INNOVATIVE MATERIALS

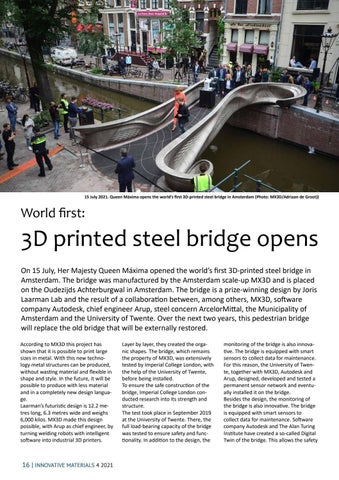

15 July 2021. Queen Máxima opens the world’s first 3D-printed steel bridge in Amsterdam (Photo: MX3D/Adriaan de Groot))

World first:

3D printed steel bridge opens On 15 July, Her Majesty Queen Máxima opened the world’s first 3D-printed steel bridge in Amsterdam. The bridge was manufactured by the Amsterdam scale-up MX3D and is placed on the Oudezijds Achterburgwal in Amsterdam. The bridge is a prize-winning design by Joris Laarman Lab and the result of a collaboration between, among others, MX3D, software company Autodesk, chief engineer Arup, steel concern ArcelorMittal, the Municipality of Amsterdam and the University of Twente. Over the next two years, this pedestrian bridge will replace the old bridge that will be externally restored. According to MX3D this project has shown that it is possible to print large sizes in metal. With this new technology metal structures can be produced, without wasting material and flexible in shape and style. In the future, it will be possible to produce with less material and in a completely new design language. Laarman’s futuristic design is 12.2 metres long, 6.3 metres wide and weighs 6,000 kilos. MX3D made this design possible, with Arup as chief engineer, by turning welding robots with intelligent software into industrial 3D printers.

16 | INNOVATIVE MATERIALS 4 2021

Layer by layer, they created the organic shapes. The bridge, which remains the property of MX3D, was extensively tested by Imperial College London, with the help of the University of Twente, before being installed. To ensure the safe construction of the bridge, Imperial College London conducted research into its strength and structure. The test took place in September 2019 at the University of Twente. There, the full load-bearing capacity of the bridge was tested to ensure safety and functionality. In addition to the design, the

monitoring of the bridge is also innovative. The bridge is equipped with smart sensors to collect data for maintenance. For this reason, the University of Twente, together with MX3D, Autodesk and Arup, designed, developed and tested a permanent sensor network and eventually installed it on the bridge. Besides the design, the monitoring of the bridge is also innovative. The bridge is equipped with smart sensors to collect data for maintenance. Software company Autodesk and The Alan Turing Institute have created a so-called Digital Twin of the bridge. This allows the safety