Page 1 1 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

At Heights

Work involving working at heights. Organisational Details Company Name: Approval Date: Company Address: Next Review Date: Director / Manager Name: Contact Number: Type of SWMS: Generic (multiple projects, jobs, or work requests) ☐ Site specific (complete section below) ☐ Site Specific Details Principle Contractor: n/a ☐ Contact Number: n/a ☐ Site Manager or Supervisor Name: n/a ☐ Other PCBU’s: n/a ☐ Site Address: n/a ☐ n/a ☐ SWMS Details What high risk work activities are covered by this SWMS? A risk of a person falling more than 2 metres Work in an area with movement of powered mobile plant. Work on or near energised electrical installations or services. What is the scope of the works? Scope of work includes the physical work of installing, maintaining, repairing, altering, removing, or adding to construction painting services. Who else was consulted/involved in preparing this SWMS? Workers / employees Principle Contractor ☐ WHS Team ☐ Additional compliance measures: Pre-start Hazard Risk Assessment Toolbox Talk Workplace Safety Inspection

Working

SWMS

Page 2 2 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022 Sign off Person responsible for ensuring compliance with SWMS: Responsible persons signature: B Hmayed Contact Number: Date: Training / Licencing Requirements Construction industry general induction (White Card) Senior First Aid Training ☐ Forklift Licence ☐ Traffic Control Ticket ☐ Asbestos Awareness ☐ Working with Asbestos of a Minor nature ☐ (Other): ☐ (Other): ☐ (Other): ☐ Personal Protective Equipment Safety boots Eye protection Respiratory equipment Safety Helmet Hearing protection ☐ Barricading and signage Communication equipment Long sleeve long pants White night suits required on night shift ☐ (Other): ☐ (Other): ☐ (Other): ☐ (Other): ☐ (Other): ☐ (Other): ☐ Chemicals PVC Cement ☐ Diesel Fuel ☐ Petrol Fuel ☐ Silicone Spray ☐ Multi-Purpose Grease ☐ Silicone ☐ MAPP Gas / LPG ☐ Oxygen / Acetylene ☐ Multi-Use Lubricant Spray (WD-40) ☐ Nitrogen ☐ Refrigerants ☐ (Other): ☐

Legislation

Jurisdictions Safety Legislation Regulator and Contact Number

Act: Work Health and Safety Act 2011 (NSW)

Regulation: Work Health and Safety Regulation 2017 (NSW)

Regulator: SafeWork NSW Number: 13 10 50

•Managing Risks of Hazardous Chemicals in the Workplace

•First Aid in the Workplace

COP NSW

•Managing the Risk of Falls at Workplaces

•Confined Spaces

•Construction Work

•Managing Noise and Preventing Hearing Loss at Work

Standards

AS/NZS 1067: Sunglasses and fashion spectacles, AS/NZS 1270: Acoustics - Hearing protectors, AS/NZS 1337.4-6 Series: Personal eye-protection, AS/NZS 1715: Selection use and maintenance of respiratory protection devices, AS/NZS 2161.1-10: Occupational protective gloves, AS/NZS 2210.1-9 Series: Occupational protective footwear, AS/NZS 1800: Occupational protective helmets - Selection, care and use, AS/NZS 4501.1: Occupational protective clothing – General recommendations on selection, care, use and maintenance of protective clothing

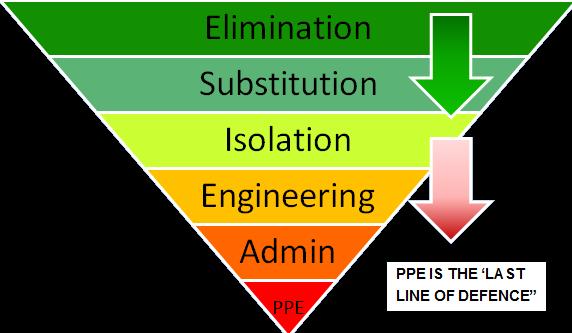

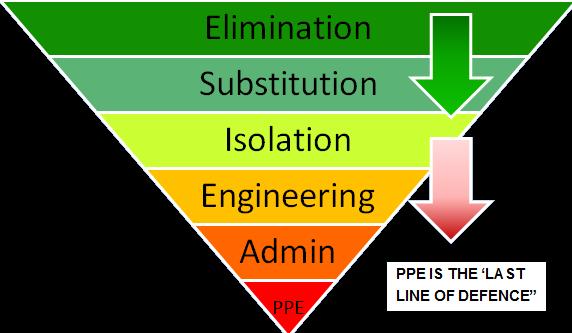

Hierarchy of Controls Definitions

Elimination

Substitution

This control measure involves eliminating or removing the risk in its entirety

This form of control involves substituting a safer process or material for the hazardous process/material found.

