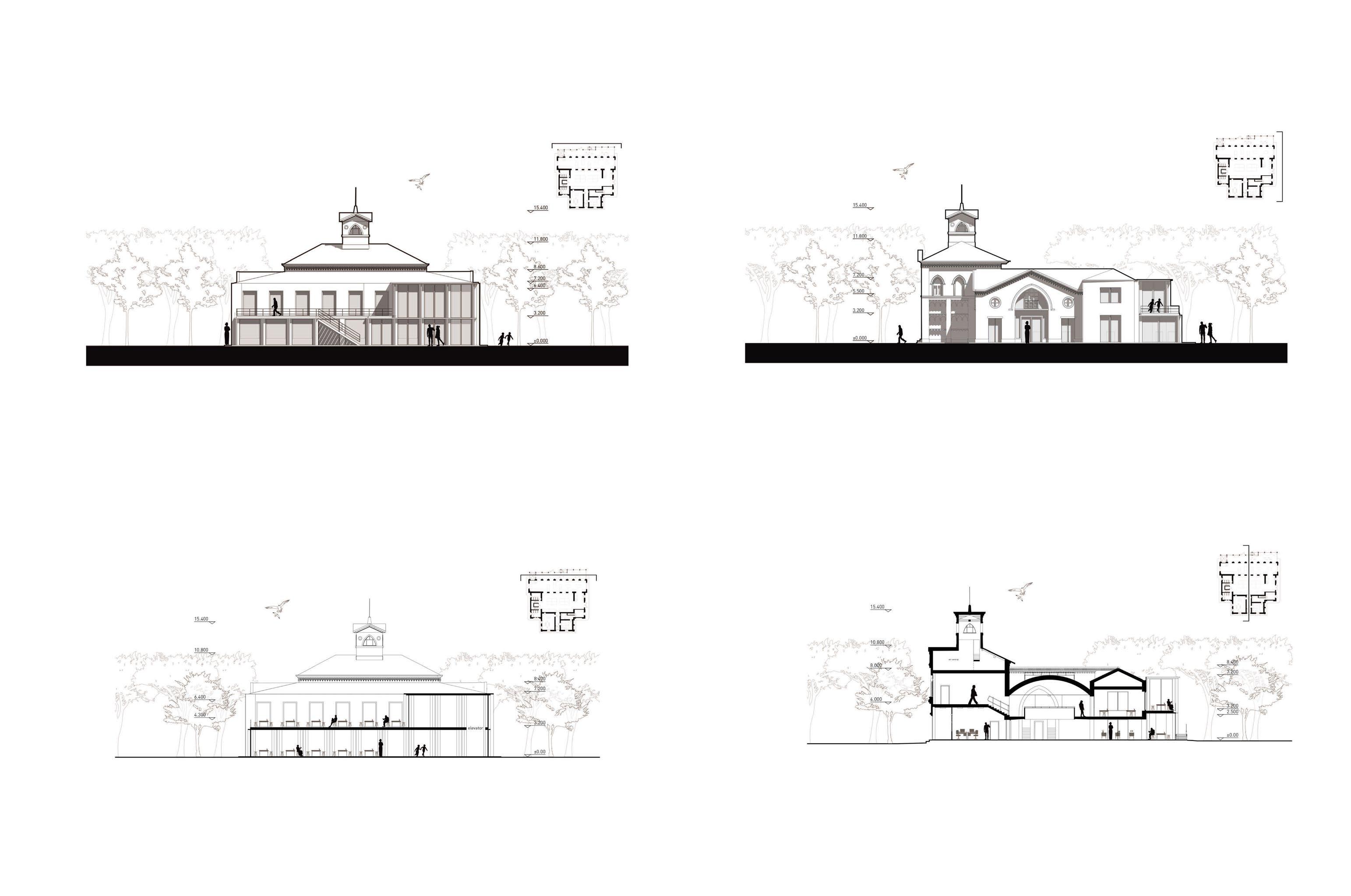

ADDAPTIVE REUSE IN ROYAL PARK OF MONZA

The project presented for San Fedele focuses on restoring the historic Cascina San Fedele, earlier used as royal vacation house, and using it as a boutique park offering organic products. The main goal of the project is to attract more visitors in order to convey the unique charm of Monza through local products.

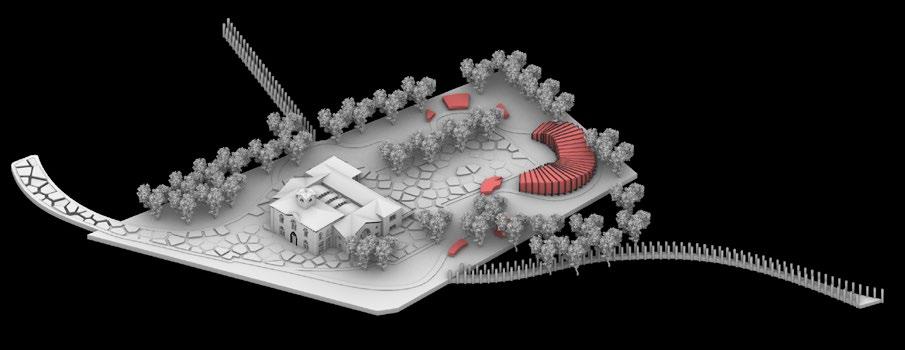

The connection between San Fedele and the surrounding historic buildings will be strengthened by creating new pedestrian paths that include small structures for visitors’ spatial experiences and activities. The conference pavilion represents an event hall for the people to sell organic products and do related activites togather

Location: Italy.

