JANUARY 2023

NEWSLETTER MONTHLY

How many short line crossings does CDL maintain?

ANNOUNCEMENTS

NEW ONLINE HANDBOOK

We are excited to announce to you the new online employee handbook! Click on the link below to view the user friendly version. A copy of the handbook is still located in UKG.

CDLGROUPOFCOMPANIESHANDBOOK.COM

NEW WEBSITE

The moment we’ve all been waiting for.... Ladies and gentleman I present to you cdlelectric.com

UPCOMING EVENTS

FEBRUARY 10-11: BUSINESS EXPO

Located at Medowbrook Mall from 10:00am-7:00pm on February 10th. and February 11th from 10:00am-3:00pm. There will be a solar demo at 1:00 on Saturday.

WELCOME TO CDL!

Paul Alexander RR Signal Maintenance , Ezra Barlett Plumbing

Install / Fire , Austin Bash High Voltage , Evan Bowlby RR SignalMaintenance , Eric Branstine Wire Shop , Ryan Breyer RR Signal

Mainenance , Jeremy Cazares RR Signal Maintenance , Joshua Dickerson, Mike Droher RR Signal Maintenance , Jeremy Dutton, Carol Gee, Lane Gentry RR Signal Maintenance , Gabriell Jackson, Jake Kalsbeck RR Signal Maintenance , Michael Morgan RR Signal Maintenance , Chad Nieman RR Signal Maintenance , Jesse Pace Siren / Radios , Todd Pastrick RR Signal Maintenance , Sintia Salazar, Seth Westhoff Electrical.

STORY TIME

Click the google link below to share something that has happened to you while working with CDL! It will be anonymously shared in the following month’s newsletter. Submit a story that happened:

• On the road

• In the office

• In another state

• Something funny

• Photos

https://forms.gle/7jbRPvpAPL1ZqupG6

HVAC’S LATEST PROJECT

CDL’s HVAC team has been working with a company called AZZ manufacturing, installing heating and cooling lines in 12’x16’x12’ metal buildings. CDL is in charge of installing and maintaining the heating and cooling units in these metal houses. Brazing is a process where metals are melted together by melting a filler metal into the joint. Once all the lines are installed, the housing units are shipped to solar farms in Canada.

Trace Freeman has been with CDL for 4 years as a project manager and estimator. On this project, his job is to braze copper pipes together and manage his install team along with the overall project deadline. Considering he was given limited direction in regard to building blueprints, Trace crafted and designed his own.

There are 5 employees on this project including our lead HVAC technician, Riley Cunningham, and 4 apprentices. Our apprentices have gained a large amount of experience working with these buildings. Riley has worked at CDL for a little over two years, showing superior hard work and leadership since day one. Without all their dedication and determination, this project would not have gone as smoothly.

Along with a multitude of other companies, this project has been an astounding opportunity for CDL and our HVAC team. This is the largest job for AZZ the HVAC team has completed. “It has been a great learning experience for our younger crew and job to flex our skills and what CDL has to offer”

-Trace Freeman

-Trace Freeman

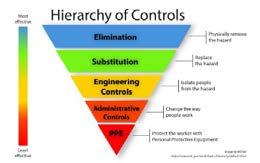

SAFETY CONTROLS

When you discover a potential hazard in your work area, the options for improving safety can seem endless. How do you know what to do first?

The five types of safety controls — also known as the hierarchy of hazard controls — help you answer that question. The hierarchy helps you systematically test solutions, from most to least effective.

According to the National Institute for Occupational Safety and Health (NIOSH), the five types of safety controls and their definitions are:

1. ELIMINATION: Physically remove the hazard

2. SUBSTITUTION: Replace the hazard

3. ENGINEERING CONTROLS: Isolate people from the hazard

4. ADMINISTRATIVE CONTROLS: Change the way people work

5. PERSONAL PROTECTIVE EQUIPMENT (PPE): Protect the worker

This method recognizes that safety controls are not all created equal. As helpful as administrative controls can be, eliminating or substituting the hazard is always a better option. What do these safety controls look like in practice? Let’s look at a few examples for common safety hazards.

EXAMPLE: FALL PROTECTION

Fall protection is the most frequently cited OSHA violation. The chances that you’ll need to look at different types of safety controls for this hazard are high. Falls can occur on both elevated and flat surfaces. Before you work your way through the hierarchy of safety controls, try to identify the root cause of the falling hazard.

1. ELIMINATION: Remove or fix a leaking faucet that’s creating a slipping hazard.

2. SUBSTITUTION: Replace narrow stairs with standard stairs that have sufficient space for the door to swing, or with scaffolding.

