PIPE SYSTEMS

Classification – the heart of thermoplastic pipes

Primary

CEMENT

Tests

Classification – the heart of thermoplastic pipes

Primary

CEMENT

Tests

and a giant leap for infrastructure

Sizabantu Piping Systems launches Africa’s first locally manufactured pipes, with capability from 710mm to 1200mm, now in full production

With capability from 710mm to 1200m now in production

As environmentally engineered structures, gabion systems have proven themselves worldwide as the preferred solution for riverine protection, embankment stabilisation and erosion mitigation. IMIESA speaks to Louis Cheyne, Managing Director of Gabion Baskets, about the key advantages, citing recent case studies that showcase innovation. P6

Within the climate change context, floods of increasing severity have become commonplace, requiring a range of engineered responses to manage rising stormwater volumes. IMIESA speaks to Scott Magnus, Contract Manager at BLOC Contractors – a leading geotechnical specialist – about an innovative solution employing handmined segmental tunnelling in Prospecton, Durban. P12

Social Infrastructure | Schools

High-impact innovation. Arbeidsgenot Primary School development redefines future-proof education 14

Sustainability

An Arbor Month initiative. Urban greening with water conservation in mind 17

The good, the bad and the most appropriate. What makes a good material? And what characterises a bad one? 18

SAPPMA’s commitment to excellence helps build enduring infrastructure 22 Classification – the heart of thermoplastic pipes 24 HDPE: The future of civil infrastructure in South Africa 26

Securing South Africa’s infrastructure: The thermoplastic pipe quality crisis 28

EDITOR Alastair Currie

Email: alastair@infraprojects.co.za

DESIGNER Beren Bauermeister

CONTRIBUTORS Geoff Tooley, Ian Venter,

Professor Mark Everard, Mike Smart, Thabang Byl

DISTRIBUTION MANAGER Nomsa Masina

DISTRIBUTION COORDINATOR Asha Pursotham

SUBSCRIPTIONS

Email: distribution@infraprojects.co.za

ADVERTISING SALES

KEY ACCOUNT MANAGER Joanne Lawrie

Tel: +27 (0)82 346 5338

Email: joanne@infraprojects.co.za

PUBLISHER

IMESA (Pty) Ltd

P O Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: info@infraprojects.co.za

ANNUAL SUBSCRIPTION: R805.00 (INCL VAT)

ISSN 0257 1978 IMIESA, Inst.MUNIC. ENG. S. AFR.

© Copyright 2025. All rights reserved.

IMESA CONTACTS

HEAD OFFICE:

Manager: Ingrid Botton

P.O. Box 2190, Westville, 3630

Tel: +27 (0)31 266 3263

Email: admin@imesa.org.za

Website: www.imesa.org.za

BORDER

Secretary: Celeste Vosloo

Tel: +27 (0)43 705 2433

Email: celestev@buffalocity.gov.za

EASTERN CAPE

Secretary: Susan Canestra

Tel: +27 (0)41 585 4142 ext. 7

Email: imesaec@imesa.org.za

KWAZULU-NATAL

Secretary: Narisha Sogan

Tel: +27 (0)31 266 3263

Email: imesakzn@imesa.org.za

NORTHERN PROVINCES

Secretary: Lethale Magagane

Tel: +27 (0)72 059 7444

Email: np@imesa.org.za

SOUTHERN CAPE KAROO

Secretary: Henrietta Oliver

Tel: +27 (0)79 390 7536

Email: imesasck@imesa.org.za

WESTERN CAPE

Secretary: Michelle Ackerman

Tel: +27 (0)21 444 7112

Email: imesawc@imesa.org.za

FREE STATE & NORTHERN CAPE

Secretary: Wilma Van Der Walt

Tel: +27 (0)83 457 4362

Email: imesafsnc@imesa.org.za

All material herein IMIESA is copyright protected and may not be reproduced without the prior written permission of the publisher. The views of the authors do not necessarily reflect those of the Institute of Municipal Engineering of Southern Africa or the publishers.

Within every nation, the public service is a vital enabler that depends on a sustained tax base to keep all departments functioning. In South Africa’s case – as for most countries – government is the largest employer, with an estimated 1,7 million personnel employed. A high percentage work in essential services that include education, health, defence, policing, public administration, and built environment services.

The key issue is not about the numbers, but the return on investment for South African society and the point at which fiscal constraints become an inhibitor rather than an enabler when there are so many social and infrastructure priorities. This is underscored by National Treasury statistics, which reveal that the public service wage bill increased as a share of GDP from 5.6% in 1994/95 to 10.4% in 2023/24. In the same period, we’ve experienced a steady contraction in GDP growth. We need to rebalance this equation.

To illustrate the point, based on July 2025 statistics around 6,17 million personnel are employed in the UK’s public sector, with the wage bill representing over 20% of total government spending. However, the UK ranks sixth in the world in terms of nominal GDP, while South Africa is in 41st position. The UK also has an unemployment rate of 4,7%, compared to South Africa’s approximately 33,2%.

It’s therefore essential that we have a realistic public and private employment ratio as we rebuild our economy.

The South African government acknowledges the challenges, focusing on cutting back on wasteful expenditure. That includes the inflated cost and unnecessary outsourcing of aspects like accounting services, which despite their widespread adoption have still often failed to yield clean audit results.

Allied to this is the need to revitalise public service performance by ensuring that those employed add value, are professionally equipped, and dedicated to ethical practices. This approach is defined by government’s Batho Pele (“putting people first”) mandate.

In regions like the European Union, a high percentage of those employed hold tertiary qualifications; we need to follow suit and ensure professional registration and accountability across all relevant disciplines.

Either way, we cannot afford to cut back on essential services – we need more specialists in every modern-day

discipline – but we must improve efficiencies in the infrastructure space that enable all meaningful progress, ensuring that allocated local government budgets are spent correctly. Delays in project awards and execution have a negative ripple effect that directly affects the construction sector in all its facets.

At a higher level, we are also seeing the downstream impact of delays in revitalising South Africa’s rail and port infrastructure, the rapid escalation in energy costs, and a weak economy. A case in point is ArcelorMittal South Africa’s decision to close its Newcastle and Vereeniging long-steel operations, with some 3 500 direct jobs lost. The ultimate result is a further loss of much-needed industrial capacity to support the country’s macroeconomic objectives.

We cannot afford this, but we must also face the realities of global competition, and the attractiveness of cheaper import alternatives. At the same time, a free and fair trading environment must ensure that all products meet the highest compliance standards.

G20 partnership

Strategic trade partnerships remain vital in navigating an evolving tariff market of increasing complexity. That’s why South Africa’s and the African Union’s membership of the G20 – comprising developed and developing countries – is so important. We have an amazing opportunity to showcase our resilience and appetite for innovation as the G20 Presidency hosts of the 20th G20 Summit in South Africa during November. Here excellence in governance is top of the agenda. The reality is that without a vibrant public sector, no country can achieve meaningful socioeconomic growth. However, this is interdependent on an equal private sector partnership that is free to flourish. That’s essential for growing the tax base needed to fulfil our transformation and broader UN Sustainable Development Goals, and strengthen public sector performance.

To our avid readers, check out what we are talking about on our website, Facebook page or follow us on Twitter and have your say.

In each issue, IMIESA offers advertisers the opportunity to get to the front of the line by placing a company, product or service on the front cover of the journal. Buying this position will afford the advertiser the cover story and maximum exposure. For more information on cover bookings, contact Joanne Lawrie on +27 (0)82 346 5338.

As we draw closer to South Africa’s 2026 Local Government Elections, one of the key factors swaying voters will be the existence or absence of municipal service delivery. In this respect, high-performing municipalities with proactive mayoral leadership standout due to their commitment to collaborative consultation with their in-house engineering teams.

Spatial planning and development are policy driven – and must be rolled out in consultation with communities and business – and in line with approved budget allocations. However, the resulting enabling infrastructure can only be achieved by empowering engineering leaders as equal stakeholders.

As IMESA, we have an expert understanding of the priorities and implementation requirements, but we fully appreciate that the public at large may not understand the nuances. In other words, who makes the big decisions. In leading towns and cities, we do once the plans have been greenlit –in conjunction with our built environment, supply chain, and financial colleagues.

The latter’s understanding and buy-in is crucial in enabling realistic, actionable budgets. That viewpoint is reinforced by past Auditor-General South Africa reports on local government outcomes, where infrastructure execution remains fragmented, despite adequate budget provision – within a currently constrained fiscus –to effectively build real value.

