21 minute read

A new liquid crystal ink for 3D printing

from IM20214EN

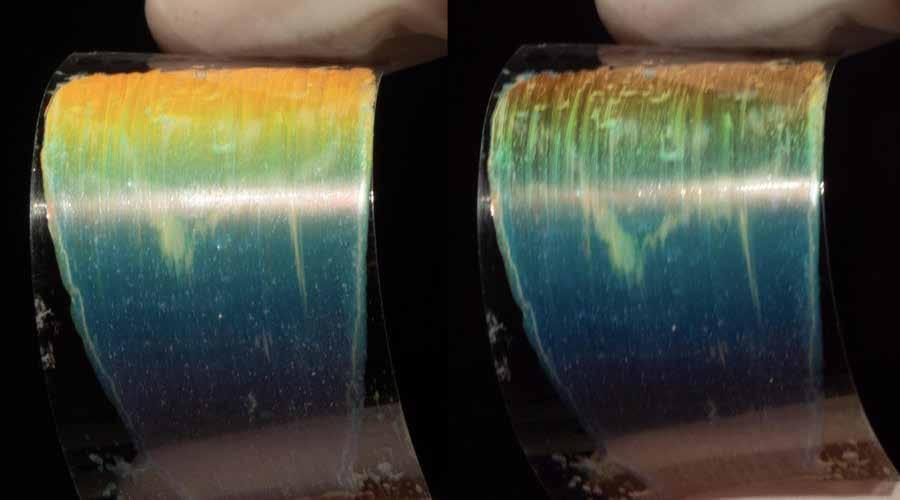

Cholesteric liquid crystals, a man-made material with properties between liquids and solid crystals, can mimic the colours of butterfly wings. Liquid crystals are used in televisions and smartphones, but future applications for healthcare sensors or decorative lighting are difficult as the materials can’t be used in advanced, rapid production methods like 3D printing. The materials are not viscous enough to make stable, solid structures, and it’s difficult to align the molecules to produce specific colors. TU/e researchers have solved these issues by developing a new light-reflective liquid crystal ink that can be used with existing 3D printing techniques. The new research has been published in the journal Advanced Materials.

In nature, iridescent materials, which exhibit a colour change when viewed from different angles, can be found in butterfly wings and in nacre (or mother of pearl) in the inner shell of mollusks. A man-made version of these natural materials is cholesteric liquid crystal, which has already been used as ‘smart’ materials in light reflectors, switchable windows, and tun-able solar energy collectors. For healthcare applications in soft wearable sensors or decorative lighting, cholesteric liquid crystals are ideally suited. Until now though, an easy way of producing these materials and making devices from these materials has been lacking.

Advertisement

Researchers from the department of Chemical Engineering and Chemistry at TU/e in collaboration with TNO, DSM, Brightlands Materials Center (in the DynAM consortium), and SABIC have created a nature-inspired liquid crystal elastomer-based ink that can be 3D printed on a surface via Direct-Ink-Writing (DIW). Lead author for the study is PhD candidate Jeroen Sol, with Albert Schenning and Michael Debije from the Stimuli-responsive Functional Materials and Devices (SFD) group heading the research project. DIW is an extrusion-based 3D printing approach where an ink is dispensed from a small nozzle onto a surface on a layerby-layer basis. Current cholesteric liquid crystal inks can-not be printed with DIW, so the scientists created a liquid crystal

ink compatible with DIW. The new liquid crystal ink has several key properties. First, the light reflective properties of the ink rely on the precise helical alignment of molecules throughout the material which requires fine tuning of the printing process. Second, the molecules in the ink can self-assemble into such structures that display colours similar to natural iridescent materials, like those in butterfly wings. Third, the new ink has greater viscosity than previous inks, which makes it suitable for DIW printing. Finally, the new ink is novel, easy to make, easy to process, and based on materials previously developed by the SFD research group at TU/e for light-reflective coatings, which help make it suitable for 3D printing. The researchers also proved to be able to control molecular alignment at the nanoscale extremely accurately by varying the printing speed. This gave them more control over the appearance and light-reflecting properties of the material. Given that the new liquid crystal ink can be printed with DIW, it could be used in future printing procedures for personalized medical devices such as thin wearable biosensors that interact visually and colourfully with the wearer.