Type: Group / academic work

Software:

Plans for new and demolished

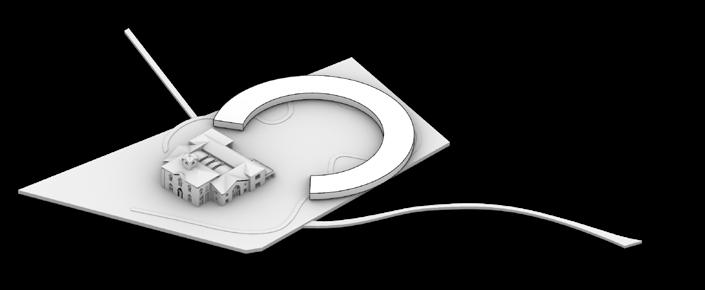

a) Rounded geometery welcoming the users coming to the backyard

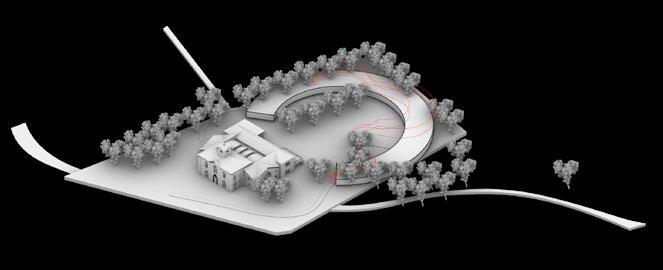

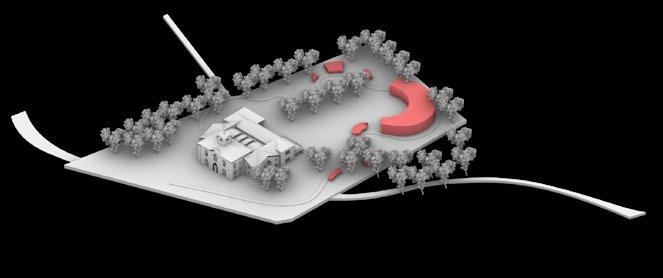

The conference and event pavilion is created from a simple circular shape that develops into an organic, serpentine structure in response to the natural surroundings.

Instead of removing the existing trees, the architecture integrates them into the spatial concept. The result is a harmonious combination of landscape and built space - a place that unites encounters, tranquillity and the experience of nature.

The pavilion becomes a living landscape element - a symbol of the respectful interplay between architecture, environment and user.

b) serpentine-like form in red colour

c) Geometries wind around the trees

d) The shape of the pavilion transforms into an organic, serpentine geometry - part architecture, part landscape.

e) The pavilion functions not only as an event venue, but also as a living structure that enables an interactive relationship between people and nature.