Across the global municipal engineering spectrum there are key lessons that we can learn and apply within South Africa’s distinctive developed and developing context. An invaluable platform in this respect is IMESA’s membership of the International Federation of Municipal Engineering (IFME). The latter is dedicated to the exchange of technical and cultural information, innovations, and experiences among municipal engineers and public works professionals worldwide. Its diverse membership includes top tier and emerging economies, which in Southern Africa currently comprise South Africa, Botswana, Namibia, and Zimbabwe.

The collective goal within IFME is to incorporate a far greater representation of

African member countries, as well as to expand the membership reach in key regions that include Asia and South America.

Each region and country face their own unique country-specific challenges within the common framework of the UN Sustainable Development Goals – and universally their municipal engineers are constantly lobbying for greater infrastructure support. In federal systems like the USA, for example, there have been growing calls for more interstate funding for aspects like dams, roads, and pipelines. Parallel examples exist within our Southern African Development Community.

Going forward, we plan to regularly publish municipal engineering case studies in IMIESA from within the IFME community, as well as sharing our local successes with affiliated publications worldwide. This will serve both as an inspiration and a valuable education process, particularly for aspiring graduates and young engineers who may not have considered a career in municipal engineering – whether in the public or private domain.

We need to rethink our approach

The theme for our upcoming 88 th IMESA Conference in East London during October 2025 is “Sustainable Engineering Solutions”. A core part of the presentations is driven by the understanding that we cannot solve our infrastructure issues with the same mentality that created them. We need to create opportunities to experiment with new innovations. Here municipal engineers are uniquely positioned to respond because they are exposed to the realities daily.

An example is the urgent need to get on top of the widespread failure in municipal

Tooley, Pr Eng Hon FIMESA, IMESA President: 2024-2026

wastewater treatment works with a fresh design, operations, and maintenance approach that includes energy efficiency. Substantial investment will be required, and with it a rethink on the technologies and processes employed.

For our rapidly growing informal settlements and rural communities not currently connected to conventional waterborne services, one option could be the more widespread adoption of decentralised sanitation treatment.

These on-site solutions, which typically employ bio-based processes, provide a far more dignified approach to VIP alternatives. Plus, they also make provision for reuse for applications like toilet flushing and small-scale agricultural irrigation.

The vital role of academia

It all comes down to fit-for-purpose solutions constructed around community needs. An interesting initiative from this standpoint is being pioneered by Dr Justin Pringle, a Senior Lecturer, Hydraulics and Environmental Fluid Mechanics at the University of KwaZulu-Natal. He has started an annual competition that requires students from all engineering disciplines to engage with the local community, identify a problem and develop a solution.

This is an excellent foundational methodology in creating a pipeline of socially conscious engineers. It also provides an invaluable pool of low-tech and high-tech options that municipal engineers can trial and potentially apply in practice in conjunction with OEMs and the consulting engineering sector.

Worldwide, municipal partnerships with academia are common, but in South Africa we need to gain more traction. This has a mutual benefit in terms of real-world research opportunities, rather than “blue sky” possibilities. Forging the way, IMESA is currently engaging with various institutions that include IFME affiliated stakeholders to facilitate increased knowledge transfer.

Ultimately, our infrastructure challenges are immense; so too are the opportunities. As more funding becomes available, backed by engineering led expertise, we can and will make a major difference.

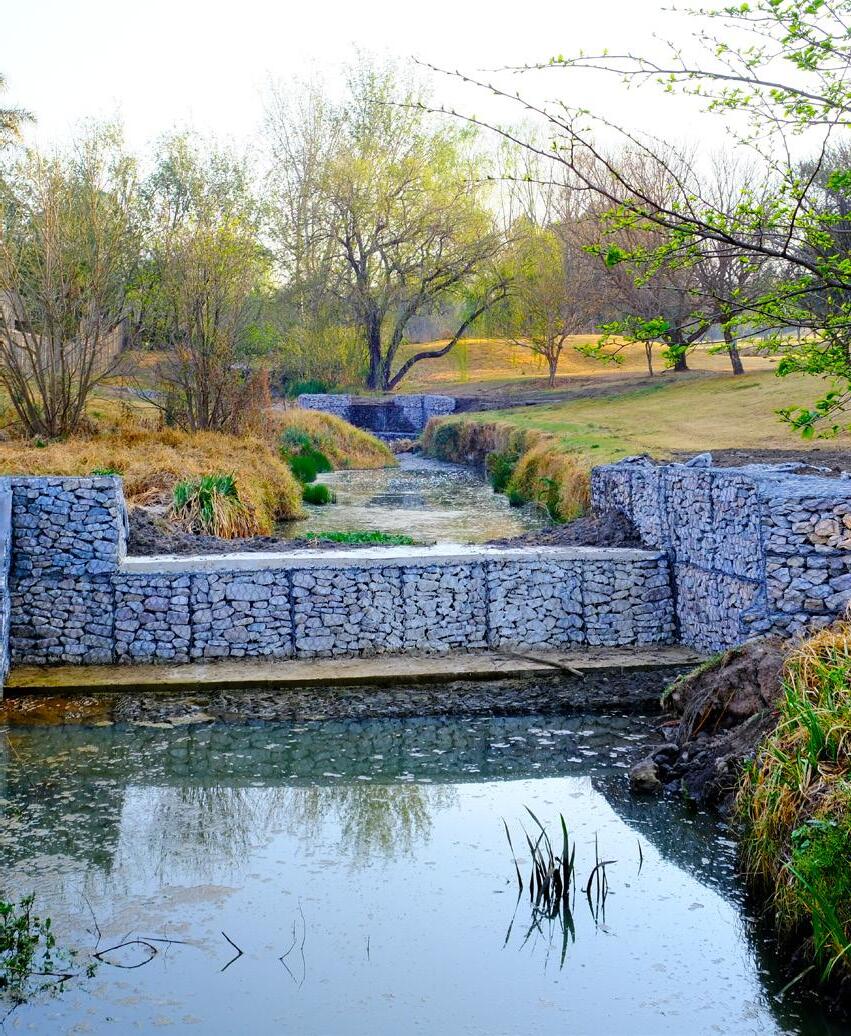

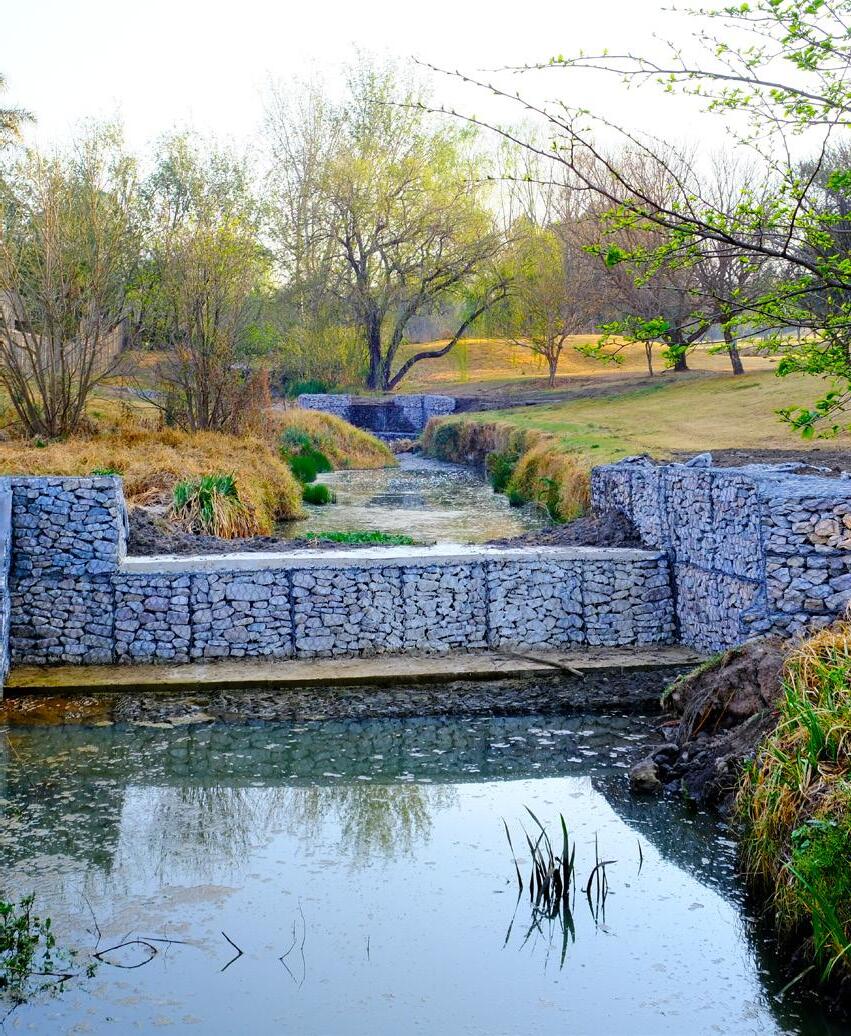

An artist’s impression of a typical weir layout, incorporating wingwall protection. Gabion Baskets makes extensive use of 3D animation to model and simulate its design proposals

As environmentally engineered structures, gabion systems have proven themselves worldwide as the preferred solution for riverine protection, embankment stabilisation and erosion mitigation. IMIESA speaks to Louis Cheyne, Managing Director of Gabion Baskets, about the key advantages, citing recent case studies that showcase innovation.

