6 minute read

Origami Glass: complex glass geometric structures

from IM20214EN

Advertisement

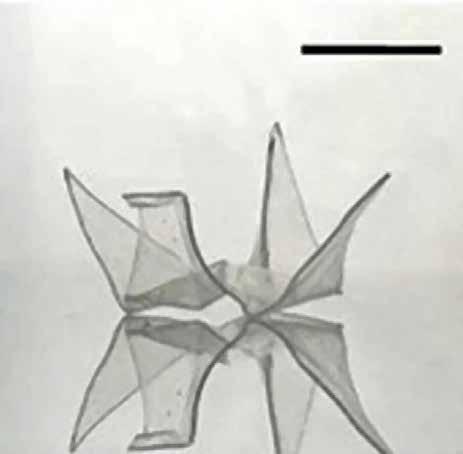

Illustration based on picture from Nature Communications

Complex glass geometric structures Origami glass

Glass is a great material in many ways, but the detailed design of glass products is not easy. This has to do with the brittle properties of the material and the high temperatures at which the (conventional) molding processes work. In recent years, research into the use of silica-polymer composites as a prepolymer for glass production has shown that this technique offers perspectives for making complex geometric shape structures of glass, but this technique still has drawbacks. The same goes for 3D printing glass. Researchers from China’s Zhejiang University have now developed a method that makes it possible to create three-dimensional transparent glass using origami techniques. The question is: ‘how to fold glass?’

Glass is indispensable in many applications, from tableware to architectural constructions and telephones to works of art. In fact, glass is indispensable in many applications because of typical properties such as optical transparency, wear resistance and thermal and chemical stability. Still, processing glass remains difficult, especially when it comes to complex geometries. Processing options are often limited compared to metal and polymers. This is due to the brittle nature of the material and the need that is often present to achieve full transparency.

3D printing

Conventional glass shaping processes operate under challenging conditions such as high temperature or chemical etching. Although sol-gel techniques make it possible to produce glass shapes under milder conditions, the geometric complexity is limited by the casting technique. Another solution could be to use silicapolymer composites as a precursor for glass making, which opens the way to low temperature casting. The material can then be machined and sintered into the final 3D glass shape. Finally - without the use of casting - such precursor composites (prepolymers) glass also can be be shaped with a 3D printer. Universities and research institutes all over the world are looking for new processes when it comes to 3D printing of glass and although interesting results have been achieved, apparently no breakthrough has been forced yet (see box on following pages).

Origami

Researchers at Zhejiang University in Hangzhou, China, have now come up with something different. They developed a method that makes it possible to make three-dimensional transparent glass using origami techniques.

Origami is the art of folding, once invented in China, but perfected over centuries in Japan. The trick of origami is to convert a flat sheet - originally paper - into a three-dimensional geometry. Modern origami techniques can be used to create extremely complex shapes, which is exactly what the Zhejiang researchers had in mind. Glass cannot be folded because of its brittle properties. The researchers now say they have found a solution for exactly that problem. It turns out that it is possible to compose the prepolymer in such a way that mechanisms are

Left: a Schematic illustration of the fabrication process. b Two mechanisms for permanent deformation via plasticity. c Dynamic polymer ester network with dangling hydroxyl groups. d Photographic image of a 3D transparent glass feather. Scale bar: 1 cm. e Demonstration of the high thermal resistance at 600 °C. Scale bar: 1 cm (Illustration from Nature Communications)

3D printing glass

All over the world, research is being done into the design of glass by 3D printing (Additive Manufacturig, AM). Two commonly used AM methods are in the spotlight: Selective Laser Sintering (SLS) and Fused Filament Fabrication (FFF, also known as Fused Filament Fabrication). In SLS, a powder is melted/sintered layer after layer into a solid product using a laser. In the case of FFF, a die extruder applies molten material layer by layer. Because the liquid material solidifies after each layer has been applied, the desired shape can thus be built up. The problem with both techniques is that they depend on increasing the temperature to just below or above the melting point of the starting material. Glass requires temperatures of over a thousand degrees Celsius.

The first studies date from around 2015. In 2015, the Israeli company Micron3DP developed a system for 3D printing molten glass, specifically soda lime and borosilicate. That same year, the Mediated Matter group of the Massachusetts Institute of Technology and MIT Glass Lab introduced its G3DP (Glass 3D Printing) platform, a 3D printer specifically designed for glass processing. In 2017, MIT presented 3D-printed glass columns made with the G3DP2 platform during Mila Design Week: a further developed G3DP printer, which according to MIT is suitable for industrial production. (Innovative Materials 2019 volume 1).

