Our 35 years of practice has taught us the importance of relationships built on trust and confidence. We trust our clients and partners to understand the needs of their customers, and they trust us to lead the design process for their spaces. licensed in states STAFF 500+ professionals

2 coast coast

We have over 500 professionals working coast to coast, and licensure across all 50 states, so we can collaborate no matter where you’re based. We seek to deliver the right balance of simplicity and innovation to align teams and technology around what matters most—your customer.

20,000+ projects permitted across OFFICES

5 COUNTRIES

2

2,000+ communities

HFA provides a unique understanding and perspective of how architecture and engineering ultimately support project proformas and long-term business goals. We approach projects from a unique design perspective, always looking through the lens of the patients, providers, and staff. Before design is even discussed, we seek to thoroughly understand our clients’ development objectives for the project.

Architecture

MEPFP Engineering

Landscape Architecture

Structural Engineering

Civil Engineering

Interior Design

Robotics Integration

3D Scanning

Energy Services

FM / Asset Management

Planning

Commissioning

Fueling

De-Risking Design

HFA aims to be the leading solutions provider to innovative client partners by targeting the disjointed nature of the industry. HFA Healthcare Design is led by Paul Sabal, Don Ness, Aric Reed, and Alex Halloran, who have over $1 billion combined healthcare design experience and a history of working together.

Education

Bachelor’s of Science in Architectural Engineering, Kansas State University, 2012

Master of Science in Engineering Management, University of Arkansas, (Expected 2025)

Registration

Licensed in AR, CO, CT, FL, GA, KS, MA, MO, NC, NE, OK, TX

Arkansas Children’s Hospital NW Springdale, AR

Aric Reed is a highly experienced mechanical engineer with over 12 years of expertise in HVAC design, specializing in healthcare and higher education sectors. Starting his career as a design HVAC engineer, Aric has progressed through roles of increasing responsibility, including project manager, project executive, director, and now serves as the Healthcare MEPFP Program Lead. In this role, Aric drives business development, oversees project delivery, and fosters strong client relationships, ensuring projects meet the highest standards of quality, safety, and patient-centered care.

Aric’s design portfolio includes more than a dozen HVAC system types, with projects ranging from hospitals, laboratories, and pharmacies to high-rise offices, indoor sports arenas, and performing arts centers. Beyond his technical and leadership roles, Aric has served as President of the Northwest Arkansas Chapter of ASHRAE from 2017-2019, contributing to the growth and education of the engineering community. He is also OSHA-10 certified, ensuring safety remains a priority in all his projects.

Arkansas Children’s Hospital Little Rock, AR

Atrium Health Enterprise Energy Efficiency Initiative GA, NC

HCA Westside Regional Medical Center

Fort Lauderdale, FL

Center for Children’s Health and Wellness –Infills Springdale, AR

New Build | As a member of the mechanical design team (EI), Aric performed all load calcs, RVS, equipment sizing, and drafting of ductwork, piping, and equipment. The design included a variety of healthcare spaces including pharmacy, labs, ORs, patient rooms, kitchen, decontamination, emergency department, helicopter fuel system, and central energy plant.

HR Building MEPF Feasibility Study

The initiative’s engineering services include Retro-Commissioning, Automatic Temperature Controls Design and Commissioning, Measurement & Verification, and Utility Incentive Application and Tracking.

AHU Replacements | Design-build project scope included replacement of 5 AHUs and their associated VAVs. The AHUs served critical areas including the Emergency Department, Kitchen, ICU patient rooms, and imaging suite. VAV replacement was closely coordinated with infection control measures. The project was AHCA approved with Dade County certified designs.

This 5-story, 86,000SF medical support building includes Arkansas Children’s Primary Care Clinic, the Schmieding Developmental Center, and University of Arkansas Medical Sciences Kids First. These programs provide diagnosis and treatment of children with neurodevelopmental and medical conditions that impact cognitive, emotional, and behavioral function through direct care, teaching, and training providers. The project met the program’s unique needs and aesthetics, including classrooms, nurseries, playrooms, therapy spaces for children with developmental delays, offices, exam rooms, support spaces, and interactive flooring.

