Architectural Design Position

“The Story of a Refugee“ is located in Attercliffe, Sheffield a historically significant industrial area, with a notable presence of diverse ethnic minorities. This project attempts to educate the public about the experience that refugees undergo in the search of a welcoming place of refuge. Therefore this design is meant to provide visual and aesthetic representation of cultural differences whilst simultaneously fostering a sense of unity and understanding within the community.

Ateliers/Personal Position (&rchitecture)

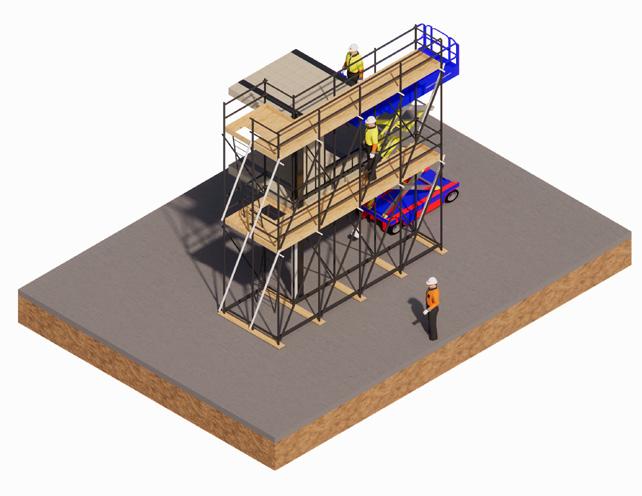

“Material First, Design Second“ Addressing the 100 million tonnes of building waste created each year. Therefore I am focusing on the disassembly and reuse of my design, tackling the issue at its root. This will allow me to ensure a increased life span of the materials used as well as promoting sustainability by minimising resource consumption. I aim to contribute to a circular economy where materials are valued and utilised efficiently.

