AIR QUALITY

Changing Mindsets to Transform Urban Filtration to Benefit Human Health

CARBON CAPTURE

Metal-Organic Frameworks Show Promise to Accelerate Decarbonization

FILTER MEDIA

Exploring Plant-Based Materials

AIR QUALITY

Changing Mindsets to Transform Urban Filtration to Benefit Human Health

CARBON CAPTURE

Metal-Organic Frameworks Show Promise to Accelerate Decarbonization

FILTER MEDIA

Exploring Plant-Based Materials

Caryn Smith Chief Content Officer & Publisher, INDA Media csmith@inda.org

Simon Payne Senior Scientist Cambustion spayne@cambustion.com

Jay Roth Industry Consultant jroth2@comcast.net +1 717.873.8717

Dr. Suman Sinha Ray CEO/Co-Founder Cabomba ssinhau6@uic.edu +1 312.320.3142

Adrian Wilson International Correspondent adawilson@gmail.com +44 7897.913134

Norman Hall Director of Sales – Industrial Valin Corporation www.valin.com

Dr. Iyad Al-Attar Visiting Academic Fellow School of Aerospace, Transport, & Manufacturing, Cranfield University i@driyadalattar.com

Joe Bodle Customer Service Manager Valin Corporation www.valin.com

Chad Kamann Applications Development Engineer, NatureWorks chad_kamann@ www.natureworksllc.com

Bob McIlvaine President, The McIlvaine Company rmcilvaine@mcilvainecompany.com +1 847.784.0013

Koen Bastiaens Strategic Marketing Manager, NatureWorks koen_bastiaens@ www.natureworksllc.com

International Filtration

is actively seeking contributed technical articles and viewpoints from qualified industry professionals and those allied to the filtration industry.

Email Caryn Smith, csmith@inda.org with article ideas.

OUR INDUSTRIES

Appliance Filtration

Cleanroom

Indoor Air Quality

Industrial Filtration

Mechanical Power

Medical

Process Liquids

Respiratory Transportation

OUR FILTRATION BRANDS

AlphaPerm™

CabinPro™

NanoWave®

NanoWeb™

Technostat®

Trupor™

OUR TECHNOLOGIES

Cellulose

Composites

Electret

Membrane

Microfiber Glass

Molecular

Nanotechnology

H&V is a global leader in filtration and energy storage solutions. Our advanced materials are used in nearly every industry and touch every aspect of modern life – helping to make air healthier, water cleaner and energy greener.

For more than 200 years, H&V has been known for continuously innovating to meet the world’s needs. Today, from 13 R&D and manufacturing facilities throughout the Americas, Europe and Asia, our entire team, including more than 100 scientists, serves our customers efficiently, accurately and cost effectively –wherever they are. We’re also doing it in new and innovative ways, including PlusZero, our comprehensive line of highperformance solutions with zero added PFAS.

Visit us in Hall 7, Stand R27 to see what makes H&V a valuable partner and a worldwide leader in filtration solutions.

CSMITH@INDA.ORG +1 239.225.6137

“No hurry, any time in the next 5 minutes is fine.” — Mr. Spacely, The Jetsons

Ihave always had pride in my ability to keep up with technological change. Early in my career, when Macintosh computers entered the workplace in the mid1980s, I was the only graphic designer at my PR firm employer willing to fire up the mysterious tiny beige box with the 9-inch black and white display. The only computer program we had installed was DOS-based Ventura Publisher. It was more like line coding text than today’s wysiwyg programs.

This bravery launched my expertise to then learn how to troubleshoot a Mac when the “spinning wheel of death” paid a visit. It compelled me to learn to hand-code many early websites in HTML-1.0 for clients. ... Yes these are my battle scars and victories.

Fast forward to me today, I understand how my elders feel when they can’t figure out how to use the remote on their new television. Technology is outpacing my ability to keep up. From the Cloud (where is it, really) to AI, robotics, automation, and more, industry is being tasked to adapt. Some companies are not ready for it, yet some are – and their employees are terrified of being replaced.

In the quest for faster, better, easier, (and safer) ... did I say faster ... automation is the answer. Yet, it still carries a price tag that greatly hinders widespread adoption.

As it becomes more commonplace, just like the Mac computer, it will be more accessible to all those in filtration and other industries who are interested. (To note: The box at left had a 8MHz Motorola 68000 processor, 128KB of RAM, a 3.5-inch floppy drive, and carried a price tag of $2,495. You can now get a power-packed Mac for that money –loaded with apps and software, too.)

If you are like me, I suggest you hang on for the ride ... and hire smart! The next gen workforce eats technology for breakfast.

On page 18, Adrian Wilson talks robotics at the BMW plant in Spartanburg, SC USA. Starting on page 22, industry expert Jay Roth bursts the bubble on the myths some believe on automation, and shares what it really can do for your company.

In other news, metal-organic frameworks can accelerate industrial decarbonization according to a new report cited in the article on page 32, and breakthroughs on nanotechnology in indoor filtration is explored by Dr. Suman Sinha Rayonn page 44.

I would like to hear your thoughts on these and other issues. Email me at csmith@ inda.org, anytime!

Caryn Smith Chief Content Officer & Publisher, INDA Media, IFN

R. Vijayakumar, Ph.D., Chair

AERFIL

Tel: +1 315-506-6883

Email: vijay@aerfil.com

Rahul Bharadwaj, Ph.D.

Lydall Performance Materials

Tel: +1 603-953-6318

Email: rbharadwaj@lydall.com

Tom Justice, CAFS, NCT

ZENE, LLC Filtration

Tel: 757-378-3857

Email: justfilter@yahoo.com

James J. Joseph

Joseph Marketing

Tel/Fax: +1 757-565-1549

Emai: josephmarketing120@gmail.com

Wenping Li, Ph.D.

Agriltech Research Company

Tel: +1 337-421-6345

Email: wenpingl@agrilectric.com

Robert W. McIlvaine

The McIlvaine Company

Tel: +1 847-784-0013

Email: rmcilvaine@mcilvainecompany.com

Rishit R. Merchant

Parker Hannifin

P: +1 (805) 604-3519

E: rishit.merchant@parker.com

Thad Ptak, Ph.D.

TJ Ptak & Associates

Tel: +1 414-514-8937

Email: thadptak@hotmail.com

the industry, IFN is the leading source for the dialogues, debates and innovations across the full spectrum of filtration and separation applications and processes.

If you would like to utilize your expertise to help shape the content in the IFN , consider applying for the IFN Editorial Advisory Board. We welcome participation through input on trends and innovations, new story ideas and overall thought leadership. This is a collaborative board that meets quarterly to discuss the state of the industry. Send an email to Caryn Smith at csmith@inda.org for consideration.

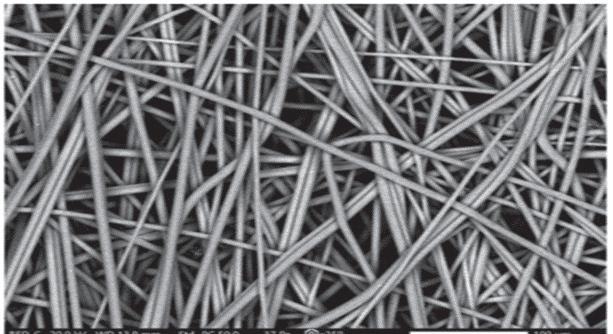

In recent years, international studies have proven the impact of the smallest particles on our health: The smaller the particles, the more dangerous they are, as they can penetrate deeper into the human respiratory system and cause serious health problems, including death in rare cases. With the evolved FreciousPlus featuring nanofibers, MANNFILTER is setting new standards in cabin air filtration. The new filter not only impresses with its filtration of ultra-fine particles, but also with the filtration of pollutants both from outside and inside the vehicle. The new filter continues to offer proven protection against allergens, bacteria, and mold.