UAMS NW Student Clinical Education

Center Renovation

Fayetteville, AR

UAMS Northwest

Fayetteville, AR

Providence Hospital Washington, DC

Baptist Health Energy Savings Performance Contract Fort Smith, AR

Texas Health Resources — Presbyterian Hospital Dallas, TX

The project combined three uses into one space: A specialty clinic of private practitioners, a clinical skills area for the teaching of students, and a continuity clinic where student doctors work with practicing professionals to address the needs of real patients. The new clinic encompasses exam and procedure rooms, conference and consultation, a break area, and the support spaces necessary for the high-tech education of today’s medical students.

Student Clinical Education Center

Chiller #2 Replacement

Sonography Renovation

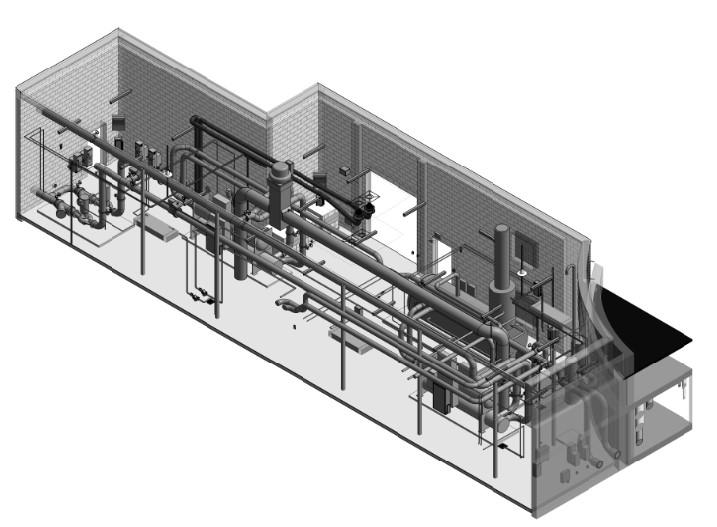

Boiler Replacement | Project replaced existing 600 HP steam boiler in hospital main central energy plant. The extreme physical size of the new boiler required it to be broken down into individual components, transported into the plant, and assembled in place on the housekeeping pad. The design and use of temporary heating was required. The new boiler design also included energy-saving components such as a stack economizer and blowdown economizers.

An energy savings performance contract, this engineering-led project included major infrastructure upgrades and replacements at three separate hospital campuses at the same time. Equipment replaced/added included 3 constant-speed water-cooled chillers (3,400 tons), 4 variable-speed water-cooled chillers (4,000 tons), 2 heat recovery chillers (350 tons), 9 cooling towers (24,000 tons), a 600HP steam boiler, hot water heat exchanger, 30 pumps, 2 desiccant AHUs, and 137 VFDs.

Washington Regional Medical Center

Core Renewal

Fayetteville, AR

Third Floor Nursing/Lab Expansion Fayetteville, AR

The project was 12-phases of both renovation of existing hospital spaces and new expansion of inpatient ICU, blood lab, and new-age imaging & procedure rooms. I was the mechanical EOR and overall project manager, managing the design and our architectural client. The phasing and 100% occupancy required constant and diligent coordination.

The project added over 12,000SF of new cutting-edge laboratory space on top of the existing second floor Cath labs and operating suite. The laboratory area included phlebotomy, pathology, blood bank/hematology, microbiology, myco-bacteriology, molecular, and the hospital’s core laboratory with WASP. Also included in the project were sixteen new med-surg patient rooms, dialysis bays, telemetry, residence sleep rooms, and future shell space.

Washington Regional Medical Center Fayetteville, AR

Fuel Oil Upgrades

Kitchen Exhaust Repairs

Pharmacy Upgrade

Endoscopy Renovation

Sterile Storage Renovation

Nuclear Medicine Renovation OR AHU-10 Replacement

Seton Medical Williamson + Hays Austin, TX

Sacred Heart Emerald Coast Destin, FL

Mercy Hospital Energy Stewardship Program

MO, KS, AR, OK

Mercy Hospital - ED/ICU Expansion Fort Smith, AR

Heat Recovery Chillers | Design-build projects to install new heat recovery chillers, fully-condensing boilers, and replacement VAV 4-row reheat coils in the operating suite. Project design in Florida was AHCA approved.