Shortly before that, researchers from the Karlsruhe Institute of Technology (KIT)

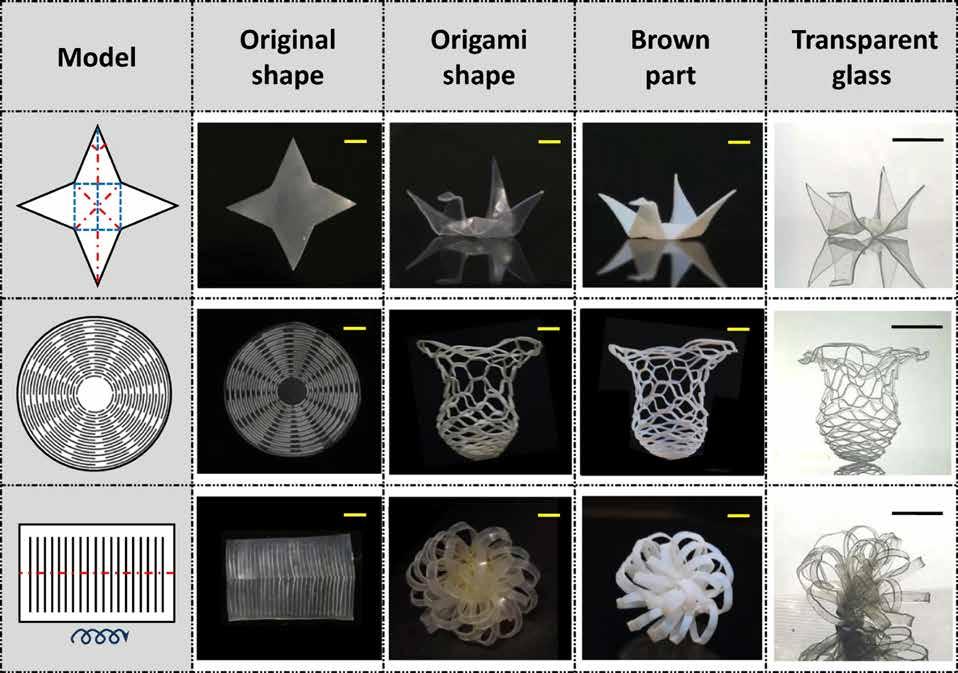

introduced into the material, as a result of which the material can actually be folded initially. They made a composite sheet by curing a liquid prepolymer filled with silica nanoparticles. The researchers then folded the material into various geometric figures using manual origami techniques. By subjecting the material to a pyrolysis and sintering process, it is converted into transparent three-dimensional glass. In this way they managed to create more or less complex shapes, including a crane, vase and flower. Although they folded the composite sheets by hand in this study, the researchers expect that the process could be automated and ultimately suitable for large-scale production.

The article ‘Transparent origami glass‘ was published in Nature Communications on 12 July 2021. It is online>

Example of the folding process. The black lines, red dashed lines, and blue dashed lines represent cutting, mountain folding, and valley folding, respectively. All scale bars are 1 cm. Credit: Xu et al. (Illustration from Nature Communications)

presented a completely new 3D printing method for glass. The method made use of stereolithography, in which a laser beam was applied layer by layer to the surface of a liquid material (usually a polymer, but in the case of KIT a mixture of a liquid polymer and nanoparticles of extremely pure quartz glass). Hardening occurs where the laser beam hits the liquid. The material which remained liquid, was then washed in a solvent bath, leaving only the desired cured structure. The polymer still enclosed in this glass structure was then fired by heating. The research was published in Nature (April 2017) under the title ‘Three-dimensio-

nal Printing of Transparent Fused Silica Glass.’It’s online>

Earlier this year, the OSA Optical Society reported the development of yet another method called ‘two-photon polymerization.’ The process was developed by researchers at the Fresnel Institute and the École Centrale de Marseille in France, the École Centrale and the University of Lorraine. Their results were published in Optics Letters showing the use of two-photon polymerization to 3D printing glass. The method is based on so-called multiphoton polymerization, which ensures that the polymerization takes place only and exactly at the laser focal point. By sending the laser - or rather the laser focal point - through a medium through a certain pattern, an object can be created. The researchers used a mixture with a photochemical initiator, a resin and a high concentration of silica nanoparticles as a medium. The high viscosity of this mixture makes it possible to form a 3D part with a double laser beam. The team managed to create several glass mini objects, including an Eiffel Tower and a bicycle.

More at OSA>