TECHNOLOGIES A & B

21308588 &ARCHITECTURE

HIRRA MASOOD 21308588 BA3 &ARCHITECTURE

HIRRA MASOOD

DR DANILO GOMES

CURTIS MARTYN

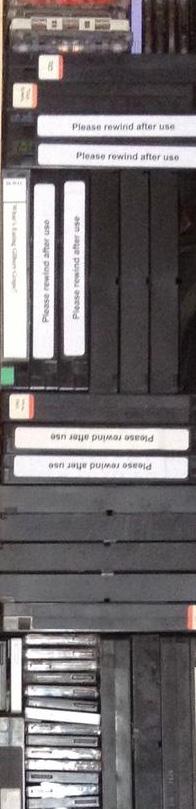

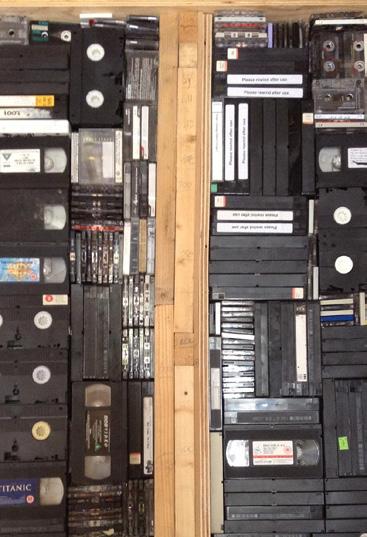

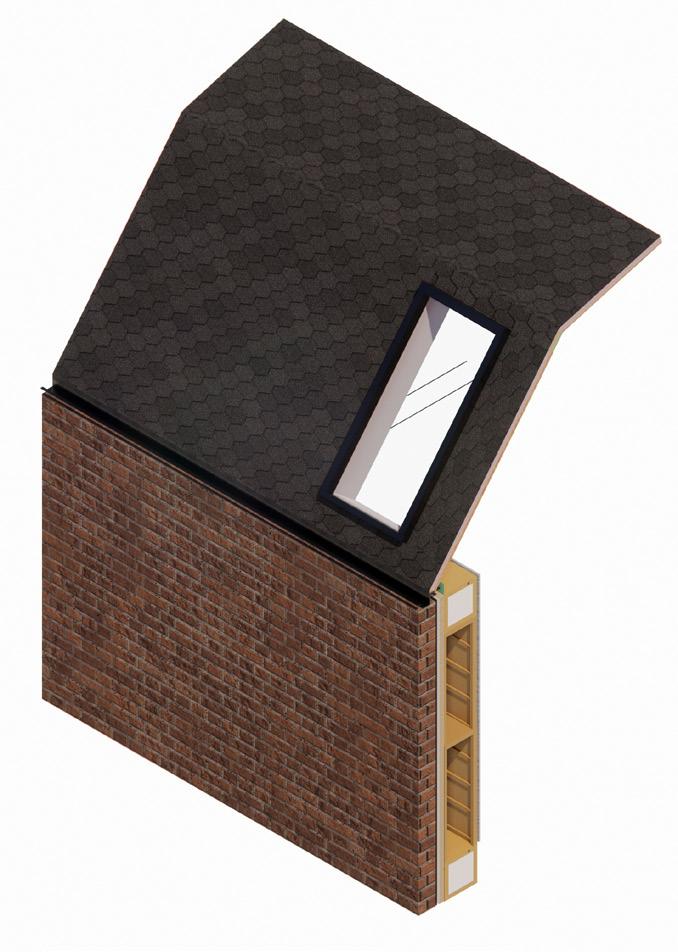

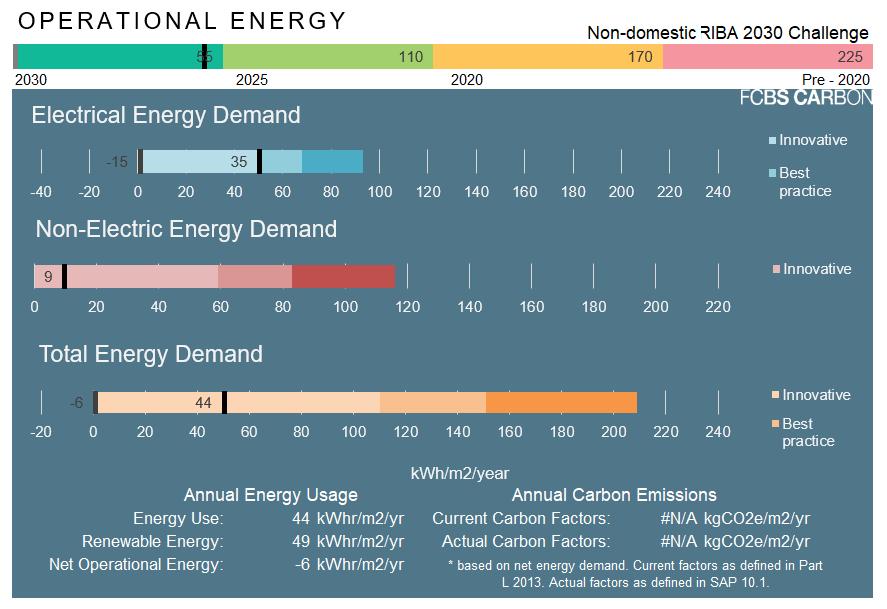

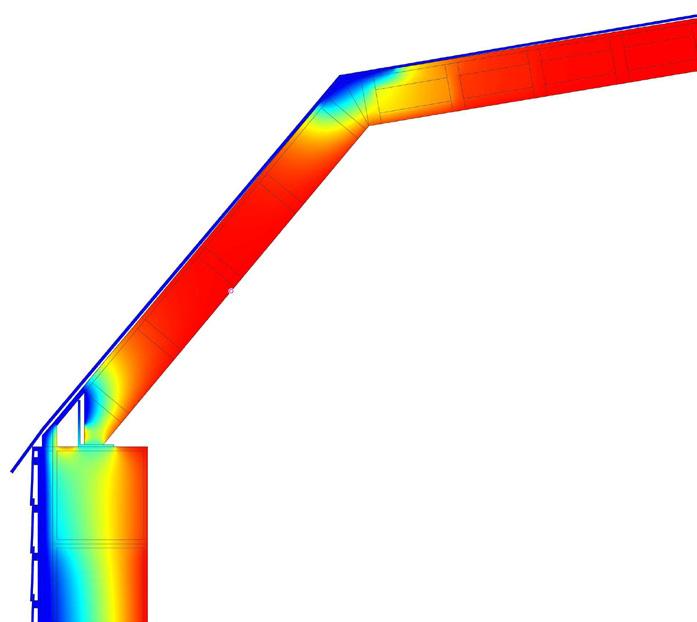

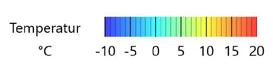

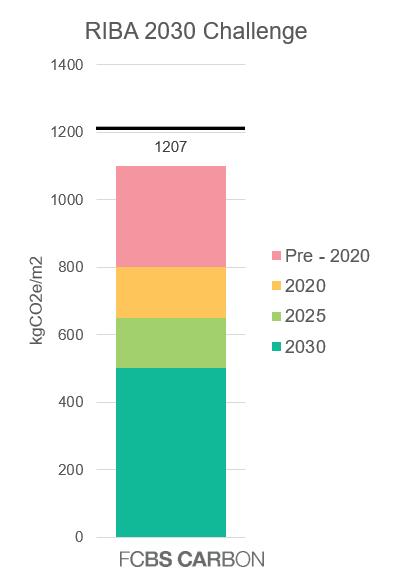

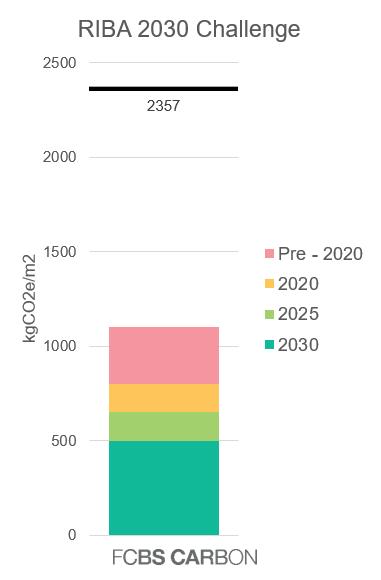

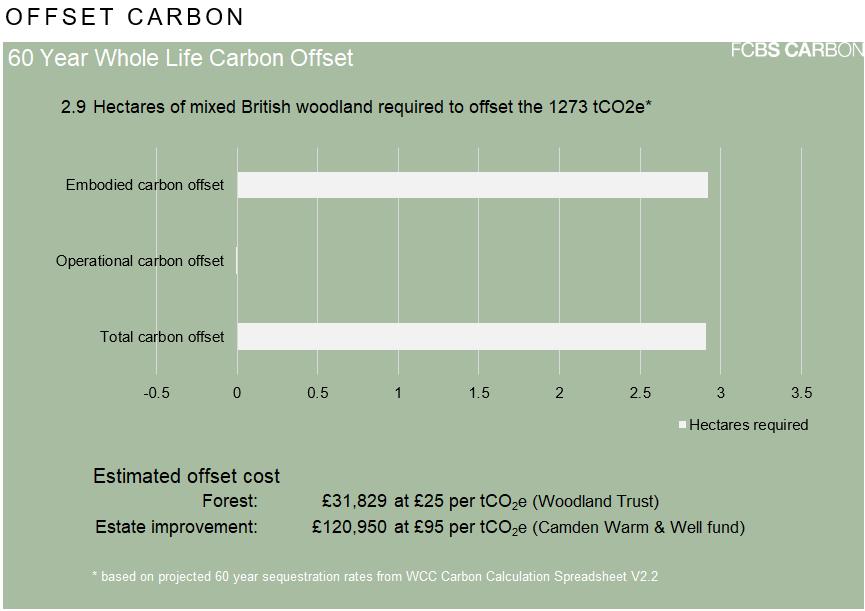

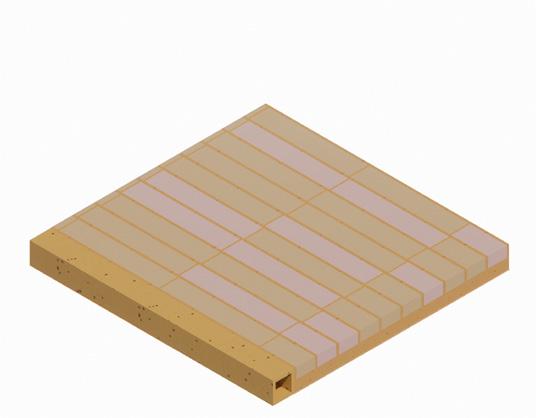

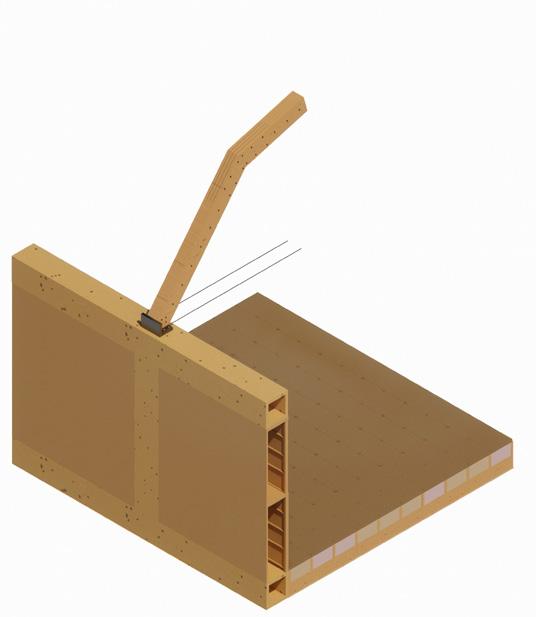

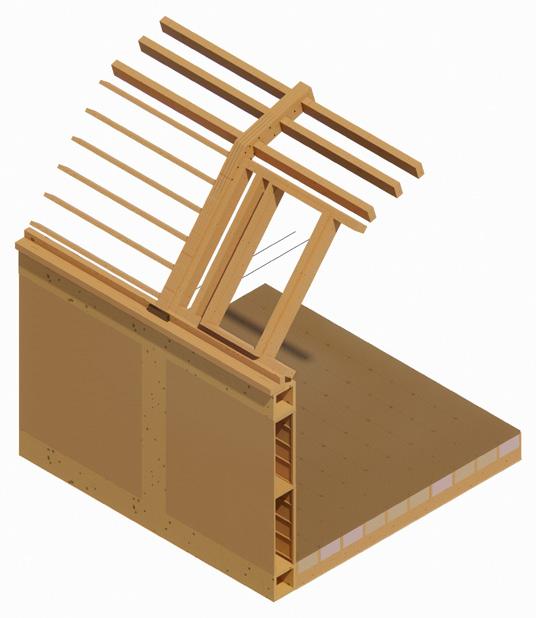

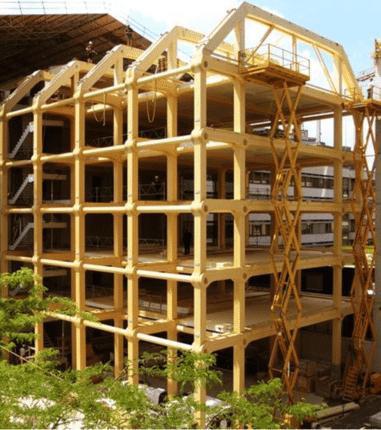

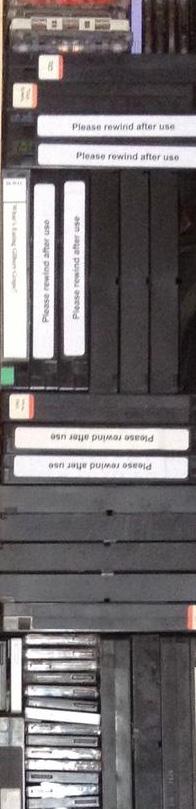

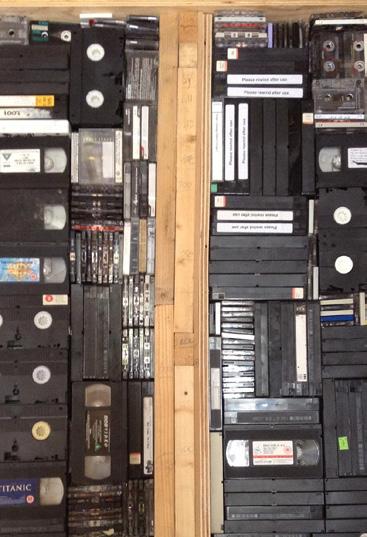

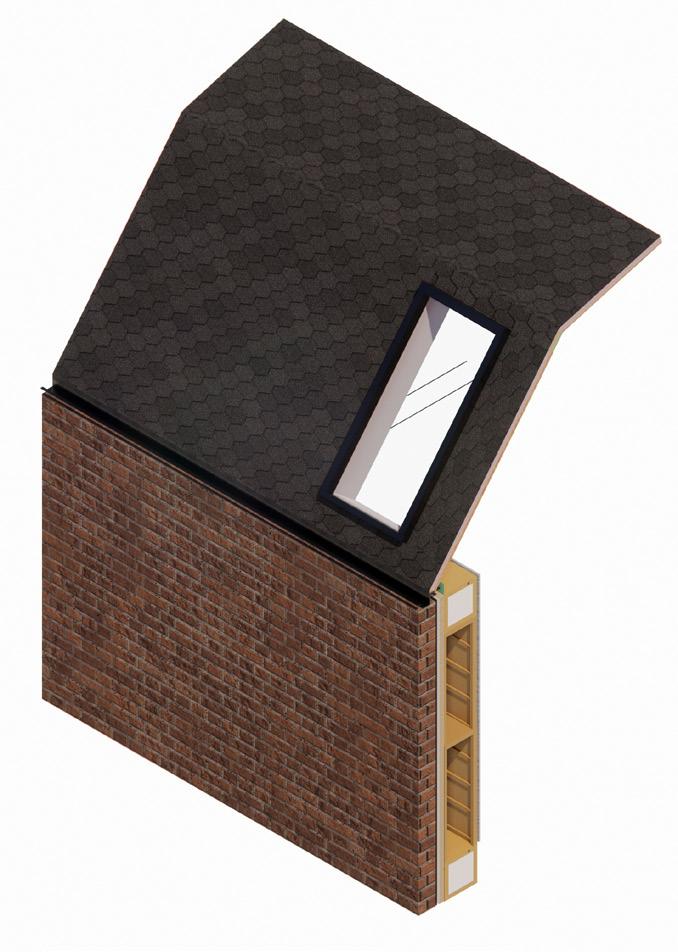

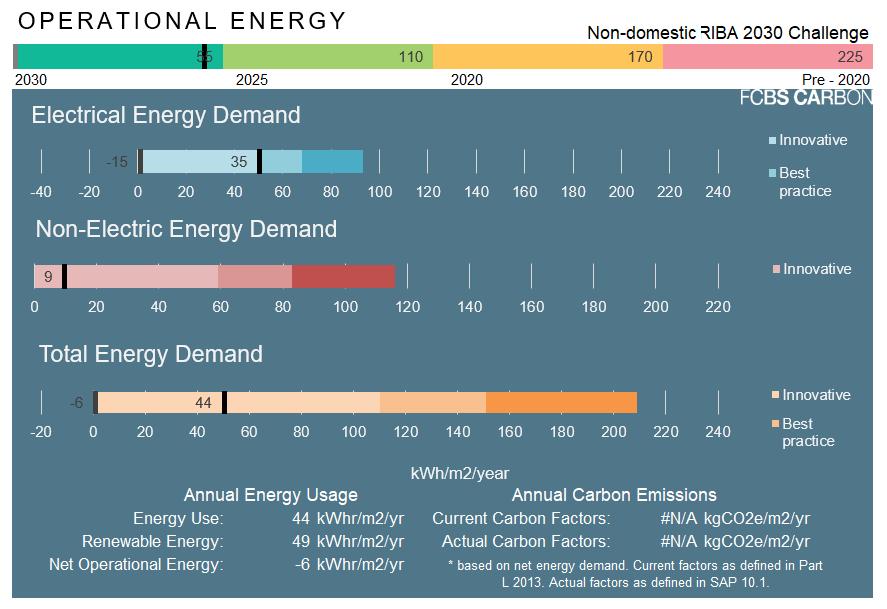

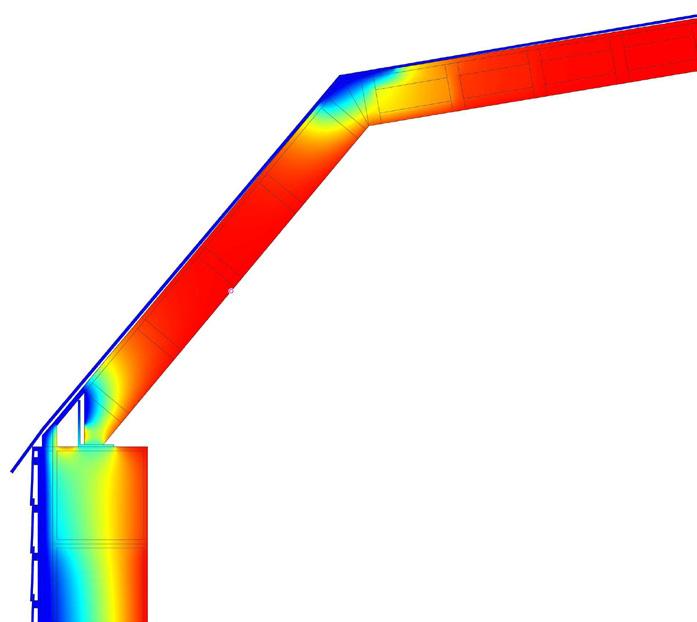

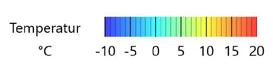

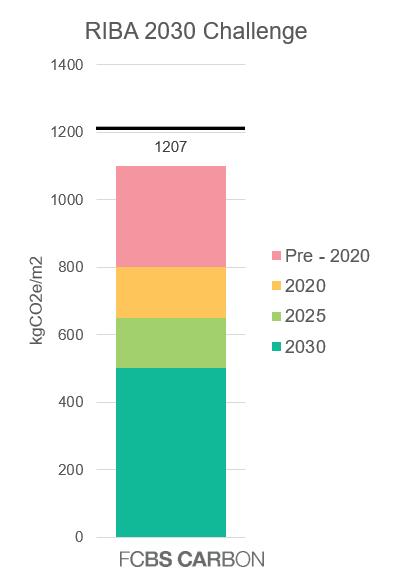

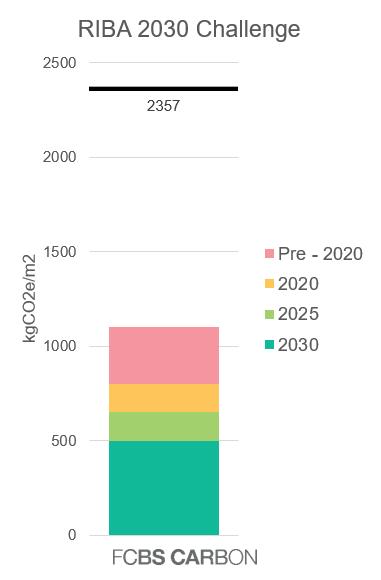

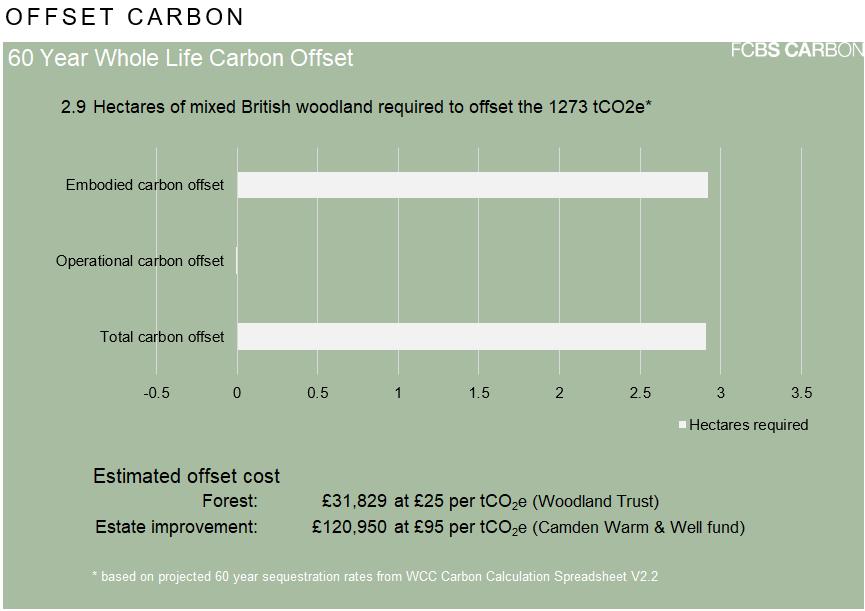

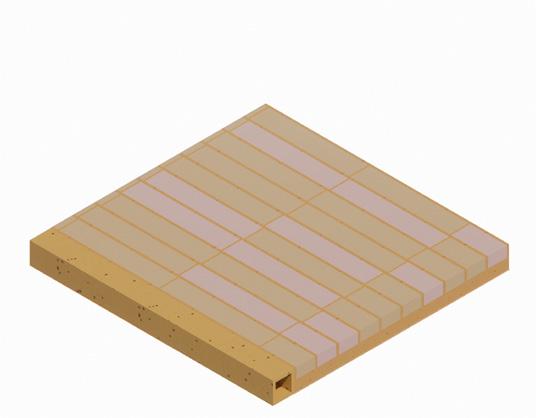

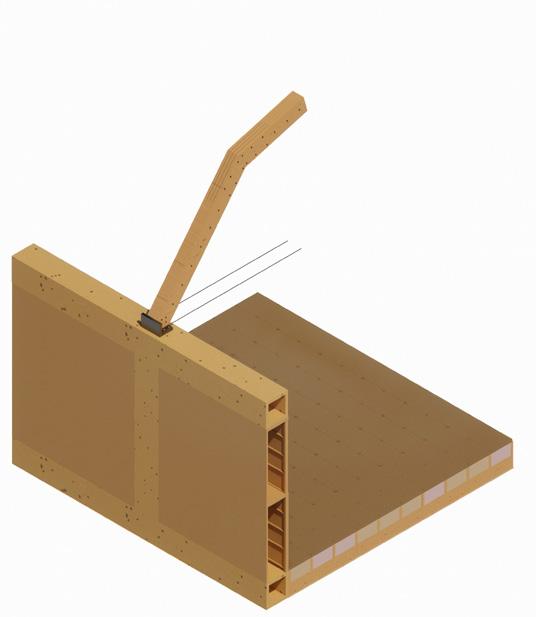

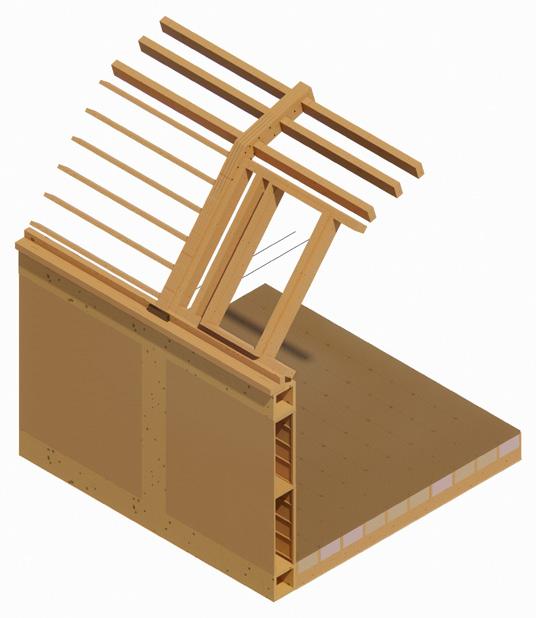

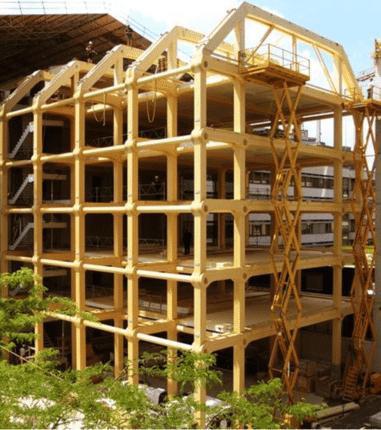

HIRRA MASOOD 21308588 BA3 &ARCHITECTURE Materials TECHNOLOGIES A Brick Facade with Shingles Alternative Cladding and Roof Finish Steel Facade with Tiles Cladding - Reused Carpet Tiles Roof - Single Ply Membrane Roof insulated clay blocks Insulation - Household Waste Structure Load L Plate Connecting Beam and Truss Threaded Rod Environment & Sustainability Awards Energy Consumption & Generation Data Construction Cost A threaded rod, secured with bolts and washers to an L-shaped plate, connects timber trusses to beams, preventing separation and ensuring load distribution, while the steel plate, strong and durable, aids in accurate alignment during assembly. User controlled windows allow spaces to be ventilated based on the users preference. Whilst there is a ramp access route provided, wheelchair users are unable to access the first floor as there is no lift available. Quantifying the environmental benefits of using recycled materials and energy-efficient systems, demonstrates tangible reductions in carbon emissions and resource consumption. The Waste House won the RIBA Sustainability Award for its use of 60 tonnes recycled materials and energy-efficient systems, showcasing exemplary sustainable design practices. The Waste House was recognized as a leading example of sustainable innovation and action in response to climate change by the 2 Degrees network, an influential platform promoting sustainability and corporate responsibility. The construction process involved the local community as well as students and apprentices, which encouraged a sense of community. In addition to that does the open plan design encourage and allow a wide range The use of waste and recycled materials create a sustainable and responsible use of material. In addition to that does the insulation prevent house waste from going into landfill and adds to the lifespan of materials. The LETI sustainability guide sets a target of 65 kWh/ m2 per year for energy consumption in educational facilities. Therefore the data presented conforms to the criteria outlined in the LETI sustainability guide. The Waste House