Global filtration company MANN+HUMMEL has been successfully using nanofiber technology to filter out the finest particles for a number of years. This technology is now also available on the automotive aftermarket for premium brand MANN-FILTER cabin air filters. Since January 2024, these have been available in the form of the MANN-FILTER FreciousPlus FP 38 004 for the BMW 5 Series and 7 Series saloons, and now feature in the 5 Series Touring wagon as well.

“Our MANN-FILTER FreciousPlus FP 38 004 has the finest nanofibers, which are about 100 times thinner than the fibers of conventional filter linings,” said Thomas Heininger, Director Engineering Cabin Air Filters at MANN+HUMMEL. “These fibers form a spider’s web-like structure over the other filtration layers with coarser fibers, enabling them to capture ultra-fine particles. This means that, in addition to the PM10 and PM2.5

particles, the FreciousPlus featuring nanofibers can remove 90 percent of the even finer PM1 class, i.e., particulates with an aerodynamic diameter of less than 1 micrometer (0.0001 cm). The nanofibers in the FreciousPlus filter up to 80 percent of ultra-fine particles (UFP) smaller than 0.1 micrometers, thus achieving maximum values. For context, these extremely small particles are about 700 times smaller than a human hair,” Heininger explained.

The extremely thin nanofiber ensures that the FP 38 004 is resistant to humidity and temperature fluctuations and provides consistently high filtration throughout the entire service interval. To ensure that the FreciousPlus cabin air filter with nanofibers can work reliably, it must be replaced once a year or every 15,000 kilometers. “We recommend that local experts regularly inform vehicle owners of the importance and benefits of the cabin air filter. Most car drivers are unfortunately unaware of this,” said Heininger.

In Germany, MANN+HUMMEL has been granted a patent for the nanofiber technology,

which protects certain aspects of the filter media and the underlying production process. In addition, a patent application has already been filed for this technology in other countries.

MANN+HUMMEL said every third vehicle interior is contaminated with bacteria, mold, particulate matter, pollen, and harmful gases. In Germany, a new VDI and ZDK guideline defines requirements for providing healthy air in cars in the long run. The new guideline 6032, sheet 1 issued by the VDI (Association of German Engineers) and the ZDK (German Association of the Motor Trade) is intended to remedy this. It regulates hygiene requirements for ventilation technology in passenger cars and trucks.

Dr. Andreas Winkens, Chair of the VDI Guidelines Committees for air hygiene in vehicles, explained: “In the new guideline, we have defined several parameters to ensure the air drawn into vehicles is hygienically clean. These include, among other things, cleaning the air conditioning system, changing intervals for cabin air filters, how these filters should be changed and, of course, the quality of filters because cabin air filters in vehicles should in fact keep out all unwanted hitchhikers. But unfortunately, filters are often old, heavily soiled or incorrectly installed. Harmful gases and noxious particles then enter the vehicle interior via the ventilation system and endanger the health of the driver and occupants. We are not talking about individual cases here, but about a mass phenomenon, since every third passenger car is marginally or heavily contaminated.”

The new guideline 6032 seeks to remedy this mass phenomenon. www.mann-hummel.com

For details on how to submit your company’s technology for consideration as a “Technology Spotlight” in IFN , contact Ken Norberg at ken@filtnews.com or +1 202.681.2022.

Kurita America, part of the Kurita Group, a leading global provider of industrial water treatment solutions, announced a collaboration with Solugen, a bio-based chemical manufacturer, to develop a suite of new carbon-negative water treatment products. These innovative solutions will introduce high-performing, bio-based substitutes to phosphorus and other petroleum derived additives currently on the market.

“We are very excited to expand our partnership with Solugen to create innovative technologies that tackle many of the challenges of traditional water treatment programs,” said Mike Mowbray, senior vice president of the Marketing and Technology Group for Kurita America. “This collaboration will significantly enhance our existing CSV (creating shared value) business that helps customers achieve sustainability goals.”

Kurita’s CSV business, one of the company’s fastest growing segments, focuses on products, technologies, and business models that save water, reduce CO2 emissions, and minimize industrial waste while improving plant productivity for customers. One of the recently developed product lines is the Tower NG series of cooling products, which replaces most of the traditional water treatment chemistries with a combination of the latest polymer technology and Solugen’s proprietary biodegradable corrosion inhibitor. By leveraging innovative bio-based solutions, the Tower NG series eliminates the dependence on traditional organo-phosphonates while providing equivalent or better results for deposit and corrosion control. www.kuritaamerica.com

t Blueair Classic Pro, the first and only air purifier with PhotonPure™ lighting technology that deactivates germs for an impeccably clean atmosphere.

Business Wire

Air wellness pioneer Blueair unveiled its most advanced and powerful air purifier to date – the Classic Pro. The new model, from the award-winning Classic family, is re-engineered with firstof-its-kind multi-layer filtration technology to deliver 40% more performance than before and cleanse the air in rooms up to 1,413 square feet in as little as 30 minutes.

Blueair artfully engineered Classic Pro to provide long-lasting, advanced protection against indoor air pollutants that can adversely affect consumers’ quality of life. Equipped with Blueair’s proprietary HEPASilent™ dual filtration technology, the Classic Pro can quickly capture 99.97% of particles as small as 0.01 microns in size. The unique filtration process delivers more clean air faster while using less noise and energy than HEPA filtration alone.

For an added layer of protection against particulates, the Classic Pro is the first air purifier to bring the patent-pending PhotonPure™ lighting technology to consumers’ homes. Previously only used in medical settings, this professional pioneering lighting technology targets the main filter’s surface with a safe violet light to reduce up to 91% of harmful viruses and bacteria trapped on the filter to prevent recirculation into the air. This visible protection is different from ultraviolet-C (UVC) lighting typically seen in air purifiers, as PhotonPure™ operates in a visible wavelength of 405nm compared with traditional UVC. www.blueair.com

Ahlstrom is launching a new range of filtration materials that offers fluoro-free technology. Ahlstrom is extending its innovative fluoro-free technologies into a wide range of industrial air filtration applications to support filter manufacturers in creating products with long-lasting filtration performance without the use of fluorochemicals. They are ideal for gas turbine air intake, air pollution control, heating, ventilation, and air conditioning (HVAC) applications.

The new range of materials offers water-repellent properties, which increase the durability and stability of the final filter in wet conditions. In global filtration markets, hydrophobic properties are essential to maintaining the highest filtration performance in challenging environments. www.ahlstrom.com

q Gas turbines play a crucial role in modern society, enhancing daily life in the industrialized world. Shutterstock

Pentair plc, and MinneapolisSt. Paul International Airport (MSP) announced a new collaboration to sustainably deliver great-tasting, high-quality drinking water while reducing the need for single-use plastic water bottles for the millions of travelers that visit and fly through the MSP international hub each year. MSP, owned and operated by the Metropolitan Airports Commission (MAC), is the 19th busiest airport in North America by passenger traffic.

Pentair is the first partner in MSP’s new strategic partnership program which aims to collaborate with businesses and community organizations to enhance the passenger experience and drive innovation. As the Official Water Sponsor of MSP, Pentair is working to help the airport promote sustainability through the installation of 10 HOPE Hydration HydroStations. The cutting-edge HydroStations, featuring filtration technology by Everpure from Pentair Water Solutions, are the first water refill stations of their kind at any airport worldwide, dispensing free, chilled, and filtered water while providing an interactive experience to users. Through the HydroStations, Pentair and MSP will be educating travelers about water-related issues and the positive environmental impact they can make by bringing and filling a reusable water bottle while traveling.

It is estimated that the current network of 80 water bottle refill stations at MSP reduce the need for approximately 600 pounds of single-use plastic bottles every day. Using integrated IoT technology, the HydroStations at MSP track real-time impact data associated with the elimination of single-use plastics. www.pentair.com

The topic of Carbon Capture and Utilization (CCU) and Direct Air Capture (DAC) has the potential to make a significant contribution to climate change and at the same time represents an important building block in the future economic system. That is why Hengst Filtration is proud to present the first CCU/ DAC system for capturing carbon dioxide (CO 2) from the air and then utilizing the carbon.“With this technology, we are fully committed to our vision of “purifying our planet,” because we adsorb the pollutants from the air and then make them available for other processes,” said Jens Röttgering, owner of Hengst Filtration.