In a partnership with Mercy (St. Louis) to provide turnkey design-build solutions through an energy stewardship program. This program’s engineering services include Retro-Commissioning, HVAC and Automatic Temperature Controls Design and Commissioning, Natural Gas Commodity Management, Monitoring-Based Commissioning (MBCx), Automatic Fault Detection, Measurement & Verification, Utility Incentive Application and Tracking, Owner-Operator Training, etc. Aric acted as project manager, design engineer of record and eventually the Project Executive of the entire ESP partnership. He managed the design-build process, including management of construction subcontractors, schedules, and the financial success of all projects and the program.

This project is a renovation of the existing Emergency Department, as well as a 3 story addition to the hospital, along with a new parking garage. Aric was the design lead for both the mechanical and plumbing disciplines throughout schematic design, design development, and construction documents. He led the teams through calculations, 3D modeling, and coordination with out-of-state subconsultants including civil, architectural, P-tube system, etc. This project HVAC scope included a brand new central energy plant with new chillers, cooling towers, boilers, pumps, and controls, along with the new expansion AHUs, air terminals, exhaust fans, duct, pipe, etc.

Mercy Hospital Northwest Arkansas | Rogers, AR

4th Floor Cardio

Cath Lab Replacement

Hybrid Cath Lab Renovation

Patient Tower Addition

Nuclear Medicine Camera

MRI Replacement

5th Floor Nursery - Med Gas Addition

Boiler Replacement

Mercy | Ministry-Wide Commodity Management (Gas)

Monitoring-Based Commissioning

Measurement & Verfication

Mercy Hosptial Fort Smith | Fort Smith, AR

OB/GYN Clinic Renovation

Sleep Center Renovation

Tower West MEPF Master Plan

Pharmacy AHU Replacement

Tower West HVAC Repairs

Mercy Hospital Springfield | Springfield, MO

Smith Glenn Callaway Clinic Lab Renovation

Endo/GI OR Renovation

Surgery Center Boiler Replacement

Education

Bachelor of Science in Mechanical Engineering, University of Arkansas, 2016

Registration

Licensed in AR, TX, GA, AL, AZ, NJ

Alex Halloran is a seasoned mechanical engineer with nine years of specialized experience in architectural engineering, focusing on healthcare and higher education projects. As the Healthcare Team Lead, Alex oversees a multidisciplinary MEP (Mechanical, Electrical, Plumbing, and Fire Protection) design team, guiding them to deliver high-impact, clientcentered solutions across the southeastern United States. With a strong track record of managing large-scale healthcare facilities, Alex has served as the engineer of record for multi-million-dollar projects, demonstrating expertise in both design and project leadership. In his previous role, Alex was named Director of Engineering, leading a team of 12 MEPF staff over the course or three years.

Throughout his career, Alex has led innovative projects, including the pioneering UAMS Proton Therapy Center, the first of its kind in Arkansas, as well as the Baptist Hospital

Inpatient Behavioral Health Center and Piedmont ICU Expansion. His work also extends to higher education, having contributed to the UCA Integrated Health Sciences Building and the UofA Rice Research Facility. Known for his commitment to quality and reliability, Alex’s approach combines technical precision with a focus on building strong client relationships that drive project success.

Baptist Sterile Processing Department Relocation

Little Rock, AR

Piedmont ICU Vertical Expansion + Renovation

Columbus, GA

UAMS Proton Therapy Center

Little Rock, AR

UCA Integrated Health Sciences Building

Conway, AR

Project to relocate the existing SPD for Baptist Hospital including multiple phased drawings to allow for minimal disruption to the SPD and materials management departments; designed new air handling system, steam system, RO/DI system, and fire protection system for the space to accommodate the renovated facility; implemented complex pressure control system and design to address pressurization and ICRA challenges.