3. ENGINEERING CONTROLS: Install guard rails and safety nets to prevent accidental falls.

4. ADMINISTRATIVE CONTROLS: Train workers how to use ladders and man lifts safely.

5. PERSONAL PROTECTIVE EQUIPMENT: Provide safety harnesses and hard hats for crews working at heights.

Make sure you also follow OSHA regulations for fall protection. Rules and recommendations vary based on your industry.

EXAMPLE: HEARING CONSERVATION

With the right safety controls, noise-induced hearing loss is preventable. In fact, implementing safety controls is the third step of a hearing conservation program.

Examples of safety controls for hearing protection include:

1. ELIMINATION: Isolate the noisiest equipment in areas where employees are rarely present.

2. SUBSTITUTION: Replace a loud, old motor with a quieter motor in better condition.

3. ENGINEERING CONTROLS: Lubricate machines regularly to decrease the amount of noise.

4. ADMINISTRATIVE CONTROLS: Schedule shifts so that employees get a break from the noise for 15 minutes every hour.

5. PERSONAL PROTECTIVE EQUIPMENT: Provide earplugs or earmuffs with the correct noise reduction rating and train employees how to wear hearing protection. To find out if you need these safety controls, you must first measure employee noise exposure and conduct audiometric tests.

EXAMPLE: RESPIRATORY PROTECTION

Failure to follow respiratory protection standards causes hundreds of deaths and thousands of illnesses each year, according to OSHA. Respirators are a key part of these standards. But if you can use other safety controls, too, you’ll be better protected.

1. ELIMINATION: Remove asbestos ceiling tiles from old buildings.

2. SUBSTITUTION: Choose chemicals and materials that are less harmful.

3. ENGINEERING CONTROLS: Install a ventilation system in your facility.

4. ADMINISTRATIVE CONTROLS: Reduce the number of people present when a process will produce dust or a vapor.

5. PERSONAL PROTECTIVE EQUIPMENT: Have workers wear respirators to purify the air they breathe and filter out contaminants.

EXAMPLE: EYE PROTECTION

According to the Center for Disease Control and Protection (CDC), most eye injuries are caused by small particles striking or scraping the eye, such as dust and metal slivers. Other common causes of injury include objects penetrating the eyeball, burns from industrial chemicals and thermal burns from welding.

To prevent these types of injuries, you could implement safety controls such as these:

1. Elimination: Get rid of an old machine that’s ejecting hazardous particles.

2. Substitution: Use cleaning chemicals that are less harmful to the eye.

3. Engineering controls: Install plexiglass in front of areas where flying objects could strike someone’s eye.

4. Administrative controls: Train welders how to protect themselves from radiant energy.

5. Personal protective equipment: Provide safety glasses, goggles or face shields to protect workers’ faces.

Read OSHA’s eye protection standards for more information.

CHOOSE THE RIGHT TYPES OF SAFETY CONTROLS

Addressing hazards haphazardly isn’t effective. The hierarchy of hazard controls helps you choose the right action steps so you can provide a safe work environment. These examples are just the starting point. Once you understand the model, you can apply it to all kinds of safety situations.

OPEN JOB POSITIONS

Pittsburg, KS Technician Solutions Technician

Pittsburg, KS Traffic Signal Installer

Humboldt, KS Administrative Assistant

Joplin, MO Plumbing Service Technician

Parsons, KS Master/Journeyman Plumber

Pittsburg, KS Master HVAC Technician

Pittsburg, KS Journeyman Plumber

Pittsburg, KS Solar Install Manager

Pittsburg, KS Journeyman Electrician

Humbolt, KS Plumbing Service Technician

Humbolt, KS

Humbolt, KS

Pittsburg, KS

HVAC Installer

HVAC Lead Installer

HVAC Service Technician

Pittsburg, KS Boring Locator

Humbolt, KS Journeyman Plumber

Pittsburg, KS Emergency Services Technician

Pittsburg, KS Fire Protection Pipe Fitter

Kansas City, MO Journeyman Plumber

Joplin, MO Plumbing Install Technician

Joplin, MO Journeyman Electrician

Parsons, KS Plumbing Technician/ Helper

Clewiston, FL Master Electrician

Houston, TX Boring Operator

Pittsburg, KS Directional Boring Tracker/Operator

Pittsburg, KS Journeyman Lineman

Pittsburg, KS Traveling HVAC Technician

Pittsburg, KS

Master/Journeyman Plumber

Pittsburg, KS Plumbing Service Technician

Pittsburg, KS Railroad Signal Installer

Pittsburg, KS Traffic Signal Technician

There are railroad supervisor positions available, as well as open maintainer positions all over the country. There is a referral program in place if you refer someone to any position. Please contact hr@cdl-electric.com if you have questions about job positions or the referral program.