Carbon Capture and Utilization refers to the filtration, transport and subsequent use of CO2. Direct Air Capture refers to the extraction of CO2 from the air. Dr. Rolf Gausepohl, Head of the TechCenter Filtration at Hengst, commented: “Our CCU unit is fully developed and works in the daily process. We are now looking for suitable partners to further develop the technology and adapt it to real-life conditions.” www.hengst.com

Compiled by Caryn Smith, IFN Chief Content Officer

International Filtration News Explores Trending Innovation

In this new feature, IFN highlights significant research from universities and institutions around the world. If you are a part of a project you would like to highlight, email csmith@inda.org. Please write “IFN Emerging Research Submission” in your subject line in order to apply. Please send a completed press release and/or summary of the research as you would want it to be printed, a link to the university online story (if applicable), and all high resolution photographs/charts/graphs, short researcher bio(s). All selections could be edited for length.

By Moni Mahesh Ghosh and Sadhan C. Jana

The global plastic waste generated annually is already in the million metric tons and the problem is ever-growing with land filling as the most popular disposal method. It is widely recognized that plastics in landfills will take hundreds of years to degrade1. Among the plastic wastes, polyolefins are most abundant due to their versatile applications and considerable chemical resistance. It is imperative to develop methods to upcycle them (i.e., to recycle this class of materials while adding commercial value to them).

The researchers in Prof. Sadhan C. Jana’s group in the School of Polymer Science and Polymer Engineering at The University of Akron have found a unique method of upcycling polyolefins from waste streams using plant-based solvents known as terpenes. The group investigated the viability of manufacturing highly porous solid structures called aerogels with polyolefins, mainly high-density polyethylene (HDPE) and isotactic polypropylene (iPP) and using them as filter media for oil-water separation and air filtration.

These aerogels are being produced by the method of thermally induced phase separation (TIPS) after dissolving the polymers in two of the more commonly available terpenes – orange terpene derived from oranges and beta pinene derived from pine trees. The properties of these aerogels depend on the solvent used, specific type of polyolefin used (HDPE/iPP),

and the weight percent of the polymer in the solution.

The ongoing research focuses on fundamental understanding of the structureproperty relationships of the aerogels and their viability as filter media, either as self-standing structures, e.g., as cylindrical monoliths, or in a hybrid structural form, such as supported by 3D-printed scaffolds.

The results of the study will be communicated to a peer-reviewed journal. The aerogel specimens were manufactured from both virgin polymer pellets and from segregated polyolefinic waste with either HDPE or PP as the base polymer and with

unknown additives. These aerogels were then used in oil-water separation and air filtration and their efficiencies were benchmarked against known commercial filters or materials that are used for similar separation operations, namely, surgical face masks and cellulose-polypropylene based oil absorbents. For some of the aerogel samples that were tested, the air filtration performance was at least 5% more and the oil absorptivity from an oil-in-water emulsion was at least 33% more than the corresponding commercial benchmark materials. The HDPE aerogels had considerably higher compressive strength while the iPP aerogels had considerably higher specific surface area and a higher fraction of mesopores.

It is known in melt-processing that mixed polyolefin wastes do not produce homogeneous materials due to immiscibility of polyolefins. However, the method adopted in this work leads to synergy, in that, co-existing, high-surface area polyolefin phases work in unison to fetter out airborne particles or oil phases. These aerogels can be manufactured in netshape, thereby opening the avenues for

potential applications like oil spill cleanup, modular air filtration, carbon capture etc.

Moni Mahesh Ghosh is a chemical engineer by training now pursuing PhD in the School of Polymer Science and Polymer Engineering. His research focuses on the manufacture and use of various porous polymeric structures. His email is mg270@uakron.edu

Sadhan C. Jana, BF Goodrich Professor and Associate Vice President for Research and Business Engagement at the University of Akron, leads aerogel research funded by industries and federal agencies for potential applications in wounddressing, air filtration, cleaning of water, among other things. His email is janas@uakron.edu.

1. Roland Geyer et al. Production, use, and fate of all plastics ever made. Sci. Adv.3, e1700782(2017).

©Article written exclusively for the International Filtration News.

By Kim Martineau

Potential applications for a light-controlled pump developed by Dartmouth scientists include filtering environmental pollutants and treating cystic fibrosis.

Tiny molecular machines in humans carry out much of the work that occurs within cells, from replicating DNA to ferrying materials across the cell membrane. For decades, scientists have tried to replicate these miniaturized workhorses outside of the body, with dreams of applying them to tasks like environmental cleanup, drug delivery, and the diagnosis and treatment of disease.

But artificial molecular machines have proven easier to design on paper than to

implement in real life. In a new study in Science, researchers offer a demonstration of their potential eight years after the Nobel Prize was awarded to three chemists for their work on molecular machines.

Researchers show that a synthetic receptor designed to both capture and release negatively charged ions, or anions, can move target molecules against a concentration gradient in solution, fueled only by natural light.

“This is a proof of concept that you can use a synthetic receptor to convert light energy into chemical potential for removing a contaminant from a waste source,” says the study’s senior author, Ivan Aprahamian, professor and chair of the Department of Chemistry.

The synthetic, tripod-shaped receptor that Aprahamian and his co-authors designed has two important properties. It comes in forms that can both trap and

discharge negatively charged molecules. At the same time, it behaves like an electrical switch, turning on and off when exposed to different wavelengths of light. When the switch is turned on, the receptor picks up target anions. Flip the switch off, and the receptor lets the anions go.

The receptor’s unusual properties allowed researchers, to control the flow of chloride ions from a low-concentration solution, on one end of a U-shaped tube, to a high-concentration solution on the other. Over a 12-hour period, the study reports, they moved 8% of chloride ions against the concentration gradient across a membrane embedded with the synthetic receptors.

In absolute terms, the chloride ions were driven almost 1.4 inches – the width of the membrane separating both ends of the tube. Relative to the receptor’s tiny size, they covered an impressive distance, fueled by light alone.

“It’s the equivalent of kicking a soccer ball the length of 65,000 football fields,” says Aprahamian.

Aprahamian’s lab has long focused on a class of synthetic compounds known as hydrazones, which switch on and off when exposed to light. During the pandemic, PhD student Baihao Shao came up with the idea to enhance the hydrazone receptor so that it could both collect and release target anions when switched on and off.

Aprahamian tried to dissuade him. “I told him that while it is a great idea, I do not think it will be competitive with the other impressive photoswitchable receptors in the literature,” he says. “Luckily, Baihao ignored me, and he went ahead and actually designed the receptor.”

They chose chloride as their target anion for two reasons.

During winter, stormwater runoff laden with road salt raises chloride levels in waterways, causing harm to plants and animals. The transport of chloride ions also plays a key role in healthy cell functioning. The disease cystic fibrosis is caused by cells being unable to pump out excess chloride. The trapped ions cause dehydration in cells, leading to a buildup of thick mucus in the lungs, among other organs.

“As a proof of concept, we show that designing synthetic chloride pumps is achievable,” says Aprahamian.

The researchers found that their hydrazone receptor worked best on chloride, bromide, and iodide ions. But it could theoretically be modified to target other anion-rich pollutants, ranging from radioactive waste to the phosphates and nitrates in fertilizers that get washed into waterways, causing massive dead zones.

“Ideally you can have multiple receptors in the same solution, and you can activate them with different wavelengths of light,” says Aprahamian. “You can target and collect each of these anions separately.”

Not only can the receptor be controlled by a renewable source of energy – light – it is relatively easy to make and modify, he adds. Researchers created the receptor by stitching the tripod together using “click chemistry,” a Nobel Prize-winning technique that chemist Barry Sharpless ‘63 helped invent years after graduating from Dartmouth.