ICU renovation and vertical expansion affecting 100,000 square feet of existing Piedmont Hospital in Columbus to add 17 isolation rooms for infectious patients, 3 protective environment rooms for immune-compromised patients, and made significant upgrades to the existing infrastructure within the operational hospital; implemented phasing plans in coordination with the contractor to ensure minimal disruption to existing facilities and project success.

Proton Therapy Center project to add 58,000 SF of oncology treatment space to UAMS and be the first proton therapy center in Arkansas; including design for an MRI machine, 3 LINAC machines, and 1 proton therapy machine, clinical space, oncology department offices, conference rooms, and a sky-bridge connecting adjacent buildings; mechanical systems required connection to the district energy loop on campus, involving directional boring of chilled and heating water pipes across active roadways.

80,000 square feet nursing sciences building with classrooms, simulated exam rooms, and support staff executive offices and conference rooms; connected the building to the district energy loop, designed redundant air-cooled chillers that supplement the campus loops; achieved 18% energy savings as compared to the baseline energy code requirements for the State of Arkansas.

Unity Health Jacksonville Emergency Department

Jacksonville, AR

UAMS Urology Surgery Center

Little Rock, AR

Baptist Health Behavioral Health Renovation

Little Rock, AR

30,000 square feet emergency department renovation to bring the facility into compliance after loss of hospital license; upgraded all existing infrastructure to meet current code requirements; closely coordinated with the contractor to procure long lead items due to supply chain issues and ensuring the upgrades of the existing systems remained within the project budget.

40,000 SF outpatient urology clinic, surgery center, and imaging facility including 4 operating rooms, 3 imaging operating rooms, and 2 CT machines; mechanical design required low-temperature operating rooms, and specialty mechanical systems to achieve the owner’s design requirements and stay within code maximums for humidity; electrical design required a new electrical service be brought to the existing building, and addition of a 1MW generator and emergency electrical service to back up the essential systems for the building and clinical spaces.

15,000 square feet behavioral health facility for high-risk patients; designed mechanical, electr ical, plumbing, and fire protection systems for ligature and tamper resistance; renovated the existing 3rd floor over the occupied 2nd-floor space and modified existing HVAC systems to accommodate a new fully ducted return system and minimize the cost impact to the project.

Registration

Certified by NICET in Fire Protection/ Building Systems Programs. Certification Number 89485 in:

• Water-Based Systems Layout Level III

• Special Hazards Systems Level II

• Inspection + Testing of Water-Based Systems Level I

Gary Sims is a seasoned professional with over 36 years of experience in fire suppression and protection design. Beginning his career in the contracting industry in 1989, Gary transitioned to the consulting field in 2009, bringing decades of expertise to complex fire protection projects. As a Senior Fire Protection Designer, Gary leads and supervises a three-person team, managing design work, conducting site surveys, performing water flow testing, and attending project coordination meetings.

Gary’s extensive portfolio spans small commercial developments, large industrial facilities, government and military projects, as well as international ventures. He holds multiple NICET certifications in Fire Protection/Building Systems Programs, including Water-Based Systems Layout (Level III), Special Hazards Systems (Level II), and Inspection and Testing of Water-Based Systems (Level I). His additional qualifications include OSHA 10 certification and proficiency in Revit/BIM technology, project management, and owner advocacy.

Some of Gary’s key accomplishments include fire protection design for major healthcare facilities, such as the Arkansas Children’s Hospital in both Northwest Arkansas and Little Rock, Methodist University Hospital in Memphis, Mercy Health Systems Tower Additions in Rogers and Fort Smith, Arkansas, Providence Hospital in Washington, D.C., and the Mother Baby Addition at Washington Regional Medical Center in Fayetteville, Arkansas. With a meticulous attention to detail and a commitment to safety and efficiency, Gary continues to deliver innovative solutions to meet the unique needs of his clients.