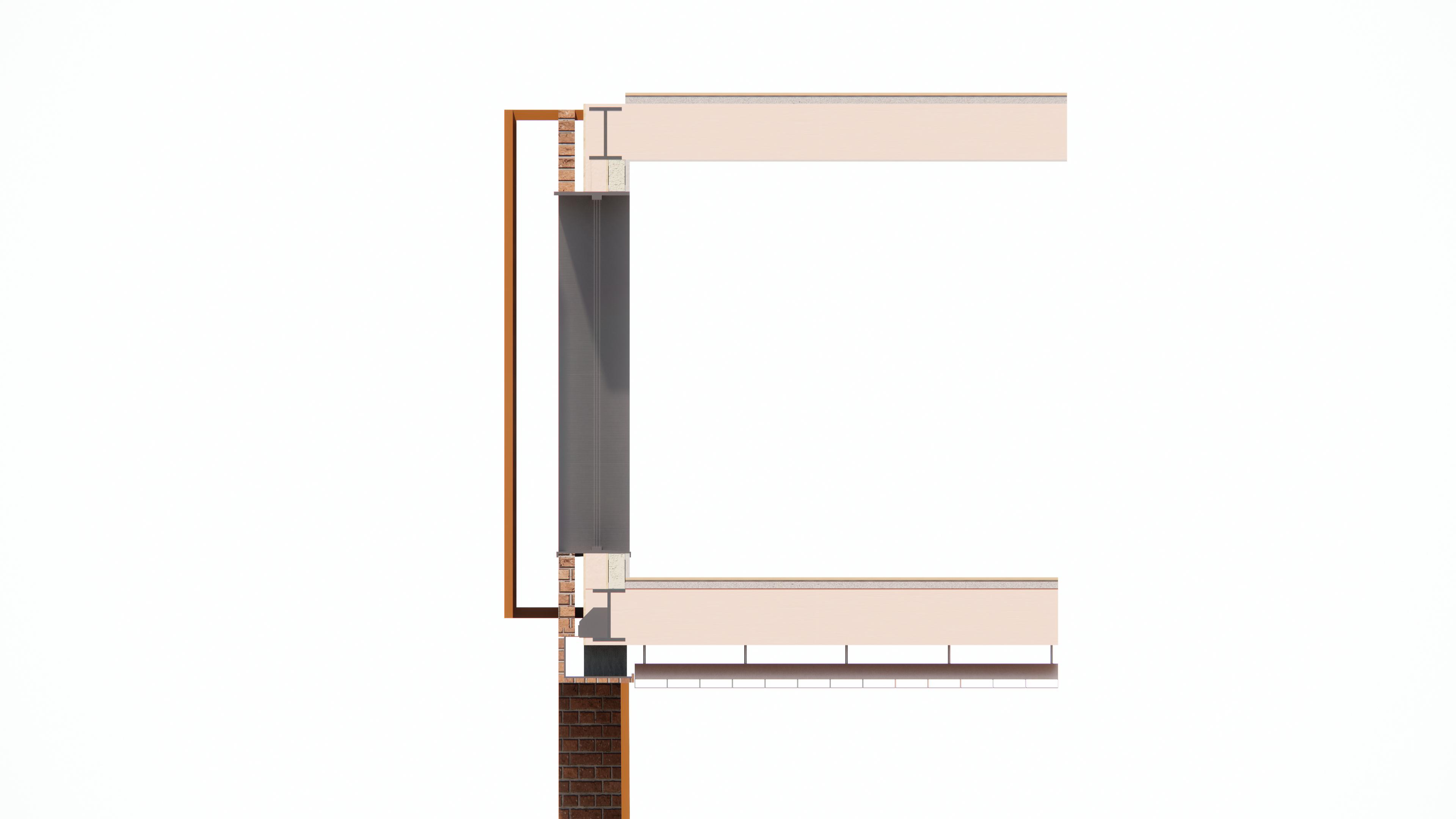

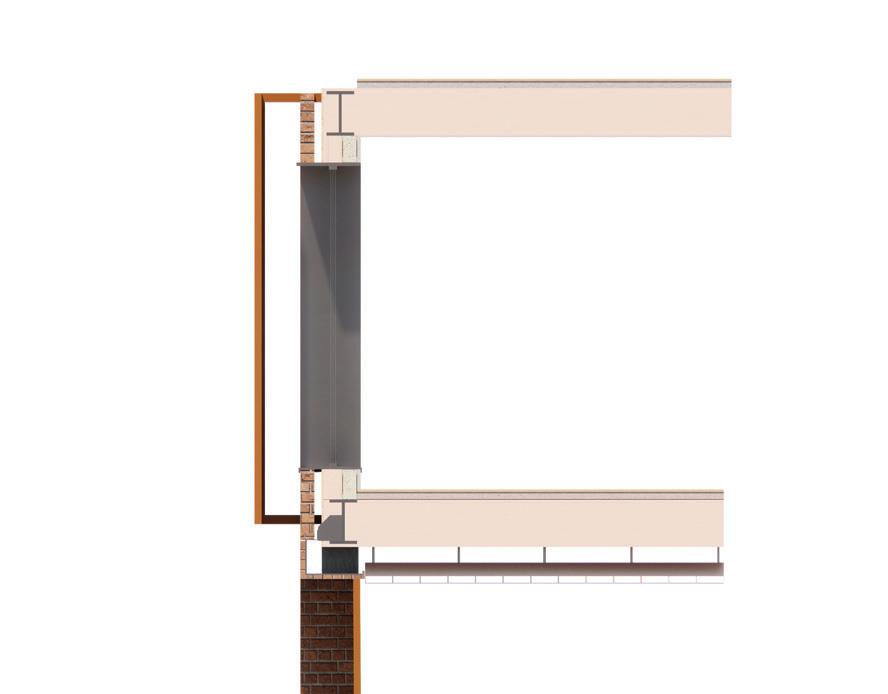

Purpose Of Technical Detail Study

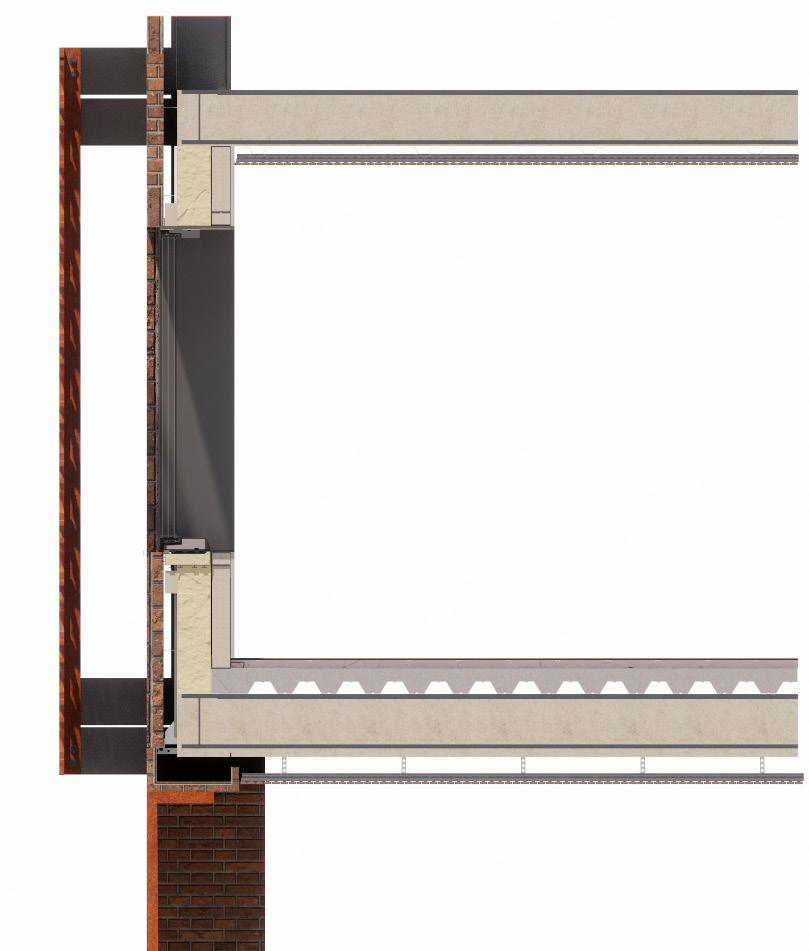

In this study, aim to optimise the thermal performance and user experience of my building, while also considering its long-term sustainability and adaptability through design for disassembly and material reuse.

Key Drivers

Visual light transmittance: Clarity of vision and light penetration through Shading device.

Solar heat gain: Absorption of solar radiation.

Fragment

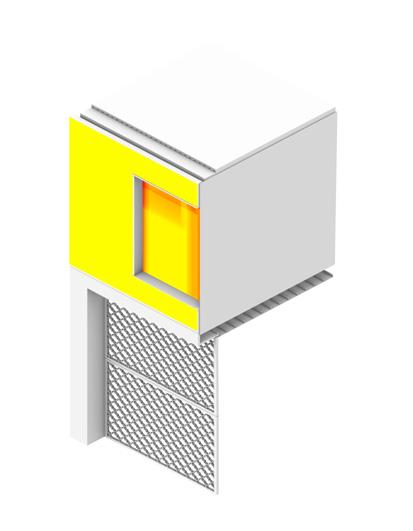

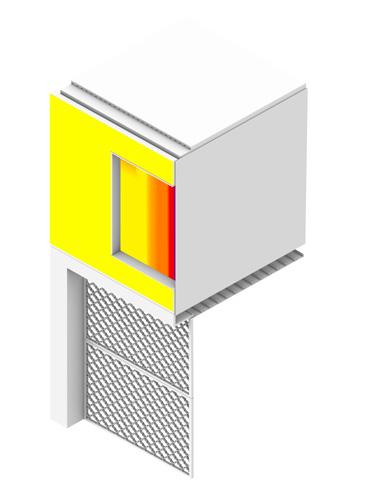

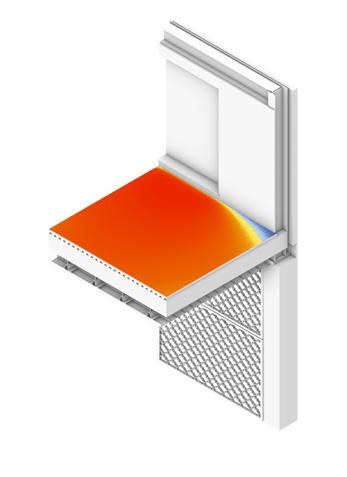

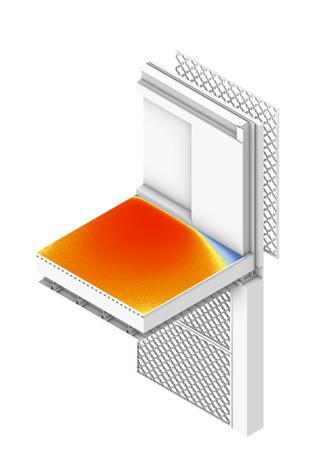

I’ve chosen to take my fragment from the west-facing side of the building as it allows me to directly test and evaluate how well the device mitigates solar heat gain and glare. Contributing valuable insights to its performance and overall energy efficiency.