Molecular machines are abundant in nature, powered by ATP in animal cells, and by the sun, in plant cells. “We want to mimic such biological processes, using sunlight as the energy source to create autonomous and self-sustaining filtration systems,” says Aprahamian.

Read: https://faculty.dartmouth.edu/artsandsciences/news/2024/08/filtrationsystem-powered-synthetic-molecules-and-light

At Berry, we leverage our unmatched global capabilities, sustainability leadership, and deep innovation expertise to serve customers of all sizes around the world. Harnessing the strength in our diversity and industry leading talent of 47,000+ global employees across more than 300+ locations, we partner with customers to develop, design, and manufacture innovative products with an eye toward the circular economy. The challenges we solve and the innovations we pioneer benefit our customers at every stage of their journey. With over 35 years of experience manufacturing filtration media, Berry Global’s products have become the industry standard in the pleat support and filter layers for air, liquid, and gas applications. Berry Global’s proprietary technologies deliver unique material solutions for challenging customer needs. Whether using our unique REEMAY® spunbond PET technology in vaccine manufacturing, or TYPAR® spunbond PP nonwovens in water filtration to create safe drinking conditions, customers trust our proven filtration solutions.

Our filtration capabilities encompass a wide range of specialty materials, process technologies, and state-of-the-art innovation centers.

• Reemay®

• Meltex™

• Typar®

• Air Filtration

• Industrial Filtration

• Water Filtration

• Automotive Filtration

• Food & Beverage Filtration

Beverlin Specialty Tube takes an indepth look at the manufacturing process, benefits, and limitations of spiral weld tubes.

In the world of specialty tubing, spiral weld tubes have gained significant attention due to their unique manufacturing process and intrinsic advantages. Beverlin Specialty Tube has witnessed a surge in demand for spiral weld tubes across a range of industries, including oil and gas, nuclear, and large-scale industrial applications. In this article, Beverlin explores how the manufacturing process of spiral weld tubes creates several application-specific benefits – and a few noteworthy limitations – compared to traditional straight seam welds.

Spiral weld tubes are produced using a continuous welding process, which is similar to high volume straight seam tubes. This process involves coiling a strip of metal around a mandrel at an angle, forming a helical shape. As the strip is coiled, the edges are welded together, creating a spiral seamed tube.

One of the primary advantages of spiral weld tubes is their inherent roundness and straightness. The continuous welding process ensures a more uniform and consistent shape than straight seam tubes, reducing the likelihood of deformities or irregularities in the tube’s structure.

Spiral weld tubes offer excellent filtration capabilities. The spiral seam allows for a 360-degree filtration flow, ensuring even distribution and efficient filtering of fluids and gasses. This makes spiral weld tubes ideal for applications that require high levels of filtration performance.

Spiral welding allows for the production of tubes with larger outer diameters and of varying lengths without the need for large-scale coil and coilhandling equipment. Instead of relying on large metal coils, manufacturers can use smaller strips of metal and create a die set to achieve the desired diameter. This flexibility in production allows for more costeffective manufacturing.

n Additional Benefits:

• Increased crush-resistance

• Increased corrosion-resistance

• Strength and flexibility in high temperatures

• Stronger, more consistent welds

Limitations

n Reduced Open Percentage

The spiral weld seam occupies a larger surface area, resulting in a marginally smaller open area for filtration or flow. This reduction is often negligible, however, and can be mitigated through proper design and engineering.

n Potential for Slower Production Speeds

Depending on the specific application requirements, spiral weld tubes may,

at times, run slower through the continuous welding process than straight seam tubes. This potential reduction in production speed should be considered when evaluating the suitability of spiral weld tubes for a particular project or manufacturing environment.

At Beverlin Specialty Tube, we have extensive experience in the manufacturing of spiral weld tubes for a wide range of applications. Our expertise allows us to optimize the production process, ensuring the highest quality and performance of our products.

Bekaert pioneers sustainable solutions and services with creativity beyond steel. Our products range from wire transformations to coating technology and everywhere in-between. And filtration is no exception. Their 40+ years of experience in filtration proves Bekaert knows fibers. In fact, Bekipor® filter media stands as a true testament to their commitment. But what is Bekipor® metal fiber media? And what makes it so special?

Bekipor® filter media features sintered stainless steel fibers. During sintering, metal fibers fuse together with up to 20 bonds per fiber. This process produces filter media for a variety of applications, especially polymer recycling. The unique structure of sintered fibers plays a crucial role in recycling. From preventing contaminants to ensuring cleanability, Bekipor® offers sustainable, long-lasting filtration.

The textile and recycled plastics industries continue to struggle without high-quality filtration. Production lines are often fraught with contaminants, broken strands, and even downtime. These issues not only stall production but cut into the bottom line. This is where solutions such as Bekipor® are enabled to shine. Ensuring increased runtime and continuous strands free from the impact of gels. The solution has never been clearer.

Are you tired of the frustration caused by hard and soft contaminants? To understand the value of Bekaert’s Bekipor® filter media, we should look closer. When a polymer is remelted two or three times over during the recycling process,

the number of gels in the final product increases. However, gels may also occur naturally in resins. These contaminants contribute to weaker polymer strands and overall breakage. As a soft contaminant, gel may even increase pressure by

changing its shape to pass through inferior filtration. This is bad news for producers in the textile industry.

Bekaert’s polymer recycling filter media technology leverages stainless steel fibers to address challenges throughout the recycling process. The unique structure of our sintered fiber plays a crucial role in polymer recycling. For the best product quality in polymer recycling, Bekipor® is your best choice in filter media. From preventing gels for continuous strands to cleanable media, stainless steel fibers are paving the way to sustainable polymer recycling.

Technology Highlights:

• High porosity

• Low pressure drop

• Cleanability

We are attending The Filtech Tradeshow in Cologne, Germany November 12-14, 2024 Booth Number: K9

Hollingsworth & Vose is a global leader in filtration and energy storage solutions. The company’s advanced materials are used in nearly every industry and touch every aspect of modern life. Wherever you work, live or travel, chances are an H&V solution is close by, contributing to a cleaner, healthier, more sustainable world. In the world of filtration, H&V’s innovative materials and solutions – including synthetic filter media, microfiltration membranes, microfiber glass, nanofibers and our new zero added PFAS line PlusZero – meet and exceed the exacting demands of customers. H&V helps clean and filter everything from air and water to fuel and industrial liquids across a wide range of industries and applications, including HVAC, cleanrooms, process liquids, health care, heavy industry, transportation and mechanical power.

H&V’s innovative filtration technologies meet customer expectations across a range of sectors and industries. For each sector, the company has differentiated filtration solutions:

Cabin Air – People in vehicles are affected by pollutants like exhaust fumes, particles from tire and road wear, pollutants from heavy industry, construction, agriculture, and VOC’s emitted from vehicle interiors. At H&V, our Cabin Air Filtration Solutions, under the brand name CabinPro™, help protect drivers and passengers by removing harmful pollutants and improving Vehicle Interior Air Quality.

Liquid – Microfiltration enables the purification of liquids in food and beverage, bioprocessing and industrial and water treatment. Improving microfiltration makes it possible to bring new products to market, make existing fluid streams safer, reduce dependence on additives and improve processing times. H&V’s Trupor™ filter media brings membrane reliability and

maximum performance with the thinnest possible efficiency layer, which is made possible by superior pore size uniformity. Its composite design delivers long life and stable performance.

Indoor Air Quality – With growing awareness of air quality, performance requirements for HVAC systems and air filtration in homes, buildings and industrial environments have increased. H&V manufactures air filtration media for high-quality control of contaminants, including dust, harmful particulates and VOCs, to maintain safe and comfortable indoor air quality.

