Bitumen & Asphalt

Precast reservoir construction Water & Wastewater IMESA The official magazine of the Institute of Municipal Engineering of Southern Africa www. infrastructurenews.co.za INFRASTRUCTURE DEVELOPMENT • SERVICE DELIVERY • ROADS • BUILDING • MAINTENANCE • ENERGY ISSN 0257 1978 Volume 47 No. 08 • August 2022 • R55.00 (incl. VAT) AECI MUCH

for sustainable asphalt BIM Technology Optimising BIM investments

ASPHALT Solutions

Why pipe jacking is a niche profession Geotechnical

First road-legal CounterMix plant for Southern Africa

The process of Molecular orientation, which greatly enhances the PVC’s physical and mechanical properties, has made the TOM500® PVC-O the most stateof-the-art pipe around. TOM500® PVC-O is unbeatable and you will not find anything else out there that is stronger or more resistant. You can take our word for it!

THE

TOM500 PVC-O

MOST

ON THE MARKET! -STRONGwww.sizabantu.com | proudly@sizabantu.com

ADVANCED PIPES

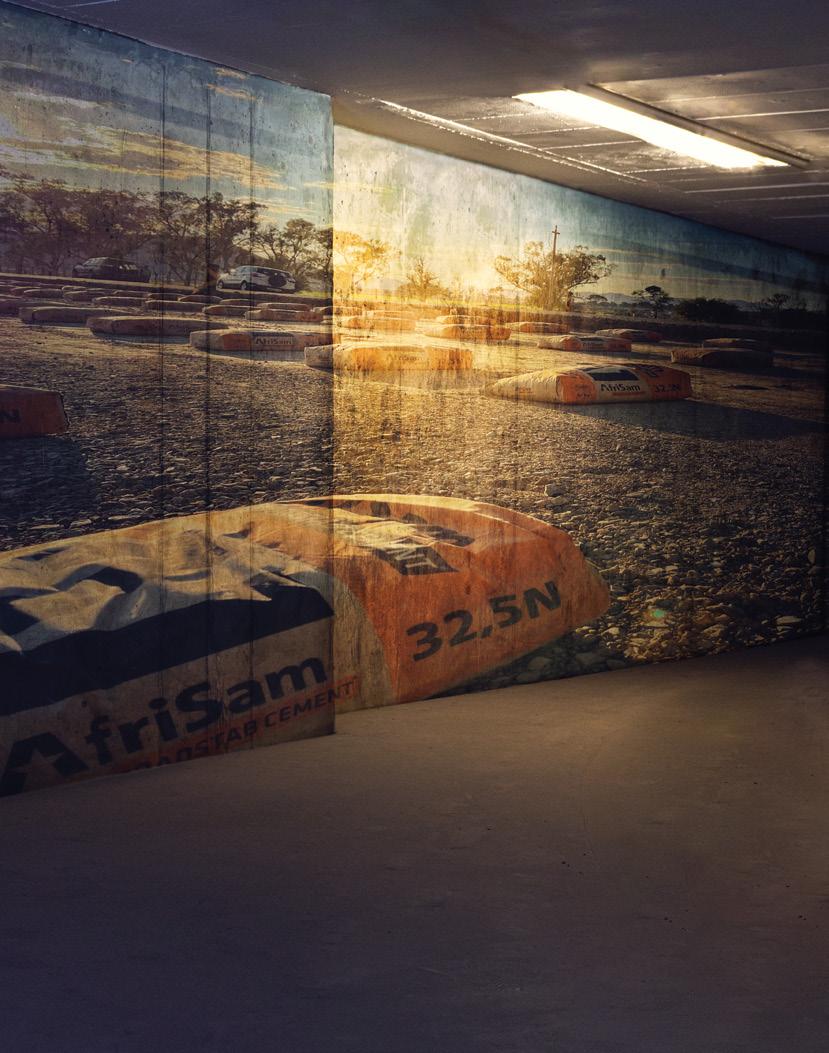

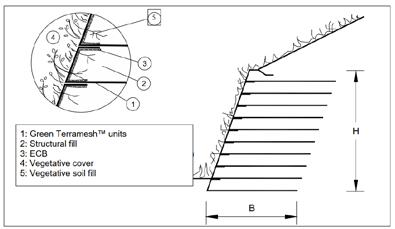

INSIDE VOLUME 47 NO. 08 AUGUST 2022 Precast reservoir construction Water & Wastewater IMESA The official magazine of Municipal Engineering www. infrastructurenews.co.za INFRASTRUCTURE DEVELOPMENT SERVICE DELIVERY • ROADS • BUILDING MAINTENANCE • ENERGY ISSN 0257 1978 Volume 47 No. 08 August 2022 • R55.00 (incl. VAT) AECI MUCH ASPHALT Solutions for sustainable asphalt BIM Technology Optimising BIM investments Bitumen & Asphalt First road-legal CounterMix plant for Southern Africa Why pipe jacking is a niche profession Geotechnical ON THE COVER Paving of New Crumb Rubber Technology warm-mix asphalt produced by AECI Much Asphalt on Clarence Drive between Gordon's Bay and Rooi-Els. P6 www.infrastructurenews.co.za Regulars Editor’s comment 3 President’s comment 5 Index to advertisers 56 Cover Story Solutions for sustainable asphalt 6 BIM Technology Getting the best value from BIM investments 10 ISO 19650 in South Africa 12 Water & Wastewater Precast concrete system accelerates reservoir construction 14 Are we driving a car without a fuel gauge? 18 Energy Taking action to bridge South Africa’s power gap 20 Women in Construction Women winning in construction –ERWIC Awards winners announced 22 Roads & Bridges Innovative solutions to African challenges 25 The road to smart mobility 26 Bitumen & Asphalt First road-legal CounterMix plant for Southern Africa 30 SATBinderrr 2022 – Reasons to be there 33 Flexible and adaptive to a changing world 30 An engineered response to pothole repairs 36 Transportation Engineering Public transport models that work 38 Geotechnical The benefits of reinforcing slopes with Green Terramesh 42 Why pipe jacking is a niche profession 44 Buildings Dinosaur-themed brickwork 46 Landfill & Waste Management Investment in mechanisation to boost municipal waste compliance 47 Green interventions for Kampala 48 Vehicles & Equipment All the bells and whistles for new E-series water tankers 50 Compaction innovation on show at bauma 52 Cement & Concrete Rocla and Technicrete recognised at CMA Awards 53 Watertight solutions for new treatment works 55 Economical foamed concrete suitable for limited budgets 56 42 GEOTECHNICAL BITUMEN & ASPHALT 36 30 50 VEHICLES & EQUIPMENT

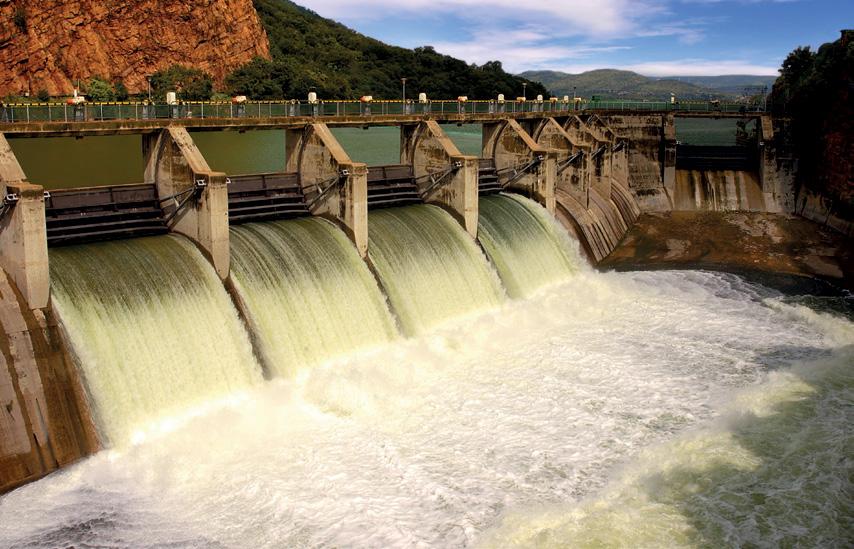

wireless Monitoring

Dam & Basin Water Levels

• Digital Water Level and Conductivity Sensors

• Highly Precise 0,02%FS*

• Wired Readout with Standard Process Signals

• Wireless Readout with ARC1 Modem Datalogger by 4G, NB-IoT (Cat M1 / M2) or LoRa

• Compatible with KELLER Kolibri Cloud

keller-pressure.co.za

Series 36XW Level Series 36XiWCTD Level Conductivity Series 46X Ultra Low Levels 2G 3G 4G

precision at room temperature, accuracy 0,1% FS total error band

*

MANAGING EDITOR Alastair Currie

SENIOR JOURNALIST Kirsten Kelly

JOURNALIST Nombulelo Manyana

EDITORIAL COORDINATOR Ziyanda Majodina

HEAD OF DESIGN Beren Bauermeister

DESIGNER Lizette Jonker

CHIEF SUB-EDITOR Tristan Snijders

CONTRIBUTORS Tian de Jager, Willie de Jager, Vernita Govender, Kobus Kotze, Thivaska Padayachee, Roger Parsons, Bhavna Soni, Astrid van der Laan

PRODUCTION & CLIENT LIAISON MANAGER

Antois-Leigh Nepgen

GROUP SALES MANAGER Chilomia Van Wijk

BOOKKEEPER Tonya Hebenton

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS subs@3smedia.co.za

PRINTERS Novus Print Montague Gardens

ADVERTISING SALES

KEY ACCOUNT MANAGER Joanne Lawrie

Tel: +27 (0)11 233 2600 / +27 (0)82 346 5338

Email: joanne@3smedia.co.za

The need for a renewed FOCUS ON ROADS

Arenewed focus on road and bridge maintenance, and new construction, is one of the most crucial infrastructure investment priorities for the South African government. This initiative is vital for socio-economic development in both the local urban and rural context, together with the key importance of transport conduits for cross-border trade and ensuing worldwide connections via regional port and air hubs.

in facilitating knowledge exchanges between engineers, contractors and municipalities. The second in the series will be held virtually on 5 October and is highly recommended for all industry practitioners in this segment. Collaboration is the foundation for future success.