needs a total of 44 kWh/m²/yr but generates 50 kWh/m²/yr therefore assume that it produces more energy than it consumes on an annual basis, resulting in a surplus of approximately 6 kWh/ m²/yr. This surplus indicates that the Waste House is not only self-sufficient in terms of energy but also has the capacity to provide additional energy to its surroundings, demonstrating a high level of energy efficiency and sustainability. assume by harnessing solar energy through PV panels installed on the roof or facade, the Waste House is able to generate electricity on-site, reducing its reliance on grid-supplied power. Carpet tiles salvaged from a former office building in Brighton were utilized for the cladding. assume underlay of the carpet tiles was positioned outwardly, due to their fire-retardant and waterproof properties. This orientation also allowed the carpet to serve as insulation for the structure. The choice of a recycled car tire single-ply membrane for the roof finish of the Waste House directly aligns with its sustainability goals by re-purposing discarded materials and minimizing waste while showcasing innovative and environmentally conscious construction practices. Insulated clay blocks were specifically used on the highest part of the Waste House roof where enhanced thermal insulation was crucial, ensuring optimal energy efficiency. The Waste House chose household waste items like re-purposed cassette tapes for internal insulation, diverting plastic from landfills and extending their lifespan, aligning with sustainability goals. assume the cassette’s rigid structure and air-trapping ability make them efficient for thermal insulation. Replacing the carpet facade with brick and the roof with shingles would substantially elevate the carbon footprint of the building due to the energy-intensive manufacturing processes associated with these materials. Brick production involves firing clay at high temperatures, while shingles are typically made from asphalt or fibreglass, both of which require energy-intensive manufacturing processes and contribute to greenhouse gas emissions. While steel recycling options exist, opting for steel would still entail significant processing and energy consumption, thus adding to the building’s carbon footprint. Even though recycling mitigates some environmental impact compared to using virgin materials, the overall emissions from processing and transportation still render steel a less sustainable choice compared to recycled materials like carpet tiles. The ceramic tiled roof would significantly increases the carbon footprint due to the energy-intensive manufacturing process involving high-temperature kiln firing. The choice of a timber structure for the Waste House is likely due to its carbon sequestration capabilities and ease of handling, making it accessible for nonskilled workers. One material they might have considered would be steel.Whilst there are recycling and reusing options for steel available, it ultimately adds to carbon emissions due to energy-intensive processes. assume due to the nature of the Waste House, it faced challenges in obtaining planning approval based on its unconventional design and use of recycled materials, which may have been perceived as diverging from traditional building standards by local authorities. Convincing