PRODUCT GUIDE 2025

1.

About Us

With over 40 YEARS of expertise in agricultural electronics, Farmscan AG (UK) and SmartAG Systems (Australia) deliver rugged, reliable control systems trusted by farmers, OEMs, and dealers worldwide

Founded in Queensland in 1976, FarmscanAG pioneered durable Australianmade technologies for broadacre farming, later expanding into the UK and Europe in 2010 to specialise in ISOBUS, spraying, seeding, and fertiliser control�

WE HAVE A CLEAR VISION.

That is, making precision agriculture technology more accessible in the industry, from OEMs to their farmers and operators�

JOHN CHALMERS FOUNDER AND CEO

2.

Our Values

3. History

ALWAYS ADVANCING

Delivering the most advanced control systems for manufacturers

INNOVATION THAT WORKS

Field-driven practical solutions that are reliable for manufactures�

PARTNERSHIP THAT LASTS

Flexible, future-ready systems developed in close collaboration with OEMs�

Farmscan Brand founded in Australia 1976

Farmscan AG established in the UK to expand precision farming solutions into Europe 2010

2019

SMARTAG SYSTEMS launched as an independent company for manufacturers

Hands FreeFarm - completely autonomous arable farm over 34Ha

2022

ISOBUS Solution released

2024

7000PRO launched across all industries�

Roto-fence - autonomous fencing demonstrations� 2025

4.

OEM Services

How We Work With Manufacturers

Our in-house team designs, tests, and supports solutions that help manufacturers get to market faster, with less risk�

ISOBUS Support & Backup

Our team are ISOBUS experts and ready to support every situation�

Custom ECU Development

In-house hardware and software tailored for specific implement types�

White-Label Branding

OEM Branding options across all products�

Onboarding Packages

Comprehensive training, wiring and installation guides�

FUTURE FOCUSED

We’re committed to keeping OEMs ahead of the curve�

Our focus is on continuous improvement, developing control systems that are more precise, more efficient, and easier to integrate�

AI SOIL ANALYSIS & DYNAMIC IMPROVEMENT

Real-time evaluation of soil conditions during seeding�

PRECISION PLANTING WITH MULTI-MOTOR SUPPORT

Individual section shutoff for seeders�

ISOBUS TURN COMPENSATION

GPS adjusts application rates dynamically�

HIGH EFFICIENCY

DC MOTOR

New gearbox design

5.

Client Solutions

AUTONOMOUS FARMING

CHALLENGE

Expanding a one-hectare autonomous research plot to a full 35-hectare farm with a fully autonomous arable fleetseeding, spraying, harvesting�

SOLUTION

Farmscan AG installed a full automation kit on 6 machines, converting them to an autonomous fleet� 35HA was successfully autonomously harvested over 3 years

OUTCOME

The Hands-Free Farm project reduced human labour requirements by more than 60 percent� A retro-fittable system to convert existing machinery to completely autonomous systems�

LIVE SOIL SENSING

CHALLENGE

Farmers in Australia face variable soils and limited moisture� These conditions make uniform seeding difficult and increase emergence variability�

SOLUTION

Built and designed a completely custom control system that adjusts tine depth in real time using live soil sensor data� 36 tines were adjusted dynamically in real-time to the correct depth

OUTCOME

Correct and consistent seed placement to the right depth Evaluating soil conditions in real-time to improves crop emergence�

6.

Farmscan AG deliver ISOBUS technology that goes beyond the basics, offering deeper functionality, stronger diagnostics and unparalleled retrofit capabilities�

FULL TC SUPPORT

Seamless integration of TC-BAS, TC-GEO, and TC-SC, ensuring compatibility across a wide range of implements and machines�

TC-BAS (Job Recording)

TC-GEO (Variable Rate)

TC-SC (Section Control)