Isolation

Engineering

This control involves separating the hazard or hazardous work practice from employee’s other work areas. This may involve sectioning off the area by erecting barriers or by moving either the hazardous work practice or the „other‟ employees and their work practices.

This method of control involves designing and/or adding physical safety features to plant or equipment.

Admin

PPE

This type of control is most effective when used in conjunction with measures mentioned above or as an interim control whilst more effective control measures are developed and implemented.

PPE is not a particularly effective control method and should only be used:

• When all other control measures are impractical; or

• In conjunction with other more effective, control measures.

SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

Page 3 3

Page 4 4 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022 Risk Level Matrix Risk Analysis Consequence Likelihood Consequence C1 C2 C3 C4 Likelihood L1 1 1 2 3 L1 Highly Likely C1 Catastrophic L2 1 2 3 3 L2 Likely C2 Major L3 2 3 4 4 L3 Unlikely C3 Moderate L4 3 4 4 4 L4 Rare C4 Minor EXTREME RISK HIGH RISK MEDIUM RISK LOW RISK General Planning # Job Step / Process / Activity Identify Hazards Risk Level (R) and the Residual Rating (RR) Identify Controls / Action Required Person Responsible L C R RR 1 Establishment of Site and Amenities • Non-Compliance with site safety rules L2 C2 HR LR • Use this Safe Work Method Statement in conjunction with

relevant Safe

•

•

•

gloves).

any other

Work Method Statement.

Location of Amenities are to be pre-determined and setup away from populated areas, schools and high traffic areas.

Exclusion zone set up around the site set up area.

Traffic control conducted by ticketed traffic controllers. Refer to Traffic and Pedestrian Management SWMS-C08). • Ensure all vehicles are parked legally (not in No Stopping and not over driveways or in a location which is obstructing traffic. • All staff are to wear PPE (hard hat, visibility vest and safety boots, safety glasses and

Workers

Use of ladder

Hazards

Safe Use of Ladders

Risk Level (R) and the Residual Rating (RR)

• Fall from ladder

• Falling object L3 C3 HR LR

Ensure the ladder:

Identify Controls / Action Required Person Responsible

• Is an industrial rated ladder and in good working order

• Is on firm, stable and level ground

• Is the correct height for the task to avoid reaching or stretching

• Is not too close or too far from the support structure. The ratio must be 4:1. For example, the distance between the ladder base and the supporting structure should be approximately one metre out for every four metres of working ladder height

• Is secured against slipping or sliding, and/or there is another person holding the base of the ladder

• Has all the locking devices on the ladder secured into position

• Is extended a minimum of 1m past the access point, where accessing the roof or platform from a ladder

Ensure materials or tools are not carried while climbing the ladder. Tools should be carried in a tool belt or side pouch. Ladders are not to be used:

• in access areas or next to doors unless steps are implemented to manage the risks of pedestrians entering through the door or past ladder

• on scaffolding or an elevating work platform to get extra height

• in very wet or windy conditions

• next to traffic areas unless the working area is barricaded.

Workers

Page 5 5 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

# Job Step / Process / Activity Identify

L C R RR 1

Use of step ladders and platform ladders

• Fall from ladder

• Falling object

• Complete works in time of low traffic volume

• Request a Traffic Management Plan to reduce speed zone if needed

• Barricade and section off work zone

2

L2 C3 HR LR

• Reduced speeds around site

• Warning & Communication Signage

• Spotters as necessary

• Re-direction of traffic

Use of trestles

• Fall from ladder

• Falling object

L2 C3 HR LR

• Use lifting devices as provided or identified as a need

• Weight capacity & load limits displayed within the workplace

• Allocation of appropriate storage space and storage areas

• Access to mechanical equipment & mechanical aids

• Weights displayed on individual boxes and other items

• Purchase of goods are considered and adjusted to keep weights and box dimensions manageable