Our innovative and award-winning filtration media, including NanoWave®, are designed to provide outsized performance in HVAC filters and deliver clean air while improving energy outcomes with superior pressure drop and dustholding properties over other medias on the market. Visit our booth to learn more about why healthy and sustainable HVAC solutions start with H&V.

Innovation has allowed H&V to evolve and thrive for more than 200 years. Today, more than 100 scientists conduct cuttingedge research at H&V. Our commitment to filtration, and the ability to innovate in every aspect of the company, has made H&V a global leader.

H&V recently introduced PlusZero, a comprehensive line of high-performance solutions with zero added PFAS. The PlusZero line is not only environmentally sound, but it offers high-quality solutions that will help customers meet performance, reliability and affordability goals. H&V’s advanced materials contribute to a greener and more sustainable planet. We are determined to go beyond that by supporting global efforts for healthier air and water.

H&V serves the global market with 15 R&D and manufacturing facilities strategically located in the Americas, Europe and Asia.

Location: Hall 7 | Stand No.: R27

Presentations:

Proline – New gradient filter media for enhanced filtration performance. Session F09 – Enhancement of Filter Media Performance – 10:45 a.m. to 12 p.m., Nov. 14, 2024.

Adsorptive filter media in cabin air filtration: Advancing filter design through modeling. Session G03 – Adsorption II –2:45 p.m. to 4 p.m., Nov. 12, 2024.

Energy savings in HVAC systems with waved 3D composites. Session G08 –Energy Efficient Air Filtration – 1 p.m. to 2:15 p.m., Nov. 13, 2024.

A2Z Filtration Specialties is a designer and manufacturer of complete customer centric machines and automation solutions for filter production and assembly. A2Z’s customer base includes industry leaders in over 75 countries. The company excels in providing superior value, durable and globally serviceable production lines. The components are sourced from leading global suppliers to ensure ease of availability and trouble-free maintenance. A2Z equipment is easy to use, efficient and offers excellent value for money, with features such as pictorial manuals and remote access for service and upgradation. With a dynamic team comprising of over 50 engineering professionals in design, manufacturing and installation, A2Z is providing complete turnkey solutions around the globe. The A2Z Design Team uses state-of-the-art Solid Works® 3D design software for the designing and simulation of filter production lines. A2Z’s deep knowledge of filter manufacturing processes and their ability to develop customer specific, innovative and efficient automation has resulted in development of fit-to-purpose solutions.

A2Z is pleased to offer yet another automation solution for the assembly of die cut frame HVAC filters. The HVAC filter assembly cell is designed for the assembly of die cut filters from 10 to 30 inches in length and width and 1 and 2 inches in pleat height. The filters are available in single and dual die cut models of filters.

The bottom die cut stack is placed on a stacker and the automatic feeder feeds the die cuts to the glue applicator. Here, the glue applicator applies an even layer of glue along the surface of the die cut board. The forming station forms the bot-

tom frame and indexes to the pleat pack placement station. An operator places the pleated pack into the formed bottom die cut frame. The pleat pack with the bottom die cut frame indexes to the top framing station. The top laminated die cut is flipped and placed over bottom frame. The process for the top die cut mirrors the process for the bottom die cut when the pleated pack is rotated. The complete assembled filter with top and bottom die cut is pushed to the curing tunnel where the curing of the glued die cut takes place.

A pick and place system picks the filter from the top of the curing tunnel and ejects the finished filter onto a chute for packing.

• Operator friendly

• Allows for quick change over of fixtures

• A production rate of upto 12 filters a minute

• Safety as per CE norms. Machine is guarded all around by steel mesh

• A laser safety scanner provided to stop the machine in case of interruption in operation, thus safe for the operator.

• User – Friendly 10” Allen Bradley HMI with a complete Instruction Manual

• Remote Support Facility

• Allen Bradley ® Controls

• Fit To Purpose manufacturing, assembly & automation Solutions

• Value prices for quick return on investment.

• Ability to Integrate various automation ssolutions and processes including online quality validation systems

• Globally serviceable lines

• Latest state-of-the-art manufacturing & automation Solutions

• IoT & Industry 4.O compliant systems

For further information, please visit our website – www.a2zfiltration.com or contact us at marketing@a2zfiltration.com WhatsApp number: +91 9871690592

By Adrian Wilson, International Correspondent, IFN

filters by preventing them from becoming clogged too easily.

While primarily associated with German engineering prowess, BMW is also, perhaps surprisingly, the largest automotive exporter of vehicles from the USA.

BMW Manufacturing in Spartanburg, South Carolina, which is celebrating its 30th anniversary in 2024, assembles more than 1,500 vehicles per day, running on two shifts, and in 2023 exported cars with a value of $9.6 billion to 120 countries.

Central to the Spartanburg operation are its two paint shops, which employ 240 of the army of 2,600 highly efficient robots that are working alongside human coworkers at the plant.

These provide each car body with five coats of paint and two protective corrosion coatings in a process which takes 12 hours, during which time the vehicle has travelled a distance of around four miles. The entire process adds just 20 pounds of weight to the body – a thickness of 120 microns, which is the equivalent to the width of five human hairs.

Filtration systems in BMW’s automotive spray booths worldwide are crucial to ensuring high-quality surface finishes,

as well as protecting worker health and maintaining environmental standards.

Designed to remove contaminants from the air within the booth, prevent dust, overspray and other particles from affecting the painting process, the technology behind these systems continues to evolve to meet ever more stringent industry requirements and environmental regulations.

Primarily based on glass or polyester media, pre-filters are the first line of defense in a spray booth filtration system, capturing larger particles such as dust and debris before the air enters the booth, in order to extend the life of the primary

At BMW’s plant in Leipzig, Germany, for example, specialists from Freudenberg Filtration Technologies – a long-time supplier to the auto maker – identified the greatest savings potential in the prefilter area. Here, existing filter elements showed excessive pressure drop in comparison to their separation rate, resulting in a high level of energy consumption. These were replaced with Viledon WinAir 45 pocket filters designed for dealing with coarse dust at very low pressure drop. Test series and service life tests have subsequently demonstrated a noticeable increase in efficiency, enabling BMW to save 700 MWh a year, corresponding to a CO2 reduction of around 365 tons.

The primary filters in the airflow path within the spray booth are responsible for capturing paint overspray and critical to maintaining a clean painting environment. HEPA filters are often employed to capture finer particles.

Exhaust filters then capture any remaining contaminants before the air is expelled from the booth and help to ensure the air released into the environment meets regulatory standards for air quality. Activated carbon filters can be used at this stage to remove harmful volatile organic compounds (VOCs) and odors.

However, even with state-of-the-art filtration technology, the content of the finest

dust particles in spray booths varies depending on the ambient air drawn in.

If the dust content exceeds the threshold, the still wet paint can trap particles, visually impairing the painted surface.

BMW specialists have been involved in a project aimed at avoiding this at the company’s plant in Munich, Germany.

Each freshly painted car body at the Munich plant undergoes an automatic surface inspection in the paint shop and the data gathered in these inspections is being used to develop a comprehensive database for dust particle analysis.

AI algorithms have subsequently been employed to compare live data from dust particle sensors in the spray booths and dryers with the database.

“Data-based solutions help us secure and further extend our stringent quality requirements to the benefit of our customers,” explains Albin Dirndorfer, senior vice president of Painted Body, Finish and Surface at the BMW Group. “Smart data analytics and AI serve as key decisionmaking aids for our team when it comes to developing process improvements. We have filed for several patents relating to this new dust particle analysis technology,”

The algorithm can detect, in good time, when dust levels are set to rise due to the season or during prolonged dry periods and is able to determine, for example, an earlier time for filter replacement. Additional patterns can be detected where the algorithm is used alongside other analytical tools.

The BMW specialists see enormous potential in dust particle analysis. Based on information from numerous sensors and data from surface inspections, the algorithm monitors over 160 features relating to the car body and is able to predict the quality of paint application very accurately. The AI solution will be suitable for application in series production when an even broader database for the algorithm has been developed.