Erosion control is the critical factor – especially in urban scenarios – where the steady increase in stormwater run-off caused by town and city developments is placing unprecedented pressure on rivers. This is being further exacerbated by the increase in extreme flood events. The knockon effect is that riverfront properties, as well

as structures like bridges and roads face the risk of being undermined,” Cheyne explains. It’s important to understand that rivers will change their course over time, which is why their condition needs to be constantly monitored, and corrected with gabion interventions when needed. As Cheyne points out, it is also essential to carrying out a hydrological study to determine known

and anticipated water velocities, taking into account existing flood line data, so that the gabion systems optimally perform their role now and in the future. This includes the installation of gabion wingwalls for channels and weirs to provide outflanking protection during major storm events.

“Another crucial consideration is ecosystem preservation. A prime example are wetlands that serve as vital habitats for fauna and flora, as well as performing a natural biofiltration function that helps to maintain downstream water quality. In this respect, our gabion fabrication and design recommendations place a major emphasis on holistic solutions. This includes the integration of fishways in our weir designs, where required. These are typically pool-and-weir or vertical-slot designs that incorporate known water velocities and hydraulic jumps to accommodate specific fish species,” Cheyne continues.

Correct material specifications

However, the foremost consideration when designing and constructing riverine structures – such as channels, groynes, weirs and mass gravity walls – is correct material specification. SANS 23-3:2020 sets the standard locally and globally for the correct manufacturing specification for

GEOTEXTILE – F-34 OR SIMILAR APPROVED

A longitudinal weir cross-section. The gabion wall is founded on a gabion mattress which extends to form part of the channel lining system. The latter slows down water velocities, as well as countering scouring caused by the hydraulic jump. Concrete capping at the spillway crest reduces the risk of debris impact damage

hexagonal double-twisted woven mesh steel wire gabions and revetment mattresses.

In turn, SANS 1200 DK:1996 governs the correct installation techniques for gabion systems.

All woven mesh gabions produced at Gabion Baskets’ manufacturing facilities meet Class A galvanised wire specifications as the minimum standard, with the added option of a PVC coating for more corrosive conditions,

and for submerged gabion structures. Depending on the hydraulic conditions, a larger diameter wire may be required for extra strength.

In many cases, Gabion Baskets’ project management division has been called in to investigate and remediate failed installations where one of the prime causes is a non-compliant wire specification. This

A bird’s eye view of a 6 m high river wall bordering the Orange River in Upington, which was constructed in 2011. Gabion Baskets provided a design recommendation, materials and project management services

A side perspective: the wall was overtopped during a major flood in 2024, but when the water levels subsided the structure was still perfectly intact

is often compounded by poor installation techniques, and incorrect fill materials.

“Gabions are highly effective because of their built-in permeability and the ability of the wire to flex in countering hydraulic flows and absorbing debris impact. However, the rock selected must be suitable and packed correctly to achieve an approximately 35% void composition. We’ve seen scenarios where building rubble has been employed in rivers – a guaranteed recipe for subsequent structural failure because these materials will break up within a relatively short space of time,” Cheyne explains.

Founding conditions and channel linings

Founding conditions are equally vital to support submerged mass gravity walls resting on riverbeds, and to prevent scouring and undermining within typically clayey soil conditions. Here gabion mattresses are employed, extending out from the toe of the wall for a predetermined distance. The mattresses also make provision for a degree of variable settlement without the risk of a slip or overturning where the retaining wall has the correct degree of batter to ensure structural stability.

Gabion mattresses are also commonly used for channel lining where their primary role is to slow down water velocities, and again the correct specification is key for long-term performance. The rate of velocity control is determined by the thickness of the mattress, the rock size and type, packing technique, plus the secure wire lacing of the mattress lid and allied connections. Smaller rock that can escape through the mesh openings must be avoided. “We’ve seen scenarios where the gabion lid is ripped

Preparing the mattress foundation for one of the weir structures at the The River Club Golf Course. The employment of geotextiles forms an essential component to mitigate soil loss and control the designed degree of permeability

Weir 3 measures 6 m in length, 1 m in width, and 2 m in height and incorporates a stormwater channel

off when the incorrect procedures have been adopted, completely compromising the installation,” says Cheyne.

“The point to emphasise is that gabion construction is a highly specialised field of civil engineering and should only be carried out by suitably qualified engineers and contractors. Aside from health and safety risks, and the rework cost for remediation, poor practice frequently ends up causing more environmental damage,” Cheyne explains.

The River Club Golf Course weirs

A recent project completed by Gabion Baskets at the The River Club Golf Course in Sandton, Gauteng serves to underscore how a professionally designed system comes together to achieve an optimal balance between environmental stewardship and aesthetics.

Advanced construction on Weir 1 (above) and the completed structure (below). This measures 9 m in length, 1 m in width, and 2 m in height and is the primary weir, forming part of five integrated weirs constructed at the The River Club Golf Course

The scope of works entailed the strategic installation of five meticulously designed weirs and associated channel improvements on sloping terrain, aimed at optimising water flow dynamics, enhancing the landscape, and contributing to the estate's overall environmental management.

Completed within a two-week timeframe, the construction programme required an estimated 140 m3 of excavation to prepare the sites and ensure the structural integrity and proper functioning of each weir as part of an interconnected system

The construction of the primary weir (Weir 1) necessitated extensive preliminary excavation to achieve the required ground level, accounting for a substantial portion of the project's total excavation volume. This structure measures 9 m in length, 1 m in width, and 2 m in height.

Following in succession, Weir 2 is sized at 8 m in length, 1 m in width, and 2 m in height, while Weirs 3 and 4 measure 6 m in length, 1 m in width, and 2 m in height. The smallest in the series – Weir 5 – measures 4 m in length, 1 m in width, and 2 m in height.

In addition to the weir installations, the construction of a robust channel system was an essential requirement. This involved the deployment of 4 x 2 x 0.3 m mattresses, designed to reinforce the channel bed and banks, thereby preventing erosion and ensuring stable water conveyance. Furthermore, at the outlet of the channel, on each side, specialised directing structures were installed, measuring 2 m in length, 0.5 m in width, and 0.5 m in height. These strategically placed structures are instrumental in guiding the water flow efficiently towards the main river and over

the newly constructed weirs, optimising the water's path and minimising turbulence.

“Every installation has its own unique requirements and we’re proud to have delivered a solution that meets the high standards expected at such a distinguished property. The weirs and channels blend in so well, enhancing the built environment. Plus, the weirs create mini reservoirs for birdlife and animals,” says Cheyne.

Parkhurst river wall

In addition to greenfield projects, Gabion Baskets is often involved on installation upgrades. Typically, the erosion measures need to be further enhanced due to escalating flood damage.

A case in point is an extension to a mass gravity river retaining wall designed to protect the embankment under a bridge in Parkhurst, Johannesburg. The original wall was installed by a Gabion Baskets approved contractor some 18 years ago and is still structurally sound. However, this now needed to be extended by a further 10 m to counter further erosion.

Once the 2 m high extension had been completed, 144 m 3 of suitable backfill material was carefully placed and compacted behind the gabion wall. This backfill serves multiple essential functions: it provides lateral support to the structure; integrates the wall seamlessly with the existing topography; and helps to manage subsurface water flow,

A 10 m gabion river wall extension was required to counter severe embankment erosion underneath a bridge in Parkhurst, Johannesburg. This provides added protection for the bridge structure and protects a bordering property from being undermined

A perspective of the completed wall extension. The backfill behind the wall enhances lateral support and serves as a platform for landscaping

further contributing to the long-term stability of the entire system.

Walls that stand the test of time

The larger the river, the greater the need for precision engineering and exacting material selection, and among southern Africa’s most challenging are the mighty Orange and Zambezi Rivers. Here Gabion Baskets has provided design recommendations, project management, training provision, and gabion supply for a series of landmark projects.

One of its longstanding installations is a 6 m high river wall bordering the Orange River in Upington. Constructed in 2011, this wall has relentlessly withstood rising flood levels of increasing severity. In 2024, the river burst its banks and overtopped sections of the wall, but when the floods subsided it was still perfectly intact. Gabion Baskets is now supplying a solution for a neighbouring property.

