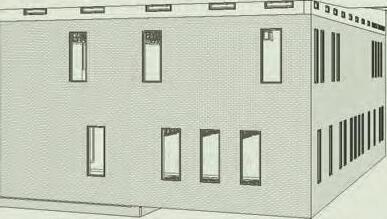

SOUTHEAST PERSPECTIVE

DESIGN TAKEAWAYS

NORTHEAST PERSPECTIVE

PROGRAMMATIC BREAKDOWN

SCALE: 1/64”= 1’-0”

SCALE: 1/64”= 1’-0”

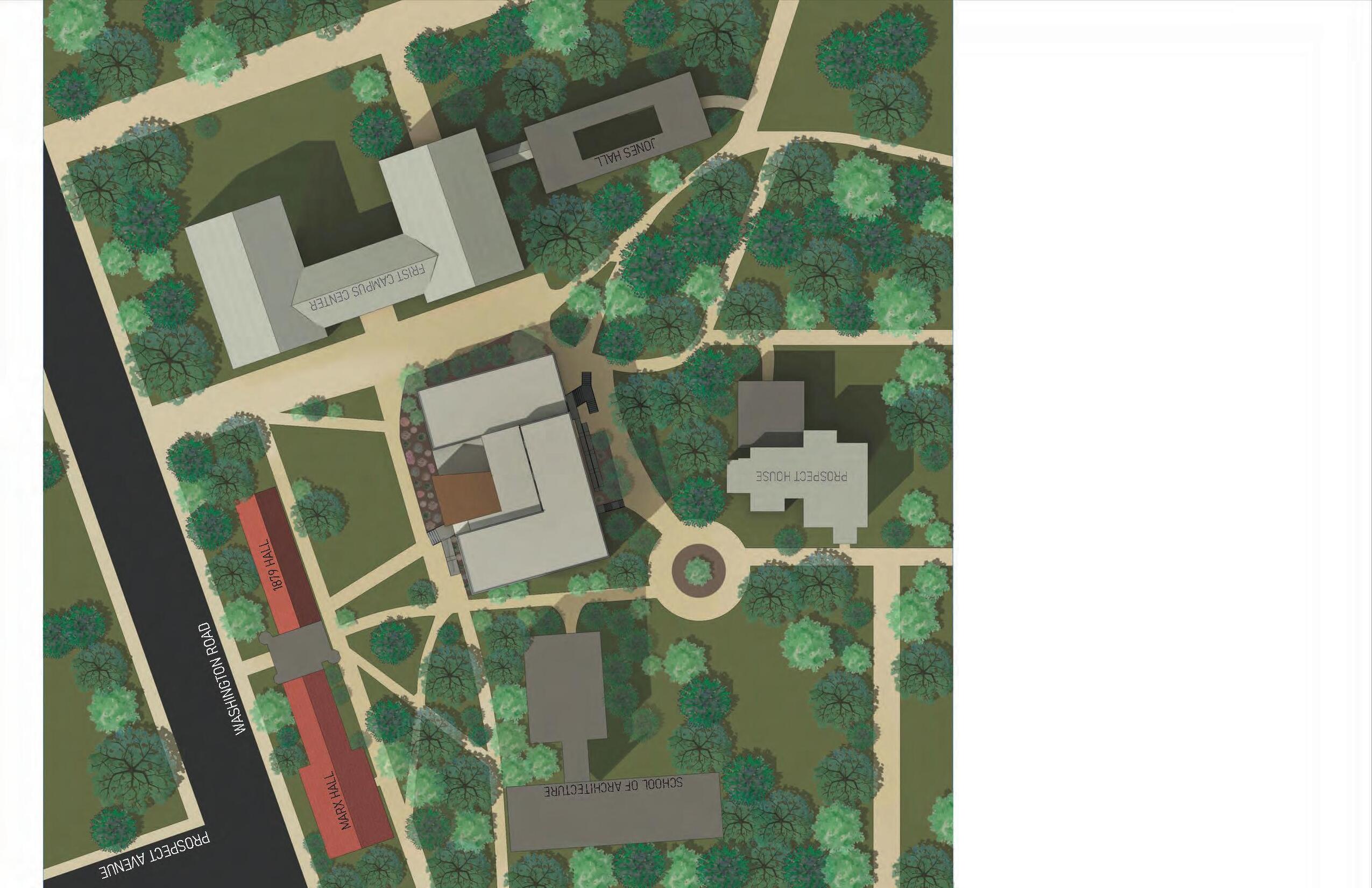

SITE CIRCULATION

DIRECT AND INDIRECT SUNLIGHT ATRIUM SUNLIGHT AND NATURAL VENTILATION

ZONING USE DESIGNATION

E2

ALLOWABLE HEIGHT

ALLOWABLE STORIES

BUILDING USE CLASSIFICATION: B (Business) with automatic sprinkler system and an emergency voice/alarm communication system