them of the project’s environmental merits likely required significant effort and negotiation to secure the necessary permissions. Multiply timber trusses offer high strength-to-weight ratio, crucial in this project for minimizing material usage without sacrificing structural integrity, while bolts and steel plates enhance stability, preventing deformation and delamination. A threaded rods is employed to securely connect and reinforce the truss 3 components, providing structural stability and distributing loads evenly across the entire roof assembly. It is typically connected Dead loads are a key consideration during the design stage of structural elements. As a underestimate can have fatal consequences on the project and its occupiers. They are a constant variable as its building components such as walls, roof and floors are static forces. Reclaimed Porotherm Clay Blocks Thermal Mass Placed on the highest part of the roof as it experiences increased load from wind and snow. It also helps to regulate indoor temperatures and reduce energy consumption. Mechanical Ventilation with Heat Recovery (MVHR) Vent-Axia donated second hand ventilation equipment Threaded Rod This element fastens and structurally supports within the three parts of the roof trusses. Beams and Columns filled with insulation Waste polystyrene from packaging and other sources was used to fill the beams and column to provide additional insulation. The connection between the two fragments of the roof truss are particularly vulnerable to thermal bridging, as this is where heat transfer can occur most easily due to the direct contact between the materials. The external wall insulation runs across that connection to ensure airtightness and prevent thermal bridging. Sheathing Board Vapour Control Layer Roof Insulation (Kingspan waste offcuts) Using waste offcuts improves energy efficiency and offers a cost-effective solution by reducing the need for new materials. Breathable membrane Allow water vapour to escape from the building interior while preventing liquid water from entering. This helps to manage moisture within the building envelope, reducing the risk of condensation, mould, and rot. Timber roof joists Old Carpet Tiles Carpet tiles salvaged from a former office building in Brighton were utilized for the cladding. These underlay of the carpet tiles was positioned outwardly, due to their fire-retardant and waterVELUX Triple Glazed Roof light assume that the roof light was placed on the north facing part of the window, as that would prevent unwanted solar gain as well as utilise the sun for energy generation. However this compromises the amount of passive heat Rainwater Harvesting System Rainwater is collected to irrigate vegetation surrounding the building, promoting sustainability and reducing reliance on municipal water sources. Breathable Membrane Black to blend in with carpet tiles Sheathing Board Floor Battens Used under floor joists primarily to create a level surface for attaching flooring materials and to mitigate potential unevenness or deflection in the floor structure. Floor Joists Kingspan offcuts insulation Floor insulation does not only prevent heat loss and thermal bridging but also reduces noise. Vapour Control Layer Floorboards Timber Blocks Roof to Wall Roof Membrane House wrap Aesthetic