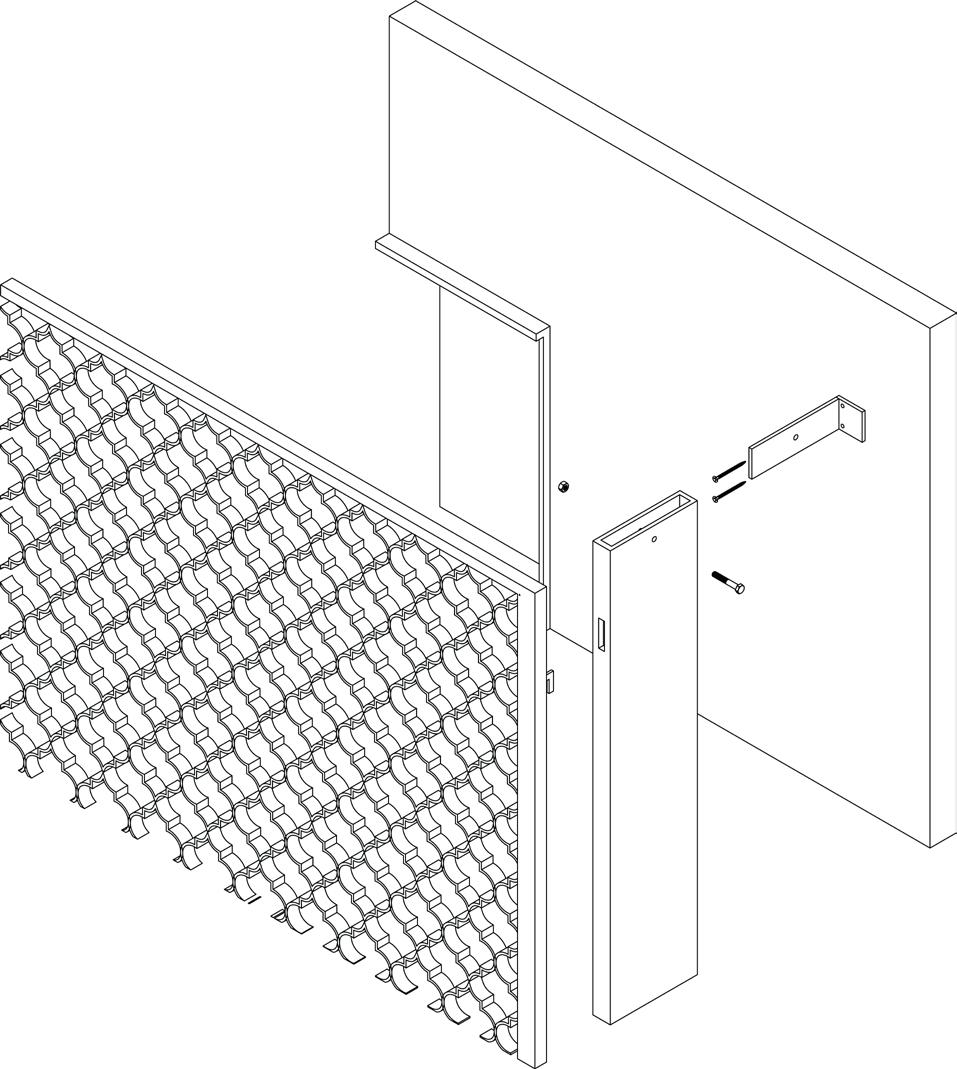

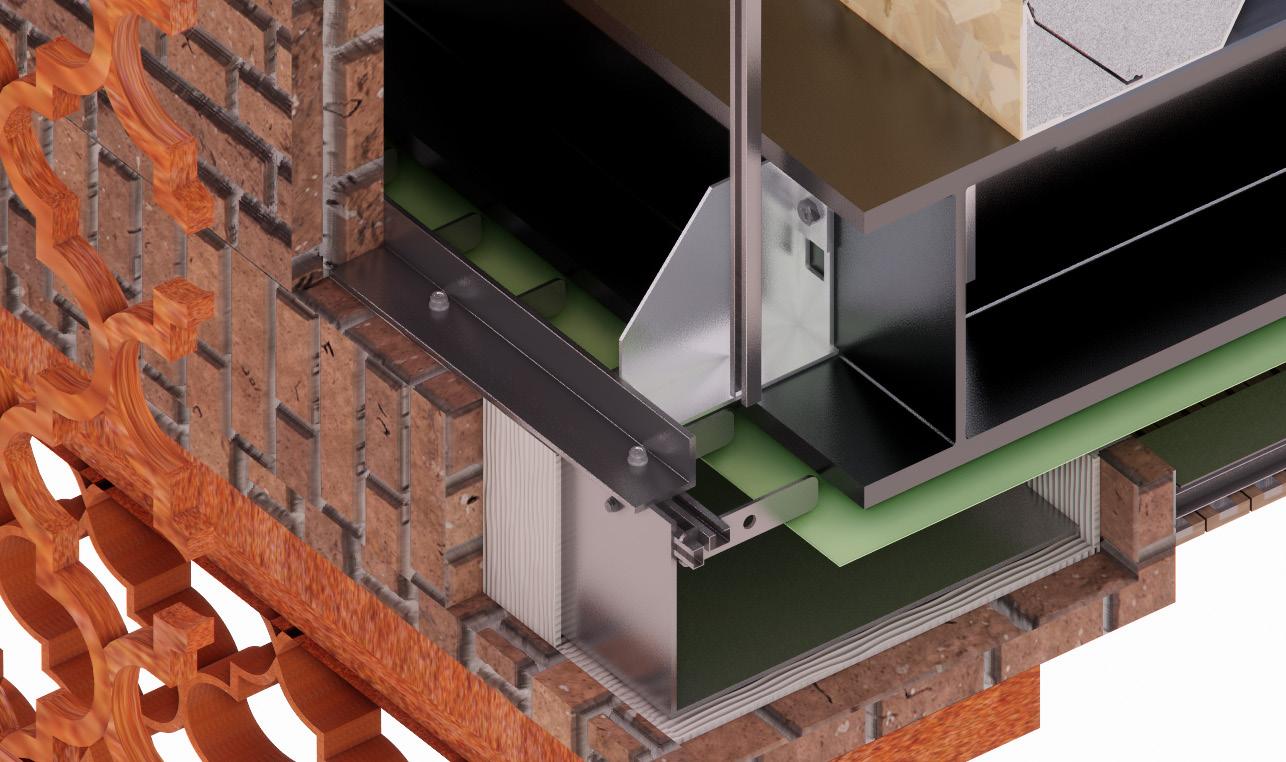

Design for disassembly: Component based construction foe reuse. Climate Performance Tools Initial Design (Materials)

Reclaimed Brick

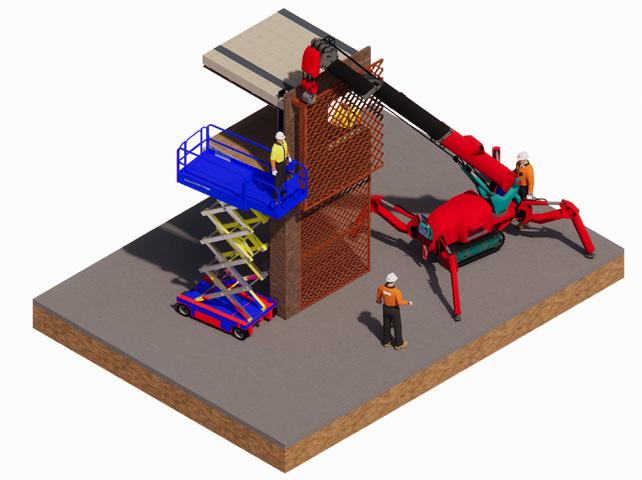

The use of reclaimed brick reflects our atelier’s principle of “Material First, Design Second” by emphasising the importance of material selection based on its inherent qualities and sustainability. In addition to that, it reduces construction waste by extending the lifespan of the bricks collected from the site. However, the reclaiming process is very labour intensive and might not be feasible

Hardwood Floor Finish A hardwood

Thermal Rockwool Insulation

Rockwool insulation is used for ( also for exposed ground-floor) due to its excellent thermal and acoustic properties, preventing thermal bridging and allowing sound absorption. Additionally, its non-combustible adding a fire safety measure.

PIR Rigid Board Insulation

Extra insulation to the ground floor (due to the ground floor being permeable), PIR was selected for its thermal performance, moisture and fire resistance,