TOTAL NUMBER OF ALLOWABLE OCCUPANTS:

*Basement = 213 Persons

*First Floor = 514 Persons

*Second Floor = 500 Persons

*Third Floor = 145 Persons

*Total = 1372 Persons

***Original Woolworth Center Total = 1316 Persons

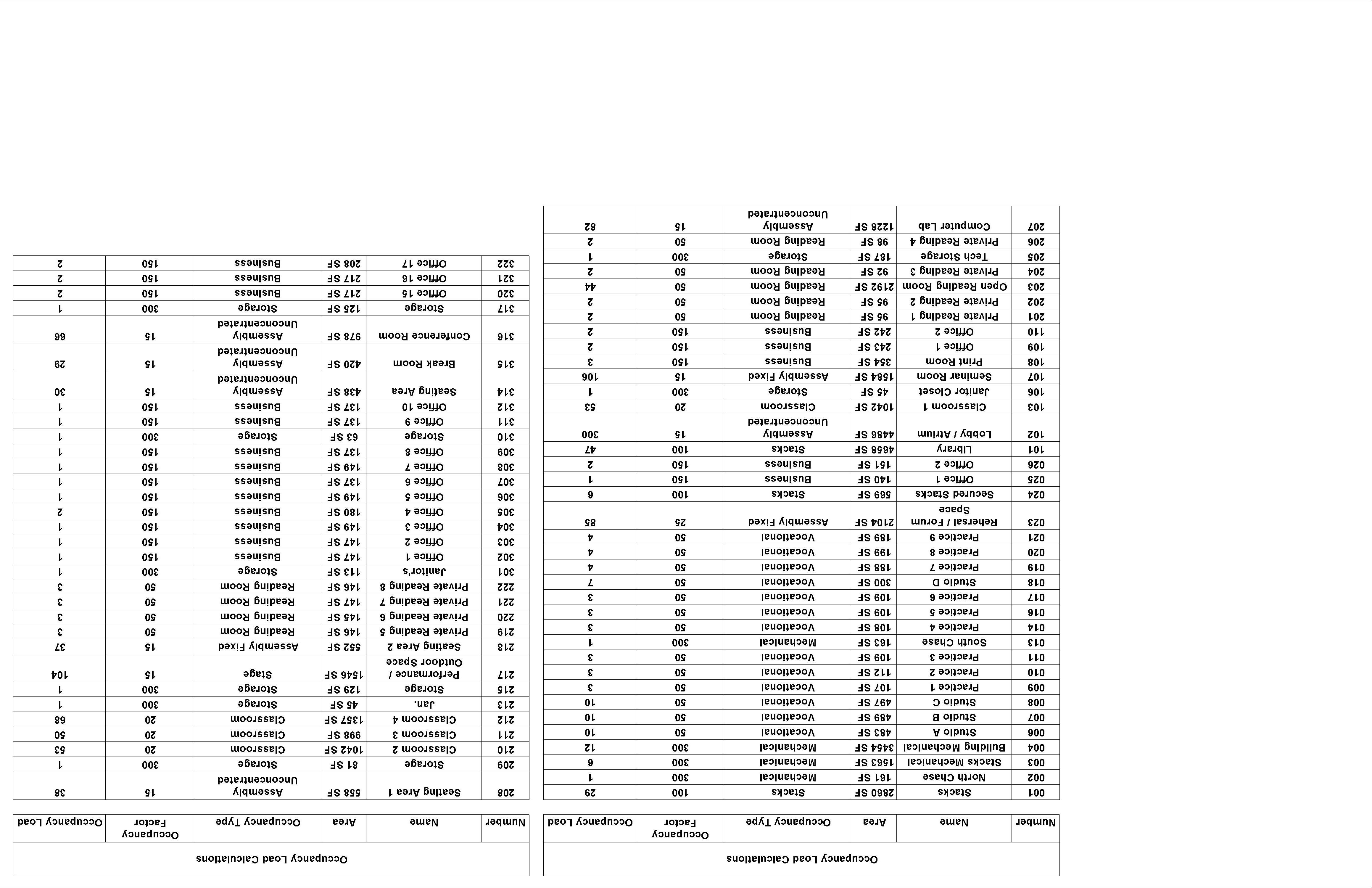

OCCUPANCY CALCULATIONS

ALLOWABLE OCCUPANCY CALCULATION BREAKDOWN: IBC 2018, TABLE 1004.5

*Stacks/Library/Secured Stacks - “Stacks” = 100 gross sqft per occupant

*Faculty/Student Offices/Print Room - “Business” = 150 gross sqft per occupant

*Mechanical/Vertical Chases - “Mechanical” = 300 gross sqft per occupant

*Practice Room/Studio Space = “Vocational” = 50 net sqft per occupant

*Rehersal Space/Seminar Room - “Assembly Fixed” = 1 fixed seat per occupant

*Lobby/Seating Area/Computer Lab/Break Room/Conference Room“Assembly Unconcentrated” = 15 net sqft per occupant

*Classrooms - “Classroom” = 20 net sqft per occupant

*Storage Room/Janitor Closet/Tech Storage - “Storage” = 300 gross sqft per occupant

*Open Reading Room/Private Reading Room - “Reading Room” = 50 net sqft per occupant

*Performance Space - “Stage” = 15 net sqft per occupant

*Restrooms/stairs/corridors - does not classify as occupiable spaces

MINIMUM NUMBER OF EXITS OR ACCESS TO EXITS PER STORY:

IBC 2018 table 1006.3.2

*Basement = 2 exit staircases

*First Floor = 3 exits

*Second Floor = 2 exit staircases

*Third Floor = 2 exit staircases

IBC 2018 section 1007.1.1, exception 2

*Distance between two exits, exit access doorways, or ramps, shall be placed no more than 1/3 of the maximum overall diagonal length apart from another.

*Overall diagonal length = 199’-10 1/2”

*Distance between means of egress = 199’-10 1/2“ x 0.333 = 65’-5 1/2”

EGRESS STAIR REQUIREMENTS:

IBC 2018 section 1005.3.1, exception 1

*Width = multiply the occupant load by the capacity factor of 0.2”

*Widths meeting requirements shall be dimensioned in plan

