Jurisdictions Safety Legislation

Act: Work Health and Safety Act 2011 (NSW)

Regulation: Work Health and Safety Regulation 2017 (NSW)

Legislation

Regulator and Contact Number COP

Regulator: SafeWork NSW Number: 13 10 50

NSW

•Managing Risks of Hazardous Chemicals in the Workplace

•First Aid in the Workplace

•Managing the Risk of Falls at Workplaces

•Confined Spaces

•Construction Work

•Managing Noise and Preventing Hearing Loss at Work Standards

AS/NZS 1067: Sunglasses and fashion spectacles, AS/NZS 1270: Acoustics - Hearing protectors, AS/NZS 1337.4-6 Series: Personal eye-protection, AS/NZS 1715: Selection use and maintenance of respiratory protection devices, AS/NZS 2161.1-10: Occupational protective gloves, AS/NZS 2210.1-9 Series: Occupational protective footwear, AS/NZS 1800: Occupational protective helmets - Selection, care and use, AS/NZS 4501.1: Occupational protective clothing – General recommendations on selection, care, use and maintenance of protective clothing

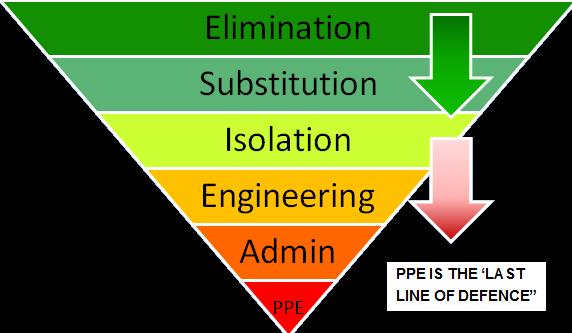

Hierarchy of Controls Definitions

Elimination

Substitution

Isolation

This control measure involves eliminating or removing the risk in its entirety

This form of control involves substituting a safer process or material for the hazardous process/material found.

This control involves separating the hazard or hazardous work practice from employee’s other work areas. This may involve sectioning off the area by erecting barriers or by moving either the hazardous work practice or the „other‟ employees and their work practices.

Engineering

Admin

PPE

This method of control involves designing and/or adding physical safety features to plant or equipment.

This type of control is most effective when used in conjunction with measures mentioned above or as an interim control whilst more effective control measures are developed and implemented.

PPE is not a particularly effective control method and should only be used:

• When all other control measures are impractical; or

• In conjunction with other more effective, control measures.

2

Establishment of site, positioning of tools and equipment

Manual handling, possible back strain, impact injury etc L2 C3 HR LR

• Ensure site is clear of obstructions (e.g. trip / slip hazards)

• Pre planning of work.

• Isolate the work area on ground level using barricades and signs to ensure persons cannot enter while work is in progress.

• Ensure all personnel have been trained and use correct manual handling techniques, if required use team lifting.

• Use mechanical equipment (e.g. portable trolleys) to reduce the force needed to lift, carry, move, hold or restrain material and tools.

• Suitable staffing appropriate to the tasks to be undertaken.

• All personnel to have Level 1 rope access qualifications.

Workers

4

3 Set up ropes on roof level Falls or slips from height - severe injury or death L2 C3 HR LR

Prepare surface to be painted (sanding, scraping).

Breathing dust, cutting finger, falling, paint chipping L2 C3 HR LR

• Any materials/equipment over 5kg to have 2 points of attachment.

• Ledge protector to be installed to protect ropes.

• Wear mask, eye goggles and gloves.

• Ensure the ladder (at ground level) is suitable for the task, in good working condition and fitted with rubber (or similar non-slip material) feet.

• Ensure the supporting surface is adequate, that it is

• Do not place tools or materials on top of the ladder

• Ensure the ladder, when leaned against the wall or edge, has a ratio of height to horizontal distance from wall of 4:1 and is secured.

Workers

Workers

5

Use of Hazardous Substances: Cleaners, Fillers, Paints

Harmful by inhalation (e.g. Irritating to respiratory systembreathing difficulties), Harmful in contact with skin (e.g. dermatitis or causes burns), Harmful if swallowed, Irritating to eyes or risk of serious eye damage.

L2 C3 HR LR

• Make Materials Safety Data Sheets (MSDS) available for substances classified as hazardous (e.g. Paints, Gap fillers, Sealers etc…).

• Ensure all personnel have been issued with and trained in the use of the required personal Protective equipment.

• Store hazardous substances safely and securely when not in use.

• Train workers in safe handling of hazardous substances.

• Label hazardous substances (includes safety and risk phrases).

• Do not store hazardous substances in food and/or drink containers.

• Wear mask, eye goggles and gloves.

6 Wash down using 30 second cleaner Burning eyes and falling L4 C3 MR LR

7 Spot prime

8 Filling

Burning eyes, falling and dripping paint L4 C3 MR LR

Burning eyes and falling L4 C3 MR LR

9 Undercoat

10 Lightly sand between the coats

Burning eyes, falling and dripping paint L4 C3 MR LR

Breathing dust and falling L4 C3 MR LR

11 Paint

Burning eyes, falling, dripping paint L4 C3 MR LR

Workers

Workers

• Wear mask, eye goggles and gloves. Workers

• Wear mask, eye goggles and gloves. Workers

• Wear mask, eye goggles and gloves. Workers

• Wear mask, eye goggles and gloves.

Workers

• Wear mask, eye goggles and gloves.

Workers

12

Working from scaffolds (at ground level)

Falls from height, severe injury or death

• Scaffolding to be erected and maintained by qualified and licenced riggers (above statutory heights)

• Keep controls in place if risk of fall ≥ 2 m e.g. edge protection, catch platform

• Provide and use adequate work

• Ensure no gaps in perimeter protection

• Use appropriate designed and erected scaffolds

• Barricade and sign work area

• Adhere to SWL (Safe Working Load) of scaffold. Do not overload with materials or personnel

L2 C3 HR LR

Workers• Do not remove any component, handrails, midrails, braces, ladders, toeboards, platforms, frames, couplers or ties that could render the scaffold unsafe.

• Wear hard hats and all relevant personal protection equipment.

• Do not climb on scaffold handrail

• Do not lean out of scaffold deck area

• Do not move/mobile scaffold while person working on it

• Do not use extension ladder/crates or any other material to increase reaching height on existing work level.

• Do not climb up/down outside of scaffold to get to work level.