Road conferences to attend

PUBLISHER Jacques Breytenbach

3S Media

Production Park, 83 Heidelberg Road, City Deep Johannesburg South, 2136

PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600

www.3smedia.co.za

ANNUAL SUBSCRIPTION: R600.00 (INCL VAT) ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2022. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste Vosloo

Tel: +27 (0)43 705 2433

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Narisha Sogan

Tel: +27 (0)31 266 3263

Email: imesakzn@imesa.org.za

NORTHERN PROVINCES

Secretary: Ollah Mthembu

Tel: +27 (0)82 823 7104

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Olivier

Tel: +27 (0)79 390 7536

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7114

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma Van Der Walt

Tel: +27 (0)83 457 4362

Email: imesafsnc@imesa.org.za

All material herein IMIESA is copyright protected and may not be reproduced without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers.

The national tolled and non-tolled routes managed by Sanral are maintained according to world-class standards. However, the condition of municipal and provincial roads varies from the occasional pothole to situations where a complete failure has occurred, with in situ recycling and reconstruction required.

Routine maintenance versus temporary repairs

As experts point out, key reasons for these failures include a lack of routine maintenance, compounded by the fact that many roads across South Africa are nearing the end of their serviceable life. In this edition, Johan Hattingh from PHB Consulting Engineers talks about the occurrence of potholes, as well as their causes, with a major emphasis on determining the right repair interventions. Without a detailed engineering insight, combined with expert experience, potholes simply become temporary patch repairs and in certain instances accelerate the deterioration of the surround pavement.

The upside is that routine maintenance lends itself to labour-intensive construction, skills transfer and SMME development. However, the extent to which programmes can be executed effectively depends on up-to-date condition assessment surveys, training and the availability of suitably qualified technical personnel within municipal and provincial roads departments.

Industry initiatives

Initiatives like Sabita’s first Roads Maintenance Forum, launched in April 2022, are invaluable

Upcoming local conferences like SATBinderrr 2022 (21 to 22 September) and the 7th Regional Conference for Africa (18 to 20 October) provide opportunities for more in-depth public and private sector engagement, while serving as a platform for showcasing South Africa’s best-in-class expertise to the world.

Project pipeline

At present, there is a shortage of work available within the roads sector, despite an obvious need. That made the headlines recently when five Sanral tenders amounting to some R17 billion were unexpectedly put on hold.

The Development Bank of Southern Africa (DBSA) was subsequently appointed “to act as the infrastructure procurement and delivery management support agency” to help get these projects back on track. DBSA’s scope includes the evaluation of compliance, plus independent construction management oversight once the tenders have been awarded. Hopefully, a fresh pipeline of Sanral work will start flowing through towards the end of 2022 and into 2023.

In the meantime, municipalities with urgent road maintenance requirements, available budgets, but limited internal capacity, should reach out to private sector investors and construction industry practitioners for the best advice and solutions.

IMIESA August 2022 3 Alastair EDITOR’S COMMENT To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

opportunity In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Joanne Lawrie on +27 (0)82 346 5338. Infrastructure News @infrastructure4 construction Water & Wastewater S IMESA infrastructurenews.co.za AECI MUCH ASPHALT Solutions for sustainable asphalt BIM Technology Optimising BIM Bitumen & Asphalt First road-legal CounterMix plant for Southern Africa Why pipe jacking is a niche profession Geotechnical The ABC logo is a valued stamp of measurement and trust. IMIESA is ABC audited and certified.

Cover

a Level 2 BBBEE Contributor: novus.holdings/sustainability/transformation

Novus Holdings is

DATES: 2-4 N ovember 2022

VENUE : Birchwood Hotel

THEME: Adapting to our changing world

Register and pay BEFORE 31 July 2022

• Members: R6 700

• Non-members : R8 000

t: +27 (031)266 3263

e: conference@imesa.org.za marketing@imesa.org.za www.imesa.org.za

REGISTRATION Register and pay AFTER 1 August 2022

• Members : R7 500

• Non-members : R8 900 HAVE YOU REGISTERED FOR THE

EARLY

BIRD REGISTRATION

STANDARD

IMESA

CONFERENCE YET?

IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) CONFERENCE ENDORSED BY

EVENT: 85 TH I MESA Conference

Earn 2.5 CPD points

attending

today.

advantage of the EARLY BIRD RATE

SAVE! CONTACT US FOR DETAILS

by

Register

Take

and

Working together to shape a BETTER WORLD

August is Women’s Month in South Africa and provides an opportunity to celebrate our role as vital change-makers in society.

This year’s South African theme was ‘Women’s Socio-Economic Rights and Empowerment: Building Back Better for Women’s Improved Resilience’. Simply put, it is about breaking down barriers, and freeing women from discrimination and gender-based threats – themes that were also reflected in various International Women’s Day (IWD) initiatives for 2022.

The UN’s 2022 IWD theme was ‘Gender Equality Today for a Sustainable Tomorrow’. Another theme run by a private sector funded IWD programme was #BreakTheBias. Both themes sum up the objectives for global transformation as a year-round movement in line with UN Sustainable Development Goal 5 on gender equality.

The reality is that girls and women in South Africa – and globally – still face various degrees of bias influenced by factors such as cultures and customs, access to education, financial circumstances, mentorship, and government policy. Bridging the gaps needs ongoing awareness and collaboration, plus equal opportunities for girls to benefit from STEM programmes starting at primary level.

IMESA’s standpoint

Within IMESA, we are committed to inclusivity and the empowerment of women, with a renewed drive on creating that crucial mindset shift. Our contributions include education and training, as well as bursaries for qualifying students.

As the first woman president of IMESA, since its founding in 1961, I’m especially honoured to have been able to help move the agenda forward, along with my counterparts within the International Federation of Municipal Engineering (IFME) – of which IMESA is a member.

It’s also significant to note that IFME recently elected their first woman president, Sanne Hieltjes, who is based in The Netherlands. I’m pleased to confirm that Sanne will be a keynote speaker at our upcoming IMESA 85th Annual Conference in November 2022, where she’ll share some of her thoughts and experiences within the municipal engineering arena.

The ultimate multitaskers

Like many women in my field, I am a wife, mother, engineer and manager. And as any woman knows, raising a family and building a career is never easy. The fact that I’ve been able to do both is due to a combination of factors, which started during my formative years in India. Encouraged by my parents, I decided to enroll for a BSc in Civil Engineering at South Gujarat University.

Although it wasn’t common for women to study engineering, the door was still open to anyone with interest and aptitude. As a first-year student, I started out with a class of around 500, of which only 12 were women. Most, if not all, went on to pursue successful careers.

In my case, and after several years working in the Indian construction sector, my path led me to South Africa where I joined eThekwini Municipality in 1997 as a structural engineer. My manager at the time identified my passion for water and sanitation infrastructure and encouraged me to specialise in these disciplines. The rest is history. Along the way, I’ve been blessed by a son and daughter, both of whom are now qualified medical doctors.

Hard Hats and Stilettos

The point to emphasise is that women have as many skills and abilities to contribute to all work environments and should not be subjected to

stereotypes in terms of which vocations are most suitable based on gender. Those were among the topics presented during our IMESA Women’s Day Breakfast in Durban.

Themed ‘Hard Hats and Stilettos – Getting the Job Done’, it was a wonderful opportunity for women to share what it takes to succeed in a technical field. The keynote speaker was Mabuyi Mhlanga from Sanral, who presented an inspiring talk on the planned upgrades and innovative engineering required for the EB Cloete Interchange N2 North and N3 West in eThekwini.

The fact that more woman engineers are now leading in senior roles is encouraging, both from an equity perspective, as well as in developing frameworks where woman team members can contribute to achieving the critical solutions needed to make a real difference in this fastchanging world.

Women are now major influencers in helping to shape our built environment. We just need to accelerate the process so that men and women – together – can excel and in turn empower their children and communities.