IBC 2018 section 1011.5.2

*Stair riser heights = 7” maximum and 4“ minimum

*Stair treads = 11” minimum in depth

*Per IBC 2018 section 1011.5.4, stair treads and risers should be uniform in shape and size

IBC 2018 section 1014.1

*Handrails = must be on both sides of stairway

* Handrail height = 34“ minimum, measured above stair tread nosings with a 38” maximum

IBC 2018 1009.3.3

*Area of refuge is not required in an automatic sprinkler system building per 2

EGRESS EXIT REQUIREMENTS:

IBC 2018 section 1005.3.2, exception 1

*Width = multiply the occupant load that will be utilizing the specific exit by 0.15”

*Widths of egress exits meeting requirements shall be dimensioned in plan

IBC 2018 section 1010.1.2

*Door swings = pivoted or side-hinged and must swing in the direction of egress travel

IBC 2018 table 1020.1

*Corridor fire resistance rating = not required for a building with sprinkler system

IBC 2018 section 1003.3

*Clearance = minimum headoom of 80” over any circulation paths for egress

ACCOMMODATIONS FOR ACCESSIBLE MEANS OF EGRESS:

IBC 2018 section 1009.1

*Required accessible means = no less than one accessible means of egress in a building

IBC 2018 section 1009.3

*Stairways = clear width of 48” minimum is not required for a building with sprinkler system, per exception 2

IBC 2018 section 1009.4

*Elevators = 4 or more stories above or below a level of exit discharge, a minimum of 1 accessible elevator must be provided and equipped with standby emergency power

MAXIMUM PATH OF TRAVEL:

IBC 2018 table 1017.2

Maximum travel distance for B (Business) occupancy = 300 feet

FIRST FLOOR EGRESS DOOR REQUIREMENTS AND CALCULATIONS

IBC 2018 section 1006.3.2, exception 1

*Number of doors required = 3

*Width - occupant load served by door as a means of egress x 0.15”

Door 1 = 36 occupants x 0.15” = 5.4“ ”

Door 2 = 57 occupants x 0.15” = 8.55”