Text: TU Eindhoven> The paper ‘Anisotropic iridescence and polarization patterns in a direct ink written chiral pho-tonic polymer’, Jeroen Sol, Lanti Yang, Nadia Grossiord, Albert Schenning, and Michael Debije, Advanced Materials, (2021) is online>

Knowledge and networking event

Materials+Eurofinish+Surface 2021

The central meeting place in the Benelux with all the aspects for a good and durable final product

15 and 16 September 2021 09.30 a.m. – 5.00 p.m. Brabanthallen, ‘s-Hertogenbosch (NL)

Free entrance Register directly via www.materials-eurofinish-surface.com

More info:

www.materials-eurofinish-surface.com

This you can discover:

• Inspiring exhibition floor with over 100 exhibitors • Focus on materials, analysis, bonding and surface techniques • Extensive and high-quality conference program • International Meet & Match • Demonstrations and innovations • VIP Meeting Areas • Presentation of the Borghardt Award • Simultaneously with Kunststoffenbeurs • Simultaneously with Nederlandse Metaaldagen

Organization:

Converting tamarind shells into an supercapacitors

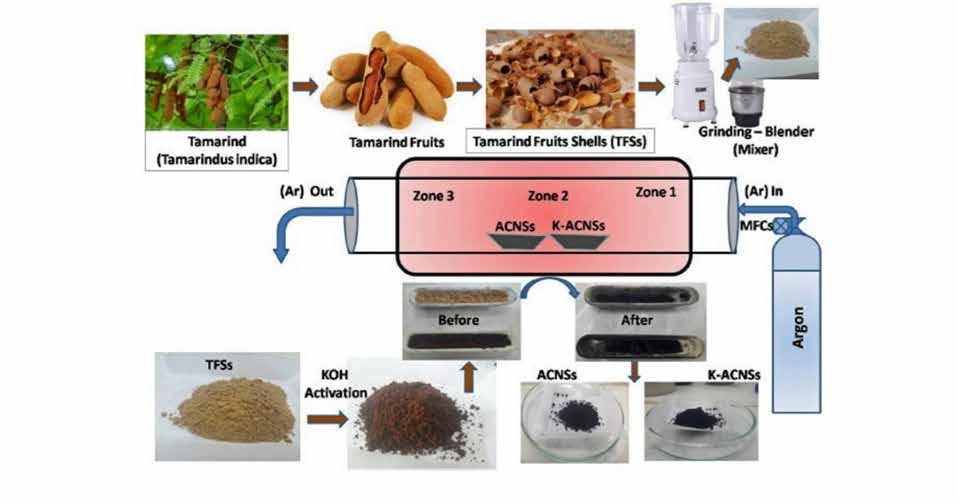

Tamarind is a tropical fruit, the pulp of which is used in the food industry. The shells are thrown away and end up in landfills in large quantities. However, a team of international scientists led by Nanyang Technological University, Singapore (NTU Singapore) has found a way to deal with the waste problem. By processing the tamarind shells which are rich in carbon, the scientists converted the waste material into carbon nanosheets, which are a key component of supercapacitors - energy storage devices that are used in automobiles, buses, electric vehicles, trains, and elevators. The team, made up of researchers from NTU Singapore, the Western Norway University of Applied Sciences in Norway, and Alagappa University in India, believes that these nanosheets, when scaled up, could be an eco-friendly alternative to their industrially prod uced counterparts, and cut down on waste at the same time. To manufacture the carbon nanosheets, the researchers first washed tamarind fruit shells and dried them at 100°C for around six hours, before grinding them into powder. The scientists then baked the powder in a furnace for 150 minutes at 700-900 °C in the absence of oxygen to convert them into ultrathin sheets of carbon known as nanosheets.

The tamarind shell-derived nanosheets also showed good thermal stability and electric conductivity, making them promising options for energy storage.