IMIESA August 2022 5 PRESIDENT’S COMMENT

IMESA

Bhavna Soni, president, IMESA

Solutions for SUSTAINABLE ASPHALT

It is not an option to continue as normal and wait for the tide to turn,” says Bennie Greyling, CEO, AECI Much Asphalt. “As a company, we are proactively preparing for what will be a very different future.”

He points out that the Covid-19-induced shutdown of the asphalt industry has been followed by several other potentially devastating impacts. “Delayed and cancelled road construction and rehabilitation projects are now normal for various reasons, despite the public outcry on the condition of our roads,” says Greyling.

Also threatening asphalt and binder production is the fact that only one South African refinery, NATREF, is currently producing petroleum-based products. “We are therefore

Within an environment currently characterised by significant risks, AECI Much Asphalt is putting its focus firmly on sustainability in response to the challenges faced by the asphalt industry following the Covid-19 pandemic.

importing bitumen on a large scale and putting extensive measures in place to ensure that we receive quality products to adhere to our stringent specifications,” Greyling explains.

Advantages of bitumen

Greyling adds that bitumen, as the bottom of the crude oil barrel, is the only crude component material that does not require further combustion processing to be useful in everyday life.

“Refined fuels, comprising the remainder of the barrel, are essentially ‘burnt’ during singleuse activities such as heating or transport, adding significantly to the emissions count during their use. Bitumen used during asphalt production does not contribute further to carbon emissions, but instead is neutralised during its many years of useful life in a roadway in its natural state as it was obtained from the refining process,” says Greyling.

AECI Much Asphalt subsidiary AECI SprayPave now produces 10/20 penetration grade bitumen through its multistage bitumen converter in Cape Town – one of only two in the world – using feedstock bitumen from NATREF or through importation.

“This capability is critical to us at present, with no other source of 10/20 penetration grade bitumen available in South Africa,” Greyling points out.

To remain sustainable in increasingly challenging market conditions, AECI Much Asphalt is also exploring new business opportunities, investigating strategies to replace non-renewable aggregate materials

in the manufacture of asphalt, and putting measures in place to conserve energy and reduce its carbon footprint.

“Broadly, we aim to seek non-traditional revenue streams, expand our footprint into Africa, and focus on operational efficiencies to remain a best-cost and quality producer,” he explains.

“I am very proud of our teams who are demonstrating their commitment by putting safety first despite all the setbacks of the past few years. Our safety record has improved from one of the worst in the AECI group to one of the best. This is a great platform on which to build our future.”

Driving sustainability

The drive to sustainability for AECI Much Asphalt goes further than the company’s bottom line. Greyling believes that as a leader in the South African asphalt industry and the biggest commercial supplier of asphalt in sub-Saharan Africa, the company has a responsibility to pioneer new and more sustainable, environmentally friendly products that also improve quality, longevity and safety for users.

Aggregates extracted from the earth such as sand, gravel and crushed stone make up about 95% of an asphalt mix by mass. “The need to explore alternative materials that can reduce our industry’s dependency and impact on the environment is critical,” says Joanne Muller, regional technical manager: Gauteng, AECI Much Asphalt. “When the solutions also reduce waste streams that are not recycled into other materials or products, this is a step in the right direction.”

The material most often recycled in the asphalt industry consists of existing sections of road that are milled out due to upgrade or rehabilitation. Most new asphalt produced at

COVER STORY

6 IMIESA August 2022

Trial at the University of Pretoria in collaboration with the CSIR, using nonrecyclable waste plastic as an aggregate and binder modifier in the asphalt

AECI Much Asphalt’s production plants around South Africa contains between 5% and 20% reclaimed asphalt.

“An extremely small proportion of reclaimed asphalt goes to waste, reducing not only the dependency on virgin aggregate from quarries, but also the volumes of virgin bitumen required from fossil fuel industries,” Muller points out.

Slag and tyres

AECI Much Asphalt’s extensive footprint has enabled some of its production facilities to leverage other aggregate streams to reduce the use of virgin aggregates. One example is the plant in Witbank where several asphalt products are manufactured using recycled slag aggregates.

Slag aggregates are obtained by processing waste material from smelting operations in steel manufacturing, among others. The waste consists mainly of the flux used to remove the impurities and/or non-ferrous constituent materials from the ore. The replacement of approximately 20 000 t of virgin aggregate with slag aggregate annually over several years has contributed greatly to the drive for sustainable use of materials at this plant.

The use of recycled ground tyre rubber into asphalt mixtures at several AECI Much Asphalt production facilities has multiple benefits. It reduces the volume of virgin bitumen used by replacing about 20% of the binder in the asphalt, aids pavement longevity, reduces noise pollution on the road, and results in fewer tyres going to landfills.

Pushing the boundaries

Some years ago, assessments by the CSIR and AECI Much Asphalt showed the use of non-recyclable glass to be technically viable as a partial aggregate replacement. Certain low-impact niche applications were identified

for further exploration and AECI Much Asphalt is collaborating with Interwaste, an integrated waste management provider, in investigating alternative recycling streams for glass waste destined for landfills.

An upcoming trial will involve the production of 20 t of hot mix asphalt, incorporating 10% waste glass, at the Eerste River plant for placement on walkways at the Strand Golf Club in the Western Cape.

Together with the CSIR, AECI Much Asphalt is also actively tackling the significant problem of waste plastics. Two full-scale trials done to date have focused on the proportion of nonrecycled and non-recyclable waste plastic that can potentially be used as an aggregate and binder modifier in asphalt.

Aspects considered include the potential presence of microplastics that may contaminate water courses. However, data to date shows product performance improvements and no environmental contamination.

Energy efficiency

As the production of hot mix asphalt requires heating to temperatures in excess of 140˚C, energy used is a significant factor in the cost and environmental impact of the final product.

IMIESA August 2022 7 COVER STORY

Ultra-thin porous surfacing with A-R 2 (warm mix ground tyre rubber binder) on the N5 in Harrismith, supplied by the Bloemfontein plant

The mix that went down in the first trial by AECI Much Asphalt using non-recyclable plastic

Much Asphalt’s Benoni flagship facility

THREE INTRINSIC VALUES: ACCURACY, RELIABILITY AND EASE OF USE. THE 6X ®. OUT NOW! Admittedly, at first glance, you can’t tell what’s inside the new VEGAPULS 6X radar sensor: A high-precision level instrument that doesn’t care if its measuring liquids or bulk solids. Only its colour gives you a hint that it’s going to be great to use. VEGA. HOME OF VALUES. www.vega.com/radar

“We are continually exploring improvements to the energy efficiency and carbon footprint of our operations,” says Muller. “Our first grid-tied solar installation was recently commissioned at the AECI Much Asphalt Benoni plant laboratory and offices.”

This pilot project for the group will now be extended to include the Gauteng regional offices and the regional laboratory, in turn expanding the overall impact footprint to other production facilities in the group that use the regional facilities.

Bitumen heating is one of the main consumers of energy at asphalt plants. The Benoni facility already uses natural gas in place of burner fuel to dry and heat material during the production

of asphalt. This plant is now conducting a feasibility study into gas generator technology to replace standard heat sources for bitumen heating. A potential CO2 emissions reduction of up to 50% is anticipated from this process.

The project entails the design, manufacture and installation a 201 kVA combined heat and power gas generator to power the heating of the bitumen tank farm for the site. Scavenged heat from this fixture will serve as an alternative heat source in the manufacturing process, with significant positive impacts for product quality and timeous delivery to sites.

All AECI’s business activities are underpinned by the group’s BIGGER values of being Bold, Innovative, Going Green and being Engaged

Asphalt core containing waste glass and Responsible. AECI Much Asphalt is confident that its drive for sustainability meets every one of these values.

www.muchasphalt.com

Recycled asphalt feeding from the screening plant

COVER STORY

IMIESA August 2022 9

Hot mix asphalt trial incorporating waste glass

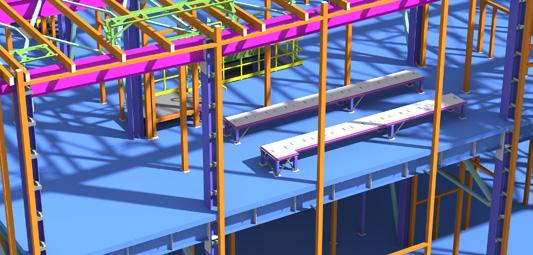

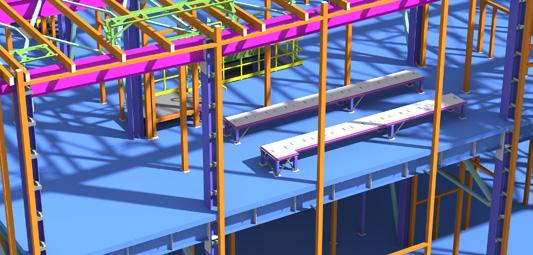

GETTING THE BEST VALUE

from BIM investments

Building information modelling (BIM) continues to evolve into all facets of the global built environment; however, in South Africa, more widespread adoption is needed to effect meaningful digital transformation.