EXPERT ENGINEERING SUPPORT

Direct access to our engineering team for support and onboarding

FLEXIBLE & CUSTOMISABLE

Support for OEM-specific configurations or custom integration

FUTURE-READY

Proud members of the AEF - ensuring our products meet the full ISOBUS standard�

PRODUCT SPOTLIGHT

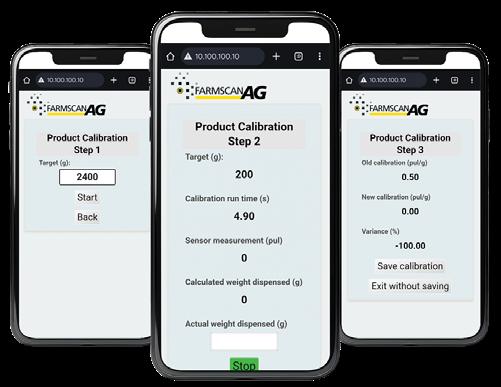

WIRELESS CALIBRATION MODULE (WCM)

Calibrate implements quickly and accurately using a smartphone or tablet over Wi-Fi�

REMOTE SUPPORT EVERYWHERE

OEMs and dealers can provide real-time diagnostics and fixes worldwide�

REMOTE ISOBUS UPDATE

Our ISO Dashboard uses the latest wireless technology to make updating ISOBUS systems simple

CUSTOM CONFIGURATIONS

Save the unique setup and calibration of each machine, making repeat builds simple and consistent�

ISOBUS SEED

6 SIMULTANEOUS PRODUCTS

Mixture of liquid and solid with capability to fit difficult seeding configurations�

SMART CALIBRATION

Automatic weight calibration with load cell technology�

Remote calibration through the WCM phone app�

ADVANCED APPLICATION CONTROL

Full Variable Rate Application with detailed reporting�

Automatic Section Control, including half-width shutoff

Split Rate Control with multiple motors per product

VERSATILE I/O MANAGEMENT

Supports up to 256 blockage sensors

Hydraulic and lighting control fully integrated into the system

SEEDING FEATURES

AUTOMATIC DOWNFORCE CONTROL

Automatically adjust coulter or tine pressure using real-time feedback Ensure optimal seedbed preparation by managing seeding force�

SECTION CONTROL

Supports individual motor shutoff, halfwidth control, clutches, and solenoids�

DEPTH CONTROL

Dynamic depth adjustment that responds to changing field conditions, maintaining consistent planting depth for improved emergence and yield

SPLIT PRODUCT APPLICATION

Control more than one motor per product Enables multiple channels per product, half-width shutoff and high resolution variable rate�

ISOBUS SPREAD

For gravity and trailed spreaders�

Full control and calibration for all belts and spinners, ensuring correct spread width and application rate

Support for up to 2 Gates, 2 Belts and 2 Disks simultaneously�

Automatic gate height measurement and control so height is always exact!

Live-in field automatic calibration through Load Cells

Section control capability to automatically adjust spread width and reduce overlap� Configurable between belts and spinners to match your application

Full headland mode / automatic shutoff to ensure covered area is not over applied�

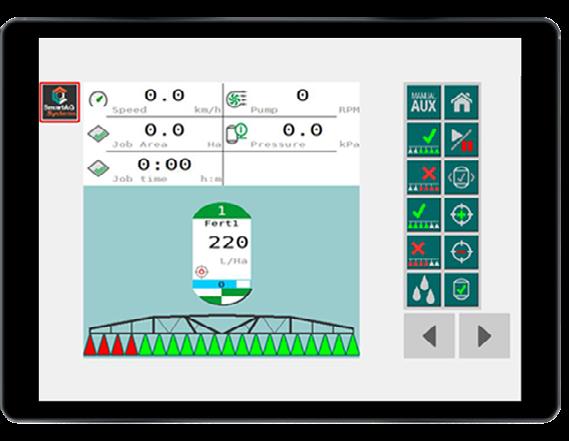

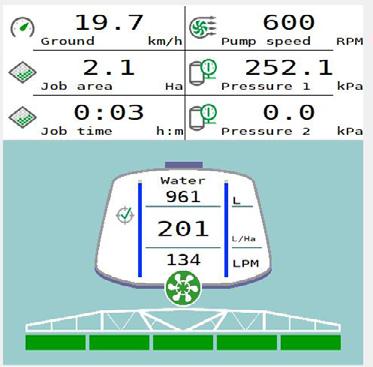

ISOBUS SPRAY

For

Boom

Sprayers,

Liquid Fertiliser,

Self-propelled, Injection systems and Orchard / Vineyard applications�

Full boom spraying support with up to 256 sections

Full section control including individual nozzle control�

Supports multiple booms - up to 3 booms at once

Multiple tanks, supporting multiple products with 2+ liquids simultaneously�

ISOBUS switchbox and control through AUX-N for tactile section control

Compatible with both electric and hydraulic pumps�

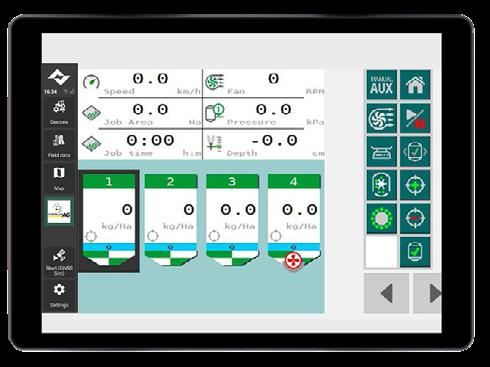

7000 & 7000PRO

Intuitive display of live data on screen using tabs and tiles that are fully customisable�

Work with pre-loaded VRA prescription field maps (shapefile via USB)

Section control and headland management included in base model�

Record multiple jobs & data –exportable to CSV format for farm management software

Easily import or export settings onto USB for remote troubleshooting�

Custom software builds and development possible (company logo on start-up screen, etc)

7000

Bright and easy to navigate 4 3” touchscreen monitor

Full USB Support through wiring harness

Supports up to 3x2 tiles

7000PRO

Full 7” TFT touchscreen monitor

Larger resolution for better visibility

Supports up to 4x2 tiles

WiFi and Bluetooth available

In-built GPS available�

In-screen USB support�

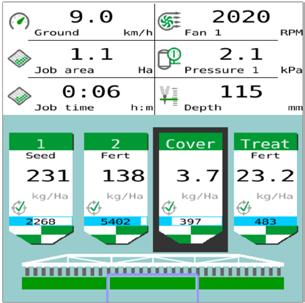

7500 SEED

Precisely control the application rate of up to 6 separate products�

Load cells for automatic calibration�

Seeding Drill Depth Management with fully adjustable (linear) depth engage switch

Blockage sensing up to 256 sensors

12v Auxiliary outputs supported –hydraulics, lighting, bout markers etc�

Full coverage mapping and automatic shutoff of individual hoppers

Full Variable Rate Map support with individual rates for each hopper�

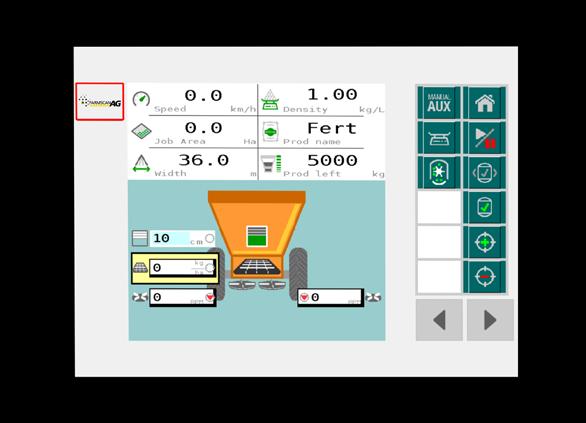

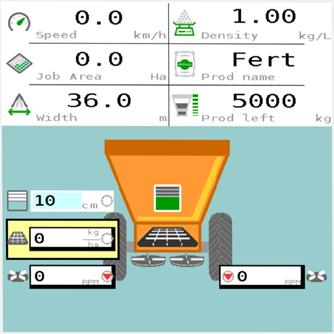

7300

FERTILISER SPREAD

For gravity and trailed spreaders�

Full control and calibration for all belts and spinners, ensuring correct spread width and application rate

Support for up to 2 Gates, 2 Belts and 2 Disks simultaneously�

Automatic gate height measurement and control so height is always exact!