A common material used to produce carbon nanosheets are industrial hemp fibres. However, they require to be heated at over 180 °C for 24 hours - four times longer than that of tamarind shells, and at a higher temperature. This is before the hemp is further subjected to intense heat to convert them into carbon nanosheets. The researchers hope to explore larger scale production of the carbon nanosheets with agricultural partners. They are also working on reducing the energy needed for the production process, making it more environmentally friendly, and are seeking to improve the electrochemical properties of the nanosheets.

More at NTU>

The paper titled ‘Cleaner production of tamarind fruit shell into bio-mass derived porous 3D-activated carbon nanosheets by CVD technique for supercapacitor applications’ published in Chemosphere, 2 June, 2021, 131033. Its online>

A representation of the experimental process, as well as photographs of the tamarind shell at every step (Source: NTU)

From left to right, foam materials consisting of whey, polyurethane, polystyrene, polyethylene and polystyrene. The top row represents unexposed materials and the bottom row represents the materials exposed to 150 °C air for one month

Milk protein plastic foam

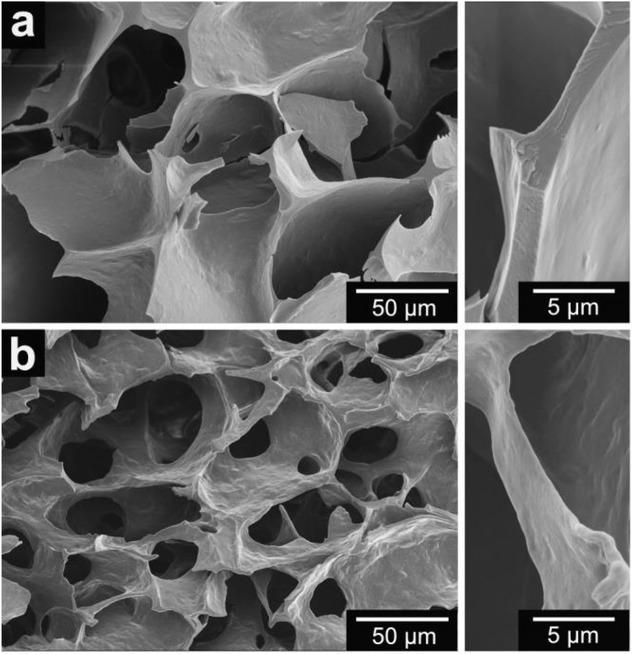

Researchers at KTH Royal Institute of Technology developed a new high-performance plastic foam from whey proteins that can withstand extreme heat better than many common petroleum based thermoplastics. The new material is based on protein nanofibrils, (PNFs), which are produced from hydrolyzed whey proteins - a product from cheese-processing - under specific temperature and pH conditions.

In tests the foams improved with aging which polymerized the protein, creating new covalent bonds that stabilized the foams. After one month of exposure to a temperature of 150 °C, the material became stiffer, tougher and stronger. Despite proteins are often water-soluble, the material proved to be water-resistant after the aging process. The foam also resisted even more aggressive substances that normally decompose or dissolve proteins. The crosslinking mechanism also made the foam unaffected by diesel fuel or hot oil. The material also showed better fire resistance than commonly used polyurethane thermoset.

Potential applications include providing support for catalytic metals that operate at higher temperatures, such as platinum catalysts for automobiles. The material could conceivably work as a fuel filter, too. Other possibilities are to use it as packaging foam and in applications for sound and thermal insulation where higher temperatures may occur and where there is a risk of an aggressive environment.

