TRUE COST

Chocolate Filtration Chocolate Manufacturing is a Large and Challenging Industry for Filter Manufacturers By Bob McIlvaine

President The McIlvaine Company Bob McIlvaine is the president of The McIlvaine Company, which is helping filter suppliers understand the true cost of their products and the impact on the Serviceable Obtainable Market. He can be reached at rmcilvaine@ mcilvainecompany.com or +1 847.226.2391.

C

hocolate comes from the seeds of a tropical fruit tree called Theobroma cacao. A weekslong process is needed to turn this fruit into a bar of chocolate. Chocolate is being made everywhere, from South Africa and the South of France, to Taiwan and rural Costa Rica. The process of chocolate making from the tree to a chocolate bar can be broken down into seven basic steps: harvest, fermentation, drying, roasting, winnowing, refining, and tempering. The U.S chocolate industry revenue has grown at a CAGR of 0.6% over the past five years, to reach an estimated $19.9B in 2023. The U.S. Census Bureau divides the industry into the following categories: 2017 Index Entries for 311351 NAICS 311351 Baking chocolate made from cacao beans 311351

Candy bars, chocolate (including chocolate covered), made from cacao beans

311351 Candy, chocolate, made from cacao beans 311351

Chocolate (e.g., coatings, instant, liquor, syrups) made from cacao beans

311351 Chocolate bars made from cocoa beans 311351 Chocolate, confectionery, made from cacao beans

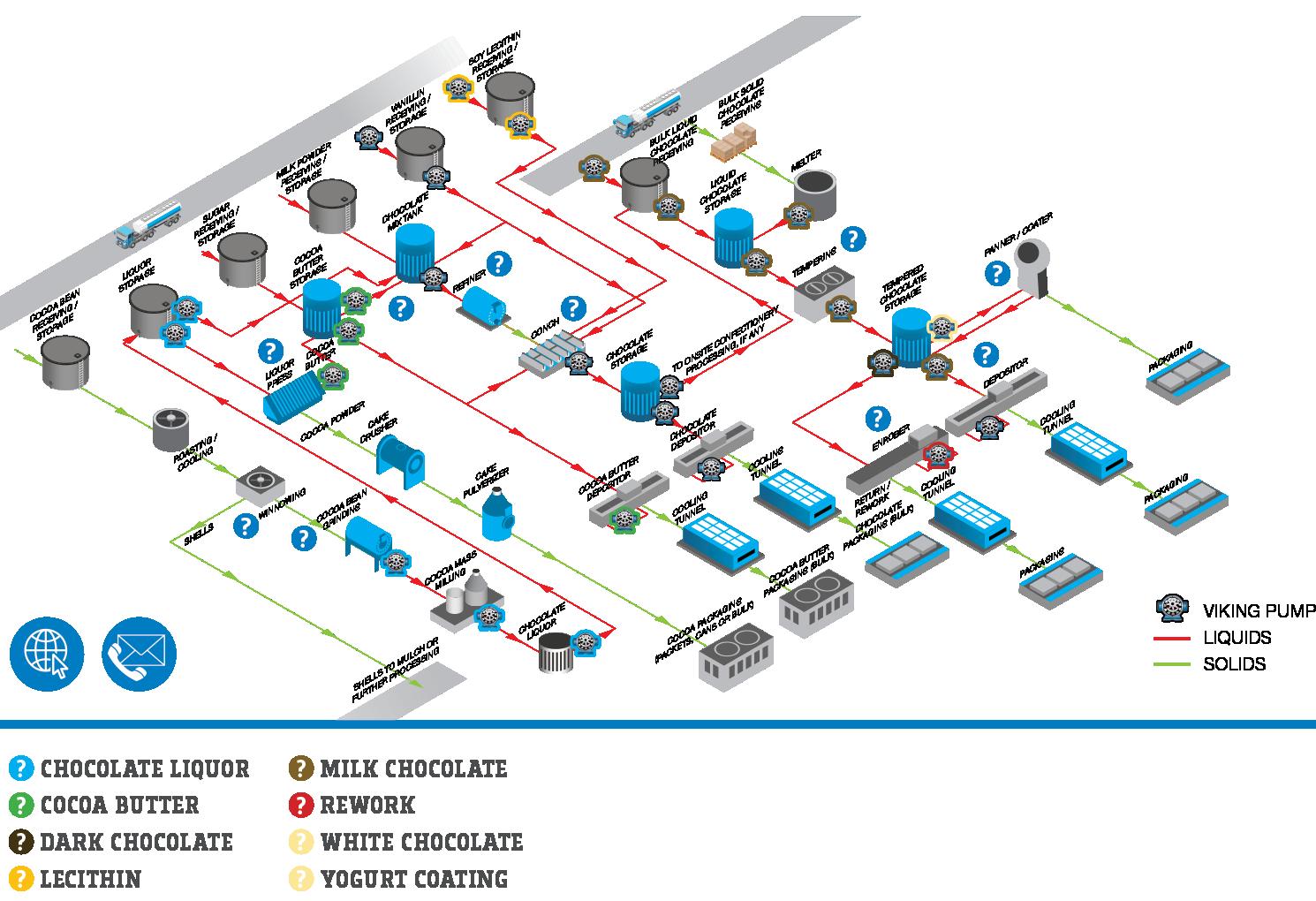

Filter Selections There are two major application categories: one is liquids and the other is dry granular solids. The filters for dust collection from bins, roasters and mills are of the same design as for other food processes, but the liquid filters have to be unique to handle viscous slurries. The types of filters used in liquids and slurries include screens, strainers and self-cleaning filters.

Russell Finex

311351 Nuts, chocolate covered, made from cacao beans

Whether producing cocoa liquor, cocoa butter, or manufacturing and processing liquid chocolate, Russell Finex has solutions. There are different screening solutions suited for all the places needing them, including incoming ingredients, post conch, post enrober, rework or tanker loading and unloading. Self-cleaning filters are totally enclosed, automatic, high-capacity screening to keep operators and environment safe. The company also offers vibratory sieve solutions for more difficult or heavily contaminated batches. With its versatile range, the filter improves product quality by removing oversize contamination from 15 microns or above. The filter does not require filter bags or cartridges, which offers significant reductions in wasted product.

311351 Syrup, chocolate, made from cacao beans

Saniclean

Three of the world’s five largest chocolate companies are headquartered in the U.S.

Chocolate is filtered to ensure a high-quality finished product free of contaminants. Additionally, because of different global consistency standards,

311351 Coatings, chocolate, made from cacao beans 311351

Cocoa (e.g., instant, mix, mixed with other ingredients, powder drink, powdered) made from cacao beans

311351 Cocoa butter made from cocoa beans 311351 Confectionery chocolate made from cacao beans 311351 Cooking chocolate made from cacao beans 311351 Drink powdered mixes, cocoa, made from cacao 311351 Fudge, chocolate, made from cacao beans 311351

Granola bars and clusters, chocolate, made from cacao beans

311351 Liquor, chocolate, made from cacao beans

40 IFN ISSUE 6 2023

This article is about providing the best purchaser decisions for chocolate manufacturing. It starts with understanding each process. Viking Pump is a step ahead of us and has a very useful process flow diagram which we are displaying in a static form with links to the interactive version. Viking Pump has specialists in each niche. Joel Fenton and Tom Ertz are specialists in chocolate. This includes understanding customer needs and addressing them. Asked for an example, they cited needs to increase safety, decrease maintenance and product loss. The latest seals for pumps eliminate leakage. This saves product, but also floor cleanup and the risk of falls.