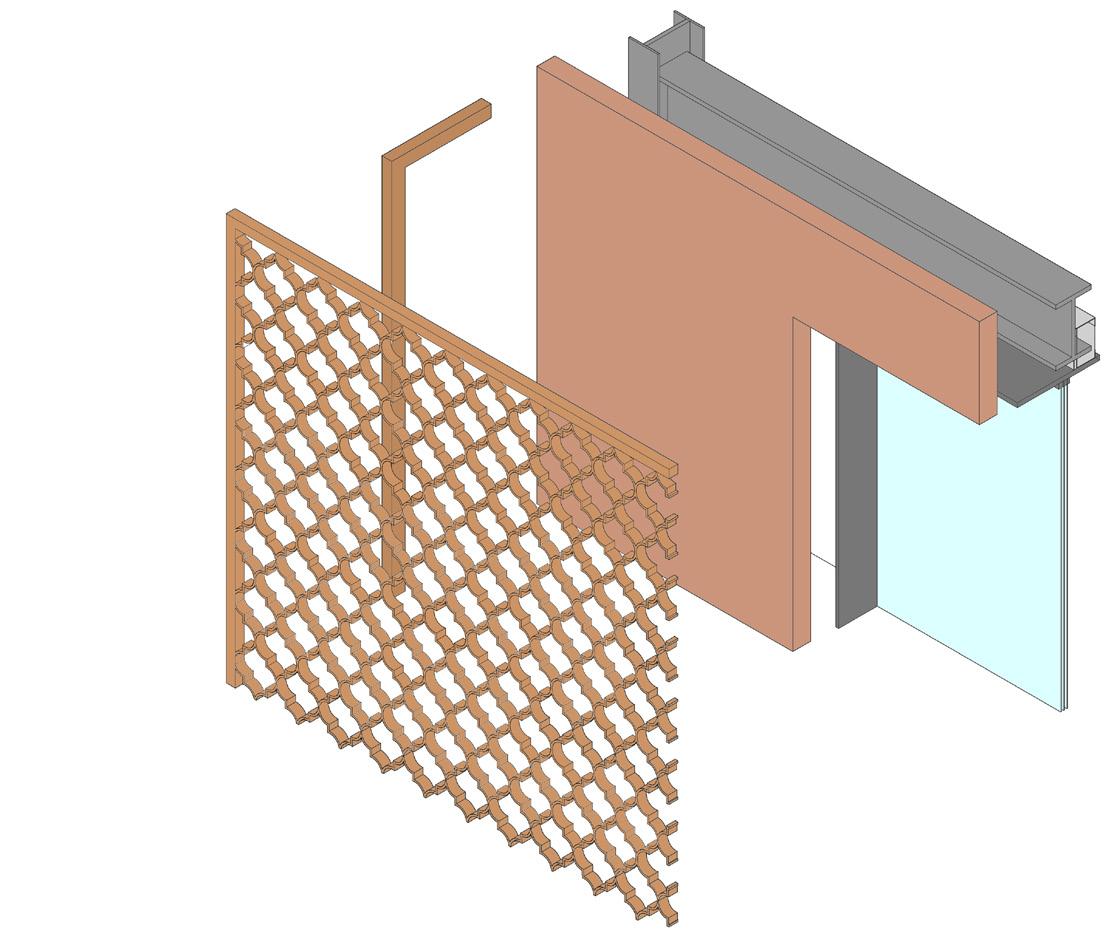

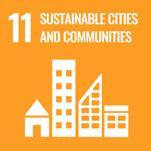

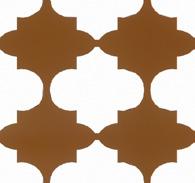

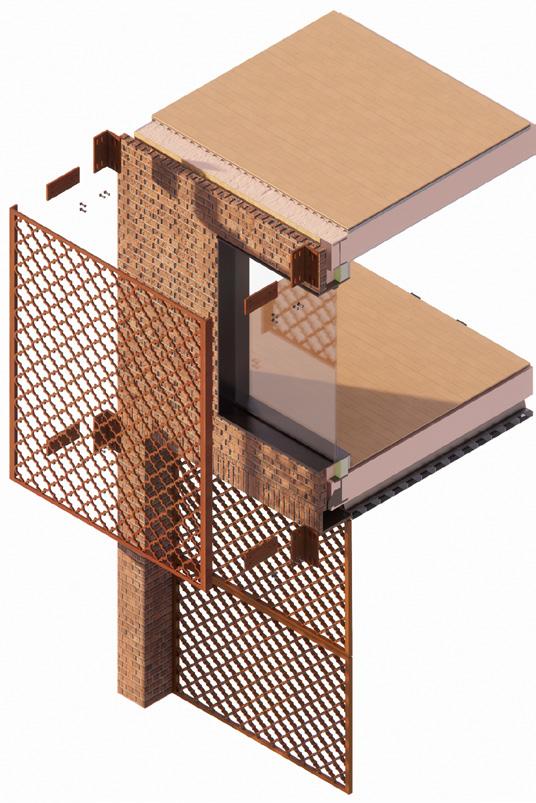

Corten Steel Shading Device

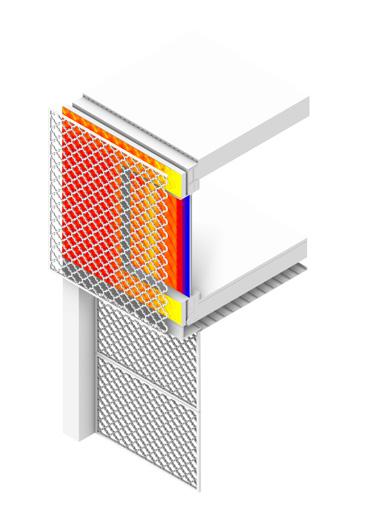

The implementation of a shading device that doubles as an acoustic buffer in the public square was driven by a need to mitigate both solar heat gain and ambient noise pollution. Corten steel has the ability to withstand outdoor conditions while offering acoustic attenuation properties, ensuring long-term functionality and aesthetic coherence with the reclaimed brick.