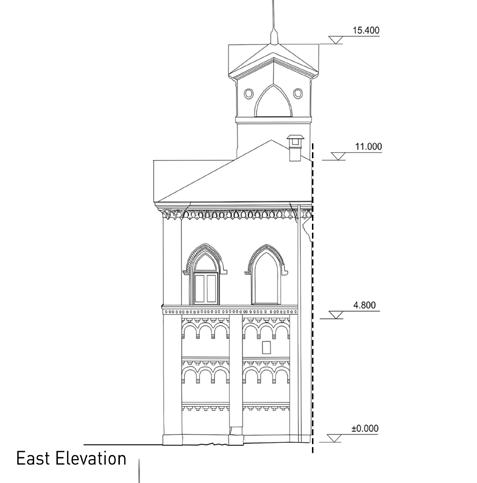

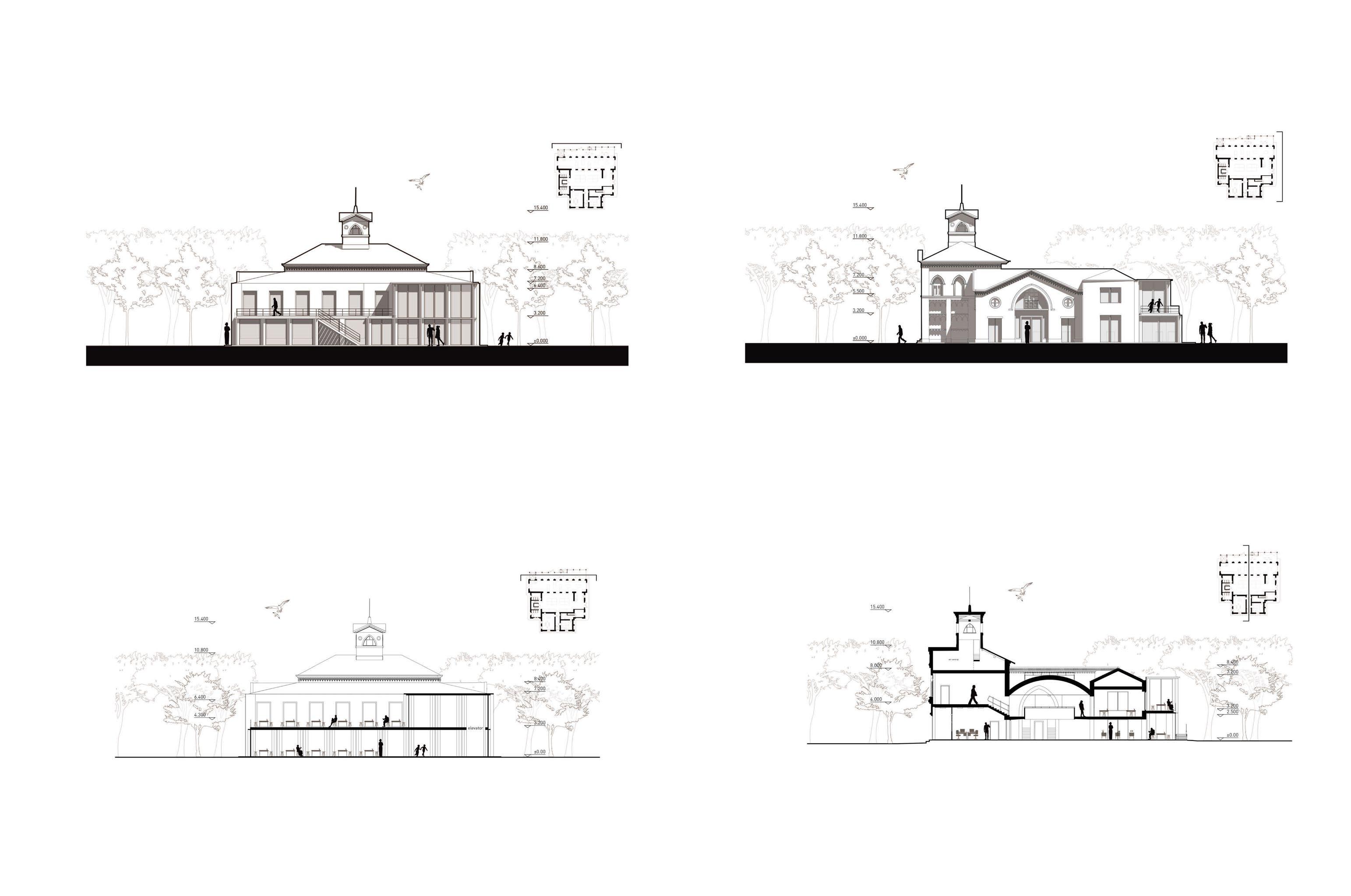

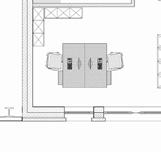

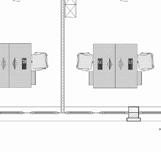

Industrial plant for water supply

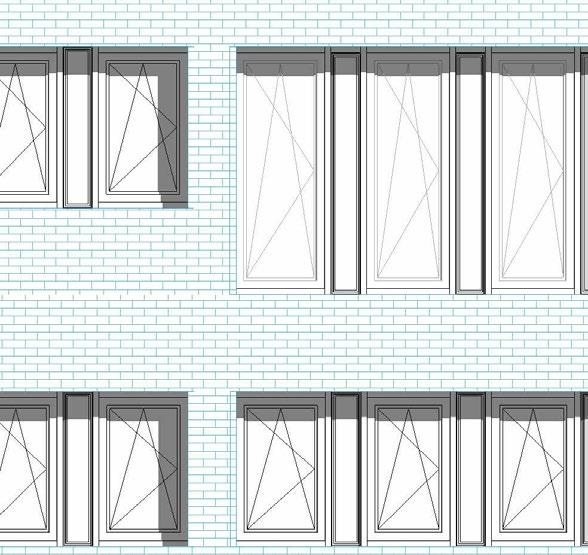

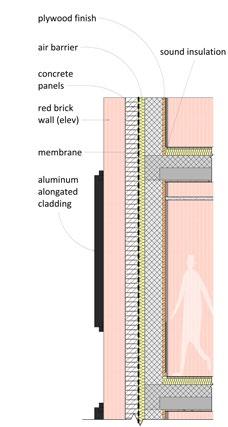

A two-storey industrial facility with multifunctional use was planned and realized on behalf of a private company in the water recycling and treatment sector. The building combines office space with technical areas for research, water treatment and storage.

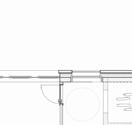

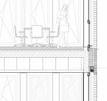

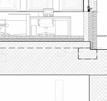

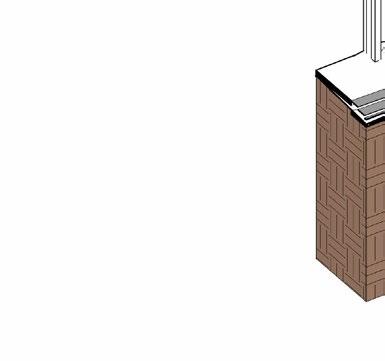

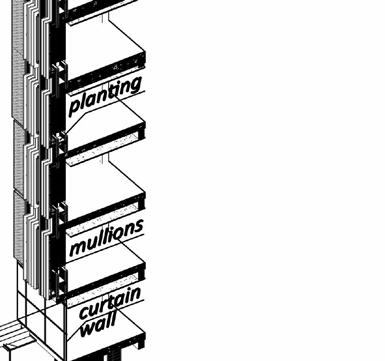

The building was constructed using prefabricated reinforced concrete. In order to integrate the design into the local surroundings, the façade was designed with red-brick exterior walls to match the traditional building style of the surrounding area. The facility consists of two functionally separate structures: an administration area and a section for technical processes and storage areas.

Location: Magdeburg, Germany

Facility: Research-oriented industrial plant for water treatment and recycling.

Client : Private company in the field of water recycling.

Work phases : Concept design phase - Excution detailed design Software used:

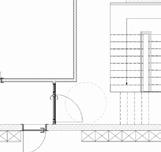

The floor plan was developed and optimized in close coordination with the client and the specialist planners and contractors involved. Coordination took place in parallel with the overall architectural management of the project.

The design and approval planning was implemented in accordance with the requirements of the building regulations and subsequently released for the execution phase. The execution drawings were prepared in collaboration with the structural engineers and handed over to the contractors and

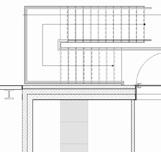

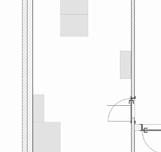

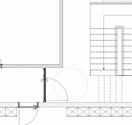

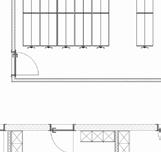

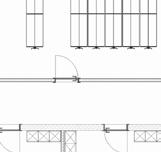

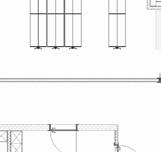

Barrier-Free Entrance Area _ 2nd floor

The section line cuts through the offices and the access core and illustrates the movement of the elevator car and the smoke extraction opening that is used in the event of a fire.

In the top right-hand corner, a 1:5 detailed section of the top floor illustrates the connection of the roof slab to the loadbearing external wall. Below this, a 1:5 detailed section shows the plinth area with the building’s plinth insulation, which illustrates the plinth insulation system.