Live-in field automatic calibration through Load Cells

Section control capability to automatically adjust spread width and reduce overlap� Configurable between belts and spinners to match your application

74V1 SPRAY

For Boom Sprayers, Liquid Fertiliser, Selfpropelled, Injection systems and Orchard / Vineyard applications�

Full section control and automatic shutoff to stop overlap and over application�

Supports 30+ boom sections and return/ dump valve�

Full section control including individual nozzle control

Supports multiple booms - up to 3 booms at once�

Multiple tanks, supporting multiple products with 2+ liquids simultaneously

Electric and Hydraulic pump compatible�

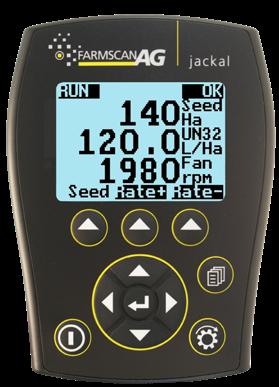

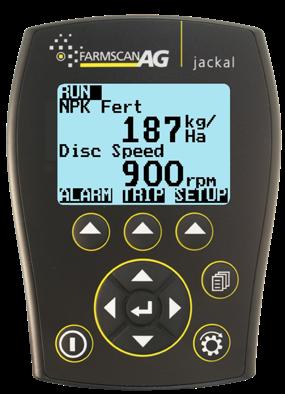

JACKAL SEEDING, SPRAYING, SPREADING

For all machinery�

Large backlit screen with 1-line, 2-line or 3-line display on each page (up to 5 pages)

Configurable I/O capable of supporting up to 9 inputs and 6 outputs simultaneously with high and low alarms�

Trip and Job data can be stored in long-term memory even after finishing job

Multi-language support�

Seeding with 3 different products

Microseeding with electric fan and motor

Spraying with 2 products, and 3 sections

Liquid Fertiliser with up to 3 products with electric and hydraulic pumps

Spreader Control with up to 2 disks, 2 gates and 2 belts at once�

Supports multiple alarms across pressure, hopper level, fan speed, RPM

JACKAL

DC MOTORS

Reliable Performance — Durable motors designed for demanding agricultural applications�

Customisable Options — Available with spur, worm, and planetary gearboxes, with ratings matched to your needs�

Power on Demand — supporting high-power applications without unnecessary over engineering�

Proven Versatility — Suitable for seeders, spreaders, sprayers, and more�

ECUs

Designed in-house to suit a range of applications�

Rugged & Reliable — IP67 weatherproof housing, designed for real farming conditions�

Flexible I/O — Configurable inputs/ outputs to suit a wide range of applications

Plug-and-Play Integration — Simple installation with customisable connectors�

Proven Versatility — Used across seeding, spraying, and spreading industries�

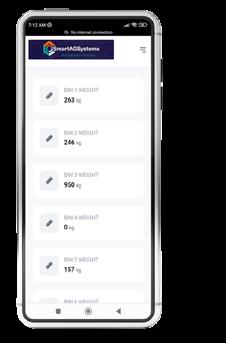

LOAD CELLS

Used to accurately manage and track weight of products�

Each system works with most commercially available loadcells�

Up to 8 cells per unit, supporting multiple bins/tank/hoppers per unit

WiFi model available – view weights directly on your mobile device!

Easily stackable to support building larger or more complex systems�

Compatible with ISOBUS and 7000 series

PWM BOOSTER

SMDB-1 MOTOR DRIVER

Designed in-house to suit a range of applications�

Rugged & Reliable — IP67 weatherproof housing, designed for real farming conditions�

Boost PWM Current to 60A�

Plug-and-Play Integration — Simple installation with customisable connectors�

Proven Versatility — Used across seeding, spraying, and spreading industries