Further afield in Zambia, Gabion Baskets has provided integrated solutions for various private tourism entities that include the Musango River Lodge, and Lolebezi Safari Lodge. Both entailed embankment reinstatement, protected by mass gravity wall retention, with varying heights up to 4 m.

Combatting erosion is a collective responsibility

“Soil loss through erosion has multiple downstream impacts that extend from land degradation to excessive sediment build up in rivers and reservoirs that negatively affect water quality and riverine habitats. The critical starting point in reversing these threats is proactive catchment management, which requires a combined response from all stakeholders,” adds Cheyne.

“Central to this process is a renewed focus on stormwater management through responsible built environment practices that take the pressure off our rivers. Flood risks will always be there, but with innovative environmentally engineered solutions we can significantly reduce them, while working towards climate change mitigation goals,” Cheyne concludes.

Representing the largest member footprint in South Africa, IMESA’s Northern Provinces (NP) Branch incorporates the Gauteng, North West, Limpopo and Mpumalanga provinces. Comprising a mix of metros and secondary cities, this region encompasses a major percentage of South Africa’s economy, making effective infrastructure delivery a crucial component.

On 29 th August 2025, the NP Branch held its annual Technical Seminar and AGM, with a strong attendance by members and delegates from across the private and public sector – all dedicated to supporting IMESA’s quest for capacity building and the highest levels of professionalism in municipal engineering.

Opening the event, Kwena Maphoto, IMESA NP Branch Chairperson, stressed the importance of delivering infrastructure that empowers society. “We know that infrastructure across South Africa is under tremendous strain, which is being felt daily in terms of factors such as water disruptions, power failures and potholed roads that add to growing community frustrations.

“As municipal engineers we understand the challenges, and our collective focus must be

on finding smart solutions for practical quick wins. That requires the widespread adoption of digitalisation to design, manage and operate services in real-time in collaboration with academia, technology providers and the built environment community.”

Keynote presentations

These viewpoints were reflected in the three Technical Seminar addresses presented respectively by Burgert Gildenhuys, Director at BC Gildenhuys & Associates; Devesh Mothilall, Head of Digitalisation: Smart City Office and Head of Knowledge Hub – ECOE, City of Johannesburg; and Refiloe Mokoena, CSIR Senior Researcher within the Smart Mobility Cluster.

Gildenhuys’ talk was entitled “Reclaiming Local Government: Municipal Service Delivery, Planning and Institutional Challenges”, based

on decades of research and applied experience within the town and regional planning arena.

As he expanded, a key element for future success is access to accurate spatial data and the expertise to meaningfully analyse it at local government level for infrastructure implementation. He said the responses must be sustainable and enabled by practical regulations that facilitate municipal autonomy, as opposed to national overregulation. Another key issue highlighted was the clear need for local government financial health to execute capital budgets, with engineers a vital part of the process. However, accurate decisions hinge on real-world information on the ground.

Next up, Mothilall’s presentation was entitled “Water 4.0: Digital Transformation in Water Resource and Utility Management”, aimed at creating intelligent systems that are resilient, cyber secure and futureproof for ensuing generations. The burning issue is non-revenue water losses, which on average exceeds 35%, but is generally much higher.

As Mothilall pointed out, this poses a major threat within the context of ageing infrastructure that unless immediately tackled

From left: Devesh Mothilall, Head of Digitalisation: Smart City Office and Head of Knowledge Hub – ECOE, City of Johannesburg (speaker); Khodani Tshovhote, IMESA NP Branch Committee member; Kwena Maphoto, IMESA NP Branch Chairperson; Refiloe Mokoena, CSIR Senior Researcher (speaker); Burgert Gildenhuys, Director, BC Gildenhuys & Associates (speaker); Linda Tyers, IMESA NP Branch Treasurer; Vuyani Gxagxama, IMESA NP Branch Council Liaison and IMESA Vice-President: Technical; and Khomotso Mdhluli, IMESA NP Branch Secretary

will undermine socio-economic development against a backdrop of unprecedented population growth and urbanisation. That requires a response well beyond traditional engineering approaches, which must be driven by greater information and communications technology (ICT) adoption.

The benefits of ICT include Artificial Intelligence and Machine Learning that can leap-frog decades of incremental improvements – something South Africa needs right now. This will be supported by devices like smart metering that help utilities manage real and apparent losses via automated leak detection. A series of projects within the City of Johannesburg – in partnership with the University of Johannesburg – have yielded measurable improvements, with downstream implementation opportunities for other municipalities.

As the concluding speaker, Mokoena’s presentation – “Emerging Technologies in Road Design for Smart Municipal Infrastructure” –spoke on one of the most enabling platforms for meaningful growth, namely transportation.

Two specific innovations highlighted were the use of recycled plastic waste for asphalt

production based on trails using the CSIR’s heavy-vehicle simulator, which has proven the durability benefits and promotes a circular economy; and the specification of climate resilient performance grade bitumen products – factoring in evolving atmospheric temperature impacts by geographic region – to optimise asset life. The latter methodology has been refined by purpose-designed software.

These interventions, among others, are vital in managing finite resources and in reducing maintenance intervals, as well as new construction costs. Future implementation will require ongoing industry collaboration.

Following the presentations, the AGM report recorded the gains made by the IMESA NP Branch over the past 12 months. In delivering on its professionalisation mandate, a series of roadshows in conjunction with representatives from the Engineering Council of South Africa (ECSA) took place to promote member registration.

Four CPD accredited training programmes were also successfully hosted on topics that included advanced hydraulic modelling, and project management. Additionally, some

1 000 learners were engaged at secondary level to highlight municipal engineering career opportunities, alongside partnership agreements concluded with various universities.

“We have now also incorporated the highly successful IMESA Young Professionals Portfolio (YP2) model first initiated by our KwaZulu-Natal Branch, to support and grow our membership base in this vital segment,” said Maphoto. Overall, the NP Branch membership base grew from 374 to 432, underscoring its successful outreach endeavours across municipalities, as well as at tertiary level.

“The journey ahead is clear. We need to recapacitate our municipalities, reinforce commitment and accountability, and re-professionalise the public sector to safeguard quality service delivery. This is a shared responsibility across multiple stakeholder platforms, with IMESA leading the charge in municipal engineering,” Maphoto concluded.

To obtain copies of the speaker presentations, email the IMESA Branch Secretary at np@imesa.org.za.

Within the climate change context, floods of increasing severity have become commonplace, requiring a range of engineered responses to manage rising stormwater volumes. IMIESA speaks to Scott Magnus, Contract Manager at BLOC Contractors – a leading geotechnical specialist – about an innovative solution employing hand-mined segmental tunnelling in Prospecton, Durban.

The widespread April 2022 floods have been recorded as KwaZulu-Natal’s worst natural disaster to date, with eThekwini Municipality being one of the worst affected areas. In the wake of the devastation, billions of rands in infrastructure damage were caused, with a much greater multiplier effect in terms of economic losses. In response, eThekwini’s Engineering Unit: Coastal, Stormwater & Catchment Management Services, responded citywide with repair works and future-proof interventions to effectively mitigate against recurring flood events.

A case in point is the town of Isipingo south of Durban, which includes Prospecton – a strategic industrial and manufacturing hub. An urgent upgrade was required to the Isipingo canal system, which flows into the Isipingo Beach lagoon. This led to the initiation of the Clark Road Sea Outfall and Culvert Stormwater Upgrade. The scope of works – completed over an eight-month period in July 2025 – entailed the construction of a new 92 m long 2 650 mm diameter (2 400 mm internal diameter) stormwater segmental concrete tunnel, traversing through an approximately 20 m high sand dune section and

interconnecting with a new stormwater outfall on the beach.

BLOC Contractors was appointed as the geotechnical sub-contractor, working in conjunction with Afrostructures as the main contractor. The latter was responsible for the precast concrete fabrication of the 50 MPa individual segments required to build the 153 rings forming the completed tunnel system. Manufactured to strict standards to meet strength and dimensional accuracy, Afrostuctures also designed an innovative interlocking mechanism to facilitate ease of installation. Each ring is composed of eight individual 600 mm wide elements.

Trenchless versus open excavation

Open excavation was not a practical option, firstly due to the depth of the dune, and secondly given the presence of nearby flats running parallel to the servitude in which the pipe needed to be installed. Plus, there was an informal settlement living on the dunes that had to be temporarily relocated to make room for the tunnel launch pit.

Mass excavation would also have required extensive shoring, which would have been too expensive, as well as impractical in the shifting sands. Given the challenging ground conditions and high water table, the traditional pipe jacking method was also unsuitable, as the tunnel's size and length, and the resulting ground pressures, posed a significant risk that the jack could seize before being completed.