Door 3 = 228 occupants x 0.15“ = 34.2” = 2’-10 2/3“

Door 4 = 539 occupants x 0.15” = 80.85” = 6’-8 7/8”

Door 5 = 509 occupants x 0.15” = 76.35” = 6’ 4 3/8”

BUILDING EGRESS STAIR REQUIREMENTS AND CALCULATIONS:

IBC 2018 section 1005.3.1, exception 1

*Width - floor’s occupancy load x 0.2 with an absolute minimum of 44“

*Third floor stair widths = 145 occupants x 0.2” = 29“ = absolute minimum 44”

*Second floor stair widths = 500 occupants x 0.2” = 7’-0“

*Basement floor widths = 213 occupants x 0.2” = 42.6” = absolute minimum 44”

INTERIOR CIRCULATION AND SLANTED WALLS

PROGRAM LAYOUT

SCALE: 1” = 20’-0”

SCALE: 1” = 20’-0”

SCALE: 3/32” = 1’-0”

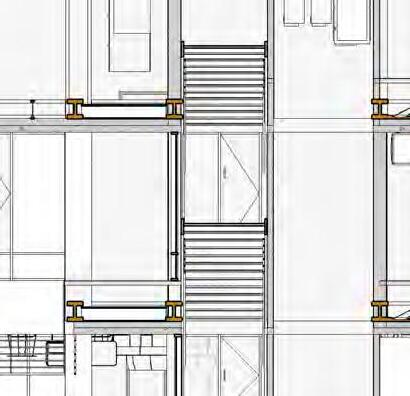

EAST ELEVATION

SCALE: 3/32” = 1’-0”

SOUTH ELEVATION

SCALE: 3/32” = 1’-0”

WEST ELEVATION

SCALE: 3/32” = 1’-0”

NORTH ELEVATION

SCALE: 3/32” = 1’-0”

SCALE: 1/32” = 1’-0”

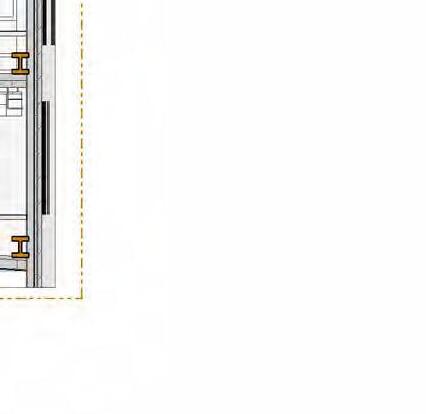

METAL FLASHING

SHEAR BOLTS

2X3 WOOD BLOCKING

WATER CONTROL MEMBRANCE

1/2" PLYWOOD SHEATHING

4" STANDARD BRICK

ADJUSTABLE BRICK WALL TIE

1" AIR SPACE

VAPOR BARRIER

2" RIGID INSULATION

6" STEEL STUD PLACED @ 24" O.C. WITH BATT INSULATION IN CAVITY

STEEL C - CHANNEL

5/8" GYPSUM WALL BOARD

DRIP EDGE

PARAPET ASSEMBLY

SCALE: 3/4”= 1’-0”