In particular, this requires additional measuring points and even more precise sensor data for the car body cleaning stations. The AI experts are confident that

once the pilot project in Munich has been completed, dust particle analysis will become standard practice at BMW’s plants worldwide.

BMW is also now on the way to powering the paint shops across its global manufacturing plants with regenerative energy, due to a new method of achieving the high temperatures needed for the thermal purification of exhaust from its spray booths and drying areas.

Before being released into the atmosphere via chimneys, exhaust from spray

t BMW specialists are developing a comprehensive database for dust particle analysis. BMW

booths and drying areas is purified to prevent paint shop solvents from harming the environment. This is done by passing it through a bed of ceramic media, where the solvent residues are burned off.

To do this, the air has to be heated up to very high temperatures of up to 1,800°F in a short space of time. The energy needed to do this could previously only be provided by natural gas, but the eRTO – electric regenerative thermal oxidation – system now makes it possible to purify exhaust with electricity from renewable sources.

The eRTO system is installed between the painting booth, drying process and chimney. Thermal energy is recovered by a flat, two-meter-deep ceramic bed which serves as a recuperator. Electrical heating rods heat the surrounding ceramics, and because most of the heat is retained, with only small amounts escaping, a connected load of just a few hundred kilowatts is sufficient to run the system.

The eRTO system was initially functiontested in ongoing paint shop operations at BMW’s plant in Regensburg, Germany, and is being further validated at the BMW Brilliance plant in China, where an eRTO system is used to purify exhaust from the drying system for car bonnets.

The first European BMW Group facility to use the technology in series paint shop operations is at Dingolfing Germany, where one of four paint lines has already been converted for electric exhaust purification. More such systems are planned for the production network, and the new BMW plant in Debrecen, Hungary, will purify paint shop exhaust purely by eRTO.

Back in Spartanburg, a further recent development has been the installation of a high pressure reverse osmosis unit for the two paint shops. This is enabling wastewater from the paint processes, which would normally be pretreated and dis-

charged to the sewer, to be filtered and reused.

In 2023, this process reduced the Spartanburg plant’s water consumption by an impressive 15.9 million gallons.

The BMW Group announced in 2022 that it would invest $1.7 billion in its U.S.

operations, including $1 billion to prepare the Spartanburg plant to assemble fully-electric vehicles, along with $700 million to build a new high-voltage battery assembly plant in Woodruff, South Carolina.

“After 30 years of successful production, we are further expanding our commitment to South Carolina and in late 2026, the production of fully-electric sports activity vehicles will get underway here in Spartanburg – as a further step towards strengthening our global resilience,” said Milan Nedeljkovic, a member of BMW AG’s board, during an anniversary celebration at the plant this June.

Adrian Wilson is an international correspondent for International Filtration News . He is a leading journalist covering fiber, filtration, nonwovens and technical textiles. He can be reached at adawilson@gmail.com.

By Jay W. Roth

When does it make sense to add automation to your process?

Let’s dive in:

In my 30 years of sales and machinery experience helping customers choose the right machine systems for their company needs, I have witnessed firsthand the power of automation on productivity, profits, employee well-being, corporate advancements, and more.

About 20 years ago, through the company I represented, we began to offer clients equipment with a FANUC robotic arm integrated into a gluing machine solution built for the filtration industry. It was the beginning of an era in equipment advancements, and a whole new conversation with clients on what these types of improvements will and won’t do for their business models.

I have walked decision-makers through all the objections, questions, and scenarios to help them make educated decisions. Frankly, most objections were due to myths they believed – and also, justifying the cost that automation carries with it. So, here is what I believe you need to know.

By Jay W. Roth

Let’s take a step back and talk about exactly what we mean by “automation.” If you Google “automation,” you’ll get a nice definition: The use of largely automatic equipment in a system of manufacturing or other production process. I like that; however, I don’t like the can-you-use-that-in-a-sentence example they include –“...unemployment due to the spread of automation.”

No, that’s not it! Your workforce is not at risk; in fact, they will greatly benefit from automation.

When implemented by a healthy growing company, automation re-tools the workforce, provides a safer more efficient workplace, and leads to better jobs – not fewer jobs.

In fact, misconceptions about robotics and automation performing the same tasks that human manufacturing workers perform is ingrained in our society. From the early days of modern industry to today, ideas are cultivated in books, film and television of what a world with automation could be. From the cyborg Tin Man introduced in L. Frank Baum’s The Wonderful Wizard of Oz, written in 1900, all the way to 1960s and ‘70s pop culture shows like The Jetsons, Lost in Space, and Star Trek®, to current entertainment brands like Avengers® and Transformers®, the lines are continually being blurred between humanity and machinery.

News stories of inventors of automation and their scientific quest to create human-like functioning “robots” also fueled the fires of misperception.

We see stories like Harry May, a professor in the UK, who built a robot he called “ALPHA” in 1932. His robot was designed to mimic human behavior, actions, and sort of appearance. May used a simple form of voice control to have ALPHA respond

to his commands. Logically, one of the first things May taught ALPHA to do was to aim and fire a revolver. Big surprise when one day, while May was setting up a demonstration for some dinner guests, ALPHA stood, aimed his revolver, and shot May in his outstretched, panicked, hand as he was preparing the real target.

I can only imagine the reception of that news as it spread and how that vision likely stuck in people’s minds for years after, as more refined engineering was being developed to better use such technology.

In 1939, another humanoid robot, “Elektro,” debuted at the World’s Fair. The seven feet tall, 265 pounds of steel gears covered by aluminum skin was able to perform tasks by voice command, such as walking and speaking (700 words). It could even smoke cigarettes, blow up balloons, and move its head and arms.

Those early images of robots with human features (like Rosie from the Jetsons) were ingrained for decades in the minds of people, and also prompted the fear of robots replacing people.

But, now we know better! Today’s fears revolve around artificial intelligence (AI) taking over our lives and workplaces. Yet, I believe there are benefits and uses for automating tasks that we previously relied on human labor to accomplish, not as a replacement of people, but an enhancement of people’s time spent on more productive efforts.

Is automation for everything and everyone? No. There are and always will be things done better with a human touch.

While automation will work to get most contact when calling a company, there is no replacement for the personal interaction of a friendly human being that answers the phone. (Just think back to a time when you repeatedly yelled “represen tative” at an automated service. Hey, it happens!)

Just because we can automate, doesn’t always mean we should. Artists and craftsmen still get my vote when I am looking for that special gift or souvenir, rather than a mass-produced trinket. I’d still rather watch grainy footage of Elvis Presley, the King of Rock and Roll, over new AIgenerated updates. Craftsmanship is of high value, with all of its perfect imperfections.

Yet, I believe there are benefits and uses for automating tasks that we previously relied on human labor to accomplish, not as a replacement of people, but an enhancement of people’s time spent on more productive efforts.

Craftmanship brands are built on the personal touch and are priced accordingly. Carmaker Lamborghini has a price tag that reflects 100% customization and hand-crafted interiors, assembled in one factory in Italy, producing 10,000 vehicles a year. Yet it still manages to make around $2.5 billion U.S. dollars a year. Rolex is another, selling one million watches per year with sales $11.5 billion U.S. dollars, where machines are operated by humans, and key parts are assembled by hand.

For most manufacturer brands, artisanship is not a factor – quality is, and automation can help with that. Automation has a wide reach. It can be applied across numerous industries, markets, and jobs.

For example, I was recently reading Convenience Store News and came across an article on automation. Although the applications are widely different, the goals were much the same as we see in the manufacturing sector – increased efficiency and production, cost reduction, improved accuracy and timeliness, enhanced safety and security. To note, there was no mention of replacing people in

In searching for a good example of automation that had negative impacts on quality, I was hard-pressed to find some. So how do we choose what to automate, and what to use labor to accomplish?

Each company must do their own homework to choose the best manufacturing practices with impact to the bottom line.

We can look to the principles of LEAN manufacturing to get us most of the way there – safety, quality, delivery, and cost, just like our friends in the convenience store business.