Another option that could have been considered by the client is closed faced microtunnelling, but the cost would have been around three times higher than the final method chosen. Therefore, BLOC Contractors’ proposal for a hand-mined segmental tunnelling approach was supported by the client.

In developing the optimal tunnelling methodology, BLOC appointed Clive Wilson from Wil-Pass and Associates for the geotechnical and structural design of the overall system, as well as the segmental sections.

“His expertise was essential in developing and presenting a design that was both feasible and safe, ensuring the project could be delivered successfully on time and within budget,” Magnus explains.

Since its formation in 2002, BLOC Contractors has completed more than 200 projects, fielding a range of services that include pipe jacking, horizontal directional drilling, lateral support, and sheet piling. The company also has the inhouse capability to design and fabricate fit-forpurpose equipment solutions. For the Clark Road project, this entailed the development of a specific custom-built shield.

“Shields typically used for pipe jacking and tunnelling projects are not items that you can generally buy as standard products ‘off the shelf’ on the open market. However, thanks to our inhouse knowledge and expertise we have a wellestablished track record for mechanical innovation. This gave us the confidence to adopt a hand-mined segmental tunnel methodology for the Clark Road stormwater outfall,” Magnus continues.

“Our unique shield for this project had to seamlessly accommodate the segments and be strong enough to push forward under high jacking loads through loose and wet sand, while maintaining precise alignment, all of which it managed perfectly. To the best of our knowledge,

Cooled air was constantly pumped into the tunnel to maintain a comfortable working temperature. The site’s high water table also

this technique has not been used in South Africa for more than 20 years, largely due to the loss of industry experience. It’s also a first for us, underscoring our ability to innovate,” Magnus continues.

During construction, the 2 650 mm diameter segmental tunnelling shield was hydraulically advanced forward to incrementally install the precast concrete segments. However, unlike in soil and rock conditions – where a front face drilling arm could have been employed – in this case the sand was manually removed by BLOC Contractors’ construction team. Since the pipe needed to be jacked on a downhill grade in saturated conditions, provision also needed to be made for continuous dewatering of the face.

“When you jack through compacted soil, engineered fill or rock, the ground naturally arches into a round protective shape, enabling you to push your pipe forward. However, loose beach sand continuously collapses. As you advance, the sand settles and closes in around the pipe being installed,” Magnus explains.

If a conventional pipe jacking approach was applied under these circumstances, the friction load would become unsustainable over a 92 m distance, resulting in damage to the pipe sections, and potentially the seizing of the hydraulic jacking mechanism.

For the Clark Road project, the front shield was pushed forward 600 mm each time – per installed segment. The rear skirt on the tunnelling shield –extending around 1,5 m over the last pipe section placed – provided space for the crew to assemble the next ring within a safely controlled environment. As the work was carried out during summer, cooled air was pumped into the face to keep working conditions optimal.

In total, 153 precast concrete rings were installed to build the 92 m long stormwater outfall tunnel. Each ring is composed of eight individual 600 mm wide segments

In total, over 500 m3 of beach sand needed to be removed to complete the tunnel, with the material removed via a trolley system equipped to handle around 1,2 m3/load.

“The project was a great success and a vital one for Prospecton, which forms part of the Durban South Basin – a low-lying area that has been prone to periodic flooding over the years,” says Magnus. “The Clark Road outfall is the final stormwater conduit to the sea within Isipingo, and therefore essential.”

“From a creative engineering perspective, this project has also demonstrated how homegrown solutions can extend the possibilities of conventional pipe jacking techniques safely and cost-effectively. Hand-mined segmental tunnelling could well become the norm on municipal projects where similar ground conditions exist,” he adds.

In parallel with the Clark Road tunnel development, over the past 12 months BLOC Contractors has been involved on a wide range of water and sanitation projects in South Africa and Namibia.

“It’s really encouraging to see a positive upturn in regional public infrastructure investment. In response, we’ve recently added microtunnelling to our suite of services to support a series of exciting projects in the pipeline. In expert hands, trenchless techniques minimise disruptions and add enduring value in a way unmatched by opencut techniques,” Magnus concludes.

The construction of the new Arbeidsgenot Primary School in Grasslands, Bloemfontein, is a milestone development for a community that has long endured inadequate access to basic education. Originally a small, under-resourced isolated farm school, the old facility was unable to meet the growing demand for education in the area. Outside the city limits, learners were forced to travel long distances to attend school.

Compounding this, most public schools in Mangaung are overcrowded, with some classrooms accommodating 50 to 60 learners – conditions that significantly affected the quality of teaching and learning.

Jointly commissioned by the Free State Department of Education and the Development Bank of Southern Africa (DBSA), this project responded directly to these long-standing challenges to construct a Mega school that will accommodate 1 200 learners. SMEC South Africa was appointed by DBSA to provide professional services spanning the full project lifecycle – from preliminary and final design to construction supervision and close-out. This included civil, structural, mechanical, electrical, water, and sanitation services.

SMEC was also tasked with ensuring that all designs met national building codes and education sector standards.

Optimally combining form and function, the school complex showcases excellence in design and construction. It also goes well beyond this by creating a learning environment that keeps pace with future educational requirements in an increasingly high-tech world. A case in point is the provision of a computer and a science laboratory – facilities still not commonly provided at primary level in South African public schooling.

Classroom capacities are now much smaller, and more teacher focused, and every provision has been made to facilitate engagement. This includes the provision for wheelchair access via appropriately sloped ramps. Furthermore,

A bird’s eye view of the school complex, situated within the rapidly expanding Grasslands community

flexible furniture solutions allow easy adaptation for diverse learning and mobility needs.

Another key feature is the multi-purpose school hall, which was strategically designed to be accessible to the broader community while remaining securely separated from academic areas, ensuring the safety of school facilities during after-hours use.

To reduce the carbon footprint, lower operational costs, and enhance comfort levels, natural ventilation and building orientation were carefully planned to optimise airflow and limit reliance on mechanical systems.

In collaboration with the architectural team, all classrooms were designed with elevated aluminium-framed windows, carefully positioned to maximise daylight penetration throughout the school day. This passive lighting strategy significantly reduces the school’s reliance on artificial lighting. Where lighting is required, energy-efficient LED fittings were installed throughout the facility.

Being a water-scarce region, the design also placed a major emphasis on conservation measures. These include the installation of low flow taps, toilets, and urinals across all ablution areas.

Plumbing systems were designed for efficiency and provision was made for situations where the local municipality cannot supply water. Part of the design included a 65 000 ℓ water storage tank that can supply the school with enough water in the absence of water supply from the municipality. The storage tank also supports irrigation – ensuring the school can adapt to changing environmental conditions and water availability.

Safety and security were primary considerations. Here the footprint layout includes well-defined vehicular and pedestrian routes, a secure dropoff zone and spacious parking. Additionally, covered walkways connect all key buildings,

The inclusion of a guardhouse, an alarm system and CCTV surveillance ensures the protection of infrastructure and occupants – features rarely implemented in similar contexts. Enhanced measures were also implemented for the computer lab, including a reinforced steel door and ceiling-mounted steel mesh to deter theft and vandalism.

The school hall stands out as a particularly demanding element. Rather than conceal the structure with a ceiling, the team opted to expose the trusses, showcasing their geometry and varying sizes as an intentional part of the interior aesthetic.

Unlike more conventional finishes, the hall’s exposed concrete columns also had to

considerable emphasis on workmanship and formwork preparation, as the visual result was entirely dependent on the accuracy and care taken during pouring.

The hall roof, too, introduced additional challenges: the large steel trusses were manufactured off-site but needed to be fitted with exacting precision on-site. Ensuring seamless integration between prefabricated and in-situ elements required a high level of accuracy and planning.

Working within tight budget parameters, the design team also opted to eliminate traditional gutters and downpipes, recognising their vulnerability to damage and ongoing maintenance costs. Instead, the roof design safely manages runoff while simplifying the structure – an elegant, cost-saving measure appropriate for a facility with limited resources.

harmony and consistency throughout the design and construction of the Arbeidsgenot Primary School. During site investigations, challenging soil conditions were identified, prompting the use of raft foundations across all buildings and the importation of G6 material to ensure structural stability, which provided an effective and practical solution. In turn, durable, low-maintenance materials were used for major building elements such as flooring, walls, and roofs, which helps reduce future repair and replacement costs. Simplicity and accessibility were further prioritised in the design of all service systems, ensuring ease of upkeep and ready access for routine maintenance.