Arkansas Children’s Hospital Springdale, AR

University of Arkansas for Medical Sciences (UAMS) Proton Cancer Treatment Center

Little Rock, AR

New green site Children’s Hospital located in northwest Arkansas. Five-story facility with labor & delivery rooms, nursery, emergency room, operating rooms, Isolation rooms, pharmacy, physical therapy, Imaging, kitchen, large electrical rooms, etc. Also included a large mechanical penthouse and separate CUP/ CEP and helipad. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Underground fire main lead-in to the CEP, fire pump assembly, underground fire main from CEP to the main hospital, horizontal standpipes, vertical and combination standpipes, underground fire department connection line & free-standing FDC, zoned wet-pipe systems mains, dry-pipe system at dock, deluge system for building exposure and preaction systems In electrical rooms and Imaging spaces.

New brown site facility consisting of exam rooms, treatment rooms, linear accelerators, new proton treatment machine, Imaging spaces, offices and mechanical penthouse. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Fire suppression consisted of underground fire main, underground fire department connection line & free-standing FDC, horizontal standpipes, vertical and combination standpipes, zoned wet-pipe systems and preaction systems protecting proton machinery, Imaging equipment and linear accelerators.

INTEGRIS Health Heart Hospital at INTEGRIS Baptist Medical Center, Northwest Expressway Campus

Oklahoma City, OK

Methodist University Hospital Expansion LeBonheur Healthcare

Memphis, TN

Washington Regional Medical Center Women & Infants Center

Fayetteville, AR

Mercy Hospital Northwest Arkansas

— New Patient Tower

Rogers, AR

New five-story heart hospital built atop existing parking garage and connected to existing nine-story hospital. Heart hospital consisted of exam rooms, in-patient rooms, ICU spaces, operating rooms, hybrid operating rooms, heart catheterization labs, large mechanical floor, etc. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Fire suppression consisted of tying into the existing horizontal standpipe distribution and extending horizontal standpipe to the new hospital, new vertical & combination standpipes, preaction system protecting new electrical & data rooms, zoned wet-pipe systems for each floor, as well as renovation work in the existing hospital.

New ten-story hospital addition built over existing city road and connected to existing hospital facility. Project included new inpatient rooms, ICU spaces, large floor of operating rooms, cancer treatment center (Including linear accelerators), mechanical & electrical spaces, large mechanical penthouse, etc. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Fire suppression consisted of tying into the existing horizontal standpipe distribution and extending horizontal standpipe to the new hospital, new vertical & combination standpipes, preaction system protecting new electrical & data rooms & high value Imaging and cancer treatment equipment, zoned wet-pipe systems for each floor, as well as renovation work in the existing hospital. Project was seismic design category D, which required redundant underground fire mains and an AHJ required roof-top water storage tank.

New five-story hospital addition. Project included new inpatient rooms, labor and delivery suites, ICU spaces, etc. Also included a small penthouse lobby and helipad on the roof, as well as a detached parking garage. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Fire suppression consisted of tying into the existing horizontal standpipe distribution and extending horizontal standpipe to the new addition, new vertical & combination standpipes, zoned wet-pipe systems for each floor, as well as renovation work in the existing hospital. The helipad was protected with a foam deluge system and the parking garage was protected with manual, dry standpipes.

New nine-story hospital addition. Project included new inpatient rooms, operating rooms, isolation spaces, a large mechanical penthouse, renovations, etc. I worked alongside the design team to 3D coordinate main fire suppression Infrastructure using Revit for the entire project. Fire suppression consisted of tying into the existing horizontal standpipe distribution and extending horizontal standpipe to the new addition, new vertical & combination standpipes, zoned wet-pipe systems for each floor, as well as renovation work in the existing hospital.

Education

Bachelor of Science in Electrical Engineering, University of Arkansas, 2015

Registration

Licensed in AL, AR, KS, NC, OK

Charles Kvamme serves as the Electrical Engineer for HFA’s healthcare team, bringing nearly a decade of experience in electrical design and engineering. His role encompasses developing design standards, specifications, and technical details to support both current and future healthcare projects, while also acting as the primary Electrical Designer and Professional Engineer on active projects.