Consideration Learning Attribution & Reflection External wall Insulation Kingspan waste offcuts Pre Fabricated Timber Panels Boxes filled with household waste insulation (toothbrushes, cassettes). assume the boxes were used to make the organisation more manageable Horizontal & Vertical Battens Vertical battens painted black to hide behind Carpet tiles Single Ply Membrane (recycled car tyres) Utilizing recycled car tires reduces the environmental impact of construction by diverting waste from landfills and promoting a circular economy. Constructibility 1 3 2 4 5 6 8 9 7 Alternative Structure Regulations Thermal Performance (HTFLUX Simulation) Thermal Performance with External Wall Insulation Thermal Performance without External Wall Insulation Thermal Bridging As the waste house used house waste materials for internal wall insulation. assume one testing that the design team carried out was the climatic performance of the envelope without external wall/roof insulation. This testing shows significant heat loss and thermal bridging, indicating a need for further insulation and building envelope design to enhance energy efficiency and comply with Part L regulations. Especially in the connections between structural elements such as the two connecting trusses and the beam to truss connection. Adding external wall insulation decreased the overall U value significantly. This was done without compromising the material selection as offcuts and damaged pieces of insulation from Kingspan was used. assume that the design team too carried out simulation and thus determined that Kooltherm K5 External Wall Board was the best option in terms of performance and availability. Conducting thermal testing allows the architects to assess the thermal performance of insulation materials and configurations, ensuring compliance with energy efficiency standards like Part L regulations. By simulating heat transfer across building components, HTflux testing validates design decisions and optimizes insulation strategies to minimize heat loss and thermal bridging within the Waste House. Design Resolution Environmental Modifiers Construction Sequence Annual heating and hot water: 29.4 kWh/m2 Annual other electrical use: 14.1 kWh/m2 CO2 emissions from energy use: 15.2 kgCO2/m2 CO2 emissions from energy use: 7.3 kgCO2/m2 Assumed U-value: 0.20 W/m²K Assumed U-value: 0.767 W/m²K Assumed U-value: 0.40 W/m²K Assumed U-value: 0.29W/m²K Part L Conservation of Fuel and Power Part B - Fire Safety assume that the use of carpet tiles as a cladding material would have been a high fire risk factor. In order to minimise the risk and comply with the approved document, the carpet tile had to be sprayed with a fire retardant. In addition to that, the tiles where placed with the fabric facing the inside to prevent the soaking up of rain water and ultimately mould on the facade. The Approved Document L Volume 2, Section 6.74 mentions that the choice of PV systems should be of appropriate size and energy generation in relation to the building. The PV system only generates about 6kWh/m2/yr more than the overall energy demand. Therefore assume that the architects had to ensure that the solar panels align with the south of the sun path as that would allow maximum energy generation. Planning Regulations (Local Planning Policies)