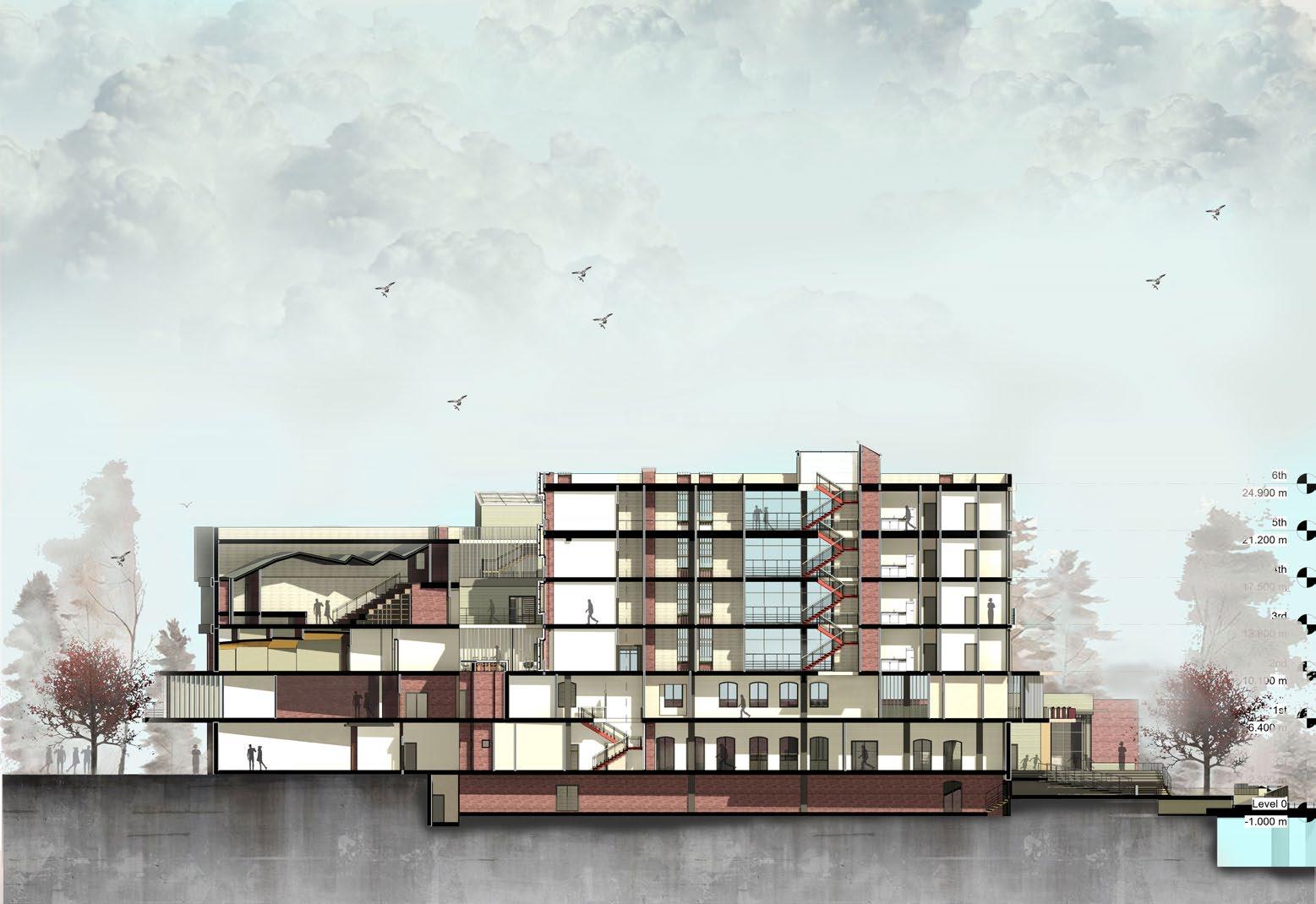

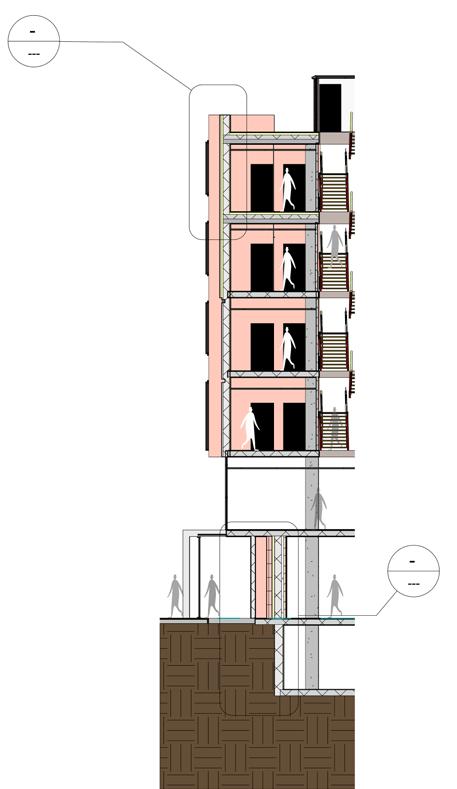

The historic building, formerly a soap factory, has been developed into a meeting place for artists and musicians The proposed adaptive reuse aims to preserve the significance of the site and create a sustainable solution.

Consists of a student residence, a music school with recording studios and auditorium, and dance areas. Addaptive reuse will make the building more efficient with a long-term positive impact on the surrounding area.

Location: Berlin

Type: Individual/academic work

Software used:

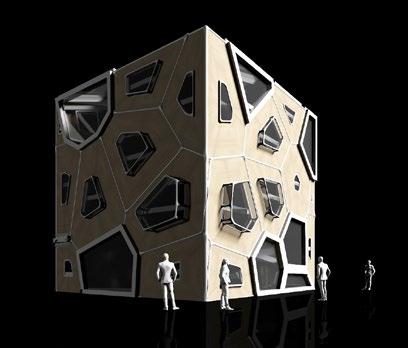

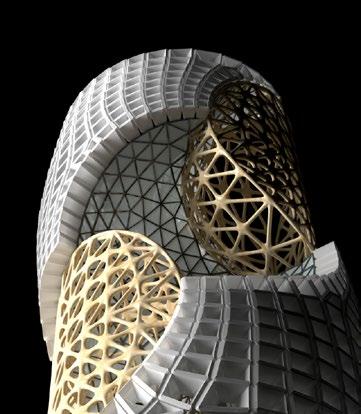

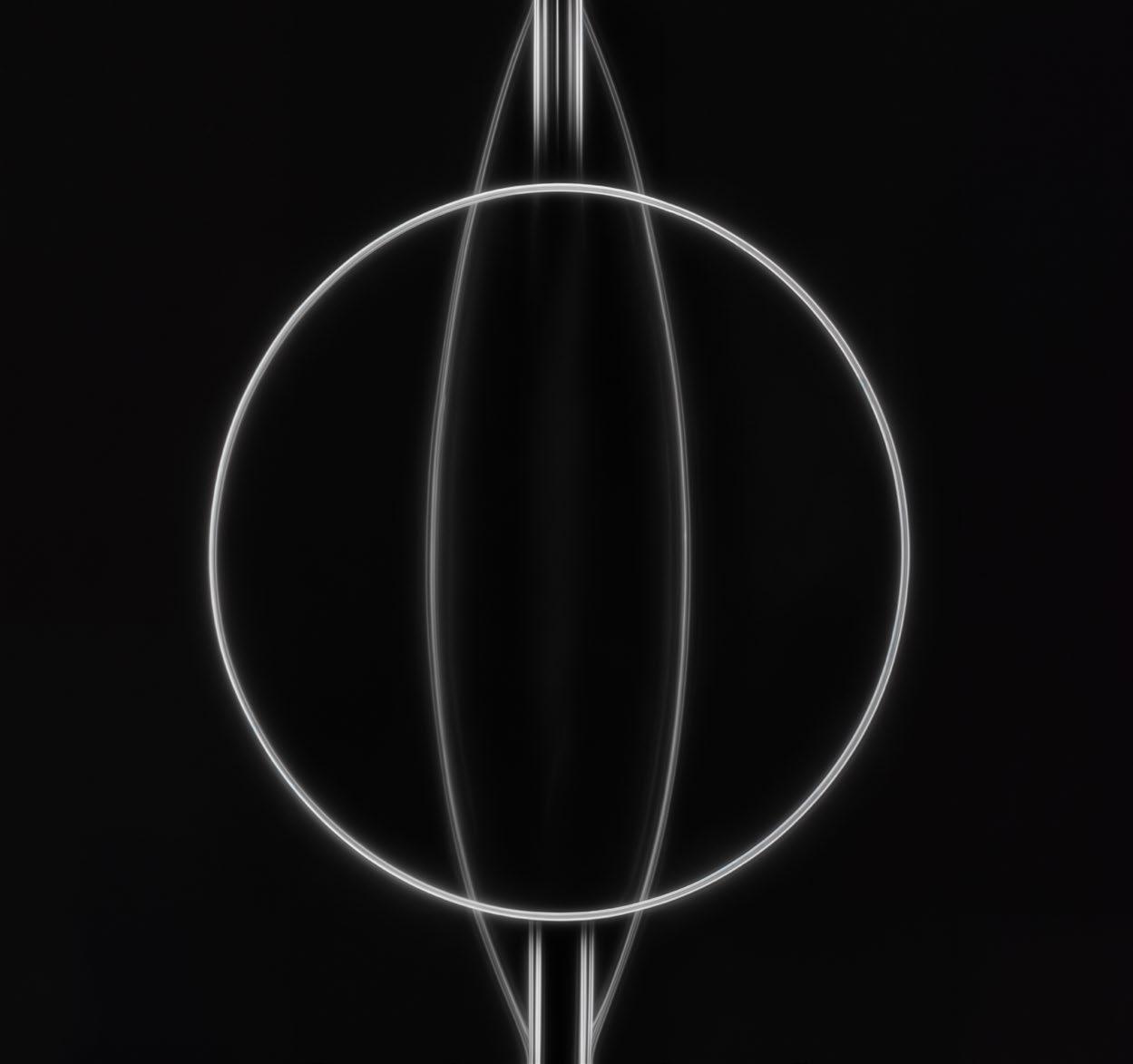

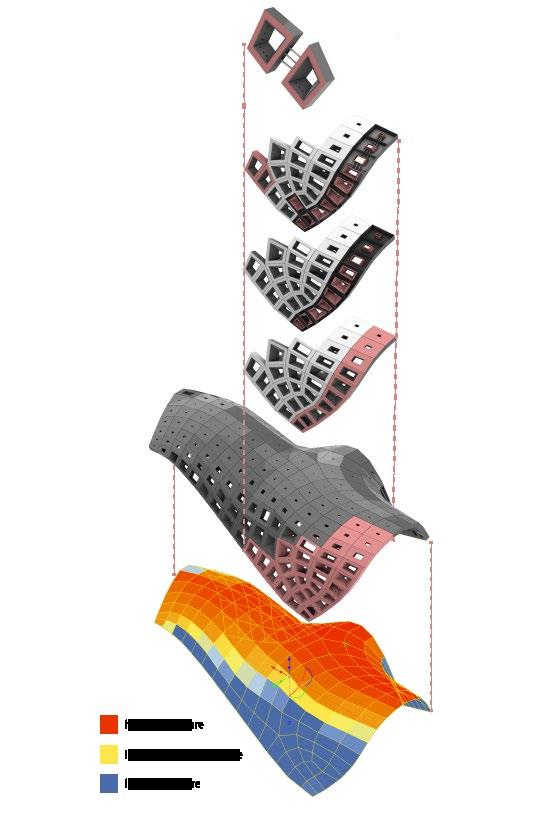

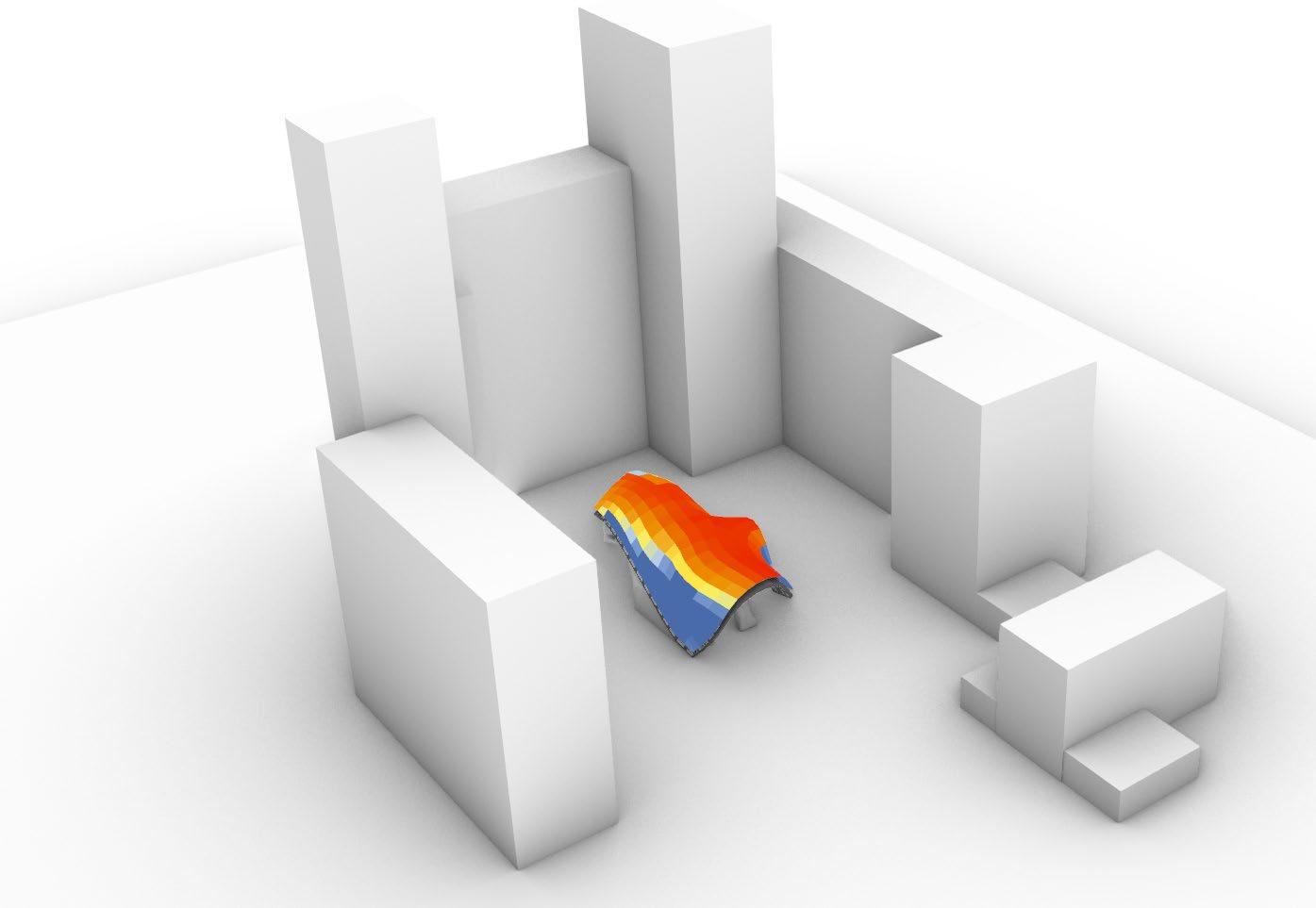

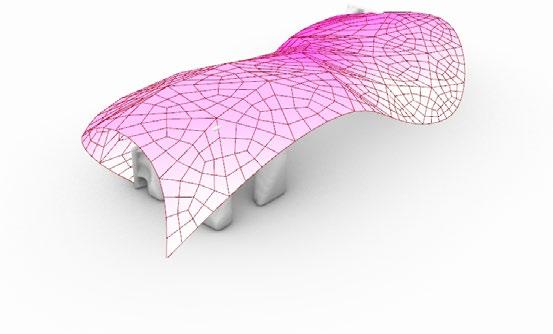

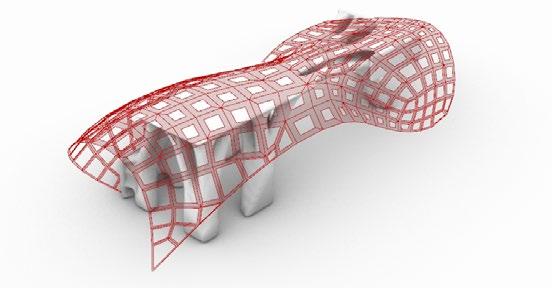

This project pursues new design approaches to tackle environmental problems in the construction sector. It aims to improve energy efficiency in the construction industry and reduce material waste.