Charles began his engineering career at IMEG in Dallas, Texas, where he worked on a wide range of project types including libraries, senior living facilities, urgent care centers, and more. In 2017, he transitioned to Bernhard in Fayetteville Arkansas, where he specialized in complex projects across healthcare and higher education. During his time there, he became a licensed Professional Engineer and led the electrical design of the new Cooper Green Ambulatory Care Facility in Birmingham, Alabama—an extensive 210,000 square foot, two-year project that exemplifies his skill in designing modern, high-performance healthcare environments. In addition to Cooper Green, Charles takes pride in his work on the U.S. Marshals Museum in Fort Smith Arkansas, a technically demanding entertainment venue, and the University of Arkansas’ J.B. & Johnelle Hunt Family Baseball Development Center, where he addressed unique requirements tied to advanced training and filming technologies.

AL

AR

NY

AR

210,000 square feet new ambulatory care center for Cooper Green Mercy Health. The project consisted of CT, MRI, multiple X-Ray rooms, several floors of exam rooms, a physical therapy lab, pharmacy, and other spaces designed to support both treatment, preventative care, and wellness. The 18-clinic facility was designed with the goal of promoting wellness and community by providing ample natural light and the use of murals and art pieces located throughout the building. Charles performed as the lead electrical engineer on this project overseeing the design of the building and site’s electrical system including distribution and power, Emergency Generator System, lighting and lighting control systems, low voltage coordination, and fire alarm.

Design engineer on the renovation of multiple inpatient and operating rooms.

This project aimed to replace one of the ageing generator line-ups with a new 1.5 MW generator, switchgear, and paralleling controls with space for future generators allowing for the option to remove additional, yet still functional, generators at a future date. Due to the hospital’s proximity to the Susquehanna River and permanently installed flood walls the project required the construction of an elevated structure to house the new generator enclosures and allowed for a more robust phasing plan for the installation and removal of equipment.

Design engineer on 3rd floor lab and nursing expansion. Revised site lighting to improve uniformity. Residency suite infills

The Children’s Center for Health and Wellness Springdale, AR

Highlands Oncology Springdale, AR

Highlands Oncology Fayetteville, AR

Mercy Hospital Ardmore Ardmore, OK

Mercy Hospital Watonga Watonga, OK

Mercy Hospital Galena Galena, KS

Mercy Hospital Kingfisher Kingfisher, OK

Assistance with stairwell, design of renovation of 2, 3, 4 floor spaces

This project consisting of renovating an existing space to accommodate new breathing lab and finished out 4th floor for new infectious disease clinic.

This project consisted of renovating existing building to be used as a new pharmacy. Project requirements included adding mixing, ante, negative storage, and

Replace failing portion of generator line-up with new 1 MW generator and revised the building distribution system to accommodate new sterilizer.

Replace existing and soon-to-fail switchboard with new QED-2 series to increase reliability and to accommodate new HVAC equipment.

RTU replacement

Chiller replacement

Education

Bachelor of Science in Mechanical

Engineering, Ain Shams University, 2006

Registration

Licensed in CA, NJ, NY, TX

Bristol Myers Building 48 Renovation

Brunswick, NJ

NY Presbyterian — Columbia Campus NYC

Martin Khallaf, pe, cem, cbcp, cxa, ccp

Martin Khallaf is an accomplished mechanical engineer with 18 years of experience in the design, commissioning, and optimization of commercial building MEP (Mechanical, Electrical, and Plumbing) systems. As the leader of the Energy and Commissioning discipline, Martin oversees the strategic direction and execution of energy efficiency and commissioning initiatives across various projects. His expertise spans building automation, energy management, and commissioning, with a particular focus on driving innovation and improving building performance.

Throughout his career, Martin has been deeply involved in projects that emphasize sustainable design and energy efficiency. He is passionate about collaborating with teams to find innovative solutions that enhance building performance while reducing environmental impact. His work has helped clients optimize energy use and ensure that MEP systems are functioning at peak efficiency.

Martin reviewed the Mechanical design and submittals, He also conducted periodic site visits to check the construction process and verify all the installed equipment are in compliance with the design drawings and all the installations are in compliance with the codes. He prepared the documents to be used in the final building testing checks before certificate of occupancy.