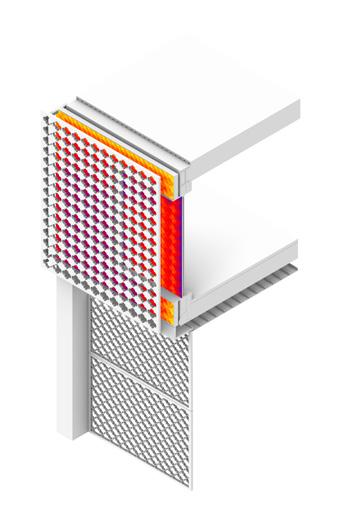

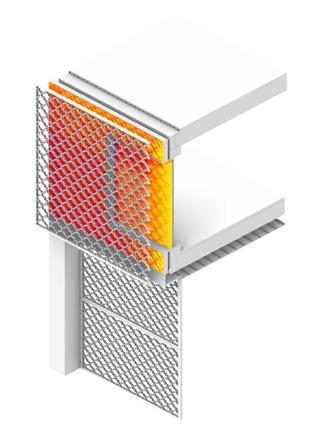

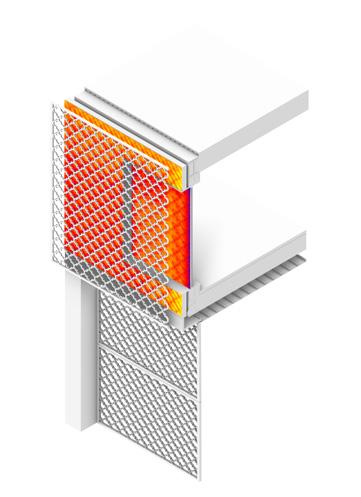

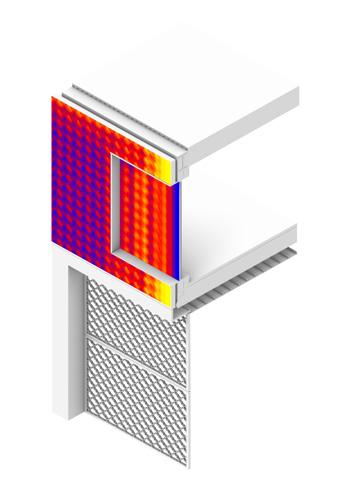

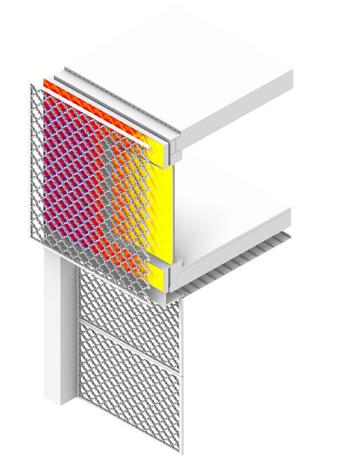

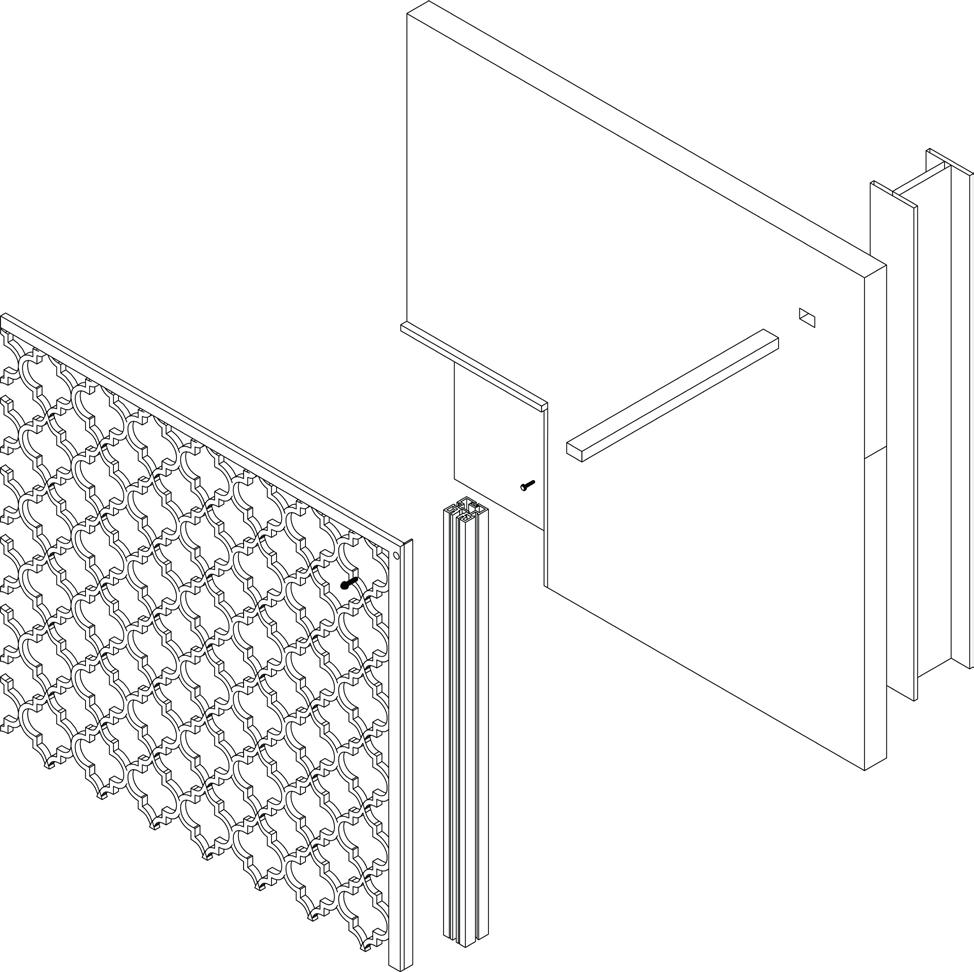

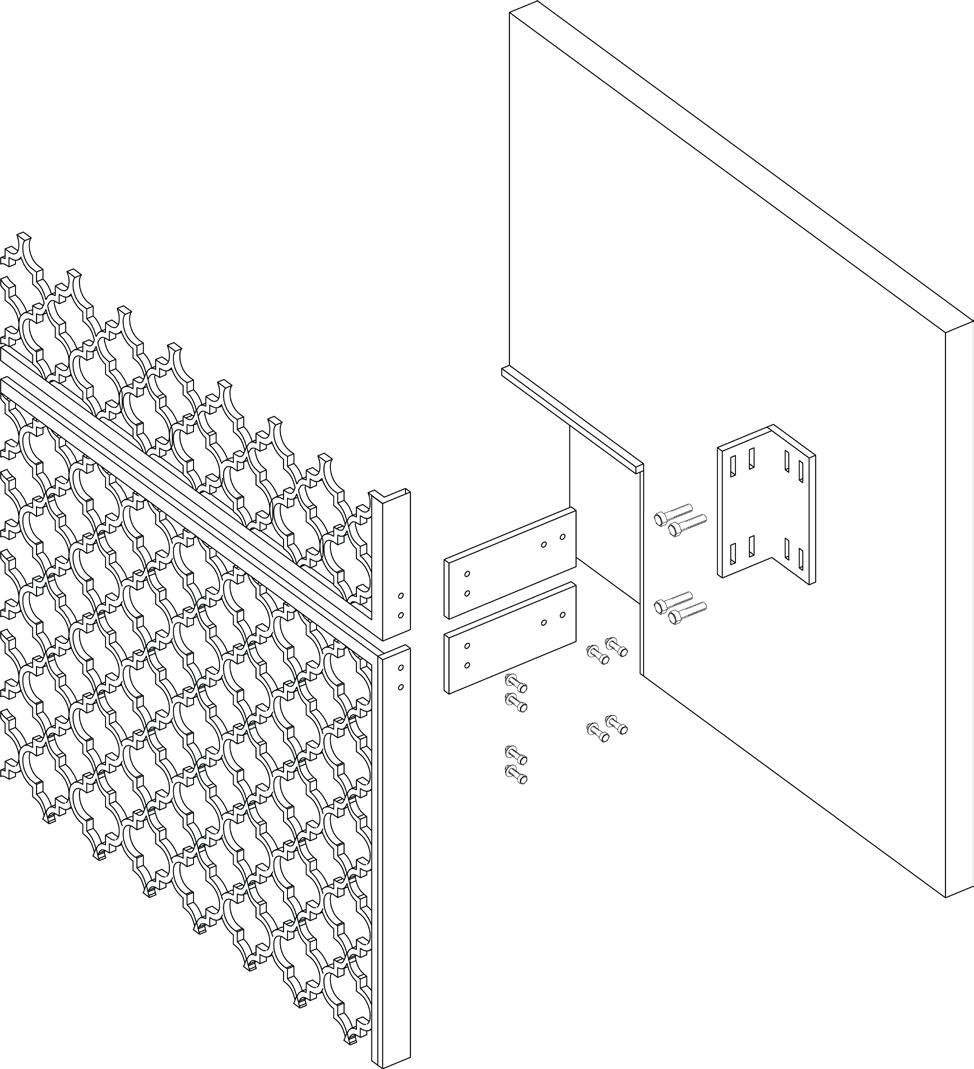

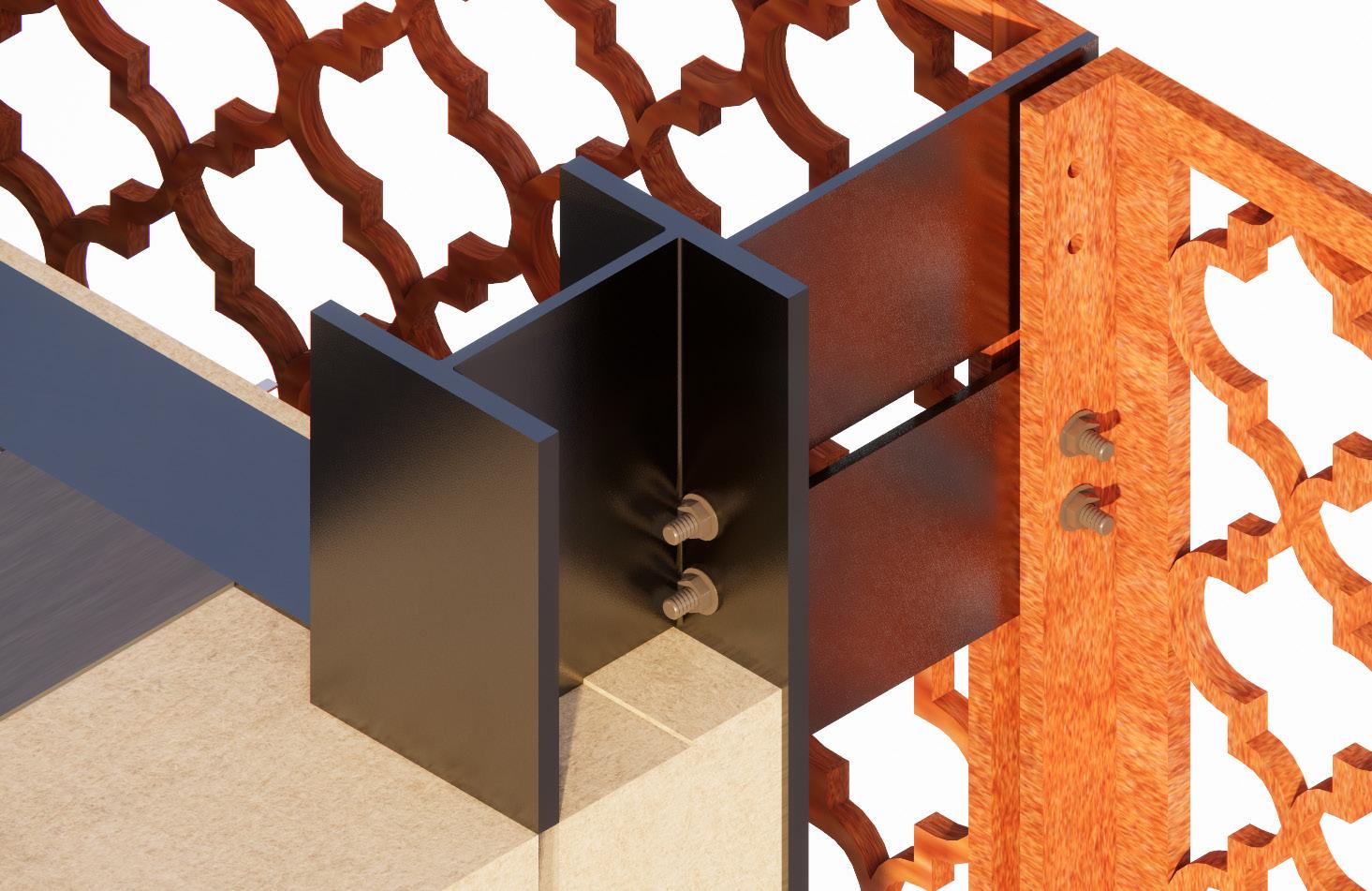

The Details show the main two systems show that my main focus was to design for disassembly. Non of the singular parts are welded and are de constructable by removing screws and bolts. This way can comply

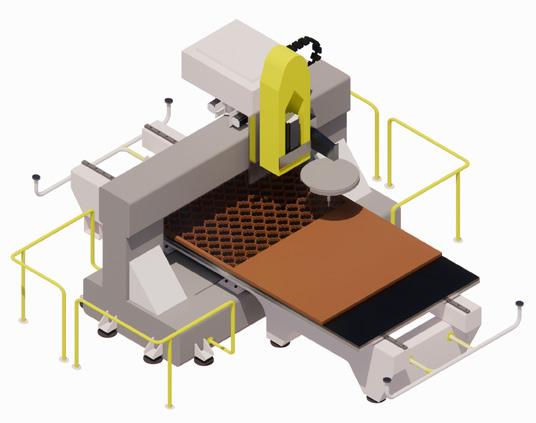

The production of Corten steel is essential due to its specific chemical composition, primarily comprising iron with added elements such as copper, nickel, chromium, and phosphorus. These alloys enhance Corten’s corrosion resistance, critical for applications exposed to harsh environmental conditions.