The results were reported earlier this year in Advanced Sustainable Systems, titled ‘High-Temperature and Chemically Resistant Foams from Sustainable Nanostructured Protein’. It is online>

SEM images of aged a) PNF-40, b) PNF-40-gly-33 foams (Picture from article)

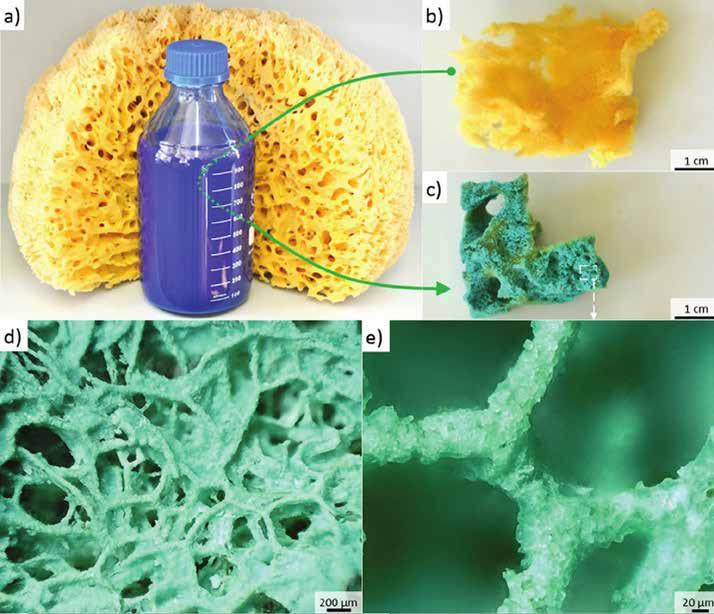

New material from a bath sponge

Prof. Hermann Ehrlich looks at a piece of the new material (Photo: TU Bergakademie Freiberg/C. Mokry) More at TU Freiberg>

The team led by Prof. Hermann Ehrlich published the results in a current publication in the journal Advanced Materials titled ´Extreme Biomimetics: Designing of the First Nanostructured 3D Spongin-Atacamite Composite and its Application´. Its online>

Researchers at TU Bergakademie Freiberg developed an innovative material from a cultured marine sponge. When the fibers of the sponge react with a copper-containing ammonia solution, the mineral atacamite is formed. This mineral, which occurs only very rarely in nature, attaches itself so strongly to the sponge fibers that a robust material is created that has catalytic and antibacterial properties and could therefore potentially be used as a bio-based industrial filter. The pieces of sponge were placed in an alkaline, copper-containing ammonia solution (pH 9) that simulates a copper bath from the manufacture of circuit boards for electronic components. About 12 hours later the sponge has turned blue - when dry it is stronger than before, but still very light.

Because of the alkaline circumstances the fibers of the spongin will open and the copper contained in the ammonia solution reacts immediately with the organic components of the spongin, especially with the amino acid residues, to form the mineral atacamite. Nanometer-sized crystals grow along with the spongin fiber and stabilize the framework and ensure that the sponge is retained in its unique micro-architecture. In an acidic solution, the reaction runs backwards: the sponge is back returns to its original state and can be processed again for further applications. The newly developed material can therefore be recycled again and again. The three-dimensional and porous material is inherently a filter. Coupled with the properties of atacamite, there is a wide range of potential for using the new material as an alternative to synthetic filters. According to the researchers, the experiment demonstrates for the first time that the composite material made from marine bath sponges can in principle be used in the development of sensors, catalysts, and antibacterial filter systems.

Biological material meets alkaline, toxic Cu-based waste. a–d) A spongin-based porous microfibrous scaffold of Hippospongia communis bath sponge with the original 3D architecture, when placed in a model ammoniacal CuCl2 solution (a,b), is covered with a dense layer of green crystalline material (c,d), which has been identified in this study as atacamite. e) The crystalline phase remains firmly attached to the spongin fibers even after 72 hours of ultrasonic treatment at 37 °C (Illustration from the article)