• Reduced weight of items

Workers

Workers 3

Page 6 6

SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

Safe Use of EWP

(R) and the Residual Rating (RR) Identify Controls / Action Required

Use of Elevated Work Platform (EWP)

• Fall from EWP

• Overturning of EWP

• Ejected from EWP L2 C3 HR LR

• Operator of a boom-type EWP must hold a High-Risk Work Licence where the EWP has the capacity to reach over 11 metres

• All workers in a boom-type EWP must wear their harness and have it connected to the EWP anchor point

• EWP should be located close to the work area to prevent the worker from needing to reach from the EWP to undertake the work

• Where outriggers are used, the outrigger pads must be sufficient to provide the needed stability for EWP

• Ensure the EWP is operated on consolidated level ground

• Workers must not stand on the handrails of the EWP

• Work must be performed from within the EWP

• A risk assessment and control measures need to be in place prior to a worker exiting an extended EWP (Refer to AS2550.10 Crane, hoists winches

– Safe use. Part 10: Mobile elevating work platforms, Section 5.9)

Page 7 7 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

1

# Job Step / Process / Activity Identify Hazards Risk Level

Person Responsible L C R RR

Workers

# Job Step / Process / Activity Identify Hazards

Use of guard rails for roofing work

• Falls while installing fall protection system

Safe Use of Scaffold

Risk Level (R) and the Residual Rating (RR) Identify Controls / Action Required Person Responsible L C R RR

• Guard rail system should include:

• toe boards or mesh infill to prevent falling objects, unless a 2 metre ‘no go’ zone has been established

• Providing insufficient protection to prevent fall L2 C3 HR LR

• a clear gap between rails not exceeding 450mm

• the clear gap between the midrail and toe board not to exceed 275mm

• no gap between the roof edge, including the gutter, and a guardrail located outside the roof line exceeding 100mm

• a clear distance between the roof cladding and bottom rail of not less than 150mm and no greater than 275mm

• an effective guardrail height above the roof surface of not less than 900mm (for roofs with a pitch over 10 degrees the effective height must be measured from a point 300 mm inside the roof edge)

• infill panels where the pitch of the roof exceeds 26 degrees

Page 8 8 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

1

Workers

Construct scaffold Mobile and fixed

• Manual handling

• Falling from heights

• Falling objects

• Sharps edges

• Structural collapse L2 C3 HR LR

• Safe means of access and egress to and from the scaffold

• Where distribution lines or services are closer than 4 metres, seek advice and approval from the electrical infrastructure owner before proceeding

• As erection work proceeds, install edge protection and fully deck at every working bay (during construction)

• All scaffold components to be installed as you go to maintain structural integrity

• Buddy lifting and handballing techniques should be used. Job rotation applied to vary the work stresses

• Maintain 4 metre exclusion zone for those not involved in scaffold erection

• Hard hats, gloves, safety glasses and safety footwear should be worn by all involved

• Install toe boards on working decks to minimise the risk of items falling

• Scaffold must be at least 4 metres away from overhead distribution lines or service supply cables

• Where the fall height is over 4m, written confirmation is to be supplied by a licensed person, identifying the scaffolding is complete and safe to use

Page 9 9 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022

2

Workers

1

Working within 4 meters of overhead powerlines

• Electric shock

Safe Use of EWP

Risk Level (R) and the Residual Rating (RR) Identify Controls / Action Required Person Responsible L C R RR

• Materials not to be carried up access ladder. Use ropes and buddy system to handball up materials

L2 C3 HR LR

• Remain on scaffold deck at all times, no trestles or climbing rails for additional height or reach

• No alterations to scaffold unless the worker holds a High-Risk Work Licence where the fall height exceeds 4 metres, or for heights less than 4 metres is a competent person