Corten steel undergoes a natural weathering process over a period of time, where the colour changes matures form a strong orange to a dark grey. This process can be delayed or prevented by applying protective coatings or sealants. These barriers, shielding the steel from exposure to moisture and oxygen, preventing maintaining its original appearance for a longer.

Corten steel undergoes initial oxidation, initiating the formation of a protective layer of iron oxide on its surface. Pick quality ore, carbon for production.

2 MONTH Development of the oxide layer on corten steel progresses, improving its resistance to corrosion and its reddish-brown hue.

2

6 MONTH Corten steel’s surface oxidation reaches a stabilised state, providing effective protection against further corrosion its.

and

5

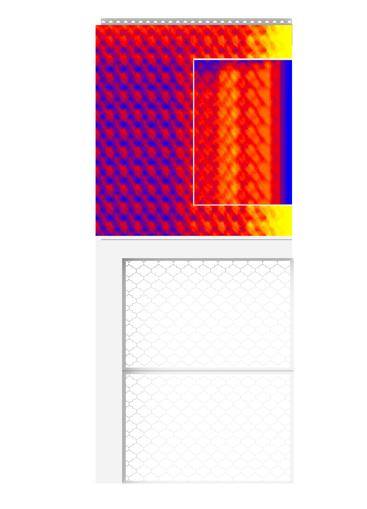

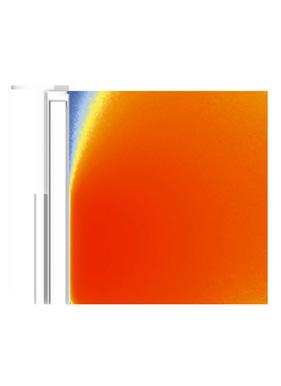

TEST 2 Daylight Analysis Methodology

Criteria sDA300,50% is achieved for at least 55% of regularly

occupied space in accordance with WELL certification requirements. (REFERENCE)

Hypothesis expect Iteration 4 to be performing the best, as it has the highest free area %.

TEST 3 Shadows (Aesthetic Considerations)

Criteria: Evaluating the internal effects of the perforated screen, focusing on its capacity to minimise shadows and visual disturbance while maintaining visual clarity. Hypothesis If the pattern size is increased, visual disturbance will increase.

cycle.

The original facade consists of a simple reclaimed brick finish with no shading device. aim to test whether a shading device is needed, as in studio 3.2 I also need a acoustic buffer due to the nature of my programme. Therefore this testing will show that if a screen is installed, if it will effect the internal spaces in terms of natural lighting.

I predict that for the first iteration the free area will likely impede airflow and natural light penetration, leading to poor ventilation and inadequate illumination within the space. As a result, occupants may experience discomfort due to reduced air quality

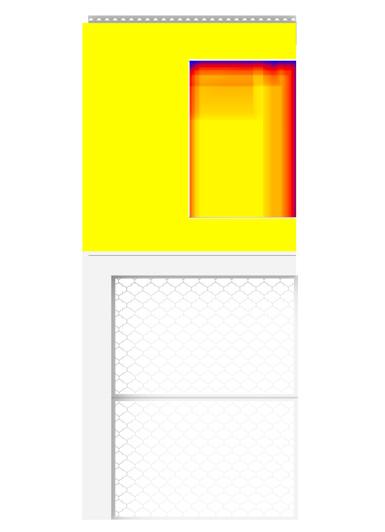

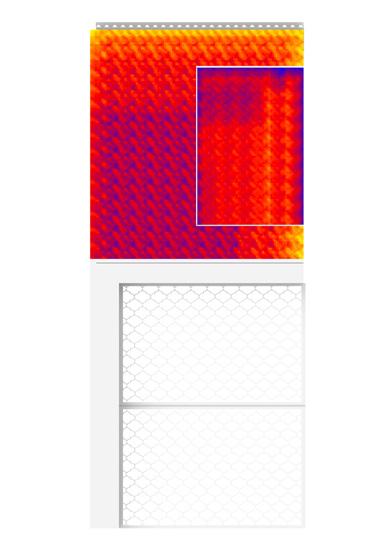

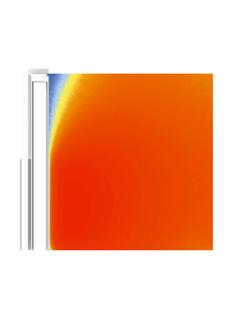

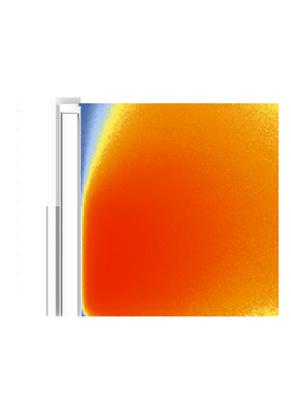

The original design, allows excessive sun hour timings and exposes the facade and the internal spaces to excessive natural lighting from June to September. There is no shading provided therefore the space might be over lit in the summer.

effectiveness of shading, particularly in regions with more

predict that for this iteration, the higher free area will enable more airflow and light penetration. However, it also raises concerns regarding the complexity of construction due to the necessity for precision

This testing shows that, the first iteration is the least suitable for this shading device. As the support would not only require the highest amount of material but would also block sunlight. In line with my ateliers position, aim to reduce my material consumption, thus the first deem to be unsuitable.

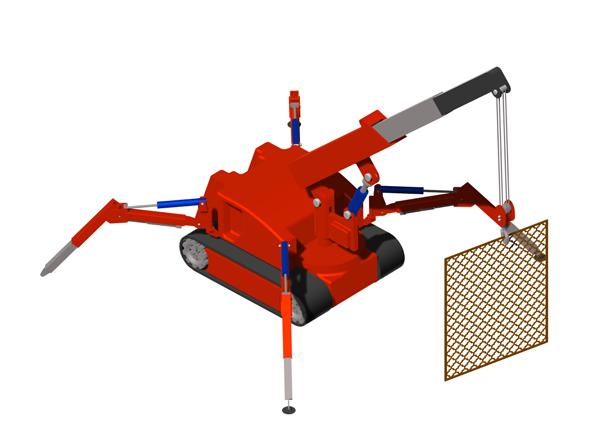

Test 4.2, seems to perform significantly better. The aesthetic proposition is the most suitable as the support system is set parallel to the main shading screen. However upon further research it became clear hat the support would need to be attached to the primary structure.

Test 4.3 presents itself to be the most suitable for this project. As the material consumption is the least evident. The support itself is very minimal as it only attaches to the corners of the screens. Thus not blocking the sunlight at any point. In addition to that, it presents ease at construction and deconstruction, once again aligning with my atelier and more importantly personal position, as this would allow the screens to be reused. However the support presented in the testing only attaches to the brick facade of the building. This would require additional refinement, as the size and the weight requires the shading to be attached to the steel framing. Thus it will have to cut through the envelope, although it poses risk of thermal bridging, it is the most structurally sound and aesthetically pleasing iteration.