EDPM ROOF MEMBRANE

23/32" PLYWOOD SHEATHING

10" RIGID INSULATION SLOPED TOAWRDS ROOF DRAIN

METAL CHANNEL

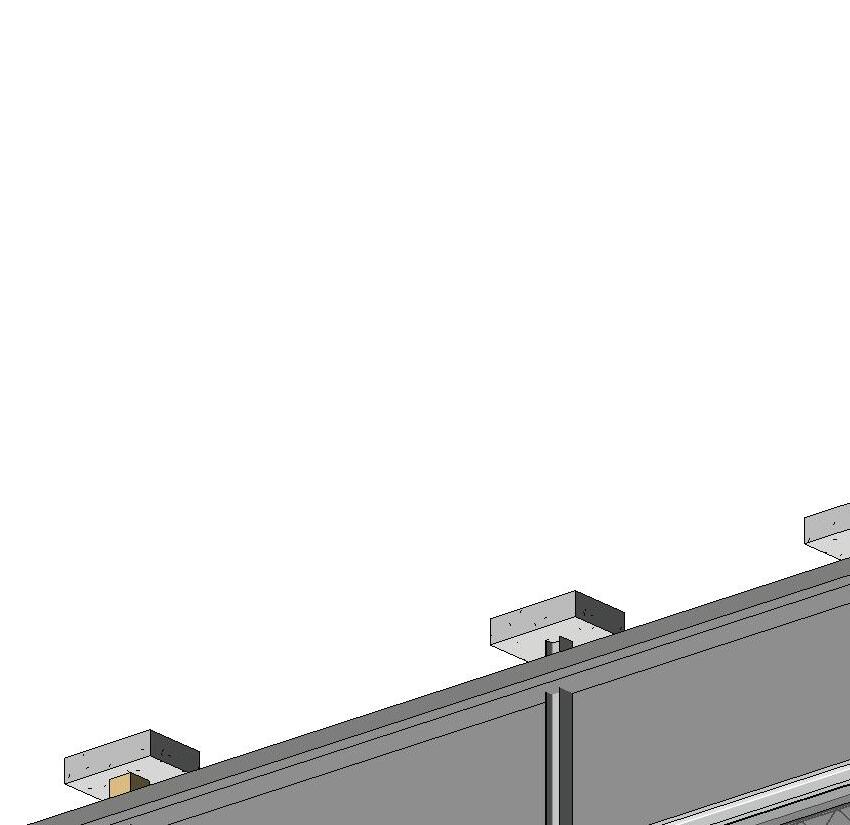

STEEL BEAM CONNECTION PLATE

W12X336 WIDE FLANGE BEAM

FLOOR ASSEMBLY

SCALE: 3/4”= 1’-0”

BRICK WALL SECTION

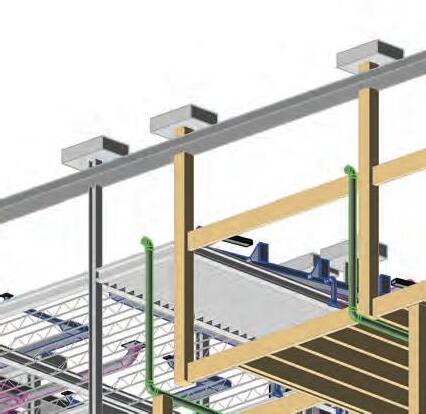

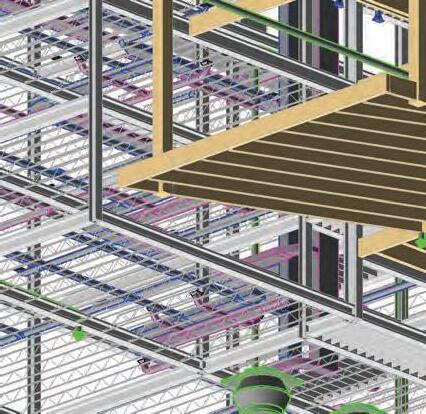

METAL SUSPENDED CEILING SUPPORT GRID

1/2" GYPSUM CEILING

WIDE FLANGE COLUMN WRAPPED IN GYPSUM

2 1/4" WOOD FLOOR FINISH

5/8" SUBFLOOR

6" CONCRETE FLOOR SLAB

3" METAL DECK

4" RIGID INSULATION

METAL CHANNEL

W12X336 WIDE FLANGE BEAM

STEEL BEAM CONNECTION PLATE

16K9 OPEN BAR JOIST

SUSPENDED CEILING ROD

METAL SUSPENDED CEILING SUPPORT GRID

1/2" GYPSUM CEILING

3'X8' FIXED WINDOW WITH ALUMINIUM FRAMING

3'X8' FIXED WINDOW WITH ALUMINIUM FRAMING

FLOOR ASSEMBLY DETAIL

3'X8' FIXED WINDOW WITH ALUMINIUM FRAMING

12" CONCRETE FOUNDATION WALL

6" METAL STUD @ 24" O.C. WITH BATT INSULATION IN CAVITY

5/8" GYPSUM WALL BOARD

2 1/4" WOOD FLOOR FINISH

5/8" PLYWOOD SUBFLOOR

6" CONCRETE FLOOR SLAB

VAPOR BARRIER

2" RIGID INSULATION

WALL SECTION

SCALE: 3/16”= 1’-0”

EDPM ROOF MEMBRANE

1" PROTECTION BOARD

8" RIGID INSULATION

2 1/4" WOOD DECK

6.75X24 GLUELAM BEAMWESTERN SPECIES

18X18 HEAVY TIMBER COLUMN

STEEL CONNECTION PLATE

8X26 GLUELAM BEAMWESTERN SPECIES

ROOF CONNECTION ASSEMBLY

SCALE: 3/4”= 1’-0”