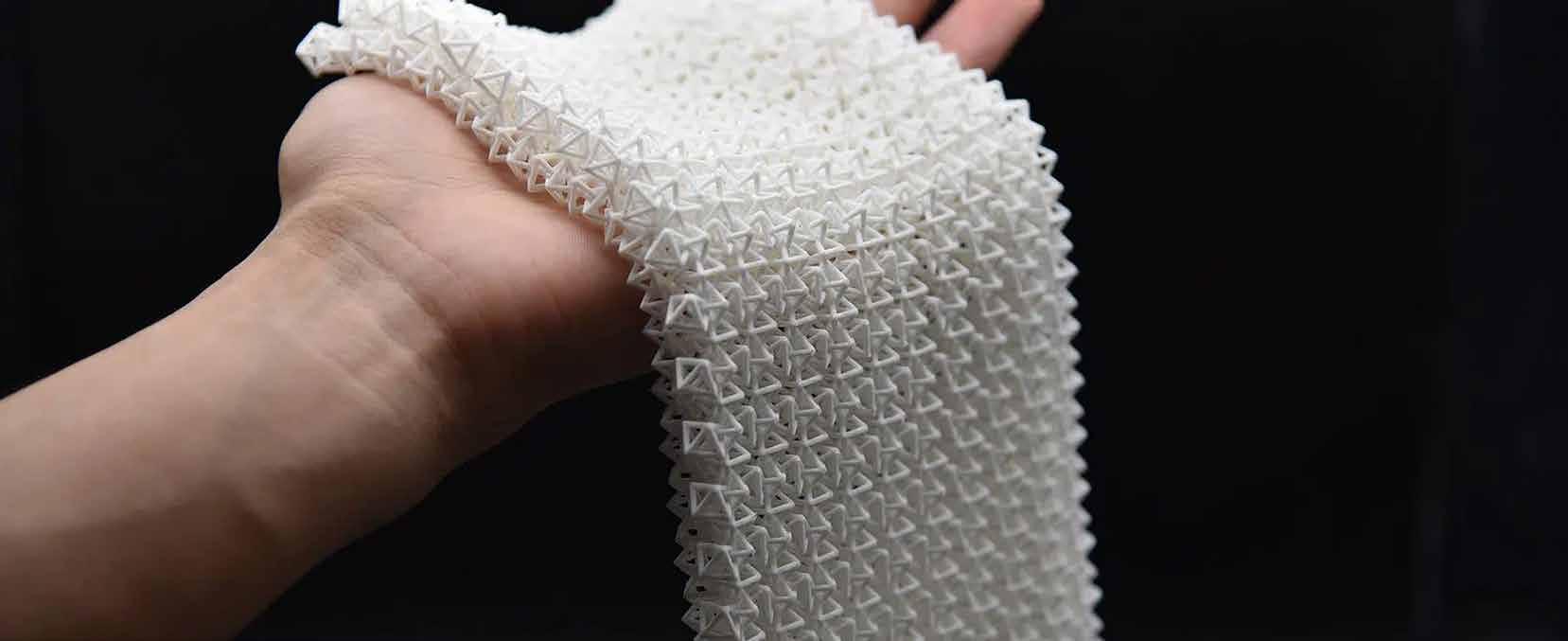

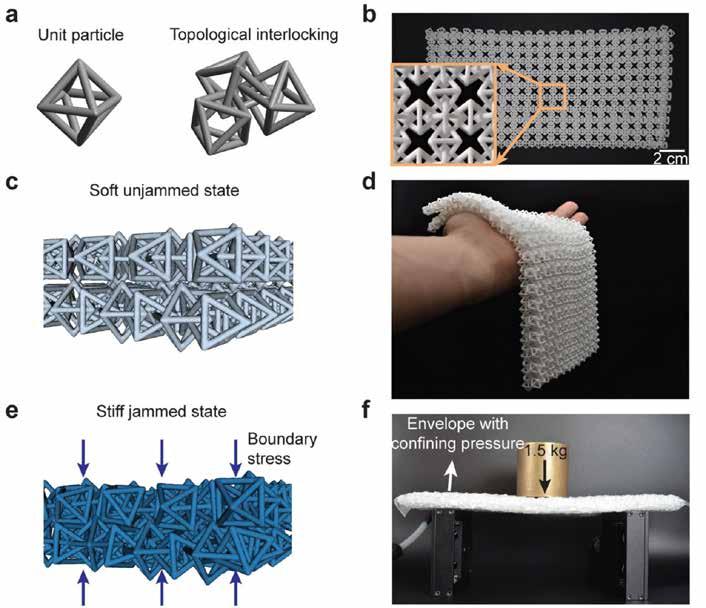

Fabric that can stiffen on demand

Scientists from NTU Singapore and the California Institute of Technology (Caltech), United States, have developed a new type of ‘chain mail’ fabric that is flexible like cloth but can stiffen on demand. This work was published in Nature on August 11, titled ‘Structured fabrics with tunable mechanical properties.’ According to Chiara Daraio, Caltech’s G. Bradford Jones Professor of Mechanical Engineering and Applied Physics and corresponding author of a study, the scientists wanted to create a fabric that goes from soft and foldable to rigid and load-bearing in a controllable way. To explore what materials would work best, Daraio, together with former Caltech postdoctoral researcher Yifan Wang and former Caltech graduate student Liuchi Li, designed a number of configurations of linked particles, from linking rings to linking cubes to linking octahedrons (which resemble two pyramids connected at the base). The materials were 3D printed out of polymers and even metals, with help from Douglas Hofmann, principal scientist at JPL, which Caltech manages for NASA. These configurations were then simulated in a computer.

This eventually led to a lightweight textile-like material, 3D-printed from nylon plastic polymers which comprises hollow octahedrons (a shape with eight equal triangular faces) that interlock with each other. When encased in a plastic envelope and vacuum-packed, it becomes 25 times more rigid and can hold up over 50 times its own weight. According to NTU Singapore This next-generation fabric paves the way for lightweight armour that can harden to protect a user against an impact, protective gear for athletes, and exoskeletons that can help the elderly to stand, walk and carry objects. Moving forward, the team is looking to improve the material and fabric performance of their chain mail and to explore more methods of stiffening it, such as through magnetism, electricity or temperature.

A - diagram to show how the eight-sided triangles interlock with each other B - a 3D printed chain mail C - how the chain mail looks like when soft and non-compressed D - photo of two layers of chain mail put together when soft E - 3D models of how the chain mail is jammed together when compressed in a plastic envelop F - the two layers of chain mail enclosed and vacuum-packed in a plastic envelope, bearing a load that is 50 times its weight Caltech>

NTU>

Video

Enterprise Europe Network (EEN) supports companies with international ambitions