Creating a warm and inviting effect, face brick was used as the primary exterior finish across all buildings, chosen not only for its durability, thermal efficiency, and low maintenance, but also for its clean, timeless aesthetic. To enhance visual

In collaboration with the architectural team, all classrooms were designed with elevated aluminium-framed windows, carefully positioned to maximise daylight penetration throughout the school day

appeal, two complementary brick colours were selected and intentionally arranged to break monotony and create a vibrant, inviting atmosphere.

The installation of insulated roofing within the classrooms further assists in regulating internal temperatures. In turn, the building envelopes and shading elements were tailored to suit the regional climate, ensuring long-term comfort and durability.

Throughout the project, more than 100 jobs were created, prioritising local labour. Workers received targeted training in trades such as plumbing, carpentry, bricklaying, and electrical works, along with health and safety, site supervision and entrepreneurial skills. Financial literacy and life-skills sessions further supported long-term personal development.

In turn, local SMMEs were subcontracted for various aspects of the build, creating short-term income and strengthening small business capacity in the area. The same

approach was applied, where practical, in locally sourcing the multifaceted materials required during the building programme.

Making a lasting difference

Constructed over a 24-month period from July 2022 to July 2024, the establishment of the Arbeidsgenot Primary School has had a profound and positive impact on educational access and learning outcomes for children in the Grasslands community.

Previously, many learners walked more than 5 km each way to the old farm school – a physically demanding and sometimes unsafe journey that contributed to absenteeism, fatigue, and reduced learning capacity. The new school, now situated in the heart of Grasslands, is within comfortable walking distance for most learners – removing a vital barrier to foundational learning.

The school’s proximity has also strengthened parental involvement and deepened community engagement, enhanced by the opening of the school hall to the public for scheduled events. The latter now serves as an important social hub.

For example, in April 2024, Arbeidsgenot Primary School hosted a Gender-Based Violence and Femicide Prayer Service, as well as the Provincial Freedom Day celebration –a clear reflection of the school’s evolving role as a space for healing, empowerment and collective progress. Events such as these reinforce the school's function beyond education, serving as a platform for awareness, advocacy, and civic participation.

Going forward, the engineering layout includes provision for three additional classrooms. This planned flexibility ensures that the school can expand sustainably as the demand for early education increases in the area.

For current and future parents, it’s reassuring to know that their children have a solid and safe environment in which to grow in preparation for the next phases in their secondary and tertiary education.

South Africa is experiencing a steady rise in urbanisation, leading to increased population densities in cities, towns, townships, and informal settlements. This overcrowding often results in environmental degradation, particularly in areas where provision has not been made for parks, street trees, and open green spaces.

Rapid urban development is frequently marked by inadequate environmental planning. However, effective planning – especially through initiatives such as urban greening – can play a vital role in enhancing the quality of urban environments and improving the well-being of residents.

To tackle this challenge, the Department of Forestry, Fisheries and the Environment (DFFE) has launched its 1 Million Trees campaign this Arbor Month (September 2025), under the theme “My Tree, My Oxygen, Plant Yours Today”. This is a key initiative under the Presidential 10 Million Trees Programme that encourages citizens, businesses, industry, labour and civil society at large to plant ten million trees (60% fruit and 40% indigenous)

across the country. The DFFE has also published a tree catalogue (https://10milliontrees.dffe. gov.za/10milliontrees/make-a-pledge) to guide in the selection of suitable species based on specific demographic regions and to support their campaign through donations.

To strive for sustainability, it is crucial that proper tree planting and ongoing maintenance are considered in any tree planting project. During the first weeks of establishment, young trees typically need frequent watering – sometimes every few days in the first month – to anchor their roots. However, it is equally important to practice water conservation during this process.

Using methods such as mulching, drip irrigation, or water-wise planting techniques helps reduce evaporation, ensures efficient water use, and prevents wastage. As trees mature and their roots strengthen, the frequency of watering should be reduced, encouraging resilience while supporting sustainable water management. As we strive to create “Greener Communities”, let us be mindful of how we water our trees.

Follow these simple steps (as shown in Figure 1) to plant trees the Water Wise way:

1 Dig a square hole, half a metre wide by half a metre deep. Keep the dark topsoil (containing essential nutrients) separate from the soil beneath it. Put the topsoil in the bottom of the hole.

2 Dampen the soil with water to avoid any shock that could be experienced by the roots.

3 Remove the plastic bag and place the tree upright in the hole.

4 To enhance the nutrition of the soil, mix compost/kraal manure with your leftover soil and pack it firmly in the hole.

5 Measure one spade-length in distance around the tree. In this area, remove all the grass and weeds.

6 Next to the tree’s roots, place a 2-litre plastic bottle with a hole at the bottom. Make sure the bottle is placed at an angle. Alternatively, a pipe can be used as a watering apparatus where water flows through and directly reaches the roots for efficient water uptake. Ensure that the other opening end of the bottle/pipe is above ground level.

7 Add a 10 cm layer of mulch (leaves, stones, straws or strips of newspapers). Mulch acts as a blanket covering the soil; it keeps the soil cool and reduces water loss from its surface. Make sure that the mulch does not touch the tree.

8 Fill the bottle/pipe with water once a week. This prevents wastage by sending water straight to the root system. Once you have watered the tree, put the lid on the bottle to prevent any water evaporation. After the first year, water the tree only when the soil is dry.

9 Some plants grow towards the sun, therefore place your stake in the opposite direction of where the morning sun will emerge. Position a wooden stake of 3 m in length approximately 30 cm from the base of the tree. Insert the stake into the soil at a depth ranging from 20 cm to 60 cm. Gently fasten the stake to the tree's trunk using a soft material, like a used stocking. This will aid in promoting the tree's upright growth.

What makes a good material? And what characterises a bad one?

Material use throughout history and prehistory has been central to human progression. From the Stone Age, through the Bronze and Iron Ages, innovations were made possible by the properties of novel materials. As the old saying goes, we didn’t exit the Stone Age because we ran out of stones! Rather, the spirit of human ingenuity drove us to explore better ways to meet our diverse needs for shelter, hunting and defence, food production, transport, medicine, communication, water management, energy and many other facets that defined civilisations and supported our continued development. By Professor Mark Everard*

Plastics, of course, have been in the crosshairs of campaigners over recent decades. There is an irony that objectors make their voices heard through social media using computers, cell phones and other devices –even pens, televisions and printing machinery – made possible through the benefits of modern materials. This includes semiconductor-based microprocessors without which the space age, the ICT revolution and medical imaging would have been infeasible, a diversity of exotic metals and novel ceramics and, of course, plastics.

Many fail to realise quite what plastics are, and how much they support their needs as they turn on the tap, flush the toilet, make phone calls, use the internet, wipe their kitchens clean, switch on the computer or domestic lights, travel, or enjoy the comfort of high-efficiency insulation in windows and other domestic fittings. Recreationally, wetsuits, fishing line, binoculars, breathable fabrics, waterproof bags, safe food storage and so many more plastic products add to the quality of modern life.

While pressing issues of potentially problematic additives, lack of recycling leading to waste

accumulation and generation of microplastics need to be addressed, a parallel and significant reality is that plastics make modern life possible in ways that are often unappreciated by those that rail against them.

None of this is necessarily news to readers of this magazine. We can though fall into the trap of regarding or selecting materials framed by a simple dichotomy of “good” versus “bad”, reinforced by a naïve regulatory environment and lazy media focused narrowly on potential hazard. We will return to the difference between hazard and risk later in this article.

Balancing the real-world elements

Every breath we take comprises 79% inert molecular nitrogen as well as around 20%

oxygen vital for our health and wellbeing. These, of course, are good materials! But scuba divers are trained that nitrogen turns into a narcotic below certain depths when partial pressures are exceeded, and more critically that oxygen in enriched air mixes can turn instantly neurologically fatal if critical partial pressure thresholds are exceeded, with fatalities occurring every year as narcotised divers lose orientation or through oxygen poisoning.

So, these “good” materials are actually pretty “bad” in different contexts! And then we have hydrochloric acid, a pretty bad substance in environmental terms – “muriatic acid” was the initial focus of the UK Alkali Act of 1863: the first regulation globally on chemical releases from industry – and yet each and every one of us is producing HCl in our stomachs at a pH of between 1.5 and 3.5, where it is essential for decontamination and digestion processes and is then safely resorbed.

Ozone in the wrong place is carcinogenic and smog-forming yet is vital for deflecting and absorbing ultraviolet radiation in the upper atmosphere and is also useful for sterilisation of swimming pool water and for other purposes. How useful is a naïve branding of “good” versus “bad” substances when context is overlooked? This is more than a mental exercise.

Subconscious division of substances into the “good” and the “bad” pervades a great deal of chemical legislation and many supporting assessment tools relating to the industrial and domestic uses. This oversimplistic dichotomy certainly underpins the current hue and cry about plastics. The debate is at least more nuanced in the field of medicine, where a balance is sought between beneficial therapeutic properties versus contraindications.