Workers

2

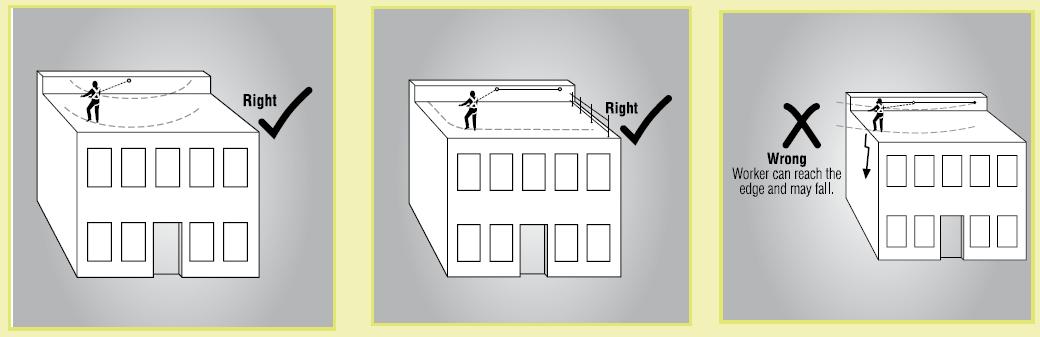

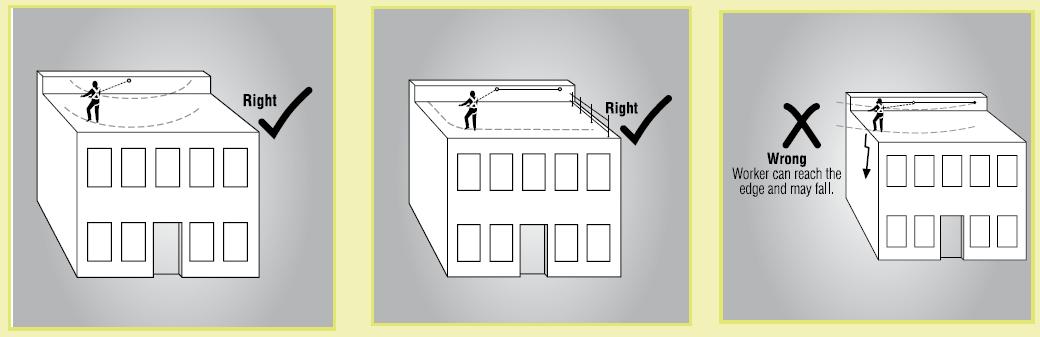

Use of work positioning systems

• Electrocution

L2 C3 HR LR

• Only full body harnesses are to be used

• The anchor point should be determined by a competent person to ensure:

• Anchorages are to be a minimum of 12 kilonewtons

• Each anchor point should be located so that the lanyard can be readily attached to prevent the worker being exposed to falling

• Set and maintain the lanyard length to prevent the person from reaching the edge

Workers

•

Page 10 10 SWMS C07 – Working

Heights SWMS | Revision: 01 | Issue date: 21/10/2022

at

# Job Step / Process / Activity Identify Hazards

Use of fall arrest systems

• Falling from height L2 C3 HR LR

Set-up of fall arrest system:

• Maximum distance free fall before arrest must not exceed 2m

• Ensure sufficient distance between work surface and any surface below to enable shock absorber to fully deploy

• Do not use shock absorber on single story

• Do not use lanyard in combination with inertia reel – leads to increased free fall distance

Note: To calculate suitable distance, take into account:

• Distance between work surface and any surface below

• Original length of lanyard

• Maximum energy absorber extension

• Height of person

• Clearance allowance for dynamic stretch.

• Ensure anchor point is as high as possible above work area. Never work above anchor point.

Inertia reels:

• Can only be used where there are no obstructions (unless manufacturer can demonstrate contact will not impair function)

• Do not use on steep pitched roof (does not lock during fall down pitched roof)

• Do not lock in place – not designed for continual support

Operator. Ensure:

• Physically fit and able to withstand possible fall

• Within weight limit (including clothing and equipment) of harness.

Workers

Page 11 11 SWMS C07 – Working at Heights SWMS | Revision: 01 | Issue date: 21/10/2022 3

4

Use of fall arrest systems emergency rescue plan

• Incorrectly fitted harness

L2 C3 HR LR

• Machine guarding of moving parts

• Safety chain brakes, clear work zones, equipment servicing to ensure safety features are in working order.

• Works are planned and programmed.

• Ensure clear exclusion and drop zones.

• Ensure plant is fit for purpose - task and environment

• Ensure plant operated within defined safety limits

• PPE - hearing protection, eyewear, chainsaw pants, face guard, long & long

Workers

Page 12 12 SWMS C07 – Working

Heights SWMS | Revision: 01 | Issue date: 21/10/2022

at