18X18 HEAVY TIMBER COLUMN

2 1/4" WOOD FLOOR FINISH

5/8" PLYWOOD SUBFLOOR

6" CONCRETE FLOOR SLAB

3" METAL DECK

4" RIGID INSULATION

16K9 OPEN BAR JOIST SUSPENDED CEILING ROD

METAL SUSPENDED CEILING SUPPORT GRID

1/2" GYPSUM CEILING

ATRIUM FLOOR ASSEMBLY

SCALE: 3/4”= 1’-0”

ATRIUM WALL SECTION

2 1/4" WOOD DECK

6X8 WOOD BLOCKING

8X32 GLUELAM BEAMWESTERN SPECIES

ROOF CONNECTION DETAIL

OPERABLE WINDOW FOR ATRIUM VENTILATION

REFER TO ROOF DECK DETAIL FOR ASSEMBLY

(2) 5/8" GYPSUM WALL BOARD SHEATHING

NRC ACOUSTIC PADDING

2" ACOUSTIC PANELS

METAL ZIP CLIPS RESILIENT CHANNEL

4'x10' CURTAIN WALL PANELS WITH ALUMINIUM FRAMING

W12X336 WIDE FLANGE BEAM

ATRIUM FLOOR ASSEMBLY DETAIL

6" METAL STUD @ 24" O.C WITH SOUND BATT INSULATION IN CAVITY

ACOUSTIC SYSTEM ASSEMBLY REFER TO ATRIUM FLOOR ASSEMBLY DETAIL

2 1/4" WOOD FLOOR FINISH

5/8" PLYWOOD SUBFLOOR

6" CONCRETE FLOOR SLAB VAPOR BARRIER

2" RIGID INSULATION

WALL SECTION

SCALE: 3/16”= 1’-0”

EPDM ROOF MEMBRANE

PERFORMANCE ROOF ASSEMBLY

SCALE: 3/4”= 1’-0”

2" WOOD DECK

2X4 ANGLED SLEEPER

EDPM ROOF MEMBRANE

VAPOR BARRIER

6" RIGID INSULATION

2 1/4" WOOD SUBSTRATE

2X10 WOOD BEAM SUPPORT TO CANTILEVER

6.75X24 GLUELEAM BEAM SPACED @ 4' WITH RIGID AND BATT INSULATION IN CAVITY

6.75X24 GLUELEAM BEAMWESTERN SPECIES

5/8" GYPSUM CEILING

ROOF DECK ASSEMBLY

SCALE: 3/4”= 1’-0”

REHEARSAL WALL SECTION

VAPOR BARRIER

2 1/4" WOOD DECK

2X3 WOOD BLOCKING

EPDM ROOF MEMBRANE METAL FLASHING

STEEL BEAM CONNECTION PLATE

8X32 GLUELAM BEAMWESTERN SPECIES

ROOF DECK DETAIL

3'X2' GLASS CURTAIN WALL PANELS WITH ALUMINIUM FRAMING

3'X8' GLASS CURTAIN WALL PANELS WITH ALUMINIUM FRAMING

2" RIGID INSULATION

VAPOR BARRIER

RESILIENT CHANNEL

METAL Z CLIPS

1" X 4" STEEL EXTERIOR CLADDIND

6" METAL STUD SPACED @ 24" O.C. WITH BATT INSULATION IN CAVITY

ACOUSTIC SYSTEM ASSEMBLY REFER TO ATRIUM FLOOR ASSEMBLY DETAIL

12" CONCRETE FOUNDATION WALL

VAPOR BARRIER

2" RIGID INSULATION

WALL SECTION

SCALE: 3/16”= 1’-0”

Roof drain, 15” strainer with 8” drain

Roof drain, 15” strainer with 8” drain

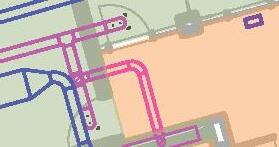

SCALE: 1”= 20’-0”