By Alastair Currie

The key advantage of BIM is that it enables enhanced, cloud-based data sharing and collaboration in unprecedented ways by multidisciplinary project teams to plan, design and construct structures ranging from buildings and roads to industrial complexes and wastewater treatment plants,” explains Tammy Venter, PrArch, AEC team lead and BIM implementation specialist at Modena Design Centres (Durban). Modena is an Autodesk Platinum Partner and provider of architecture, engineering and construction (AEC) consulting services.

“BIM is an intelligent virtual process that passes on significant time, cost and quality benefits, but implementing it effectively requires a culture change within the construction industry, as well as within individual organisations,” Venter continues, adding that BIM adoption also needs to be driven more at tertiary level to prepare nextgeneration professionals.

Technology leaders

“For BIM to work within organisations, the transition process needs to be led by its business leaders and adopted holistically, working in conjunction with their design and project teams,” Venter explains. “Ideally, the process should be spearheaded by a BIM leader, chief technology officer or similar to select the right people, processes and software tools.”

While some may view the adoption of BIM methodologies and technology as an unnecessary added cost, Venter says that once organisations experience the productivity benefits, there is a permanent transition from traditional standalone 2D and 3D design practices.

BIM goes beyond 3D design to incorporate time, cost and as-built drawings – respectively referred to as 4D, 5D and 6D – within a real-world simulation model that can be accessed by project team members that include the architect, design engineers, quantity surveyors, contractors and subcontractors. Working in the cloud, all stakeholders are able to collaborate in one environment and draw data from a single source of truth, maximising productivity benefits and project predictability.

Optimising workflow

“With BIM, you build what you envision, aided by a series of software tools to interrogate, test and validate. The selection tools will depend on the nature of the business. For example, architects and engineers will each have their own specific requirements,” Venter explains.

Modena’s consulting services determine the optimal IT infrastructure requirements in conjunction with fit-for-purpose software, supported by ongoing education and training.

At the centre is Autodesk’s BIM software, which enables the importing, rendering and management of data during the

BIM TECHNOLOGY

Tammy Venter, AEC team lead and BIM implementation specialist at Modena Design Centres, Durban

10 IMIESA August 2022

design, construction and operations phases. The detailed 3D digital models created can communicate seamlessly with the Autodesk and competitor CAD software packages on the market.

A major plus is that, as the design stages develop, the BIM model is continually updated in real time with fresh data to incorporate revisions in terms of aspects like elevations, plans, sections and schedules.

Venter says that a growing number of construction companies in South Africa are switching to BIM to streamline their interdepartmental collaboration on projects and avoid duplicating data. BIM’s cloud-based approach also enables engineering firms to communicate effectively between the design office and site teams as construction progresses.

A culture of learning

Successful BIM implementers embrace learning as a culture and understand that the internet of things is rapidly changing how built environment professionals interpret data during their modelling, design and project execution processes.

“Errors and the need for rework can be significantly reduced, with projects completed on time and within budget,” Venter continues, adding that BIM workflow data, along with Autodesk Construction Cloud’s data management system, can also prove invaluable in arbitration disputes.

In preparation for BIM training and implementation, Modena’s approach starts off by getting to understand the client and their internal structures. “We then identify key players that we believe will be instrumental in facilitating BIM integration, leading the change within their organisation,” she explains.

“Translating an organisation’s CAD processes into a BIM environment can be challenging and it takes time. Our training support is therefore crucial as team members experience their first live BIM project. Over time, our role is to facilitate the cross-pollination of knowledge to

the point where organisations can thrive independently,” Venter explains.

Adding predictability

BIM is a concept, methodology and process that has redefined project and programme management. This is an especially important factor within the current inflationary environment, where price escalation is unpredictable.

“BIM – by its nature – provides a high level of predictability and repeatability. Going forward, artificial intelligence will play a key role here in manipulating and automating processes. However, the human interface is what drives the process,” Venter continues.

Asset and facilities management

Asset management and facilities management are also being enhanced with BIM to create more cost-efficient and greener structures.

“There are BIM software modules – such as Archibus and SpaceIQ – that enable facilities managers to access a database of parts and components, as well as specific serial numbers, warranties, guarantees and manuals. You can also calculate energy consumption as well as future operations and maintenance costs,” says Venter.

Within the world of BIM, the ISO 19650 standard series maps out the framework for optimally managing information over the entire life cycle of a built asset, irrespective of its scale. This includes upfront planning, design, engineering, construction, document management, refurbishment and end-of-life.

“Once mastered, BIM is not complicated; it’s just geometry with information attached to it to create a single source of truth. BIM interfaces with any environment that requires information, like database management, GIS, 3D scanning and digital twinning platforms. Essentially, and thanks to digital technology, BIM takes us into an exciting new world of better information management,” Venter concludes.

Gabions and River Mattresses

Gabion Rocks

Hexagon Wovenmesh

Square Weldmesh

Geotextiles

Gabion Tool Sets

Biodegradable Soil Blankets

Soil Bioengineering

Sandbags

Gabion Barriers

011 882 5788 www.gabionbaskets.co.za

ISO 19650 IN SOUTH AFRICA

The

importance of pursuing global BIM standardisation and certification trends

We are currently facing a global evolution of professional work. With the rise of the Fourth Industrial Revolution, and the buzz around the potential impact of artificial intelligence, machine learning and big data, there are still many professionals in the architecture, engineering and construction (AEC) space asking, “What is BIM?”

By Astrid van der Laan*

Building information modelling (BIM) – a collaborative process involving the generation and management of digital representations of physical and functional characteristics of places –is a concept that has been in development for a few decades, gaining prevalence in the early 2000s. The ongoing development of standards surrounding BIM has led to the international ISO 19650 standard.

Adapted and developed from the UK PAS 1192 standards, the ISO 19650 standard suits both vertical and linear project approaches. Thus, it is relevant to all stakeholders within the AEC industry.

ISO 19650 ‘Organisation and digitisation of information about buildings and civil engineering works, including BIM’ currently consists of several parts, with some still in development. ISO 19650-1:2018, namely Part 1 ‘Concepts and Principles’, is currently

a SABS Draft Standard – the public enquiry stage ended on 31 July 2022.

Existing standardisation within the AEC industry, construction contracts, building methods and professional titles are well established and regulated. But there is no agreed-on consensus as to what a BIMcapable individual or organisation should be able to do. And, erroneously, BIM has become synonymous with software competencies. The current lack of a unified

12 IMIESA August 2022

BIM TECHNOLOGY

JOIN US!

BIMcommUNITY.Africa brings together all built environment industry stakeholders. We are a rallying point for BIM initiatives in the country and are currently driving the adoption of ISO 19650 through the SABS. We are in the process of garnering support for a BIM Codesa – an initiative that brings every stakeholder in the built environment together to craft a way forward to achieve the Digital Transformation of the Built Environment.

We welcome any person or company to join us and help us Raise the BIM Tide. Join BIMcommUNITY. Africa and stay abreast of the latest developments. Email angela@bimcommunity.africa or visit www.bimcommunity.africa.

framework leads to a focus on technology. BIM processes may indeed make use of the latest technology; however, technology should not be the driver.

Those of us making use of BIM tools and processes have considered working collaboratively in tandem, but we often end up adding an extra layer of complexity, with additional software solutions, extra modelling requirements and 3D collaboration deliverables – all over and above the existing documentation and contractual obligations surrounding a built project.

Bearing in mind that there is currently no globally agreed-on specification against which an individual can be ISO 19650 BIM accredited, there definitely is a need to seek training and certification.

At present, there are nowhere near enough ISO 19650-BIM-savvy people within the AEC industry to make BIM processes business as usual. The current ISO 19650-ready practitioners need a much larger majority of people throughout the industry to upskill and maintain the momentum required to see the standard adopted successfully.

So rather than being part of the crowd waiting until they’re forced to learn, it is highly beneficial to peruse any relevant training now. This will benefit not only an individual, but their organisation as well as the entire AEC industry, which will be better off for it.

“One of the things we’re working on as a community is to work across the whole value chain to assess what information each stakeholder requires, ensuring every stakeholder has all the information relevant to them. Then we move from ‘information for information’s sake’ to ‘the right information, to the right person, at the right time’.”

– Angela Lang, BIMcommUNITY.Africa

Key criteria

The following are what to look for in BIM certification programmes:

• It’s not about attendance certificates, but demonstrated capability.

• It’s not about what software to use, but the information to exchange.

• It should focus on the information management process, not the data generated.

Increasingly, such training should also address the need for improvement of soft skills for information managers, who are driving the digital transformation within an organisation. However varied the roles of individuals seeking certification, ISO 19650 is ultimately about information management.

There are over 40 activities within an allencompassing ISO 19650 standardised information management process, and no one person has the capability, capacity nor authority to undertake all of them. Over half of these activities are upstream of BIM model production. No one person is an expert in the entire process, one just needs to understand how to undertake their role effectively. Seeking ISO 19650

certification is but one pillar in organisational accreditation; companies that already focus on well-organised and thorough workflows for managing information are well on their way.

Information and business goals

An organisation should be able to demonstrate capability and capacity to undertake a role; confirming that specific people on a specific project have been evaluated for their roles. It should also align information goals to business goals, identifying defective workflows and mitigating negative effects, rather than just advocating the positives of successful BIM implementation.