2014) (Alyn Griffiths, 2014) Construction cost £200,000 Construction cost per m² £2500 Construction cost £92,000 Construction cost per m² £1,150 The Waste House (80m2) UK Terraced House 2014 (80m2) (Hartman, 2014) (Construction costs: departmental reductions 2013-2014, 2014) U value: 1.1 W/m²K Solar Control Coating Despite receiving less direct sunlight, north-facing roof windows can still stabilize temperatures. As there is no HVAC system implemented, glass coatings prevent excessive heat gain in the summer and heat loss in the winter. MVHR The use of a Mechanical Ventilation with Heat Recovery (MVHR) system acts as an environmental modifier, enhancing both energy efficiency and indoor air quality. By recovering heat from outgoing stale air and transferring it to incoming fresh air, MVHR systems significantly enhance energy efficiency. This process notably reduces the demand for heating and cooling, consequently leading to a substantial decrease in carbon emissions. Personal Reflection & Considerations The Waste House, as a prototype, may incur higher construction expenses compared to conventional building methods due to its innovative design features and use of recycled materials. Costing around 200k, exceeded the typical 92k expense for a terraced house in 2014, however this contradicts the concept of using waste materials to build. assume that the project raises the concern and the need for cost-effective solutions in the field of sustainable architecture. (VELUX Triple Glazed 78 x 118cm Pine Centre Pivot Roof Window MK06 GLL 1061 Sunlux Roof Windows, n.d.) (RIBA, 2019) The vertical battens used to secure the carpet tiles onto, have been painted black to create a seamless look and prevent the colour of the wood peaking through. The deliberate use of waste materials in the Waste House showcases the design team’s commitment to reusing resources. This encourages the Architecture course at the University to rethink material use, promoting sustainability in design education and inspiring future architects to embrace environmentally responsible practices. This aligns with my own technological position, advocating for a forward-thinking approach that prioritizes resource efficiency, resilience, and ecological consciousness in architectural practice and education. By integrating sustainable design principles and real-world examples like the Waste House, architectural teaching can empower students to address pressing environmental challenges and innovate towards a more sustainable future in the built environment. Beam and floor joists installed on top of the existing ground floor structure to provide structural support for the first flooring system. Prefabricated insulation panels where put in as internal insulation, as it eases the process of filling the panels. This was screwed in with a drill and screws to ensure stability Added after the floor joists to reinforce the floor structure, preventing bending or movement and providing a stable surface for further construction. Sheathing board under floor joists and timber blocking added to reinforce the floor structure and provide a stable surface for subsequent layers. Column and vapour control layer for floor erected to support additional loads and prevent moisture penetration into the floor structure. To complete the construction, including membranes, weatherproofing, and finishes, ensuring that the building is fully enclosed and protected from external elements before interior finishes are Overall assume that a replication of the waste house is feasible, however due to the materials being predominantly waste, it would be difficult to acquire the exact components. In addition to that such project requires through research and a very difficult planning application process as it is not a typical way of building. Furthermore, my calculations show that although many of the materials are ‘free’ the cost of construction and the contract are beyond the costs of a terraced house. The clay blocks where added on the highest part of the roof as additional thermal mass. The high placement allows maximum passive heat gain. The roof rafters where added for stability of the roof and a cut out for the window to be placed in. The rafters are fixated to the truss using a drills and screws. Column and floorboards added to extend the floor area and provide support for roof structure, following the installation of the column and vapour control layer to ensure proper alignment and load distribution. Envelope U-Value :0,20 W.m-2.K-1 Envelope U-Value :0.95 W.m-2.K-1 Waste House Building Type School, college, university Construction Year 2014 Architect: Duncan Baker-Brown Architecture firm: BBM Sustainable Design Sustainable Material Use: Circular Economy Principles: Energy Efficiency: Prioritizing the use of recycled and reclaimed materials to minimize waste and reduce environmental impact. Emphasizing the principles of a circular economy by promoting resource efficiency, material reuse, and waste reduction throughout the building’s life cycle. Implementing strategies to enhance energy performance and reduce operational carbon emissions. (QUICK SPEC, n.d.) (blackstairswd, n.d.) Bolts and plates creating Multiply-truss (Baker-Brown, 2018) (Steel recycling, 2016) Timber blocks were used as thermal blocks, which have a modified cellular structure, making it more resistant to temperature changes and improving its insulating capabilities. The over lapping roof membrane allows water to run off into the gutter and thus prevents water to penetrate and damage the envelope of the building. The insulated beams incorporate polystyrene within their structure, providing better thermal resistance compared to traditional beams. These connections are often prone to heat loss, this helps to minimize heat transfer through the building envelope, reducing energy consumption for heating and cooling and improving overall energy efficiency. External Insulation Clay Blocks Roof to Roof Wall to Floor Insulated Beams to an L plate by securing its threaded end through a hole in the plate and fastening it with a nut, ensuring structural support, stability, and the ability to bear loads or transmit forces. Steel, with its superior strength, durability, and versatility, is preferred over aluminium for connecting threaded rods in structural applications where robust connections are essential. proof properties. This orientation also allowed the carpet to serve as insulation for the structure.

(Alyn Griffiths,

Concrete v Timber. Postawa encouraged us to consider in our own work “Which material is best suited for this application?“ followed by “Which material has to lowest carbon? or is more sustainable?“ He argued that labelling a material as inherently “sustainable” might not be the right approach as ultimately its environmental impact is depended on the project conditions, lifespan and quantity of material used. For example, timber stores carbon emissions until its demolition, the release of carbon after 40 years would give timber the highest rate of embodied carbon, however if the structure is in use for 100 years it becomes carbon negative. Consequently, the application of structural materials to a project heavily depends on a range of factors, as timber might not be able to perform as well as steel in moisture prone conditions. Therefore the ‘sustainability’ of timber structures depends on the life span rather than it being a natural resource, as unlike steel, timber cannot be reused as a structural element. This aligns with the views of my atelier on sustainable practice, as we are encouraged to consider demolition waste before our design, therefore in my Studio 3.1 project have used of steel as a structural element as it is easier to reuse than timber.