In making a case for automation, safety is probably the easiest to justify. OSHA does a great job of outlining what we can and cannot have people do. We should ask ourselves: Where our workers are getting injured and why.

What environments are we requiring them to work in?

Are there distractions that keep them from focusing on the task at hand?

• Are they getting bored and/or careless?

• Are there repetitive motion impacts and injuries?

These are the considerations that plant managers can easily identify, and begin to consider automation options.

I was visiting with a medical disposables customer who was rolling undercast padding, the soft cotton material that a doctor wraps around your broken arm before applying the cast. They had a process that remained the same for decades. It became quite routine, but the machine they used was starting to wear out. As we looked at replacing the machine, we saw that improvements could be had.

We looked at how involved the operators were in the process. Although technically they were using an automated piece of equipment, the actions were so labor intensive that the operators had to rotate tasks every half hour to prevent fatigue.

The machine would wind the cotton onto ½” diameter rods. The operator had to pull the full rod out of the machine and place it into a strip-off unit that pulled the rolls off and onto a conveyor.

They had to manually keep track of how many rolls they were making and place the rod in the proper position to stack up the finished rolls.

They were using a squirt bottle to lubricate rods. They actually just hosed down

the area and the rods ‘just happened’ to get lubricated in the process.

Our engineering team built them a machine that automated all interaction with the winding rod, automatically lubricated each one, precisely stacked the finished products, and made life a whole lot easier.

Addressing employee concerns, I could see the worry on the operators’ faces when our engineering teams were studying their efforts. They were proud of what they were doing, moreover they wanted the job security to keep on doing it. I visited again after the machine was installed, and I thought they were going to hug me. No one lost their jobs. Efficiency improved. Each worker was now staying at their position for the full shift. They now had time to conduct quality control testing of the finished products – carefully and not skipping details. The area was clean, and the company began to look downstream to make additional improvements.

This illustration shows the impact of solving the most significant problem, in this case safety, and gaining other many other benefits in the process.

In the case study, quality did improve, but it was not the focus. Quality can come from the repeatability that automation can offer. When we get tired, we get sloppy. When our back hurts, our performance suffers. When we cannot focus, quality drops off.

A survey by the National Safety Council finds that 90% of U.S. employers have been impacted by exhausted employees. Half of the respondents’ report catching someone sleeping on the job. Ninety percent say they will meet with the affected employee to try to understand the root cause of their fatigue, but only 55% say they would be willing to adjust the employees work schedule as a result.

Furthermore, a Forbes article defines a condition called “boreout” – chronic boredom at work. Studies show that being bored at your job can cause depression, anxiety, stress, insomnia, and higher turnover. A Korn Ferry survey claims that boredom is the top reason why people leave their jobs.

Consider the placement of glue lines in a spiral wound reverse osmosis element. For those not familiar, a spiral element contains a number of “leaves.” Each leaf uses a u-shaped bead of glue to create the active filtration area. Typically, an operator uses a manual glue applicator, not unlike a pneumatic caulk gun, to apply or draw the glue path onto each sheet. Those sheets are then combined with a permeate carrier and rolled into a spiral element. The effectiveness of the finished element relies very much on the placement of that glue path.

Imagine spending your eight-hour work shift leaning over a table and drawing glue paths over and over, hundreds of times per day. I’ll bet that first line is fantastic – straight lines, perfectly placed, in the making an exceptional element. However, I bet that last line – the one right before heading for the door, one last element to hit your goal for the shift – doesn’t need those little lines on the tape measure to check deviation.

In the beginning of this article, I mentioned that the first robotic arm integration we implemented worked with a filtration application. We used a FANUC robotic arm to apply the glue lines onto membranes. Not only does that robot place the line precisely where we tell it, the precision doesn’t waver. It improved the operator’s work life by eliminating repetitive motions, thereby fatigue and boredom stressors.

Also, the throughput increased, and more significantly, increased the effective area of the finished element. Consistent, quality results provide the company sales team more confidence in products they sell, leading to more sales, and so on!

How many companies lost production time during the COVID-19? How many are still worrying about sufficiently staffing each shift? The more we automate, the more we control production demands.

In a machine shop, you can stack boxes of work in front of a row of a manual milling machine, it will get done, with great precision. A skilled machinist will load each piece of raw material into the machine and craft it into a finished part. It will be manually checked against the drawing, and it will function properly to be installed on its intended machine.

I visited again after the machine was installed, and I thought they were going to hug me. No one lost their jobs. Efficiency improved. Each worker was now staying at their position for the full shift. They now had time to conduct quality control testing of the finished products – carefully and not skipping details.

Yet, this all requires the machinist to show up for his workday; not be interrupted with another request; and/or pick and choose the easier jobs first for the day. By automating, not only are we putting the responsibility of quality onto the equipment, but we are streamlining spindle time and machine shop efficiency. We now have equipment capable of running “lights out” manufacturing. We feed it a list of jobs, make sure it has the proper tooling loaded, line up our raw materials, and away we go. We no longer need to

have one man tied to one machine. We elevated machinists to be supervisors of our second and third shifts. They check on the automated cell, then tackle the next job on the list.

Productivity.com gives a nice explanation of automation versus delivery: We need to maximize the labor available to us.

Over the next three decades more than 76 million workers will retire with only 46 million new workers available to take their place. Your labor challenges are not going away!

We offer the following services to our customers:-

MINI-PLEAT-GLASS

Mini-Pleat: H.E.P.A.,

Pleat heights 1/2” to 12” upto 39” wide. Interrupted beads, many configurations.

Mini-Pleat: H.E.P.A. & ASHRAE

Pleat heights 3/4” to 4” upto 25” wide. Interrupted beads, many configurations.

Automation provides the option for 24/7 productivity, “just in time” manufacturing, and more up time. Automation makes time for operators to perform secondary operations like gauging, washing, deburring, etc. It can include real-time factory communications. Equipping new machines with Ethernet connectivity allows you to send production data and communicate with other production equipment. Automation can provide quick changeover for multiple parts, tooling, etc., and flexible multi-operations capability.

Yet, we sometimes must “unlearn” some things. You have to be open to change old habits. You must work closely with your machine designers and builders to reduce bottlenecks in their process to improve quality, get cost out of commodity products, and improve employee satisfaction.

Find partners in this process that seek to collaborate with you, and appreciate being involved from the start of a process review. They should be working not only the top-level management, but also considering the needs of the front-line employees who must operate the equipment daily.

The biggest hurdle is often cost.

As a career salesman, I’ve tackled the “how much” question sometimes just to get in the door of a potential customer. However, when we talk about the cost of automation, we have to make sure we don’t have our blinders on. Total system cost is important and must make financial sense, but other cost factors of lost opportunity, lost productivity, lost time, and lost employees should be added into the equation.

On the plus side, make sure to calculate the new corporate opportunities and employee/workplace benefits that new automation can trigger. The financial or accounting team must consider the long-term gains, as well as the quick ROI calculations.

Here is a notable scenario: Consider investing in machinery versus securities. An example from Investopedia.com illustrates a business with $20,000 of available funds.

In deciding to invest or purchase of a new machine, whichever they choose, the potential profit from the other is called “opportunity cost.” In the example, investing the money would return 10% per year. At the end of the first year, they will gain $2,000. At the end of the second year, $2,200 and $2,420 in year three.

On the other hand, if they purchase a new machine, the company will be able to increase the number of products they sell. The first year will include training, installation costs, and require time before maximum efficiency is achieved. At the end of the year, they may only see a $500 gain in profit. They will begin to hit their stride and gain $2,000 the second year, then the increased sales capacity will earn them an extra $5,000 in year three.

The point is, if we only look at a two-year plan, we are not seeing the full potential.

The key is to be educated and understand what your company is entering into. Automation has complex impacts and is not for every situation.

Here are some things to consider:

High initial investment. Careful planning and ROI calculations are needed with the considerations we discussed earlier.