The PVC window frame that I’m sitting by

as I type this article is a classic example. Green campaign groups might have me choosing timber as it can be sourced from renewable forests through excellent accreditation schemes such as the Forest Stewardship Council (FSC)1 that is also protective of forest dwelling communities. However, wood is biodegradable and so is often pre-treated but certainly requires regular applications of biocides and barriers in one form or another throughout the use phase of the window frame, and even this simply slows degradation processes.

Taken in a whole lifecycle context, the wooden window profile receives substantial inputs of biocides, energy and time to keep it functional over a shorter lifecycle than the 30+ years over which my PVC window frames have been in place. My PVC window frames provide efficient insulation, saving energy on heating, have received no inputs of chemicals or energy to keep them functional over that third-of-a-century, and are still going strong. When they reach the end of their useful life (the metal locking mechanism rather than the PVC gave up the ghost in another of our windows), the PVC element is fully recyclable within a functional British recycling infrastructure.

Looking across the lifecycle, the petrochemical and chlorine inputs have had impact at the point of extraction and vinyl chloride monomer (VCM) is a hazardous substance but is wholly contained in the PVC production process, but inputs beyond that point have been negligible over a long service life after which recycled chemical constituents can have further lives that might span centuries.

Now let’s talk about pipes, which I’m sure will be of great interest to readers of this magazine, which includes SAPPMA members. Our house was built in 1955 with a ductile iron pipe running, we discovered, under our living room. Around a decade ago, the pipe failed and, when exhumed, had almost completely turned into a rusty colander, creating havoc and disruption in its wake! Concrete or even asbestos pipes also have limited lives, and they also poorly resist torsion.

Our failed pipe was replaced with polymer (PE I think but I was not home when it was installed) with an estimated life expectancy of a century, and possibly lasting a whole lot longer. Protestors might be unhappy that the new water pipe is plastic, but material efficiency over the pipe’s long lifecycle is substantial, beyond which the plastic is recyclable.

This amounts to a very substantial benefit-tocost outcome in material and financial terms over the whole lifecycle of this particular pipe, and potentially also further recycled material lifecycles beyond that. Furthermore, a lot of my work is in south and east Asia, and it was clear after a major earthquake in Nepal that plastic pipes flexed with ground movements while other harder pipe materials fractured. So, there are lifecycle and other technical properties of plastic pipes that simply cannot be matched by many alternatives.

The above mix of personal narrative versus scientific observation builds upon a longstanding case I have been championing as a systems scientist to contest the naïvety within received assumptions as well as myopic regulations, assessment tools and expectations that there are automatically 1 https://fsc.org/en

“good” and “bad” materials and constituents. I said I would get back to hazard versus risk later in this article and here it is: we all know that risk = hazard x exposure, so why is this truism almost wholly lacking in the regulatory environment? VCM is hazardous but, if wholly enclosed in the PVC production process, there is no exposure as none remains in the finished plastic.

Likewise, efficient recycling averts systemic environmental accumulation of constituents beyond product end-of-life. More significantly, we have almost entirely overlooked the benefits that materials serve in terms of meeting our needs safely and efficiently when assessed in risk terms across the whole societal lifecycles of the products into which they are integrated.

The most appropriate material choices and innovations rest not on “good” or “bad” judgments based on oversimplistic hazard criteria in isolation, but through wider consideration of how most appropriately to meet human needs safely and efficiently. This wider context of the meeting of human needs in the safest and most efficient manner is a vital underpinning of the many pressing sustainability challenges faced today by a world with rising human population and per capita resource demand, dwindling natural resources and a changing climate.

Many will know the “Brundtland definition” of sustainable development – “Development that meets the needs of the present without compromising the ability of future generations to meet their own needs” – to which the global community signed up in 1987 following publication of the report of the World Commission on Environment and Development2

Recognition of the priority of meeting needs, not merely now but as a bold intergeneration commitment, has little to do with the current focus on hazard alone – judging materials as “good” or “bad”. Nor does the negative focus on hazard chime with the goaloriented emphasis of the 17 UN Sustainable Development Goals3

Refocusing on the endpoints of meeting the needs of humans and supporting ecosystems reasserts the aspirational “lost half” of the Brundtland conception of sustainable development that has been serially overlooked in its transposition into legislation, protocols and common understanding4.

This talk of sustainable development goes far beyond altruism.

Wise businesses seek to anticipate emerging markets, as the insuperable forces of environmental change, resource flows and societal tolerances ultimately shape future regulations and market expectations. Pressures driving us to seek a more sustainable future – the climate emergency, the biodiversity crisis, rising concern about pollutant accumulation, issues

2 World Commission on Environment and Development. (1987). Our Common Future. Oxford University Press.

3 United Nations. (2015). Sustainable Development Goals (SDGs). United Nations. [Online.] https://sdgs.un.org/goals, accessed 19th April 2024.

4 Everard, M. and Longhurst, J.W.S. (2018). Reasserting the primacy of human needs to reclaim the 'lost half' of sustainable development. Science of the Total Environment, 621, pp.1243-1254. DOI: https://doi.org/10.1016/j.scitotenv.2017.10.104.

5 Everard, M. (2024). Seeking Sustainable Development on a Level Playing Field: A PVC Case Study. Routledge.

of distributional and intergenerational equity, and more – are far beyond the conceptual, as they will frame the successful markets of the future that provide optimally safe and efficient means to enable people to meet their needs.

This is why, for example, smoking in public places is banned in many countries, and why arsenic and methyl bromide are no longer permitted for use as insecticides. Tomorrow’s successful businesses will be those shaping their thinking and innovations around optimal ways to enable people to meet their needs in an inevitably different future.

Levelling the playing fields

All this and more is expanded substantially in my 2024 book Seeking Sustainable Development on a Level Playing Field: A PVC Case Study5. The case study used in the book is PVC, addressing the “good” and the “bad” in a balanced way, but within the context of risk across the full societal lifecycles of the products into which it is incorporated.

Wider cross-material application of this “level playing field” approach based on common sustainability-relevant criteria reveals that ALL materials used by society in our less than sustainable world have beneficial, problematic, and more or less appropriate aspects at different lifecycle stages, many of them generic to societal resource use habits rather than inherent to the specific substance.

The use of plastics for pipe manufacture to serve a variety of societal needs seems a good option from that perspective albeit, like all materials, with areas for improvement highlighted by “level playing field” analysis!

Reorienting thinking around what materials best help humanity meet its needs safely and efficiently in a changing future is a sound strategy for innovation, choice and future profitability, and one that can (or at least should) better inform the policy environment.

For further discussion you can phone me at +44-7747-120019 or email Mark.Everard@uwe.ac.uk.

* Co-Director at Pundamilia Ltd, a visiting Professor at Bournemouth University and Associate Professor at UWE Bristol. He recently presented at the PVC Transformation: Driving Progress in a Changing World conference held during August 2025 in Johannesburg, co-hosted by the Southern African Vinyls Association (SAVA) and the Southern African Plastic Pipe Manufacturers Association (SAPPMA).

When procuring plastic piping systems, purchasers are advised to ensure that all products and manufacturers meet the highest quality and compliance standards to ensure the product meets the design life requirements. The following considerations and requirements are recommended and to be stated in any RFQ (request for quotation). THE FOLLOWING BUSINESSES AND INDUSTRIES CAN QUALIFY FOR A SAPPMA

• ISO 9001 QMS (Quality Management System) Certificate or Quality Management Plan of the production facility with a copy of the latest Quality Audit Reports to be submitted throughout the supply period

• Product Certification (e.g. SANS ISO 4427-2 if HDPE, SANS 966-1 if uPVC, etc.)

• Raw material Certification (e.g. SANS ISO 4427-1 if HDPE)

• Certificate of analysis (COA) of polymers used

• Certificate of conformance (COC) of products

• Undertaking not to use any bought-in recycled material

• Laboratory test results, in accordance to the certification bodies’ Specific Permit Conditions (SPC), for each supplied pipe batch shall be submitted

• Full traceability of the pipe Batch Number to the raw material used

• SAPPMA Membership Certificate with a copy of the latest SAPPMA Audit Reports throughout the supply period

• Pipe to be marked in accordance with the relevant standards, with the logo of the certification body and SAPPMA clearly visible.

• Pipe to be inspected for dimensions (OD, wall thickness and ovality) and damage (scratches, gouges, cracks, missing rubbers, etc.)

• Is the manufacturer open to unannounced inspections during production?