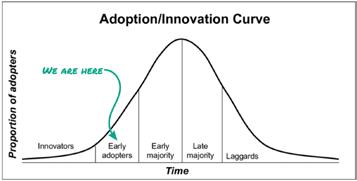

Accepting ISO 19650 Part 1 nationally is only the first step. Understanding that the implementation strategies surrounding the standards are still developing is critical. We are all learning, implementing and trying to do things better. Rather than implementing something different for every built project, let’s get everyone behind the same standard. Let’s move the industry past the question: “What is BIM?”

*Principal computational designer, Zutari, and member of BIMcommUNITY.Africa

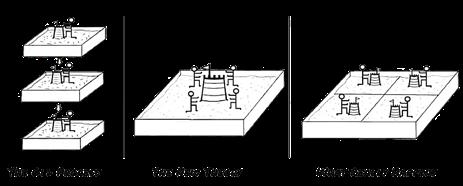

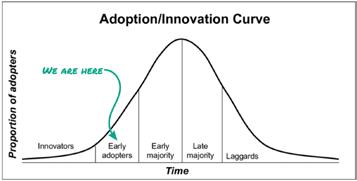

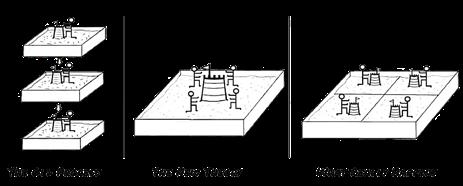

The Rogers Adoption Curve

(Source: https://www.researchgate.net/figure/Adoption-Innovation-CurveAdapted-from-Rogers-1995_fig3_228757766)

IMIESA August 2022 13

BIM TECHNOLOGY

TPrecast concrete system

his system enables various trades to work simultaneously, saving construction time in the process. Using cast-in-place methods, work starts with the construction of the concrete floor slab, followed by the wall and ending with the roof.

The roof and wall of a 25 M ℓ reservoir were erected recently, in as little as three months after the cast-in-situ floor, as were the bases for the precast concrete roof structure and ring foundation, which were completed by the principal contractor. This reservoir has an inside diameter of 65.2 m and water height of 7.8 m. The roof column grids for the roof slab and beam span are 10.87 m by 10.87 m.

ACCELERATES RESERVOIR CONSTRUCTION

The construction of reservoirs ranging between 10 Mℓ and 60 Mℓ in size is being significantly accelerated using a unique precast concrete system that was designed in South Africa.

The system harnesses the precast concrete design skills and experience of Infinite Consulting Engineers and Corestruc’s know-how in concrete design and application, as well as rigging and erection. It is manufactured by precast companies that have been approved by Corestruc to ensure a final structure of the highest possible quality.

By Willie de Jager, Kobus Kotze & Tian de Jager

appropriately maintained. This is considering that the concrete used to manufacture the various prefabricated elements that make up the system has a permeability index that far exceeds 10, a sorptivity index well below 6 mm/√h, and a chloride conductivity of less than 0.75 mS/cm.

These reservoirs have been designed to provide up to 100 years of service if they are

Self-compacting concrete is used to manufacture elements that contain significant reinforcing and where conventional vibrating pokers cannot be used effectively. Trial mixes are prepared and tested for strength and durability, while also taking into consideration the workability of the concrete. Working in controlled factory environments, the perfect dosages of admixtures are also achieved to ensure timely strength development, which is imperative for uninterrupted production.

In these factories, the perfect water-tocement ratio is also maintained to ensure concrete strength. Moreover, aggregates

from suitable suppliers are graded appropriately to avoid early concrete shrinkage.

The prefabricated elements are inspected and approved for dispatch to ensure the accuracy of the placement of the cast-in components. Reinforcement bar size and placement are also verified as part of the quality control procedures at the approved factories.

Setting out and installation

These steps are complemented by the checks and balances introduced by Corestruc ahead of mobilising to site to commence erecting the structure. The company manages the setting out and installation of the column anchors for the precast concrete roof. By confirming the dimensional accuracies before erection, the company ensures that the beams of the roof structure fit the first time round. The precast concrete wall panels are placed and positioned in a similar manner with the assistance of permanent locating plates that are fixed to the ring foundation. As an extension of the principal engineering consultant’s office, Infinite Consulting Engineers provides professional project input. The firm also collaborates

C M Y CM MY CY CMY K

WATER & WASTEWATER

14 IMIESA August 2022

The precast concrete system consists of a prefabricated roof and wall

with the engineering team to ensure that the various aspects of the work scope integrate seamlessly to avoid delays. Moreover, Infinite Consulting Engineers approves and accepts liability for the final precast concrete structure.

Constructing the roof structure

The roof structure consists of hollow-core slabs that are placed on precast concrete beams, which are supported by prefabricated columns. They are connected to the in situ bases by components that are cast into the precast concrete columns, also referred to as column shoes.

Similar to the construction of a conventional steel structure, the precast concrete columns are connected to hold-down bolts in the base. Suspended precast concrete beams are then installed on to the columns. They are secured with dowels that protrude from the columns.

The hollow-core slabs are then installed on to the beams and secured in place. This is achieved by tying the steel reinforcing and placing in situ concrete into the cores of the prefabricated slabs. Stirrups protruding from the precast concrete beam act as a

mechanical interlock to form a composite mechanism with infill concrete.

Using traditional methods, a reservoir roof is the most complex and timeconsuming aspect of the entire build. It is undertaken once the wall and in situ columns reach their final height. Many tonnes of scaffolding must be installed inside the reservoir to support the forms for the frame of the roof structure. The extensive associated reinforcement and concrete works, including placement and stripping of the shutters, also requires close and careful management. This is in addition to the timely coordination of the concrete trucks to site for the continuous concrete pours.

Circular walls

The circular precast concrete wall comprises panels that have been prestressed vertically. They feature 32 mm diameter polyvinyl chloride sleeves that have been positioned according to the post-tensioning design.

The panels are placed into position and then supported by push-pull props and

steel brackets at the top of each. Unbonded cables are pushed through the sleeves, which are then grouted monolithically with the joints of the panels.

The grout is poured continuously in-between the wall panels and horizontal cable sleeves. It is important to achieve a high-strength, high-flow grout with an extended pot-life and free of segregation. To achieve this, the water-to-cement ratio of 0:37 is manipulated with the use of admixtures and the water temperature reduced and controlled to act as a chiller in the mix. Furthermore, only cement is used in the grout mix, which also contains an unhydrated cement that reacts with water and seals possible leaks.

After the grout has cured to a strength of 80 MPa, the cables are stressed to 75% via precast concrete buttress panels that have been spaced along the perimeter of the reservoir.

The wall is then pinned by casting a 200 mm to 250 mm high reinforced kicker on the wall footing on both sides of each panel. Joints between the panels are grouted with a high-flow, high-strength

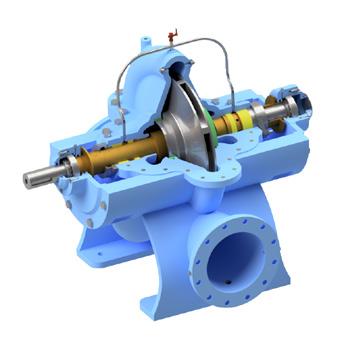

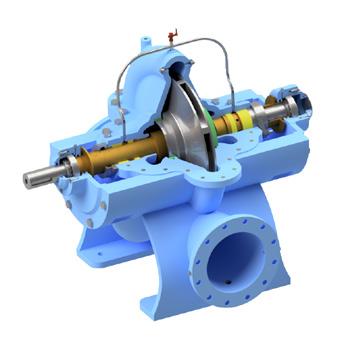

Operating Range

Flow - 10m³/hr up to 2500m³/hr

Head - 4m up to 120m

Applications - General liquid pumping - Power plants - Bulk Water - Steel mills - Refineries - Chemical plants - Cooling and heating systems

WATER & WASTEWATER www.matherandplatt.com

ISO 9001.2015 +27 11 824 4810 +27 83 676 5904 26 Nagington Road, Wadeville

APE Pumps Split Case Pump

Register and pay BEFORE 31 July 2022

• Members: R6 700

• Non-members : R8 000

• Members : R7 500

• Non-members : R8 900

Birchwood Single: R1 000

Birchwood Sharing: R1 200 Silverbirch Single: R1 100 Silverbirch Sharing: R1 300

Birchwood Single: R1 250

Sharing: R1 700 Silverbirch Single: R1 350 Silverbirch Sharing: R1 800

BED

& BREAKFAST

t: +27 (031)266 3263 e: conference@imesa.org.za marketing@imesa.org.za www.imesa.org.za IMESA ORGANISER THE INSTITUTE OF MUNICIPAL ENGINEERING OF SOUTHERN AFRICA (IMESA) CONFERENCE ENDORSED BY EVENT: 85 TH I MESA Conference DATES: 2-4 N ovember 2022 DINNER, BED

EARLY BIRD REGISTRATION

& BREAKFAST

Birchwood

STANDARD REGISTRATION

Register and pay AFTER 1 August 2022

BOOK YOUR accommodation NOW Hotel rates are noncommissionable if

book

used is IMESA CONFERENCE.

subject

availability. www.birchwoodhotel.co.za

delegates

through travel agents. Bookings to be done directly with Hotel. Reference to be

Rooms are

to

Are we driving a car without a fuel gauge?