The Enterprise Europe Network (EEN) is an initiative of the European Commission that supports entrepreneurs in seeking partners to innovate and do business abroad. The Network is active in more than 60 countries worldwide. It brings together 3,000 experts from more than 600 member organisations – all renowned for their excellence in business support.

Database

Every company can participate by adjusting its profile to the database. This company will be brought to the attention in the country in which it wants to become active. At the same time it is possible to search for partners. EEN advisers actively assist in compiling the profile, which is drawn up in a certain format. The EEN websites also contain foreign companies that are looking for Dutch companies and organizations for commercial or technological cooperation. The EEN advisers support the search for a cooperation partner by actively deploying contacts within the network. In addition, Company Missions and Match Making Events are regularly organized. All these services are free of charge.

There are five types of profiles:

• Business Offer: the company offers a product

• Business Request: the company is looking for a product

• Technology Offer: the company offers a technology

• Technology Request: the company is looking for a technology

• Research & Development Request: the organization seeks cooperation for research

When a company has both a Business Offer and a Business Request (or another combination), two (or even more if applicable) profiles are created. The profile includes the most essential information about the nature of the supply or demand, the ‘type of partner’ that is intended and the expected cooperation structure.

Get in touch with your local network contact point by selecting the country and city closest to where your business is based. They can help you with advice, support and opportunities for international partnerships.

For sustainable building and the creative industry, contact ir. drs. Hans Kamphuis: T: +31 (0) 88 042 1124 M: 06 25 70 82 76 E: hans.kamphuis@rvo.nl

For Materials contact Nils Haarmans: T: +31 (0) 88 062 5843 M: 06 21 83 94 57

More information websites can be found at the Europe Network websites:

Video: How Enterprise Europe Network works

www.enterpriseeuropenetwork.nl

http://een.ec.europa.eu

The Enterprise Europe Network Materials Database: Request for partnership: August 2021.

Intrested? contact hans.kamphuis@rvo.nl>

A French company in the childcare industry is looking for eco-friendly materials (recycled and bio-based materials) in plastics and packaging industries.