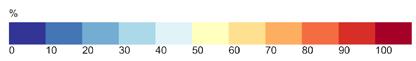

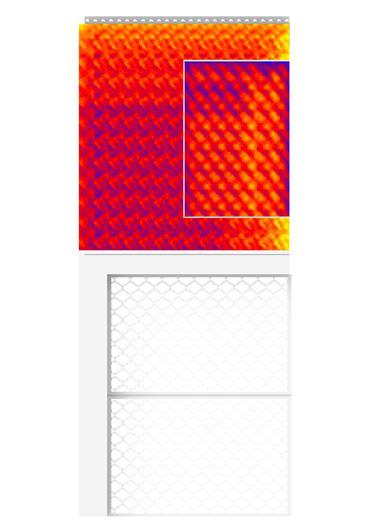

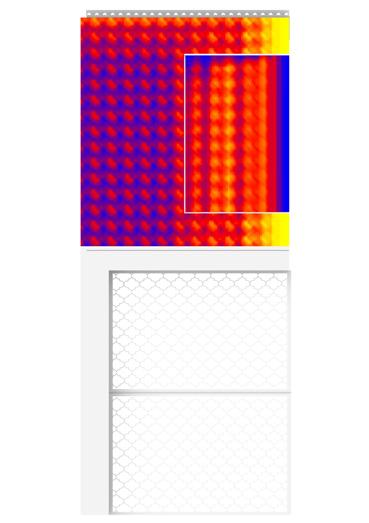

Tools: Sun hour Scale hours/year Performance Criteria 150-200 h/yr

Tools:

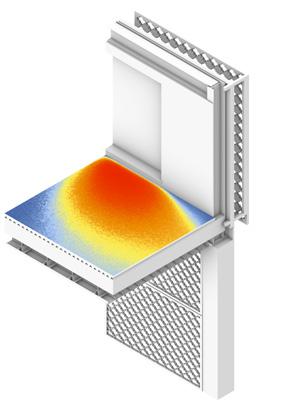

In the winter the Sun hours are lower as the sun angel is lower as well. Whilst the main facade area receives a identical amount of sun hours, the window shows significant changes. Therefore, iterations of the shading screen will have

For this first iteration tested a low percentage of free area, to assess how it affects the shading effectiveness and the amount of sunlight penetrating through the window during peak sun hours. The low results suggests that with a

By increasing the free area for this iteration, there is a clear yet considerably small change in the percentage of sun hours. The main changes have occurred within the window frame and the lower left side of the facade. It is visual that

This testing result demonstrates a significant improvement in lighting distribution, as evidenced by the reduction in blue patches throughout the facade. Additionally, the testing results indicate a consistent amount of sun hours across the

Here the test results show that the shading pattern is very similar to Test 1.3. However upon closer investigation it is clear that shades some shades yellow are becoming visible. Indicating that the amount of sunlight during the summer

The overly yellow indicates there is a need for shading to ensure thermal comfort as well as visual clarity. The window is slightly inset into the wall it provides some degree of shading. low percentage of free area, the shading device may block out too much sunlight during peak hours, potentially leading to not enough heat gain and natural lighting inside the building. the shade of orange has slightly brightened indicating a minimal change in natural light penetration. This highlights the need of further increasing the free area percentage. entire facade, which is beneficial for thermal mass considerations. This uniform exposure to sunlight can contribute to better heat absorption and retention within the building is slightly higher than optimal for achieving comfortable thermal performance. Thus, there might be a increased possibility of overheating.

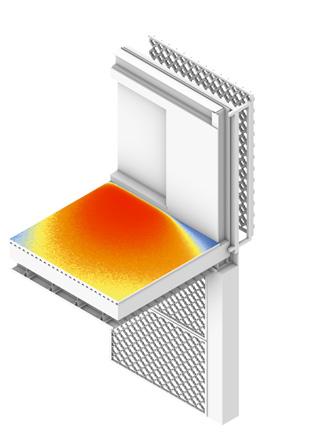

to consider performance during winter times, from December February. Consequently, iterations must consider winter conditions to ensure optimal performance the year.

The winter solstice results indicate that during the time between December and February very little natural lighting penetrates through the shading device. Especially the left side of the window shows that there is very little to no

This test shows that there is excessive natural lighting in the space, as indicated by the significant red area. The increased solar radiation can raise indoor temperatures, especially during periods of intense sunlight, making the space uncomfortable for occupants. Overheating can

increase the demand for air conditioning, leading to higher energy consumption and associated costs.

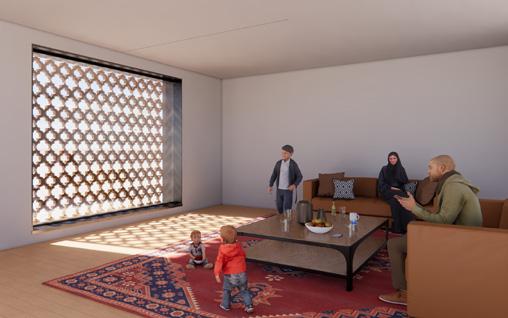

This render illustrates a compromise of privacy in the living room due to the absence of a shading device making it more visible from the outside. T he lack of shading exacerbates the issue by al-

lowing unrestricted views into the space. Therefore, the installation

This render shows a significant disturbance in

sun hours for that space. Therefore the percentage of free space needs to be increased to allow a higher percentage of light to penetrate through the screen during winter times.

The winter solstice results continue to indicate a lack of natural lighting within the space. This deficiency persists due to the shading device’s limited ability to allow sufficient sunlight penetration, particularly during the lower sun angles

characteristic of winter months.

This highlights the importance of adjusting the shading device to enhance natural light ingress, ensuring year-round comfort and illumination.

Similarly, these results show a remarkable increase in the sun hours received throughout the winter period. Although there is a blue path on the left side of the window, assume that is simply due to the lower position of the winter sol-

This Iteration requires the highest amount of material, as the support system runs the full length of the panel. It fixates to the brick of the wall system. This indicates that the panels are required to be smaller in order to ensure stability and safety. In addition to that, this iteration might also influence the amount of natural lighting entering the space, due to the large support system.

The blue areas in the test results indicate inadequate lighting levels within the room, suggesting a deficiency in natural light penetration. Insufficient natural lighting can create shadows and dark spots within the room, affecting usability and aesthetics. Additionally, relying ex-

tensively on artificial lighting can increase energy consumption and contribute to higher utility costs.

In this iteration, there is a noticeable increase in daylight anatomy, with the space being better illuminated compared to previous versions. However, the space is not yet optimised in terms of lighting. Further refinements are needed to achieve the ideal balance between shading ef-

fectiveness and natural light penetration, ensuring optimal comfort and illumination levels throughout the year.

nectivity with the surrounding environment. Moreover, the insufficient natural lighting may create a

ed in better distribution of natural light, creating a more visually appealing and dynamic environment.

The Tests reveal that the original facade lacks a shading device, leading to excessive natural lighting and compromised privacy in the living room. This exposes occupants to discomfort from overheating and privacy concerns from external visibility. The design must consider the installation of a shading device to mitigate these issues while paying attention to the effectiveness of an acoustic buffer to ensure optimal comfort and functionality in the internal spaces. Further tests need to be conducted to determine which shading device would be best in terms of free area and sunlight penetration. This will help identify the optimal solution, ensuring comfort and energy efficiency within the internal spaces.

Reflecting on the test results, it is clear that this iteration allows inadequate solar radiation and natural light penetration. This underscores the importance of a higher percentage free area. The observed deficiencies in natural lighting during the winter months emphasise the need for adjustments to enhance light penetration. Additionally, the rendered image highlights disturbances in the view and a lack of natural lighting, highlighting the necessity for improvements to enhance functionality and aesthetic appeal. Therefore, this iteration is not chosen for implementation due to its poor performance in testing in terms of natural

stice sun, indicating a natural occurrence that cannot be altered. Overall, these results demonstrate a good balance between shading and lighting

These results show a fainter pattern on the brick facade indicating that the shading device might not be as well performing as the previous iteration. There is an increased in yellow, indicating a hightned amount of sunlight. Although the

higher sun hours during winter are desirable, the heightened sunlight during summer may lead to discomfort and increased energy consumption for cooling.

This system is visually more subtle, as the elements are thinner in appearance, in comparison to Test 4.1 The support attaches to the rear side of the shading panel, thus allowing it to be not a visible. It fixates to the primary or secondary structure of the building, thus ensuring structural stability. However this requires to cut into the envelope.

This daylight autonomy result shows that there is adequate lighting consistently across the room. There is some indication of blue and yellow which may need to be readdressed. However consistent red results would mean that

the space is overlit. Therefore, believe that the current balance achieved is optimal for ensuring both comfort and energy efficiency within the space.