Groundwater is the most extracted material in the world, providing about half of the drinking water supply worldwide. Locally, it might be considered less important, given that only 13% of all water used comes from aquifers. However, most of the drier western part of the country is dependent on groundwater for its water supplies. More than 400 cities, towns and villages in this country use groundwater – either as a sole source or in conjunction with surface water supplies. And almost all rural water supply schemes are groundwater driven, with the development of springs and shallow boreholes fitted with handpumps being a key.

Recent droughts in the Southern Cape (2009-10), Western Cape (2016-19) and Eastern Cape (ongoing since 2015) have seen municipalities, businesses and individuals turn to groundwater in the face of potentially failing municipal water supplies. Its ubiquitous nature and the ability of most rock types to store and transmit water make groundwater exploration an obvious mitigation action in many instances. It is a renewable resource and resilient against

the effects of drought, but it needs to be used within its sustainable limits.

Challenges

The use of groundwater is not without challenges. Unlike a dam where water is drawn at a single point, groundwater is unevenly distributed underground in both quality and quantity. It has to be abstracted from multiple locations, transported to a single point and then reticulated to users.

Furthermore, groundwater does not benefit from the economies of scale when compared to large dams, but the cost of development of groundwater supplies is typically much less than its surface water counterparts. The management of groundwater schemes is typically more labour-intensive, requiring regular interventions to keep the systems running smoothly.

Possibly the biggest challenge related to the development and use of groundwater is that it cannot be seen. It is invisible to those who haven’t specialised in this field and, as a result, is poorly understood. In their book, Groundwater Around the World, Margat and Van der Gun observe that what most people know about groundwater is not in proportion

Groundwater management is critical to keeping water supplies available and safe for future generations.

By Dr Roger Parsons

ABOUT THE AUTHOR

Dr Roger Parsons is a hydrogeologist with almost 40 years’ experience. He is the director of Parsons & Associates Specialist Groundwater Consultants and former provincial branch chair of the Ground Water Division. He was awarded the Ground Water Medal for outstanding service and dedication to furthering the science and technology of groundwater.

to the use they make of it. Groundwater resources are often poorly assessed and hardly managed. In some parts of the world, the resource is excessively exploited and wasted, but elsewhere groundwater is underestimated and unused.

Department of Water and Sanitation

The Department of Water and Sanitation (DWS) used to have a division of experienced

18 IMIESA August 2022

The diligent collection of data and having it reviewed by a hydrogeologist is key to successfully managing any groundwater scheme. This requires approximately eight hours of their input each year. It is also prudent to include a hydrogeologist in the commissioning process to check that the scheme has been implemented correctly, but thereafter the review can be done every 6 to 12 months.

The DWS has been restructured around the National Water Act (No. 36 of 1998) and this expertise now sits in the private sector and, with only one or two exceptions, municipalities are devoid of this expertise – even when their entire water supply is sourced from underground.

During the drought that resulted in Cape Town facing ‘Day Zero’, the Western Cape Provincial Government assigned hydrogeologists to each support four or five municipalities as they sought to mitigate falling dam levels and dry taps. The purpose of this was to guide better decision-making and promote a better return on their investment when contemplating groundwater development or expansion. In my opinion, this was a wise move, but it needs to be extended if headway is to be made against the lack of groundwater management at municipal level.

A recent visit to a R150 million groundwater scheme in the Eastern Cape reminded me of the sorry state of affairs of groundwater management. Five boreholes are being used

South Africa hydrogeologists who developed groundwater resources and provided support to municipalities. At the time, it was also the training ground for most hydrogeologists in the country.

to supply groundwater to the town, all fitted with flow meters. This is a requirement of the DWS, either as a licence condition or under various regulations governed by them. The purpose of the flow meter was not clear, as the borehole was being pumped at 7.8 ℓ /s when the pumping rate recommended by the hydrogeologist was 5.0 ℓ /s. Despite the cost of the scheme, R50 000 could not be found to install data loggers in each borehole. Data loggers are used to measure the groundwater level over time, which in turn provides a measure of the reaction of the aquifer to pumping and the sustainability of the abstraction.

Operating a production borehole without this information is like driving a car without a fuel gauge. It is guaranteed that you will run out of fuel at some stage. In this example, the borehole may continue to deliver 7.8 ℓ /s for a day, a week or even a month but, at some point, the borehole will fail and the residents of the town will be without water. Groundwater will probably be blamed and declared unreliable.

Managing groundwater

Managing groundwater is not complicated. A set of operating rules (like rate of pumping) needs to be specified from the outset.

The availability of hydrogeological capacity is not a limitation. The Ground Water Division has more than 300 signed-up members, most of whom are skilled and experienced in groundwater management. Many graduates that have completed groundwater-focused courses battle to find employment. A programme where an intern is tasked with managing four or five municipal groundwater supply schemes is an ideal way for young hydrologists to gain work experience while overcoming the lack of groundwater management. We just need visionary leadership.

A data logger is suspended in a 40 mm PVC pipe installed in the borehole at a level directly above the pump inlet to monitor aquifer response to pumping and assess the sustainability of the groundwater use

WATER & WASTEWATER

SOUTH AFRICA’S POWER GAP Taking action to bridge

Unveiled by President Cyril Ramaphosa on 25 July 2022, South Africa’s latest energy action plan provides a more immediate response to the country’s power crisis and opens the door for widespread private sector participation.

What was great about the President’s speech was that he has opened the energy challenge to a shared solution with opportunities for everyone to have an impact, no matter how small,” says Janice Foster, market managing director: Energy, Zutari.

A highlight of the plan is the doubling of new generation for Bid Window 6 of the Renewable Energy IPP Procurement Programme (REIPPPP) from 2 600 MW to 5 200 MW. Zutari has supported client projects in all REIPPPP bid windows to date, including the latest round.

Another significant step is removing the licensing threshold for embedded generation capacity entirely. Raising the threshold to 100 MW last year has already unlocked a pipeline of more than 80 confirmed private sector projects with a combined capacity of over 6 000 MW. “This is a significant increase in capacity for private offtakers, which we expect to see starting to come online in the coming months,” says Foster.

Priority focus

She stresses that preferred projects in Bid Window 5 should be prioritised. “These have already been awarded and in theory would be the quickest to get online if we can overcome the obstacles to those achieving financial close.” Foster adds that Bid Window 6 projects are anticipated to factor these constraints into their costing and delivery.

Another important move is the announcement of an Eskom feed-in tariff for small-scale embedded generation. “That is a real signal of incentive to Eskom’s commercial users and private residential customers that they can also contribute and support their own needs at the same time,” says Foster.

Government’s planned battery energy storage initiative to supplement Eskom’s capacity also represents a multifaceted approach to the energy crisis. “This opens up the energy storage market to private investment. The addition of battery energy storage systems will support the grid by catering for peak shaving, providing network stability,” Foster continues, adding that these systems will enable greater penetration of renewables into the future.

An equitable transition

While the current energy crisis is the result of years of load-shedding, the situation is not unique to South Africa. “Globally, we see different parts of the world facing energy challenges that might look different but are based on some of the same fundamental issues,” she explains. These include the shift from coal-fired power plants.

“It is a global imperative for the world to reduce its reliance on carbon-intensive energy solutions. This is a problem likely to be with us for the foreseeable future. It entails both an energy security challenge and the need to reduce the carbon footprint of our energy supply,” explains Foster.

A ‘just’ energy transition is probably the most important consideration from a local perspective. “The bulk of our power supply is still coal-based. As we transition away from fossil fuels, we need to ensure there are opportunities for the participation of all stakeholders, especially the thousands employed in the coal-mining industry. Our energy crisis is a relatively solvable problem from a technical standpoint, but the number of social and institutional challenges it brings are equally, if not more, important,” concludes Foster.

20 IMIESA August 2022 ENERGY

Janice Foster, market managing director: Energy, Zutari

EPWP candidates assist with a wiring alteration on an AMV12 switchboard control cubicle under the watchful eye of site supervisor Kaizer Sithole, at a substation in Tshwane recently refurbished by Actom Power Systems

REFURBISHING TSHWANE’S fire-damaged substations

Earlier this year, the City of Tshwane awarded two contracts worth R200 million to Actom Power Systems to revamp the Pyramid and Kentron substations following extensive fire damage. In both instances, the initial focus is on constructing new control and switchgear buildings to house the replacement equipment.

Thereafter, Power Systems will supply, install and cable up a total of 109 new 11 kV switchgear panels – 49 for Pyramid and 60 for Kentron – including associated protection schemes, a Scada overlay, and DC chargers with battery backup.

The replacement 11 kV switchboards will consist of the modern premier class AMV12

brand of switchgear developed by Actom MV Switchgear in conjunction with an international partner and now well proven in the local market.

“Impromptu repairs were carried out by the municipality to restore power supply as quickly as possible, but the longer-term security of supply shall remain compromised until permanent solutions are implemented, which is what we are doing now,” explains John McClure, GM at Power Systems.