Critical Reflection Design Methodology & Technological Strategy In this discourse lecture Cooley explored the use of brick within a chronological framework from 1235BC to its potential future in architecture. Brick has served as a primary construction material throughout history due to its high compressive strength and long lifespan. Notably, brick buildings in the United Kingdom often last over 150 years, predominantly prominent during the Victorian era but still present in modern constructions. Of particular interest was the innovative ‘Click Brick’, although currently unavailable in the UK market due to ongoing testing, it is accessible in European

HIRRA MASOOD 21308588 BA3 &ARCHITECTURE 01: ADVANCED FACADE SYSTEMS 02: LOW IMPACT BUILDINGS 03: DESIGNING STRUCTURAL FRAMES 04: BRICK: THE PAST AND FUTURE OF MASONRY BUILDINGS 05: DESIGN FOR HIGH ENVIRONMENTAL PERFORMANCE STANDARDS Speaker: Rhodri Evans Position: Facade Consultant & Architect Organisation: BDA Speaker: Kevin P. Flanagan Position: Senior Architect Organisation: PLP Architecture Speaker: Les Postawa Position: Structural Engineer Organisation: Les Postawa Associates Speaker: Andrea Cooley Position: Technical & Design Support Manager Organisation: Winerberg Speaker: Laura Stafford Position: Associate Architect Organisation: 5PLUS Critical Reflection Design Methodology & Technological Strategy This lecture introduced glass in the context of façades, it discussed how the use of different types of glass infl uences the visual appearance and internal experience of a spaces. In addition to that, Evans presented different types of glass and their particular performance in regards to thermal and visual performance. The concept of glass coatings is especially intriguing, as the use of a specific coating might determine the visual appearance of a facade. Depending on the architect’s/client’s goal, a reflective glass Pyrolytic Glass facade will refl ect the surroundings of the building. In contrast, a high transparency glass (Low Iron Glass) facade, creates a visual connection of internal and external spaces. My Atelier’s position of “Material First, Design Second”, can be considered to align with the use of Solar Control Coated Glass as this type of glass enhances energy efficiency and improves thermal comfort in buildings by controlling the transmission of solar energy. For my design project, using Solar Control Coated Glass is useful as the south-facing elevation might suffer from overheating from direct sunlight, therefore this coating would reduce the need for air conditioning. Critical Reflection Design Methodology & Technological Strategy This lecture presented timber as a structural construction material, replacing concrete and steel in the construction industry entirely. He highlighted not only the environmental advantages such as carbon sequestration but also the ability to build taller structures on an identical foundation. One approach that particularly aligns with my own ideas of good design practices is the concept of replacing trees as we harvest them as timber might be a finite source, it does need to be planted for future use. Timber might have the ability to replace concrete and steel, however in order to achieve this there has to be consideration of other aspects of the environmental systems such as the ocean and atmosphere, as ultimately one change in the environment can have a cascading effect on the rest. Furthermore, the concept of a Hybrid Structure where 50-60% of the structure is made of concrete, which he argued is an ineffi cient use of materials, as the carbon footprint is relatively high whereas carbon sequestration is low. This does not align with the core concept of my atelier (&architecture), as it encourages us

design

extraction

new

timber. Critical Reflection Design Methodology & Technological Strategy This lecture explored the broader implications of the three primary materials used in construction as structural elements, Steel v

to

with “cheap/free/recycled/found materials” rather than

of

materials such as

nations such as the Netherlands . The Click Brick introduces a more sustainable approach to brick construction, utilising a dry stacking system that facilitates easier brick reuse compared to traditional methods (Clickbrick, n.d.). This approach resonates deeply with the core values of my atelier and my personal believes, empha-

importance

material

minimise demolition waste. Furthermore, the lecture highlights ‘Eco Bricks’, which offer a slimmer profile

utilize 36% less material

maintaining the durability and strength of traditional bricks

n.d.). The lecture underscored the importance of environmental impact and sustainability without compro-

the imperative of technological advancements in enhancing both performance and structural integrity. Critical Reflection Design Methodology & Technological Strategy This lecture highlighted the increasing importance of sustainable development within the architectural industry. Design strategies such as regulated solar gain and user-controlled ventilation allow architects to create spaces that require a reduced amount of operational energy. Laura discussed the terms “Net Zero/Net Zero Carbon“ as phrases used for the operational and post-construction assessment. The use of energy-efficient technological systems in order to meet comfort needs has become more common in contemporary Net Zero Projects. This approach in particular contrasts with my idea of good practice, as often the design of a building incorporates systems projected to achieve a lower Energy Use Intensity (EUI). However, it’s important to note that actual energy consumption post-construction often deviates from these projections, as occupant behaviour and operational practices can not always be projected accurately. Contrasting this, the concept of reusing materials and existing infrastructure to reduce our impact on the environment particularly aligns with my atelier position. The diversion of demolition waste from landfills helps reduce the need for new materials. Therefore, this lecture underscored the imperative for architects to consider the entire lifecycle of a building, from conception to demolition, in fostering a more sustainable built environment. Responsibilities In relation to the Beetham Tower in Manchester, the architects at SimpsonHaugh and the main contractor Carillion plc bore responsibility to guarantee the safety of occupants, particularly in the utilisation of glass elements. In 2012, 21 windows in the tower had to be replaced after showing signs of cracking, at a cost of £630.000. In 2014 it was discovered, that the sealant securing the shadow box units failed, posing a risk of glass panes falling out of the structure and thus becoming a hazard to pedestrians (Beetham Tower, another window falls onto the street, 2023). A temporary repair was set in place using stitch pressure plates, however, this did not prevent panes from breaking out of the structure as toughened glass was used. As discussed in the lecture, the use of tempered/toughened glass reduces the risk of severe injuries from sharp edges as it shatters into small, relatively harmless fragments. However, the breakage characteristic itself can be a concern at higher levels, as shattered pieces may fall, potentially causing harm to people or property below. Stitch plates can only be used as a temporary solution for 3 Years, however, Carillion did not propose a permanent solution until 2018 following a court case. In this case, the main contractor and architects had a legal obligation to specify a structural glass sealant that complies with relevant safety standards and building codes, to ensure not only the safety of the occupants but also the public. This poses a critical analysis of materials used in my design proposals, as such mistakes initially might seem minor, however, can have fatal consequences. Responsibilities Architects must consider and integrate health and safety regulations into the design process to ensure that the fi nal structure meets necessary safety standards for occupants and users. In the case of the Tamedia building, the project was approved by direct communication with the local authority rather than compliance with building regulations, this was due to the exceptional height of the proposed project. Here the architects were responsible for the structural integrity of the building, as there was no governmental research to prove that a seven-storey timber structure is feasible. In addition to that it was the professional’s responsibility to ensure the comfort of the users, here it was prioritised by the use of exposed timber structures. Wood is known to have positive impacts such as reducing stress levels, and on occupant’s mental well-being, as this building is an offi ce building, the workers benefi t