Although the overarching pattern of these results are similar to the previous Test 2.3. It is visible that the shades of red have darkened indicating a high amount of light luminance, indicating that the space may be overlit. This could poten-

tially result in increased glare and discomfort for occupants, raising critical concerns regarding the effectiveness of the shading device in managing light penetration.

This method of fixating the shading device does not require the structural support to extend into the envelope. As it is fixated into the brick using structural bolts. However this iteration requires the shading device to be smaller and lighter in weight. Otherwise this technique would not be stable enough to support a larger panel.

shading iteration is effective in its purpose. Although the results are relatively successful, there is po-

This render demonstrates a significant level of illumination streaming through the window, to the extent that the shading device pattern is no longer

turbance, it compromises the user experience of the space. Therefore, it is evident that this iteration

Stainless steel serves as an optimal material for structural components interfacing with Corten steel. Its exceptional corrosion resistance and inherent compatibility with Corten’s weathering characteristics ensure enduring structural integrity and stability. Through the formation of a protective oxide layer, stainless steel safeguards against galvanic corrosion when connected to Corten Steel.

Aluminum’s corrosion resistance and lightweight properties make it an ideal complement to Corten steel, offering both durability and versatility in construction. Furthermore, aluminum’s strength, light weight, and ability to be shaped easily allow for accurate construction and intricate designs.

Galvanised steel can be problematic when used in conjunction with Corten steel due to the potential for galvanic corrosion. Galvanised steel is coated with zinc to protect against corrosion, but when it comes into contact with Corten steel, which naturally develops a protective rust-like patina, galvanic corrosion can occur. Therefore, it’s

Carbon

Overall, the testing results demonstrate a substantial enhancement in lighting distribution across the facade, evidenced by the reduction in blue patches and consistent sun hours. This uniform exposure to sunlight is good for thermal mass considerations, contributing to improved heat absorption and retention within the building. The daylight autonomy analysis confirms the success of the shading strategy, with consistent lighting levels observed throughout the room. However, despite the relative success, there remains potential for further testing and refinement to optimise shading configuration.

Based on the test results, this iteration closely resembles Test 1.3 but indicates excessive summer sunlight and potential overheating issues. The shading device on the brick facade appears less effective compared to the previous iteration, leading to compromised thermal performance and user comfort. The visual disturbance is low, however it fails to adequately block excess sunlight, impacting the overall user experience negatively. Comparatively, the previous iteration performed better in terms of shading effectiveness. Furthermore, it’s worth noting that the mesh, despite its theoretical effectiveness, may be too fine to be manufactured, potentially compromising the structural integrity of the shading device and rendering it unsuitable for practical implementation.

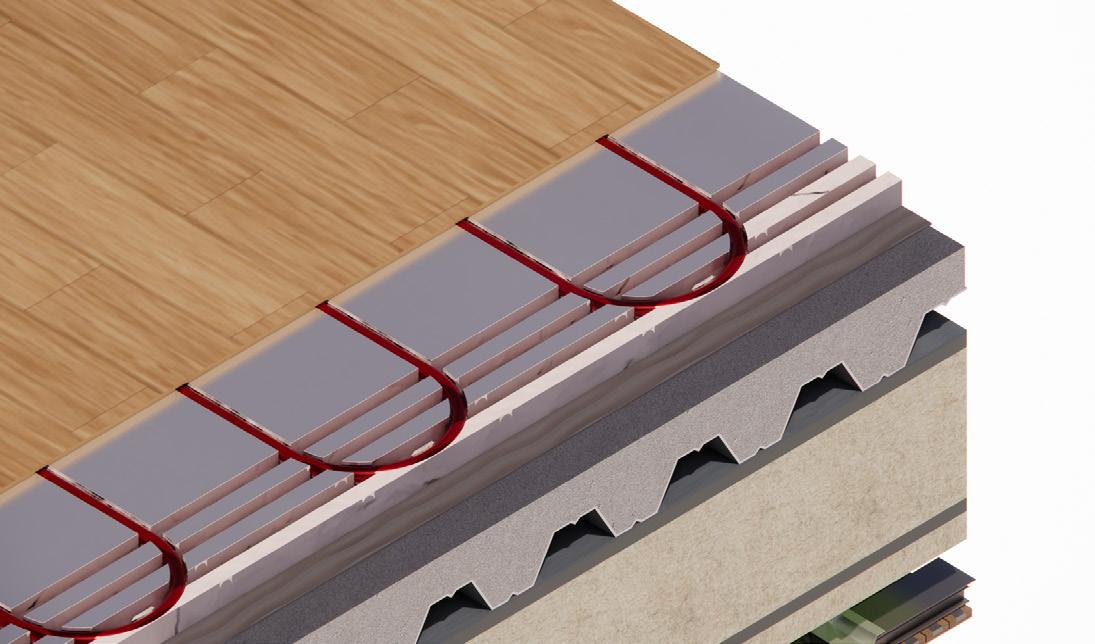

10mm - Acoustic Rubber Underlay

A 10mm Acoustic Rubber Underlay was placed on top of beams and floor joists to dampen sound transmission, creating a quieter and more comfortable environment within your space. This underlay also serves to mitigate impact noise, enhancing the acoustic performance of your flooring system. This is particularly important due to the ground floor being exposed.

Insulated Columns

Surrounding the steel columns is essential to prevent thermal bridging, which can lead to energy loss and decreased building efficiency. Due to the high thermal conductivity of steel it allows heat flow from areas of higher temperature to areas of lower temperature. By insulating columns, heat transfer between the interior and exterior environments is minimised.

Suspended Ceiling System

A suspended ceiling system was implemented as it allows easy maintenance and replacement. In addition to that, this system provides convenient access to wiring and utilities thus optimizing functionality and reducing downtime for any necessary adjustments or repairs.

Underfloor Heating With Insulated Panels

The rigid insulation boards laid onto the sub floor using a A1 Adhesive, this is done to combine the benefits of underfloor heating with the insulation properties of rigid board insulation to improve energy efficiency and heating performance. In addition to that the insulation boards do not require additional floor space, unlike typical underfloor heating systems.

Additional Underfloor Insulation

Additional underfloor insulation wrapping around beams and joists was necessary because the ground floor being exposed increases the risk of heat loss through the floor. This significantly increases the floor thickness, necessitating adjustments in the building height and design to accommodate the additional insulation depth.

Bibliography

• Astroflame Intumescent Expansion Joint/Linear Gap Seals (2024) Rawlins Paints. [Online] [Accessed on 22nd April 2024] https://www.rawlinspaints.com/home/fire-retardant-paints/fire-stopping/5375-astroflame-intumescent-expansion-jointlinear-gap-seals.html?gad_source=1&gclid=Cj0KCQjwlZixBhCoARIsAIC745By66JlXV_XrrWXeDXpeNlZofQS5cNN21NqX9txiW4VbdEn8zwr0VoaAo8lEALw_wcB.

• B.O.S.S. (n.d.) IG Masonry Support. [Online] [Accessed on 22nd April 2024] https://igmasonrysupport.com/brick-slip-systems/brick-slip-soffit-systems/boss/.

• BREEAM | BRE Group (2022) bregroup.com. [Online] https://bregroup.com/products/breeam.

• Daylight modeling WELL Standard (n.d.) standard.wellcertified.com. [Online] [Accessed on 23rd March 2024] https://standard.wellcertified.com/light/daylight-modeling#:~:text=Spatial%20daylight%20autonomy%20(sDA300%2C50.

• Slatted timber ceilings | Slatted timber walls (n.d.) stil-acoustics.co.uk. [Online] https://stil-acoustics.co.uk/Timber-Acoustic/Fine-Line.html.

• Unique, L. (2023) What is Corten Steel? A Comprehensive Guide. LuxUnique. [Online] [Accessed on 22nd April 2024] https://luxunique.co.uk/what-is-corten-steel/#:~:text=At%20the%20start%20 of%20the.

• What PPE Is Required For A Construction Site? (2021) XAMAX®. [Online] https://www.xamax.co.uk/blog/what-ppe-is-required-for-construction.html#:~:text=The%20Types%20Of%20PPE%20 Needed%20On%20A%20Building%20Site&text=be%20made%20for%3A-.