Phased equipment upgrade

Both substations will receive a major upgrade over the three-year contract term,

as annual funds are released. New outdoor equipment includes 132 kV circuit breakers, isolators, current transformers, voltage transformers and surge arrestors supplied by Actom High Voltage Equipment. In addition, the cable and cabling accessories required for the works will be sourced from Actom Electrical Products.

For both contracts, Power Systems is obligated to involve and upskill local labour under the Extended Public Works Programme and earmark sections of work for local subcontractor participation.

The growing challenges of the climate crisis are forcing investment in green hydrogen and technologies based on it, as an essential building block for climate protection. Hydrogen, as a new promising ecosystem, can help reduce CO2 emissions in many ways.

To fully exploit the potential of hydrogen, solutions must be found to the challenges of production, storage, transpor t and use.

HILTON HOTEL | SANDTON | JOHANNESBURG Richard Morrak Executive Director 19 Edison Way, Millennium Business Park, Block A, Century City, 7446, Cape Town, South Africa Email: richard@hydrogen-africa.com Tel: +27 81 370 6495 ABOUT THE EVENT G r e e n H y d ro g e n i s o n e o f t h e l a r g e s t e c o n o m i c o p p o r t u n i t i e s o v e r t h e n e x t 3 0 y e a r s . D r i v e n b y i n t e r n a t i o n a l a c t i o n s t o c o m b a t c l i m a t e c h a n g e , i t h a s t h e p o t e n t i a l t o r e v o l u t i o n i z e n u m e ro u s v a l u e c h a i n s i n t h e e n e r g y i n d u s t r y a n d a c ro s s b o t h m o b i l i t y a n d m a n u f a c t u r i n g s e c t o r s .

ENERGY

WOMEN WINNING IN CONSTRUCTION

ERWIC AWARDS WINNERS ANNOUNCED

This year’s awards have 12 categories that recognise companies and individuals who support the gender transformation, development and mentorship of women in the construction industry.

The event was attended by the Deputy Minister of Infrastructure and Public Works, Ms Noxolo Kiviet, who congratulated the nominees and winners in her impassioned keynote address. She stated that the event, held during Women’s Month, celebrates the strength, dedication and resilience of women committed to building the country.

The Construction Industry Development Board (cidb) hosted the prestigious Empowerment and Recognition of Women in Construction (ERWIC) Awards on 24 August 2022.

“These awards should always stand as the clarion call for gender transformation within the construction sector, showcasing the strength of women and serving as a vision of what women can achieve

when given the necessary support,” Kiviet explained.

Bongani Dladla, CEO of the cidb, stated,

WINNERS

“The ERWIC Awards were developed by the cidb to celebrate and encourage the development of women in the construction industry. He explained that the competition at the ERWIC Awards has always been fierce, with this year being no different.

“The winners were all well deserved and stood out in their respective categories.”

Project Delivery Excellence of the Year – Grade 1

Winner: Boitsholo Trading and Projects CC for its Coega Feltex Trim Factory Pretoria project

Runner-up: Sbonzin Trading for its Upgrading of Gravel to Surface Roads, including the associated stormwater project

Project Delivery Excellence of the Year – Grade 2

Winner: Tumagole Trading Enterprise for the Renovations of the City of Johannesburg Recreation Centre project

Runner-up: Magiya Women’s Developers for their Construction of Stormwater in the Mhluzi Ward 25 project

Third place: Letsogo Trading Enterprise

WOMEN IN CONSTRUCTION

22 IMIESA August 2022

Join leading road specialists and decision makers at the 7th Regional Conference for Africa, hosted by SARF (South African Road Federation) in collaboration with IRF (International Road Federation) and PIARC (World Road Association) where we will examine and discuss ways to expand and improve our road networks, specifically in Africa, but also to then take the lessons learnt further abroad

The conference, which also includes a trade exhibition of of over 35 exhibitors, is taking place from 18 – 20 October 2022 at the Cape Town International Convention Centre under the theme Connecting Africa through Smart, Safe and Resilient Roads: Stimulating Growth and Trade on the Continent PIARC will also host two specialist seminars of vital concern on Safe and Efficient Transport by Road and The Role of Low Volume Roads in Rural Connectivity

This year’s conference brings a truly global perspective with a high number of papers submitted from around the world indicating a strong interest in the event, not only from the countries that usually attend including the UK, USA, various EU countries as well as those in the Middle East and Africa, but also from Japan, Mexico and New Zealand

Our keynote speakers include:

Mr Anouar Benazzouz – Director General of Moroccan Highways (Autoroutes du Maroc) and the first African President taking the helm of IRF.

Mr Nazir Alli – President of PIARC, World Bank Consultant and Civil Engineer, and formerly the Founding CEO of the South African National Roads Agency (SANRAL).

Professor André Roux – Head: Futures Studies Programme, University of Stellenbosch Business School

Dr Pierre Voges – CEO of the Atlantis Special Economic Zone Company and former CEO of the Mandela Bay Development Agency.

Other topics on the three-day programme include Determination of roads needs and financing mechanisms Preserving Africa's road assets Safe and efficient transport by road Innovative practices to optimise road networks Roads and the environment

The role of low volume roads in rural connectivity Capacity development in the roads sector

7 T H R E G I O N A L C O N F E R E N C E F O R A F R I C A & P I A R C I N T E R N A T I O N A L S E M I N A R O N R U R A L R O A D S A N D R O A D S A F E T Y C O N N E C T I N G A F R I C A T H R O U G H S M A R T , S A F E A N D R E S I L I E N T R O A D S 2 0 2 2 S A R F • I R F • P I A R C 2022 1 8 - 2 0 O C T O B E R 2 0 2 2 | C a p e T o w n I n t e r n a t i o n a l C o n v e n t i o n C e n t r e C O N N E C T I N G A F R I C A T H R O U G H S M A R T , S A F E A N D R E S I L I E N T R O A D S S t i m u l a t i n g G r o w t h a n d T r a d e o n t h e C o n t i n e n t W I T H T H A N K S T O O U R S P O N S O R S REGISTER NOW at www.sbs.co.za/sarf2022

Mr Anouar Benazzouz

Mr Nazir Alli

Prof André Roux

Dr Pierre Voges

Innovative solutions to AFRICAN CHALLENGES

The 7th Regional Conference for Africa, hosted by the South African Road Federation (SARF) – in collaboration with the International Road Federation and the World Road Association – will explore challenges and solutions for local and global road networks.

Under the theme ‘Connecting Africa through Smart, Safe and Resilient Roads: Stimulating Growth and Trade on the Continent’, the three-day event takes place from 18 to 20 October 2022 at the Cape Town International Convention Centre.

“While many of the papers presented will no doubt be of global value to international delegates attending, we are placing a strong emphasis on how to preserve and develop Africa’s own road assets,” says Basil Jonsson, operations director for SARF, adding that rural road optimisation is a prime example.

“Low-volume, rural roads play a hugely significant role in low-income countries, providing critical connectivity to agricultural operations. However, financial constraints often place the upgrading of these roads on the back-burner,” Jonsson elaborates.

“What solutions can we offer to both the financial and physical constraints of improving these all-important rural networks? What have other countries across the globe done to tackle these challenges? How do we assess the use of these roads and ensure that they are both safe and fit for purpose? A number of

the planned presentations will address these questions,” he explains.

Climate change, technology and transportation

Other presentations will tackle sustainability, including the impacts of climate change on road networks, as well as technological and other advancements made to optimise road transportation.

“Nanotechnology is increasingly playing a role in the development of cost-effective and sustainable road and pavement construction materials,” says Jonsson. “We are seeing an escalation in the development of alternative materials to those traditionally used in road pavements.”

As examples, Jonsson cites the trials commissioned in Ethiopia by the UK’s Foreign, Commonwealth and Development Office (in terms of High Volume Transport). These trials examine the use of long-life epoxy modified asphalt and fibre mastic asphalt road surfacing. Other independent trials conducted closer to home in KwaZulu-Natal have investigated the use of asphalt manufactured with recycled waste plastic. The findings of both studies are scheduled for presentation at the conference, as are innovative approaches for the assessment of bridges, and the collection of road traffic data.

Safety and efficiency

Safety and efficiency will also play a key role at the conference, with comparative work

being presented. This includes research on skid resistance versus surface texture, as well as possible proactive solutions to South Africa’s high road fatality rates. The latter includes the assessment of driver crash risk factors, road safety audits, and setting credible road speed limits.

International

financing and economics

Capacity development will also feature high on the conference agenda, as will financing around infrastructure. In terms of the latter, Jonsson notes: “We will hear from leading experts in international financing and economics about the comprehensive and systemic approaches other countries have adopted to identify, appraise and implement road rehabilitation projects – some of which have even developed successful public-private partnership models.”

Delegate registration

Registration to date confirms participation from Africa, the Asia-Pacific region, EU, North America, Middle East and UK. The event is anticipated to draw more than 420 delegates in total, and ECSA accreditation has been secured by SARF with 1 CPD point in Category 1 for each of the three days of the conference. Delegate registration is currently open. Special accommodation rates for out-oftown delegates have also been secured at a number of Southern Sun Hotels close to the conference venue.