The pavilion utilises perforated outer skin to control the amount of sunlight entering the interior and create a comfortable temperature for users.

Comprehensive environmental and structural analyses were used to calculate the diameter of the perforations and the structure of the steel frame. Structural optimisation algorithms were used.

Location: Italy

Type: Individual/academic work

Software used:

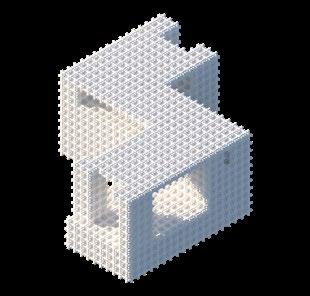

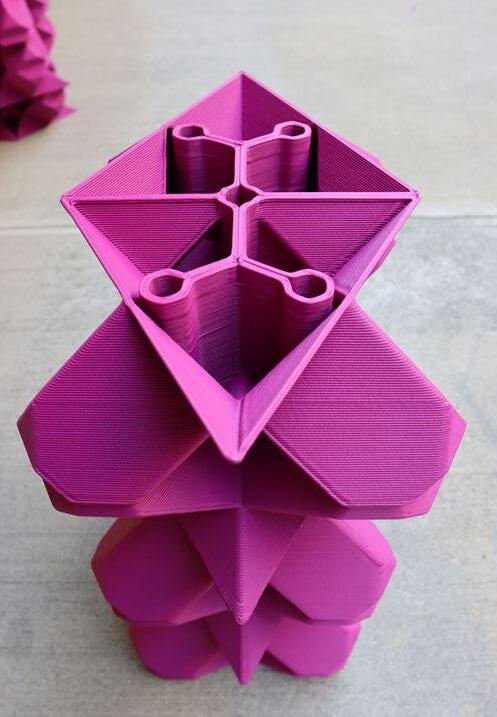

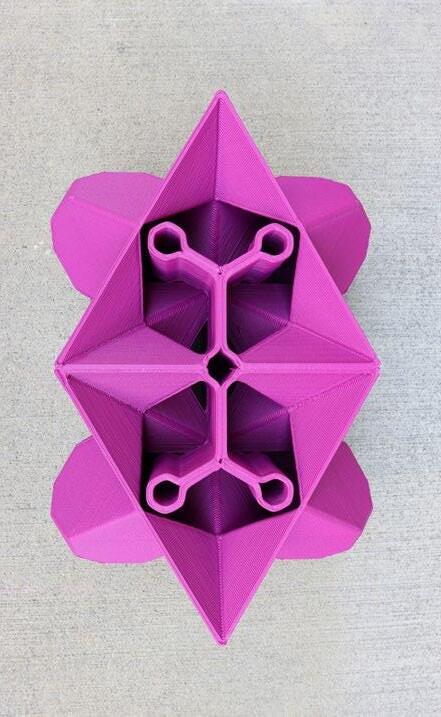

The modules have been modified so that they can accommodate tension rods thanks to milled perforations.