timber

the design Arnold

The

Gap

achieved

reduction

2030 target of a 68% reduction in carbon emissions (Emissions Gap Report 2023, 2023). In light of the evidence, it is an obligation upon architects to make efforts to reduce carbon emissions within the building and construction industry. However, this duty extends beyond the profession, as educational institutions play a vital role by incorporating sustainable practices into architectural education. Responsibilities In the case of No1 Court Wimbledon the main contractor Sir Robert McAlpine was responsible for appointing a specialist structural engineer specialising in roofing systems. The hydraulically operated roof at No1 Court Wimbledon measures 65x75 meters and features a ‘folding fabric concertina’ design supported by steel trusses. The translucent fabric skin allows natural light to reach the court’s grass, while airfl ow prevents condensation, ensuring optimal player performance and spectator comfort (Fairs, 2012). Lindner Prater ensured a minimised use of trusses, as otherwise, the weight of the steel would have caused the retractable roof to collapse entirely or remain static. In addition, they were obliged to maintain a comfortable environment inside as the player’s performance and the overall experience could be affected by the conditions brought by the closed roof. In this precedent, steel was the only viable option for the engineers due to the specifi requirements of the Wimbledon roof (Fairs, 2012). Timber or concrete would not have provided the necessary strength, flexibility, and durability needed to support the hydraulically operated roof and the folding fabric concertina design while maintaining the desired aesthetic and functionality. Ultimately, the engineers had to ensure the buildability of this roof in relation to the most sustainable option available, as Movement and relative defl ection would have compromised the structural integrity of not only the new retractable roof but also the existing structure of the court. Responsibilities In the case of one residential block at the Hoxton’s Colville Estate in Hackney, six years after its completion signifi cant concerns had risen about the cracking brick facade and combustibility of the insulation (Jessel, 2019). This might be due to poor-quality bricks or mortar may lack the necessary durability to withstand environmental stresses, leading to premature cracking and deterioration. One significant responsibility of the architect and contractor in this case was to consult a brick specialist such as Wienerberger to ensure the right durability-coded brick was used such as an F2S2. This issue was mainly due to the materials and methods used at the time of construction rather than post-construction or environmental impacts. Another important factor in using brick in façades is the mortar used, if it is too hard or too soft in relation to the bricks it can result in cracking. Mortar that is too hard may not provide sufficient fl exibility, causing stress concentrations that lead to cracking. Conversely, mortar that is too soft may not adequately support the bricks, leading to settling and cracking. In addition to that, was it the obligation of the brick-and-mortar supplier to ensure that the right product was delivered for the project being built, as architects might have limited knowledge about this issue. Ultimately, there are multiple bodies of professionals such as building inspectors that bear the responsibility of ensuring the right supplies are used in construction projects like the one at Hoxton’s Colville Estate. Responsibilities The refurbishment and extension project of the Trafford Town Hall carried out by 5PLUS, highlights the importance of adaptive reuse of existing buildings in order to meet the 2050 Net Zero Carbon target. Here the architects bore the responsibility of refurbishing and extending a building whilst meeting the needs of the future occupiers as well as ensuring that the fi nal building is as close to Net Zero as it can be. In the case of the Trafford Town Hall, a range of mechanical and passive strategies were implemented to create comfortable interiors whilst demonstrating environmental awareness. In the design process, 5PLUS architects used data and software to test internal temperatures, however, this testing only revealed temperatures based on the entirety of the space. Shortly after the extension was completed and occupied, offi ce workers observed a temperature difference between areas nearer to the glazed windows. However, whilst the double-glazed windows were effective in minimizing heat loss, as external temperatures decrease, the glass cools accordingly, leading to a deviation of 2 degrees in temperature across the space. Laura mentions, that here the architects should have used triple-glazed windows instead as they would have provided better insulation against external temperature fluctuations. Overall, architects carry the responsibility of not only designing buildings that meet the regulations and specifi c requirements of their clients but also safeguarding the environment, given the signifi cant contribution of the construction industry to CO2 emissions. Compliance According the BS relegations to the all silicone sealant must meet the requirements found in BS EN 1279, which states that seals must be tested regularly to ensure the allowable strain of the silicone sealant is not exceeded (Matthias Haldimann et al., 2008:156). In the case of the Beetham Tower the sealant failed due to adhesion between the structural sealant and the polyester powder coating used on the cladding frames, as wrongly measured components or improper mixing of ingredients can change the overall performance (Matthias Haldimann et al., 2008:157). This issue could have been raised during the extensive control protocols conducted before, during, and after construction, the issue of sealant failure could have been identified and rectified in a timely manner. Whilst the regulations were met and the application was approved by the local authority, the delay in providing a permanent solution to the issue was vital to ensure that health and safety of the occupants and the public. Compliance The Tamedia Office building in Zurich by Shigeru Ban is Switzerland’s first seven-storey mass timber structure. However at the time of completion in 2013, it was technically “illegal“ to build, as the local building codes only allowed 6-storey timber structures at the time (Hahn, 2023). The GVZ building insurance company ensured that the building envelope had additional fire safety measures put in place, as otherwise, the fire safety aspect of the planning application would not have passed. Two years post-completion, the national building code was changed, it allowed timber structures to be built with no height limitation. Therefore this project paved the way for other professionals to adopt a more sustainable practice, however, the structure is not entirely built of timber, as concrete was used for fireproofed staircases. Ultimately, limited regulations are in place concerning the safety and performance of high rise timber structures, however there is a need to shift towards more sustainable practices, challenging established norms and regulations in the construction industry. Compliance As the retractable roof of No1 Court Wimbledon is made from steel, the structure has to be in compliance with the Eurocode 3: Design of steel structures, which states the principles and criteria ensuring the safety and functionality of structures. Particularly focusing on fire safety, Lindner Prater had to comply to part EN 1993-1-2:2005 of the regulation which determines the fi re resistance of structural elements and systems, as well as methods for calculating the effects of fi re on steel structures. This is important as No1 Court Wimbledon is a space occupiable by about 12,345 viewers and thus fi re emergencies pose a significant risk to their safety and well-being. Furthermore, Eurocode 1: Actions on Structures mentions guidelines for assessing and designing structures to withstand various environmental loads and imposed loads, ensuring their safety and durability. Part EN 1991-1-1:2002 of the document is vital as the retractable roof structure must withstand, including its own weight, imposed loads from spectators, equipment, and other environmental factors such as rain and snow. Compliance In the UK, the use of bricks in construction must comply with various regulatory documents, particularly regarding durability, structural stability, materials, and workmanship, which is essential for preventing cracking in brick façades. According to Approved Document A, Section 4 Bricks used in construction must meet specifi ed durability standards to ensure they can withstand environmental stresses, including temperature variations, moisture exposure, and freeze-thaw cycles. The cracking may have occurred due to the brick being unable to withstand the load of the blinding, therefore the brick should have complied with Approved Document A, Section 5. The document PD6697:2019 outlines specifi c design considerations for brickwork, including the selection of appropriate brick types and durability which is especially important for the Hoxton’s Colville Estate. By integrating the requirements and recommendations outlined in these regulatory documents, construction professionals can help prevent cracking in brick façades or other forms of brick deterioration and ensure the long-term durability and stability of buildings. Compliance In terms of the Trafford Town Hall, it was likely subject to conservation and heritage regulations, any proposed alterations or additions would need to comply with these regulations to preserve the building’s architectural integrity and historical signifi cance. Heritage buildings are often assigned grades refl ecting their historical signifi cance, with corresponding restrictions on renovation and alteration works to preserve their architectural integrity and cultural heritage. However as the main theme presented in the lecture was the need for more buildings to meet the LETI/Net Zero Carbon goal, 5PLUS architects faced the challenge of reconciling sustainability objectives with heritage preservation requirements. Although the UK is committed to NET ZERO by 2050, the current building regulations do not reflect that, instead it is crucial for architects to utilise documents such as RIBA 2030 Climate Challenge guide or the LETI Climate Emergency Design Guides. 29/01/2024 31/01/2024 05/02/2024 05/02/2024 Facade Systems Carbon` Net Zero by 2050 RIBA Sustainable Outcomes Guide Responsibility Recycling Building Materials Regulations Ateliers Position: Material First Design Second Energy Reducing Operational Energy Renewable Energy Sources Passive Design Strategies Mechanical Systems Mechanical systems improve environmental sustainability by optimizing energy efficiency, reducing emissions, and promoting renewable energy integration in building operations. Rely on natural elements like sunlight, airflow, and thermal mass to regulate temperature and enhance comfort, resulting in lower energy consumption and reduced environmental impact. Government Initiatives Reducing Embodied Carbon Glass Advanced Facade Systems Brick The Past And Future Of Masonry Buildings Structural Systems Future Climate Crisis Current Concrete vs Steel vs Timber Designing Structural Frames Timber Designing Structural Frames Glass Coatings and their impact on thermal performance underscores the crucial role of glass in enhancing operational energy efficiency. Primarily due to the energy-intensive firing process and transportation logistics of bricks, brick’s embodied energy can be substantial No structural material is inherently good for the environment, as each carries its own set of limitations and environmental impacts. Understanding these limitations is crucial for architects and builders to make informed decisions and prioritize materials with lower environmental footprints in construction projects. Reducing embodied carbon in buildings is paramount to achieving the Net Zero target by 2050, as it mitigates the environmental impact of construction activities and contributes to overall carbon neutrality in the built environment. Provides architects and designers with practical strategies and guidelines to integrate sustainable principles into building design, construction, and operation, ultimately contributing to the reduction of carbon emissions and the creation of environmentally responsible built environments. Timber is the most suited structural material for carbon sequestration, as it effectively stores carbon dioxide, offering a significant advantage in reducing carbon emissions during construction. Transparency Levels Coating Technologies Solar Control Coating Deviation from optimal composition or manufacturing practices can result in compromised structural integrity, susceptibility to damage, and shortened lifespan of the end product. Manufacturing Design The structural engineer or architect must ensure the correct choice of structural material for the project, ensuring both structural integrity and efficient material use.

sising the

of

reusability to

and

while

(Eco-Brick,

mising

from the utilisation of

in

Laver, 2022).