A Greek medical technology start-up has invented an innovative splint for arm fractures.

The company researches solutions for future development to include in their range of products for babies. The company wants to establish technical cooperation agreement or manufacturing agreement.

Swiss SME is looking for a board manufacturer that produces or a research & development partner that develops an open-pore, air-permeable, flame retardant, lightweight board.

The board size is approximately 3.0 m x 1.2 m. The product can be redeveloped or delivered as already existing board material. It will be used in the building industry. The SME seeks a partner for a manufacturing or a technical cooperation agreement possibly including development.

A Spanish technology research centre specialised in plastics, composites, polymer blends, and polymer materials for packaging is looking for novel commercial biobased and biodegradable polymers.

The technology centre is looking for bio-based alternatives to adapt to current expanded polystyrene packaging under commercial agreement with technical assistance. If they do not find the commercial solution they consider a future development under research or technical cooperation agreement.

The splint is made of PLA (polylactic acid). TIn order to expand their production, the startup is looking for companies with ISO 13485 certification who provide PLA laser cutting services. The type of partnership considered will be a manufacturing agreement.

Matchmaking event at the Kunststoffenbeurs 15 & 16 September in Den Bosch:

Get in touch with potential new partners! Meet interesting plastics, materials and surface treatment experts, bonding experts, researchers, developers, engineers, SMEs, OEMs, suppliers and intermediaries. In the B2B matchmaking sessions you have 30 minute bilateral meetings with a variety of participants of your choice that are focused on plastics, other materials and coatings. The international B2B matchmaking will be a tailor-made hybrid activity, it will be possible to have both on-site meetings and /or virtual meetings. The Kunststoffenbeurs+Materials+ Eurofinish+Surface Matchmaking 2021 is organised by the Enterprise Europe Network.

More at: https://kunststoffenbeurs-materials-eurofinish-surface-21.b2match.io/

De NVDO Sectie Techniek organiseert in samenwerking met de Bond voor Materialenkennis op dinsdag 21 september bij Stork Thermeq in Hengelo;

In 2050 moet Nederland volledig circulair zijn. Het gebruik van biobased materialen zou o.a. kunnen bijdragen aan het verlagen van de CO2, maar waar moet je rekening mee houden wanneer je biobased materialen gebruikt? Is er een groot verschil met ‘normale’ materialen met betrekking tot het gebruik, de veroudering en het onderhoud?

Programma (13.00-16.30 uur)

Ontvangst en Registratie Welkom en Opening door de Dagvoorzitter; Jos Weekers; Senior Consultant bij Stork Asset Management Solutions en Voorzitter NVDO Sectie Techniek

“Het verschil tussen bio- en conventionele brandstoffen en mogelijke impact op de onderhoudsstrategie”

Maarten Van Haute, Q8Research Gedreven door wetgeving worden voor transporttoepassingen steeds hogere hoeveelheden biobrandstof gemengd met conventionele brandstoffen. Het voordeel en doel is een lagere CO2-voetafdruk en het verminderen van de afhankelijkheid van fossiele grondstoffen. Maar, er zijn ook nadelen aan het gebruik van biobrandstoffen.Maarten licht toe wat het verschil is tussen biobrandstoffen en fossiele brandstoffen en zoemt in op de problemen die je kan verwachten bij opslag, het verbruik en wat je kan doen om operationele problemen te voorkomen met goed onderhoud

“Biobrandstoffen om energie op te wekken”

Martijn Hinderdael Senior Energy Consultant at Stork Thermeq De vraag naar het gebruik van alternatieve (bio)brandstoffen wordt steeds groter. Bij installaties in verschillende industrieën zijn al aanpassingen gedaan om conventioneel gestookte stoomketels om te bouwen naar biobrandstof ketels. Zo’n transitie kan niet zomaar doorgevoerd worden. Martijn deelt de ervaringen bij twee projecten en geeft inzicht in de keuzes die gemaakt zijn, de gevolgen voor het onderhoud en in de succesfactoren voor een geslaagd biobrandstoffen project

Rondleiding Stork Thermeq en netwerkpauze

Biologisch afbreekbare smeermiddelen of Milieuvriendelijkere smeermiddelen?