Load analysis and structural optimisation with Karamba3D

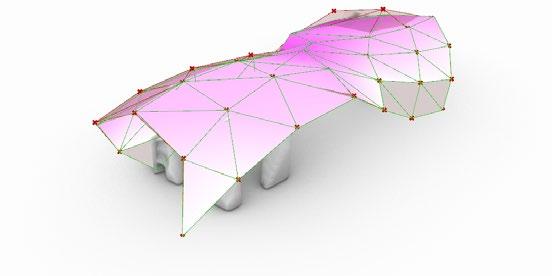

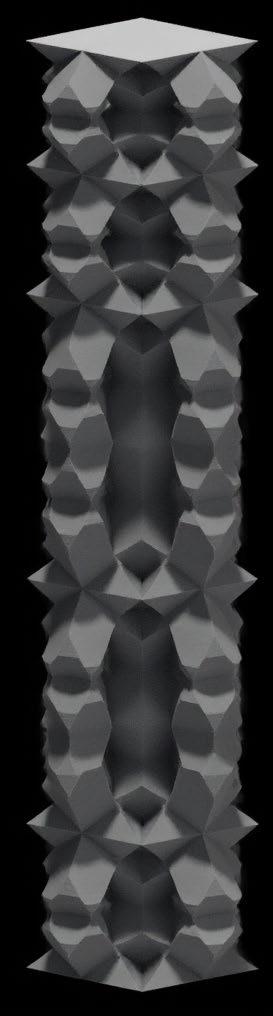

Through the architectural realisation of parametric design and 3D printing technologies

Traditional construction processes are rapidly evolving due to the need for more time, cost and energy efficient construction processes, leading us to be better able to fulfil our current needs. On the one hand, this means a rapid shift towards automation, which is an effective solution to reducing the construction industry’s large environmental footprint, and on the other, the search for alternative material resources that contribute to the reuse of material waste. Polymers are widely used and wasted in construction, while nowadays they are digitally researched and enhanced by different fibres to improve structural properties, making them a smart material used more widely in today’s architecture.

Computer-aided design has enabled the exploration and creation of complex geometric elements that can be assembled in various ways to create customised architectural elements. Additive manufacturing technologies such as 3D printing and robotic material extrusion represent an efficient design approach that enables real-time physical simulation in parallel with digital design, creating an interactive experience between the designer and the product.

Location: IndexLab, Lecco, Lombardi, Italy

Type: Individual/academic work

Organisation: Anhalt University of Applied Sciences, University Politecnico di Milano

Software used:

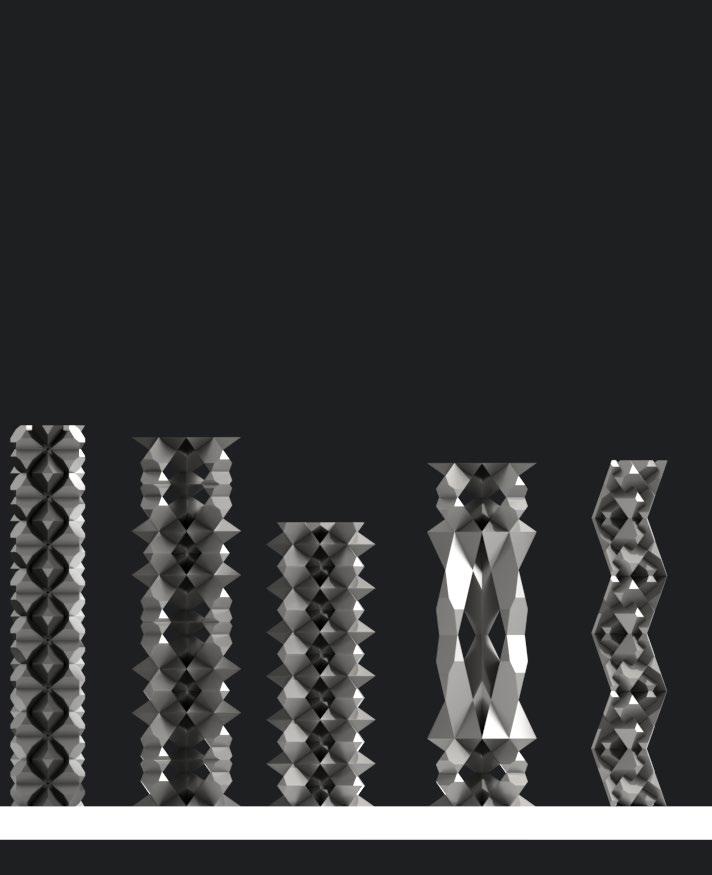

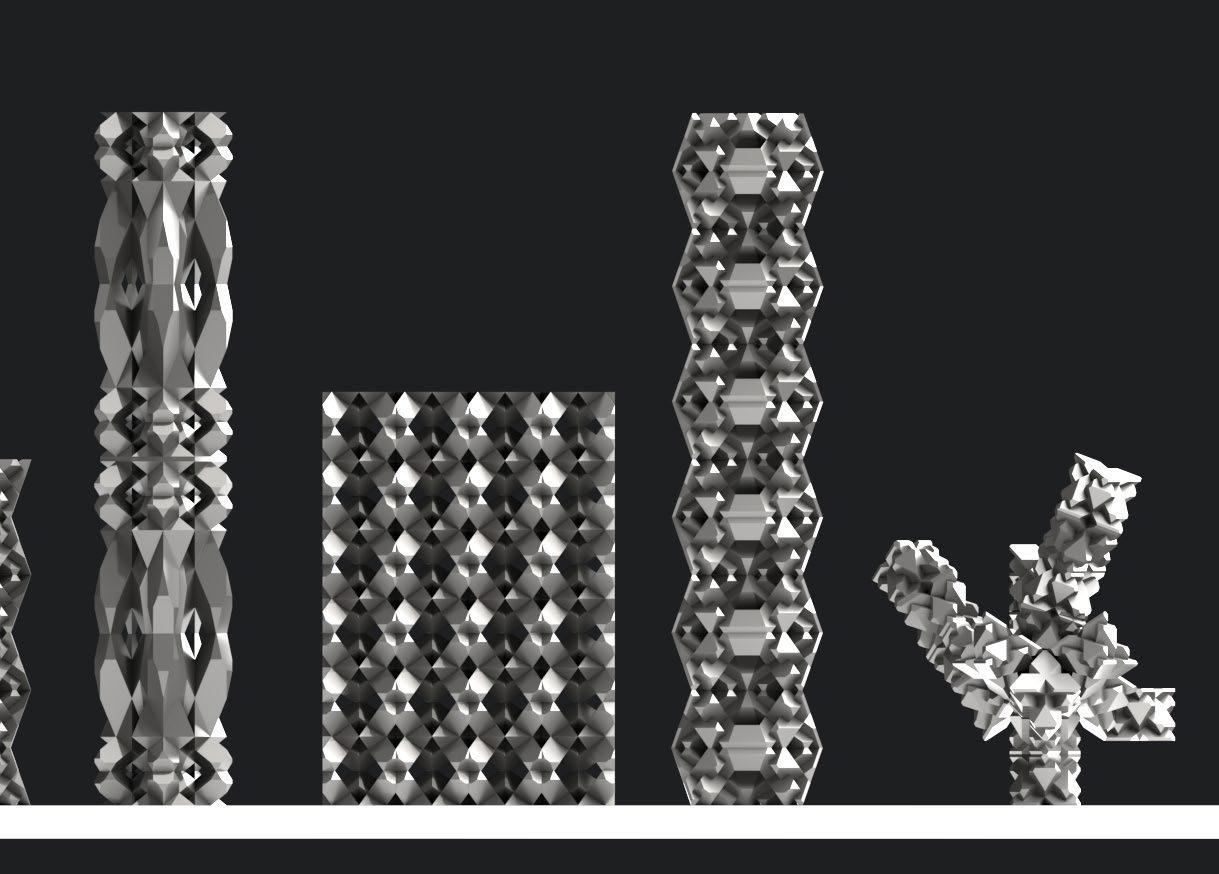

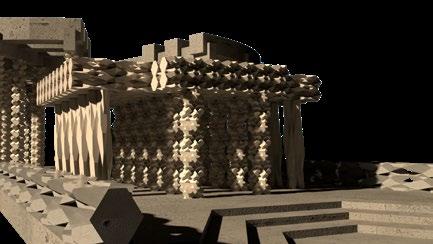

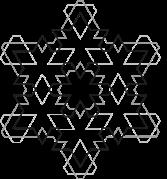

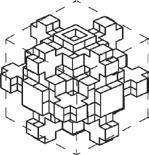

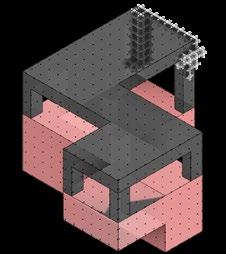

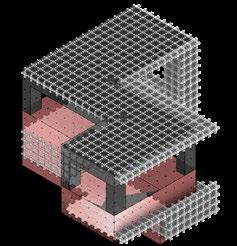

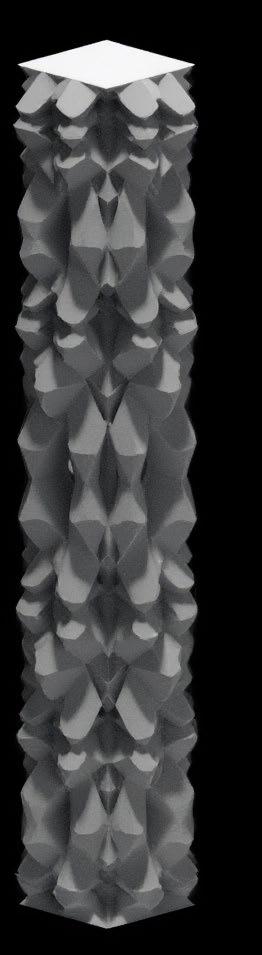

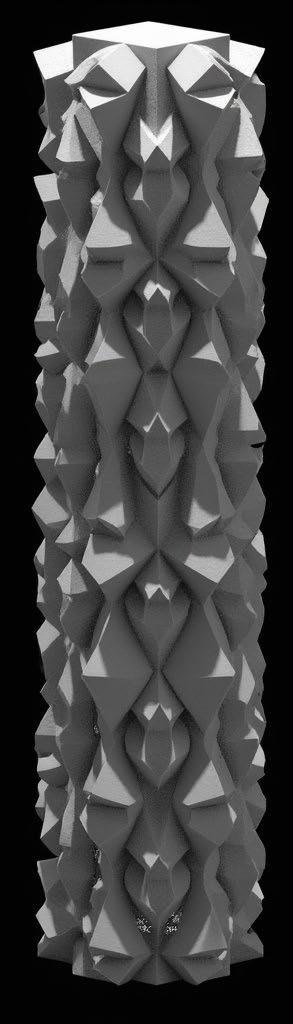

Recursive subtraction is a process in design or geometry in which a shape is iteratively and repeatedly subtracted from a larger shape, often resulting in intricate, complex forms.

This technique is used to create patterns or textures by gradually removing parts from the whole.

Field-controlled modular assembly showing the aggregation process of a single module in response to vector fields with Rhino and Grasshopper.

Modules align, orientate and vary their density depending on field strength and flow direction.

This demonstrates a scalable system that can generate both finite structures and continuous architectural fields.

Cross-shape essential module

Cutting geometryCompound of two Tetrahedron

Vertical cutting plane

Horizontal cutting plane

Discrete parts

Discrete part assembly

Gen 1 Gen 2 Gen 3

Discrete part assembly

Discrete part

Scale-up

The project seeks to reinterpret the geometric principles in traditional ornamentation, translating the geometric patterns into 3D elements, creating discrete parts and assembling them into various complex architectural elements.

This will be driven by a certain level of structural performance using algorithmic visual coding. Finally, robotic material extrusion will be used to produce a scale model of a modular architectural column.

A variety of discrete modules were developed that were optimised for the construction of specific architectural elements.

The design process made it possible to understand the ways in which these parts could be assembled and then to visualise the possible outcomes of their structural assembly.

The elements were virtually assembled using digital simulations, but only one of them was selected to be further optimised and manufactured using the extrusion robot.