For more information, contact SBS Conferences & Exhibitions on +27 (0)71 348 1780, email info@sbs.co.za or visit sbs.co.za/sarf2022.

IMIESA August 2022 25

ROADS & BRIDGES

Asphalt surfacing between Hermanus and Stanford, Western Cape (Credit: Imile van Rhyn, EFG Engineers)

Basil Jonsson, operations director, SARF

THE ROAD TO SMART MOBILITY

OSanral is using technology to optimise its road infrastructure. Effectively managing existing road networks can lessen the demand to build new roads.

By Kirsten Kelly

ver the past few years, we have shifted from a network provider (provision of road infrastructure as well as its maintenance and upgrades) to network manager and operator. We are using technology to effectively manage the road space. With thousands of technology options available, Sanral is focused on finding bespoke solutions for the South African context,” explains Siveshni Pillay, project manager: Northern Region, Sanral.

Projects implemented Implemented in 2005, the freeway management system (FMS) monitors freeways 24/7 in Gauteng, Pietermaritzburg, Durban and Cape Town. This is where operators manage congestion using various intelligent tools like CCTV cameras, variable message

signs and vehicle detection systems. Strategic partnerships have been formed with the police, emergency services and other organisations like Tracker and Waze, where information is shared among stakeholders.

“The Gauteng network covers 251 km of national roads. The infrastructure includes 302 CCTV cameras, 111 video detection systems, and 59 variable message signs. We also use on-road services (ORS), a first-line emergency response that comprises incident response vehicles like light towing vehicles, heavy recovery units, and motorcycles for medical response. Automatic vehicle location technology is used where data is retrieved from our system to locate the nearest ORS and direct it to an incident on the road to help clear it. Basic life support staff form part of ORS and the service is free of charge. We have a service level agreement with the contractor, whereby ORS must be on the scene of an accident within 12 minutes of it occurring,” adds Pillay.

Before the formation of ORS, it took up to five hours to clear a fatal incident.

A smart mobility solution, electronic toll collection (ETC), aims to reduce delays at toll plazas. This can be used throughout the country, where an e-tag is connected to an account and vehicles do not need to stop and physically pay at a toll road. ETC reduces the need for Sanral to add additional toll plazas and lanes, as the current infrastructure is improved by using technology. Vehicleto-infrastructure communication occurs between an e-tag and gantries.

Sanral also offers an app that allows road users to have an easily accessible means of managing their toll/mobility account. It can be used for:

• balance enquiries and a mini statement functionality

• managing the user profile

• managing vehicle data

• real-time top-up to mobility account

• travel information

• parking at selected malls countrywide.

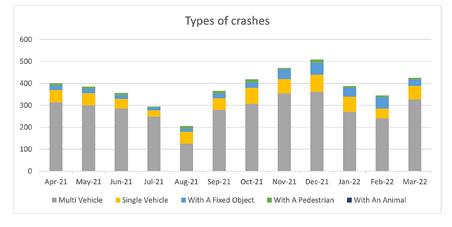

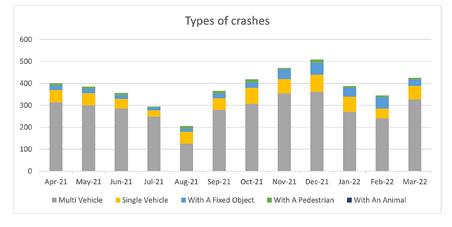

• 4 565 accidents

• 75% involved multiple vehicles

• 15% were single vehicle crashes

• 8% involved a fixed object

• 2% involved pedestrians

• 3 accidents involved animals

26 IMIESA August 2022 ROADS & BRIDGES

Recorded accidents along Sanral’s Gauteng FMS in 2021/22

Siveshni Pillay, project manager: Northern Region , Sanral

The monthly breakdown of the extent of injuries suffered by those involved in crashes

“We have agreements with some of the shopping centres where parking fees are deducted directly from a user’s mobility account, and no physical payments have to be made,” adds Pillay.

Moving from the concept of a toll account to a mobility account

A key focus area for Sanral is to repackage and expand the function of its Transaction Clearing House (TCH) from exclusively clearing e-toll collections to providing a

host of other potential mobility services (such as the already implemented parking payments), as well as vehicle licence renewal payments, fuel payments and driving licence renewals.

One of Sanral’s most exciting projects is Account Based Ticketing (ABT), which is a form of integrated public transport fare management where commuters would have one ticket for all public transport throughout the country. ABT will provide significant cost savings (less cash handling and transaction

costs) and simplify operations. Users will no longer have multiple cards for different public transport systems. If a ticket is lost, it can be replaced as the money is contained in the mobility account. The front-end system or the automated pay collection system will still be implemented by the municipality or transport service provider.

“The most important part of the ABT system is that it’s a step towards mobility as a service. When all public transport is integrated into a single back-office system, the next step would be to get private transport on board and there would be a user-based individual system where technology can assist a person with finding the quickest or cheapest route to a destination. We are far in the process with communicating and collaborating with municipalities, provinces and other role players that provide public transport. Six municipalities have already signed memorandums of understanding,” states Pillay.

Currently, the TCH processes 2.6 million transactions a day, and this is expected to increase to over 17 million transactions per day once ABT is implemented.

CONFERENCE SESSIONS INCLUDE: Raw Materials • Installation • Product Standards • Quality, Design Case Studies • Energy & Environment • Rehabilitation • Certification

Bruce Hollands PVC Pipe Ass, USA

Peter Sejersen TEPPFA, Denmark

Norbert Jansen Borealis Group, Germany

David Fink PPCA & PPI, USA

KEYNOTE SPEAKER: Dr Roelof Botha - Economic Advisor to the Otimum Investment Group - South Africa

Lennert Bakker Soluforce, Netherlands

Albert Vaartjes Rollepaal, Netherlands

Dr Mike Troughton TWI LTD, UK

Norbert Jansen Borealis Group, Germany

Christian Schalich SIKORA AG, Germany

Dolores Herran Molecor, Spain

Alaster Goyns Pipes cc, SA

Grigorios Vigellis Union Pipes Industry LLC, UAE

Mario Messiha Polymer Competence Centre, Austria

Beverley Manikum Sasol, SA

Mike Smart Genesis Consulting, SA

Simon Thomas Simon Thomas Consulting, UK

Victor Pinedo Georg Fischer Piping Systems Inc, Switzerland

Caitlyn Kleingeld Plastic & Chemical Trading, SA

Ilija Radeljic Pipelife, Norway

George Diliyannis Safripol, SA

Jacques van Eck Avesco, SA

Peter Sejersen TEPPFA, Denmark

Ian Venter SAPPMA, SA

Kirtida Bhana Plastics|SA

Ricardo Pascual Aenor, Spain

ROADS & BRIDGES

SPEAKERS AND SPONSORSHIP OPPORTUNITIES AVAILABLE.

BY MEDIA PARTNER MAIN SPONSORS

EXHIBITION,

ORGANISED

of the best 4

Whether its loading, haulage or general site maintenance, access globally acclaimed equipment from four of the world’s leading equipment brands - Bell, JCB, Finlay and Kobelco – all from one point of contact, Bell South Africa

Contact us today to experience premium equipment backed by our leading support network.

Bell1672 Strong Reliable Machines Strong Reliable Support Tel: +27 (0)11 928 9700 • E-mail: sales@bellequipment.com www.bellequipment.com

Telehandler

Skidsteer

Wheel Loader Backhoe Loader

Compaction Equipment

Rough Terrain Forklift

B60E 4x4 B45E 4x4 B30E 4x4 B50E B45E B40E B35E B30E B25E B20E SK220XD SK260LC SK380XDLC SK520XDLC SK850LC SK300LC SK135SR

Excavator

Conveyor

Jaw Crusher Cone Crusher Impact Crusher

Incline Screener Heavy Duty Screener Horizontal Screener

Data

Smart mobility collects valuable data –internal data that Sanral can use to inform its infrastructure strategies and external data that can be fed in real time to road users and other stakeholders.

“Our toll gantries provide time and place data and are a critical resource with law enforcement. Sanral receives a number of subpoenas a week for information around crimes from cash-in-transit heists to hijackings and murders,” explains Pillay. She adds that, from a government point of view, data collected will also inform future infrastructure decisions.

However, the management of big data also needs policy decisions around who has access to it and how it can be used.

Research and innovation projects

Sanral has 28 research projects under way in collaboration with universities and industry experts. They are tackling topics around:

• big data management

• technology foresight study

• sensors, IOT, remote sensing and smart transport

• road funding model

• driver behaviour analysis

• advanced bituminous binder

• self-healing asphalt and concrete

• innovative ways to protect assets

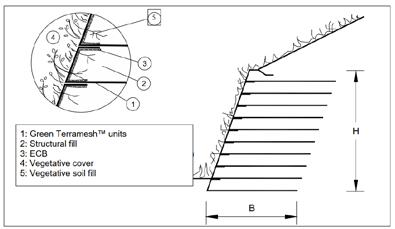

• accelerated pavement testing and long-term pavement performance.