Technological complexity. There are learning curves and challenges that come with new technology. Such as, now needing an IT person working the factory floor. Job displacement. The goal should be to retrain or relocate employees to a new opportunity in your company. Yet, you may not always be able to elevate your workforce to take on these new roles.

Increase in cyber security protection required. As we connect our equipment to the internet there are dangers associated. Companies should invest in protecting their data assets against cyber risks. In the end, we must find a balance. Consider how you will proceed.

• Carefully select the areas that will most positively gain from automation.

• Train and reskill employees. Don’t make it about simply reducing head count.

• Collaborate with technology partners. You don’t have to go it alone. There are engineering teams dedicated to providing automation solutions. Take advantage of their experience. I’ve seen companies try to keep their automation and engineering projects internal and then repeat the same mistakes others have made.

• Find a partner you can work with and leverage experience. Balance confidentiality with sharing technology. There are times when specific pieces of the puzzle are unique to one customer, but often the bigger picture automation works for the broader market.

Overall, many companies in the filtration industry are still doing the same manual processes. When working with an automation partner, broaden your scope to include improvements in other areas in the future.

Many times, one project leads to another. Planning for it ahead of time can save money later. Automation empowers your production efforts to be ready for growth and potential opportunity. It is the future.

Jay W. Roth is a seasoned industry professional, combining years of sales and leadership experience with an engineering perspective. He can evaluate a company’s production value from many angles to offer a fully integrated approach to machinery and production issues, as well as to identify potential automation applications. With over 30 years of experience, he has helped companies evaluate their facility’s production equipment and processes, to address productivity, quality control, efficiency, including workplace safety concerns.

He has a strong engineering background with degrees from The Pennsylvania State University in both Electrical and Mechanical Engineering Technology and a bachelor’s degree from Drexel University. Working at Elsner Engineering Works, Inc. for 29 years, he started as a fulltime employee in the machine shop while attending Penn State to obtain his degrees. Overall, he spent more than 10 years as a machine designer in the engineering department, combining mechanical and electrical skills. Then, moving into sales, he ultimately oversaw the Elsner Sales team. You can reach Jay at jroth2@comcast.net or 717.873.8717.

New for 2025! The American Filtration & Separations Society (AFS) is partnering with INDA to create a world-class FiltXPO™ conference program.

The two-day FiltXPO conference program will share technical insights in filtration innovations and technologies from industry professionals all over the world. Conference program details will be released in the fall of 2024.

Immerse yourself in the next generation of filtration technologies and innovations. Discover the latest developments from world-class exhibitors. Gain new intelligence on what is driving the filtration market.

Unlock business opportunities, gain exposure to new products, and build connections with key players in the filtration industry. Your next success story starts here.

The urgent need to align our built environment and human health becomes more apparent with every pandemic, wildfire, and the resulting boom and bust of air quality. Unmasking air quality ignorance is essential amid the noise and need for consistent definitions of clean and fresh air, healthy buildings, and sustainable living.

If the health and well-being of city inhabitants is the main intent of building cities, then urban development should have a human-centric foundation. The myopia of focusing only on providing thermal comfort for conventional buildings and their envelopes neglects the intricate connections between the built environment and how it is designed, constructed, and operated.

In today's rapidly urbanizing world, it is evident that human-centric and healthfocused architecture is the essence of enabling sustainable living. Ultimately, worsened urban and indoor air quality

Dr. Iyad Al-Attar

necessitates dynamic governance to mitigate potential health implications due to wildfires, sandstorms, pandemics, weather inversions, industrial accidents, and other environmental disasters. Therefore, policies and politics must govern through technological innovations to navigate the emerging climate change challenges impacting cities and businesses worldwide.

The World Health Organization (WHO) (2014) has identified air pollution as the most significant environmental threat to health, leading to respiratory and cardiovascular conditions. In 2019, greenhouse gas (GHG) emissions from transport and buildings accounted for 15% and 16%, respectively1. Immediate action is needed to steer our planet towards a sustainable trajectory by retooling businesses with sustainable models that embrace purpose and profit. Countries and communities must tap into an ethical shift in how we live, commute, consume resources, generate, and use power. Cities can substantially reduce their emissions by

promoting efficient industrial processes, healthy and energy-efficient buildings while reducing reliance on motorized transport and fossil fuel combustion.

It may seem utopian to tackle urban air quality issues and filtration challenges to improve human health and well-being through reinvigorated urban design. Striving for the highest living standards must go beyond constructing buildings that focus on pleasing aesthetics, structural integrity, and thermal comfort. Incorporating air quality into urban design standards ensures that buildings contribute to, rather than detract from, urban air quality, providing healthy indoor environments for occupants. The premise of understanding the interconnectedness of urban planning lies in addressing the intricate correlation of air quality with other factors such as transportation, energy use, waste management, and land use. Therefore, a holistic approach integrating air quality into these elements gives a starting point for creating cleaner, greener, and more sustainable cities.

Application-focused solutions are necessary to address the insights needed to reduce air pollution and filter out harmful particles that can enter our buildings and respiratory systems. Most aerosols contain a range of particle types and sizes, and to appropriately select air filters, their concentrations and size distributions must be considered. Airborne pollutants such as particulate matter (PM) (Figures 1, 2, and 3), gases, and bioaerosols represent a major health risk to city inhabitants indoors and outdoors. In urban environments, outdoor pollutants emitted from automobile exhaust, power stations, and industries can inundate installed air filters in HVAC systems and infiltrate buildings through structural openings or porous surfaces. Examples of these emissions can range from PM to nitrogen and sulfur oxides, ammonia, radon, volatile organic compounds (VOCs), and microbial volatile organic compounds (MVOCs), which are only a few examples of gaseous pollutants

that can negatively impact urban air quality. When outdoor air is brought indoors through HVAC systems, it can contain high concentrations of contaminants (Figure 4) depending on their geographic location, potentially leading to premature clogging of air filters (Figure 5). Higher concentrations of gaseous pollutants require deep beds of chemical filtration for complete removal, necessitating more space and energy for installation and operation, respectively.

Capturing various contaminants can be technically and economically challenging in light of increasing anthropogenic emissions, and sustainable operation of multistage filtration can be energy-intensive. Therefore, the challenge of urban air filtration for city dwellers – from outdoor to indoor settings – involves addressing complex exposure to multiple pollutants with different physical and chemical characteristics. From a health perspective, a comprehensive understanding of the staggering complexity of multiple pollutants exposure and their impact on HVAC systems and air filter performance is essential.

Air quality can vary due to inconsistent filter performance, where filter capture efficiencies cannot be guaranteed amid fluctuating ambient conditions and urban air quality prompted by environmental events such as sandstorms and wildfires. Indeed, there is an emerging emphasis on widening the lens of air quality to think beyond filtration technologies when drafting and crafting our urban plans.

A comprehensive approach to air quality should entail filtration systems that address gaseous and bioaerosol pollutants, going beyond traditional particle-capture methods (Figure 6). Relying solely on mechanical air filters to capture all contaminants with different concentrations and size distributions is naive. Tackling gases and bioaerosols cannot be overlooked when considering the “freshness” and the “cleanliness” of outdoor and indoor air, considering appropriate filter media selection and their application sensitivity.

Indoor air quality (IAQ) is a critical determinant of health and well-being, especially considering that we spend up to 90% of our time indoors2. IAQ issues are interdependent and not entirely filtrationspecific, and continuing to assume that frequent filter replacement will exonerate facility managers from any IAQ deterioration is a fallacy. The first alignment is knowing what we are up against in terms of pollutant exposures. We can gather valuable data by monitoring the air quality throughout our daily activities, from waking up, taking the elevator, using public transport, working, and returning home.

Today’s air quality monitoring technologies provide reliable and affordable data collection, allowing us to understand what our respiratory systems are exposed to. Such knowledge underscores the importance of technology in monitoring and maintaining healthy air quality in urban environments.