Kees Oskam Trainer/Consultant Van Meeuwen Industries De behoefte aan biologische smeermiddelen wordt steeds groter, maar er zijn nog veel vragen over het gebruik. Kees geeft antwoord op: -Wat zijn dit voor smeermiddelen en wat is de afbreekbaarheid hiervan? -Wat zegt de wet- en regelgeving hierover? -Welke schade brengt een conventioneel smeermiddel aan het milieu? -Kunnen we smeermiddelen ook hergebruiken?

Inspiratie met het rode bankje

De Dagvoorzitter spreekt een senior- en junior professional uit de praktijk over de toepassing van biobased materialen. Hierin is er ruimte voor de zaal om gezamenlijk de dialoog aan te gaan Henk Jonkers onderzoekt de ontwikkeling van innovatieve, biobased en duurzame bouwmaterialen en is wetenschappelijk adviseur van TU Delft spin-off bedrijf Basilisk Pablo Borkes richtte zich tijdens zijn afstudeerstage op de ontwikkeling van Grasfalt, een innovatief asfaltmengsel waarbij bitumen is vervangen door het biobased bindmiddel lignine dat afkomstig is uit olifantsgras

Aanmelden klik hier!

The corona crisis makes it uncertain whether events will actually take place on the scheduled date. Many events are postponed or online. The Agenda below shows the state of affairs as of September 2021. For recent updates: www.innovatievematerialen.nl

Kunststoffen 2021 15 - 16 September 2021, Den Bosch

Materials+Eurofinish+Surface 15 - 16 September 2021, Den Bosch

Nederlandse Metaaldagen 15 - 17 September 2021, Den Bosch

Plastics Recycling World Exhibition 2021 29 - 30 September 2021, Essen

Vitrum 2021 5 - 8 October 2021, Milan

Lijmen 2021 12 Oktober 2021, Veldhoven

Deburring EXPO 12 - 14 October 2021, Karlsruhe

Fakuma 12 - 16 October 2021, Friedrichshafen

Euro PM2021 Congress and Exhibition 17 - 20 October 2021, Lissabon

Architect@Work 2021 Belgium 21 - 22 October 2021, Kortrijk

iENA Nürnberg 4 - 7 November 2021, Neurenberg BOUWXPO 12 - 14 November 2021, Kortrijk

Fastener Fair Stuttgart 2021 9 - 11 November 2021, Stuttgart

3D Delta week 6 - 10 December 2021

Digital BAU 15 - 17 FebruarY 2022, Cologne

Solids 2022 16 - 17 February 2022, Dortmund

Ulmer Betontage 2022 22 - 24 February 2022, Ulm

ESEF 2022 15 - 18 March 2022, Utrecht

JEC World 2022 8 - 10 March 2022, Paris-Nord

BLE.CH 2022 8 - 10 March 2022, Bern

ESEF 2022 15 - 18 March 2022, Utrecht

Material District 2020 5 - 7 April 2022, Utrecht

Innovative Materials, the international version of the Dutch magazine Innovatieve Materialen, is now available in English. Innovative Materials is an interactive, digital magazine about new and/or innovatively applied materials. Innovative Materials provides information on material innovations, or innovative use of materials. The idea is that the ever increasing demands lead to a constant search for better and safer products as well as material and energy savings. Enabling these innovations is crucial, not only to be competitive but also to meet the challenges of enhancing and protecting the environment, like durability, C2C and carbon footprint. By opting for smart, sustainable and innovative materials constructors, engineers and designers obtain more opportunities to distinguish themselves. As a platform Innovative Materials wants to help to achieve this by connecting supply and demand.

Innovative Materials is distributed among its own subscribers/network, but also through the networks of the partners. In 2021 this includes organisations like M2i, MaterialDesign, 4TU (a cooperation between the four Technical Universities in the Netherlands), the Bond voor Materialenkennis (material sciences), SIM Flanders, FLAM3D, RVO and Material District.