• Is the quoted price realistic in terms of current polymer prices? (Beware of tenders where the selling price in R/kg is suspiciously low)

• Pipe & fittings manufacturers

• Raw material suppliers • Consultants • Construction companies • Contractors & Installers • Individuals • Municipalities • Water Boards

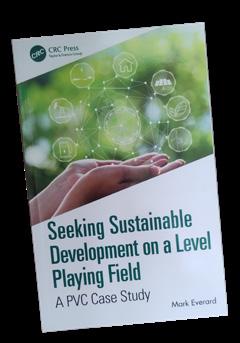

The first use of thermoplastic pipes for municipal water reticulation dates back to the 1930s in Germany. Since then, ongoing adoption has been exponential across all sectors worldwide. IMIESA speaks to Jan Venter, CEO of the Southern African Plastic Pipe Manufacturers Association (SAPPMA) about industry gains and why plastic pipes are part of the future.

What are some of the major milestones in local and international R&D?

It is a dynamic industry that never stands still. In recent years there have been significant developments in polymer technology as well as processing equipment. A key innovation is that the design stress of materials has increased considerably over the past 40 years, enabling higher operating pressures and more economical application. This is opening the door for the wider adoption of plastic pipes for bulk water distribution. Furthermore, modern extruders enable very fast line speeds and superior quality control.

Are plastic pipes sustainable?

Indeed. Lifetimes of more than 50 years are expected when installed correctly. Plastic pipes are also environmentally friendly as they require far less energy to produce compared to steel and concrete. Plastic pipes also don’t corrode, which is key in water lines to prevent potential

potable water contamination. Plus, there is scope for recycling, but within strict parameters.

When is recycling an acceptable practice in pipe manufacturing?

It is inevitable that a small percentage of pipe production will be off spec (particularly

when a line is started up). These pieces are recycled (mostly on site), and this granular material is allowed to be used in new pipe production. National standards do not allow importing of recycled material for certified pipe. However, it may be used for non-spec pipe in non-critical applications, or to produce other plastic products as part of a circular economy initiative.

What are the key considerations when specifying plastic pipe for sewer systems?

As with all other infrastructural installations, only certified products conforming to the relevant national standards set by accredited organisations can be used.

Is there a clear understanding in industry about the different performance characteristics of PE, HDPE, and PVC?

Unfortunately, there are still degrees of ignorance, but it remains one of the prime focus points of SAPPMA to inform and educate designers and decision makers. To that end various tools are implemented, such as seminars, formal training courses, our informative website, as well as a comprehensive technical manual (now in its 5th edition). The fact that the latter is issued by an independent and non-profit organisation adds value and credibility.

What is the current percentage of installed systems for plastic pipe in South Africa versus other materials like concrete, GRP, and steel?

A full-scale independent study has not been done for quite a while. The last such investigation reflected approximately as follows (ref. LHA 2014).

For pressure pipe up to 250 mm diameter, plastic (PVC and HDPE) dominated with an approximate share of 80%. For pipe sizes ranging from 280 to 500 mm, a similar trend was recorded at around 75%. However, steel continued to dominate for pipe diameters of 800 mm and above.

Within the sewer pipe segment, plastic pipes (PVC and HDPE) in a range up to 250 mm achieved a 100% market share, dropping to around 59% for pipes with a diameter of 250 mm or greater.

It is estimated that the percentage of large diameter plastic pipes for sewer and water applications have increased since then. Furthermore, it must be noted that there are big differences in material properties and hence also in applications.

Are SAPPMA members facing cost pressures in terms of polymer prices?

Polymer costs are indeed very high. Interestingly, although a high percentage of our polymers are manufactured in South Africa, they seem to follow a price parity policy in line with global producers in this sector. So, there’s no local saving.

The best pipe will fail if installed incorrectly. What is SAPPMA doing to promote industry best practice?

A valid statement. SAPPMA endeavours to cover the full spectrum of the industry and hence also the downstream end. We therefore have a division within SAPPMA that focuses on standards and best practices for the installation of pipe systems.

How can industry specifiers know for certain that they’re buying SAPPMA approved products?

SAPPMA approved products are clearly marked with the SAPPMA logo. In addition, specifiers should request suppliers to provide a valid copy of their SAPPMA membership certificate, which is updated every semester.

What are some of the key issues that SAPPMA would like to see addressed in its sector?

The critical importance of reliable pipeline infrastructure should be better recognised and supported by authorities – local and national. Specifiers and buyers should also refrain from a short-term approach by buying cheaper non-certified products that are certain to fail prematurely, with downstream implications in terms of service disruptions and socio-economic impact.

Water and sanitation pipeline systems are long-term investments that are the vital conduits for a healthy and functioning society. We need to look to the future.

Operating Range

Flow - 10m³/hr up to 2500m³/hr

Head - 4m up to 120m

Applications

General liquid pumping - Power plants

Bulk Water - Steel mills - Refineries - Chemical plants - Cooling and heating systems

The 1 000 mm PVC-O orientation chamber at Sizabantu Piping Systems’ factory in the RBIDZ. The first 1 000 mm TOM®500 PVC-O pipes were manufactured by Sizabantu Piping Systems in June 2025

PVC pressure pipes were first used about ninety years ago on the stadium for the Berlin Olympics. PVC-O pipes are about forty years old, during which time they have undergone five iterations of Classification By Mike Smart, Pr Eng*

The applicable SANS 16422 Pipes and joints made of oriented unplasticised poly(vinyl chloride) (PVC-O) for the conveyance of water under pressure – Specifications specifies all five Classifications. It is critically important that Classification is not confused with “Class”, the pressure rating (PN) of a pipe.

The strength of the material used to manufacture a pipe determines the Classification, whereas “Class” is the maximum allowable continuous working pressure for the service life of the pipe. The service life of all thermoplastic pipes shall be not less than 50 years at 20⁰C, specified by ISO (International Standards Organisation) protocol, although some thermoplastic pipes provide 100 years’ service life.

The raw material’s Classification is determined by its MRS (Minimum Required Strength) in MPa (Mega Pascals) at 50 years

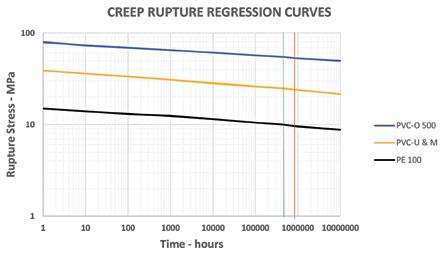

from the 20⁰C CRRC (Creep Rupture Regression Curve), as shown in Graph 1. Classification is 10 x MRS, and the five Classification iterations of PVC-O are 315, 355, 400, 450 and 500

based on their MRS of 31.5, 35.5, 40, 45 and 50 MPa respectively.

Historically, steel, ductile iron, reinforced concrete, and other “traditional” materials

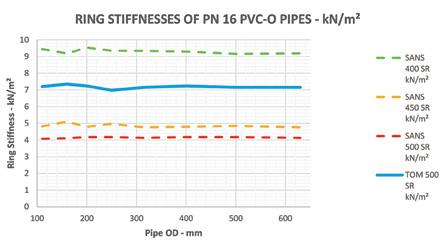

dominated the large diameter high pressure trunk water main market. However, with recent developments in PVC-O it can now compete in this market with TOM®500 (Tubos Orientado Moleculara Classification 500 ), the brand name of Sizabantu Piping Systems’ PVC-O Classification 500 PVC-O pipe. Sizabantu Piping Systems has the capacity to manufacture a 1 200 mm diameter PN 25 bar pressure class TOM®500 PVC-O pipe at its factory in RBIDZ (Richards Bay Industrial Development Zone).

The increase in size and pressure class of PVC-O pressure pipes was enabled, inter alia, by improved polymer technology, improved production technology – including in-line orientation and socketing that avoids reheating and repressurising – with variable orientation depending on the location on the pipe.

The development timeline of the manufacturing systems is:

- Year 2010: DN 315 PN 12.5 to DN 630 PN 25

– M-OR-P3136

- Year 2013: DN 630 PN 25 to DN 800 PN 20

– M-OR-P3180

- Year 2020: DN 800 PN 20 to DN 1000 PN 16

– M-OR-P3180

- Year 2024: DN 1000 PN16 to DN 1200 PN 25

– M-OR-P5012

- Year 2024: PN TOM®500 PVC-O PN 25

– All diameters

The current ISO 16422, single document standard, was converted to a five-part 1, 2, 3, and 5 document, the same format as SANS 4427, in Europe in 2024 promoted primarily by Molecor, Sizabantu Piping Systems’ Spanish technology partners. The ISO 16422 has been voted for adoption by the SABS and will become the applicable standard in the future. It specifies orientation, that determines MRS and thereby Classification, in greater detail.