Emissions

Report 2023 highlights that the UK has not

the necessary

in CO2 emissions to reach its 2030 goal. Ultimately, the United Kingdom is not progressing toward reaching its

1:

use

toughened glass for the windows of the Beetham Tower, combined with the failure of the structural sealant, resulted in the cracking and eventual detachment of the panes fromthebuilding.(source:Online) Design For High Environmental Performance Standards The transparency levels of glass, represented by its G values, indicate the fraction of solar radiation transmitted through the glass. Depend on the molecular structure and purity of the glass composition, impurities are capable of modifying light transmission properties and thus influencing the overall energy performance of the glass. The recycling processes for concrete and steel involve significant energy consumption and may not be as effi cient as timber recycling in terms of environmental impact. Production Construction Usage Demolition Recycle British Standards are technical specifications developed by the BSI to ensure quality and safety in various industries, including construction, although compliance with them is not legally mandatory. These are government-issued documents providing practical guidance on complying with building regulations in the UK. Compliance with Approved Documents is mandatory. British Standards Approved Documents No mandatory regulations for structural glass sealants Outside Inside Reflected Coating Direct transmittance Re- directed inwards Re- directed outwards The current trajectory suggests that the UK is not on track to meet the Net Zero 2050 target, signaling the need for urgent and comprehensive measures to accelerate progress towards carbon neutrality. Steel and concrete are among the most carbon-intensive materials due to the energy-intensive processes involved in their production, making their widespread use a significant contributor to greenhouse gas emissions in the construction industry. The construction industry must radically change in response to the climate crisis, necessitating innovative and sustainable practices for a resilPolicy frameworks are essential for renewable energy deployment, serving as critical tools to mitigate the effects of climate change by promoting widespread adoption and investment in clean energy solutions. Reduction of the reliance on finite fossil fuels is crucial. To enhance energy security, and foster sustainable economic development for present and future generations. Figure5:Thedouble-skinnedfacadeoftheTraffordTownHallextension,implementedforeffectivesolarcontrolandenergymanagement.(source:Online) Figure 4: Click Bricks during construction, illustrating the dry stacking system and modular designthatallowsforeasyassemblyandefficientuseofmaterials.(source:Online) The brick firing process relies on fossil fuels like coal, emitting greenhouse gases and causing air pollution. Figure 3: The retractable roof of Wimbledon No. 1 Court, made of steel for its durability and strength,providesstructuralintegritywhileallowingnaturallightingtopermeatethespacewhen closed.(source:Online) Figure2:TimberframestructureandjointsoftheTamediabuildingshowinghowtheframestructurallyconnects,whichdifferentiatesfromtypicaltimberstructures. Glass panel had cracked out its frame and fallen from the facade The roof allows the programme of the stadium to proceed, despite the weather being unsuitable Bricks can be laid without cement, connected by structural components Double skinned facade controls solar gain and provides shading to the north facing facade. 19/02/2024 TECHNOLOGIES B

Figure

The

of

Alyn Griffiths (2014) Waste House by BBM is ‘UK’s first permanent building made from rubbish.’ Dezeen. Dezeen. [Online] https://www.dezeen.com/2014/06/19/waste-house-by-bbm-architects-is-uks-first-permanent-building-made-fromrubbish/.

Architect (2014) Waste House Construction, Brighton, UK Sustainable Solutions Architecture Student Chronicles. [Online] [Accessed on 28th February 2024] https://www.architecture-student.com/architecture/waste-house-constructionbrighton-sustainable-solutions/.

Baker-Brown, D. (2018) Waste House construction21.org. [Online] https://www.construction21.org/case-studies/h/waste-house.html. blackstairswd (n.d.) U Values Clayblock Ireland. [Online] [Accessed on 28th February 2024] https://www.clayblock.ie/u-values/. Construction costs: departmental reductions 2013-2014 (2014) GOV.UK. [Online] https://www.gov.uk/government/publications/construction-costs-departmental-reductions-2013-2014. Hartman, H. (2014) Brighton Waste House. The Architects’ Journal. [Online] https://www.architectsjournal.co.uk/buildings/brighton-waste-house.

QUICK SPEC (n.d.). RIBA (2019) Sustainable Outcomes Guide www.architecture.com. [Online] https://www.architecture.com/knowledge-and-resources/resources-landing-page/sustainable-outcomes-guide. Steel recycling (2016) Galvanizers Association. [Online] https://galvanizing.org.uk/sustainable-construction/steel-is-sustainable/steel-recycling/. VELUX Triple Glazed 78 x 118cm Pine Centre Pivot Roof Window MK06 GLL 1061 - Sunlux Roof Windows (n.d.) sunluxroofwindows.co.uk. [Online] [Accessed on 28th February 2024] https:// sunluxroofwindows.co.uk/timber-roof-windows/1231-velux-triple-glazed-78-x-118cm-pine-centre-pivot-roof-window-mk06-gll-1061-5702328325395.html?gmc_currency=1&gad_ source=1&gclid=CjwKCAiA0PuuBhBsEiwAS7fsNd0IDNnMtPtvXMpDa_3HMIf9Cp04G8uLrQGS29jQUJuqJ4zLTR7jOxoCvNAQAvD_BwE.

Technologies B

Emissions Gap Report 2023: Broken Record – Temperatures hit new highs, yet world fails to cut emissions (again) (2023). Nairobi. Beetham Tower, another window falls onto the street (2023) Confidentials. [Online] [Accessed on 25th February 2024] https://confidentials.com/manchester/beetham-tower-another-window-falls-onto-the-street. Clickbrick (n.d.) Netherlands. [Online] [Accessed on 25th February 2024] https://www.wienerberger.nl/en/clickbrick.html. clickbrick - Google Search (n.d.) www.google.com. [Online] [Accessed on 25th February 2024] https://www.google.com/search?sca_esv=f82d15fe49af92c2&sca_upv=1&sxsrf=ACQVn0_FOu-5eSQOCY_adn9s-8qsO4Ilrw:1708820198302&q= clickbrick&tbm=isch&source=lnms&sa=X&sqi=2&pjf=1&ved=2ahUKEwidn56nm8WEAxUfZkEAHV5_BAUQ0pQJegQICxAB&biw=1536&bih=695&dpr=1.25#imgrc=mHZw8yYQeAq3nM. Eco-Brick (n.d.) United Kingdom. [Online] https://www.wienerberger.co.uk/products/brick/eco-brick.html. Fairs, M. (2012) Wimbledon’s Centre Court sliding roof designed by Populous Dezeen. [Online] [Accessed on 6th February 2024] https://www.dezeen.com/2012/07/08/is-the-centre-court-roof-the-real-star-of-wimbledon-2012-telegraph/. Hahn, J. (2023) Shigeru Ban’s timber-skeleton Tamedia building left engineers ‘incredulous.’ Dezeen. [Online] https://www.dezeen.com/2023/03/17/tamedia-office-building-shigeru-ban-timber-revolution/. Jessel, E. (2019) KCA speaks out over design and build process on defective Hackney block The Architects’ Journal. [Online] https://www.architectsjournal.co.uk/news/kca-speaks-out-over-design-and-build-process-on-defective-hackney-block. Kuda, D. and Petříčková, M. (2020) (PDF) Modular timber structures ResearchGate. [Online] https://www.researchgate.net/publication/341492834_Modular_timber_structures. Matthias Haldimann, Luible, A. and Overend, M. (2008) Structural use of glass Zürich Iabse, p. 157. Morby, A. (2019) Beetham Tower owner ordered to replace glazing Construction Enquirer News. [Online] https://www.constructionenquirer.com/2019/02/01/beetham-tower-owner-ordered-to-replace-glazing/. Secondary Sealants in Structural Glazing Applications Sika UK (2021) gbr.sika.com. [Online] [Accessed on 30th January 2024] https://gbr.sika.com/en/media/blogs/guide-to-secondary-sealants-in-structural-glazing-applications-.html. What are the health benefits of using timber in construction? Arnold Laver (2022) Laver. [Online] [Accessed on 1st February 2024] https://www.laver.co.uk/blog/what-are-the-health-benefits-of-using-timber-in-construction. html#:~:text=Bring%20Down%20Stress%20Levels&text=Wood%20is%20shown%20to%20lower.

HIRRA MASOOD 21308588 BA3 &ARCHITECTURE

BIBLIOGRAPHY Technologies A