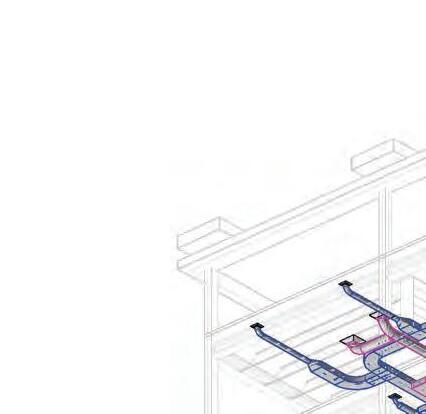

HVAC ZONE 1North section of building, 3 floors + basement

SUPPLIED BY: Vertical split system air handling unit, located in north vertical chase

HVAC ZONE 2Atrium + Rehersal, first floor + basement

SUPPLIED BY: DX Vertical packaged air handling unit, located in building mechanical room

HVAC ZONE 3South section of building, 2 floors + basement

SUPPLIED BY: Vertical split system air handling unit, located in south vertical chase

Supply air terminals: 12” x 12” diffuser with 8” diameter neck

Supply branches: 18” x 8”

Return branches: 24” x 8”

Supply branches: 8” diameter

Return branches: 12” diameter

Supply air terminals: 12” x 6” perforated supply grille, supplying atrium above

Air Handling Unit: Vertical split

Return air diffusers: 24” x 24” diffuser with 12” diameter neck

Return air diffusers: 12” x 12” diffuser with 12” diameter connection

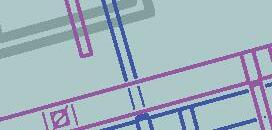

SCALE: 1”= 20’-0”

Supply trunk: 24” x 16”

Return trunk: 36” x 16”

Return air diffusers: 60” x 5 1/4” linear 3-slot hosted diffuser with plenum, returning rehersal space

Supply air terminals: 4’-0” x 6’-0” sidewall diffuser, supplying rehersal space

Air Handling Unit: DX Vertical packaged

Return trunk: 36” x 36”

Supply trunks: 24” x 24”

Return trunk: 36” x 16”

Supply trunk: 24” x 16”

Air Handling Unit: Vertical split system

NOTE: All supply components used throughout buildinng are specified on “Basement Mechanical” sheet

NOTE: All return components used throughout building are specified on “Basement Mechanical” sheet

NOTE: All supply components used throughout building are specified on “Basement Mechanical” sheet

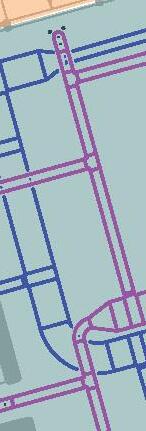

SCALE: 1”= 20’-0”

Supply

Return

NOTE: All return components used throughout building are specified on “Basement Mechanical” sheet HVAC

SCALE: 1”= 20’-0”

Rooftop centrifugal exhaust fan

Supply

Return

Rooftop centrifugal exhaust fan

NOTE: All supply components used throughout buildinng are specified on “Basement

Mechanical” sheet

NOTE: All return compoonents used throughout buildinng are specified on “Basement

Mechanical” sheet

NOTE: All supply components used throughout building are specified on “Basement

Mechanical” sheet

NOTE: All return components used throughout building are specified on “Basement

Mechanical” sheet

NOTE: All supply components used throughout building are specified on “Basement Mechanical” sheet

NOTE: All return components used throughout building are specified on “Basement Mechanical” sheet

Rooftop centrifugal exhaust fan

Supply

Return

Rooftop centrifugal exhaust fan

Return

Supply

NOTE: All supply components used throughout building are specified on “Basement

Mechanical” sheet

NOTE: All return components used throughout building are specified on “Basement

Mechanical” sheet

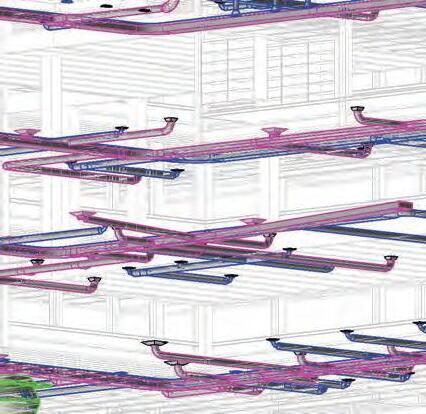

NOTE: All structural components used throughout building are specified on “Structural Axonometric” sheet

Rooftop centrifugal exhaust fan

Rooftop centrifugal exhaust fan

Roof drain, 15” strainer with 8” drain

Steel structural system

Rooftop centrifugal exhaust fan

Rooftop centrifugal exhaust fan

Roof drain, 15” strainer with 8” drain

Steel structural system