Martin worked in the existing buildings design review and assessments. He was responsible for the building condition assessments and gathering information to be used in energy assessment calculations. He also participated in the energy assessment calculations and reports. He recommended facility changes and improvements to help save energy and verified it would comply with the current codes and safety at that time. He worked on implementing the recommended design changes. He performed comprehensive commercial energy assessment by evaluating the thermal envelope, mechanical systems, energy consumptions, and health and safety. He participated in writing the scope of work required to implement the changes. He verified all the field installations and insulation for ductwork, piping and HVAC equipment are compliant with the codes and NY state regulations and in good working conditions. He created a punch list to list all the deficiencies found during the assessment and followed up with the building managers and engineers to discuss how to fix the deficiencies. He also created another list that has all the energy conversation measures that can be implemented to modify the existing equipment to help the client save energy and verified all the modifications are in compliance with the codes. He participated in the design work for the approved modifications.

NY Presbyterian — Cornell Campus

Martin worked in the existing buildings design review and assessments. He was responsible for the building condition assessments and gathering information to be used in energy assessments calculations. He also participated in the energy assessments calculations and reports. He conducted a study for the hospitals’ operation and Isolation rooms using the Tab results carried out by the balancer to verify the rooms pressurization is correct and is within the ASHRAE standards for air change and pressurization tolerance, He recommended design changes to comply with the ASHRAE standards, He also helped designing and implementing these changes.

Martin was part of the team responsible for assessing the damage done to the facility’s infrastructure by Sandy storm, He was responsible for assessing the piping and insulation conditions, HVAC and plumbing equipment. He was responsible for recommending if the units inspected are still in an acceptable condition to be repaired or recommended replacement to the damaged units based on health and safety regulations as well as applicable codes and regulations.

HFA has extensive experience completing architecture and engineering projects of various types, sizes, and complexity. Attached are examples of projects completed by this project’s key HFA personnel that illustrate the capacity of the proposed team to complete projects of similar scope and complexity as would be expected under this contract. Projects or experience denoted with “*” were completed by HFA primary or secondary point of contacts listed on the project team and are only intended to show experience of specific staff on this project team.

Rogers, AR | 380,000 SQ. FT.

Mercy Hospital Northwest Arkansas is located in Rogers, Arkansas which is one of the fasted growing MSA’s in the country. Due to the explosive population growth in the region, the original 200 bed Hospital, which opened in 2008, was experiencing bed shortages, and other capacity stresses by early 2013. That year, in the role of Planner, Paul Sabal prepared a Strategic Facility Masterplan for Hospital leadership which clearly identified that all nursing units and the ED would be at capacity by 2015, and all D&T and support service departments would be at capacity by 2019. In 2015 Mercy Hospital NWA re-engaged Paul to prepare a phased expansion Master Plan ofthe Rogers campus. This time, in the role of Principal-in-Charge and Planner, Paul recognized that the key factors for the successful outcome of the project to be:

• Optimize patient experience and staff/user efficiencies

• Develop a fastest path to additional bed capacity

• Relocate the Hospital main entry for greater visibility

• Conform the appearance of the existing facility to current Mercy Brand standards

• Locate the expansion to maximize new construction SF, minimize renovation SF

• Locate the expansion to provide the best adjacency for expansion of the support and D&T departments on the lower floors

• Locate the expansion to minimize impact on existing operations

• Locate the expansion to minimize impact on the existing ED

• Expand surface parking to address future parking need and compensate for loss of parking due to new construction

After testing many options with leadership, Paul chose a solution which places a 7-story bed tower to the West of the existing Hospital. This location provides space directly adjacent to support service departments on the 1st floor, Imaging and Diagnostics on the 2nd floor and Surgery on the 3rd floor for expansion. Floors 4 through 7 connect directly to existing Nursing units and are serviced with dedicated public and service elevators. On the North elevation, the relocated Main Hospital Entry gives patients easy access to all destinations through a 2-story gallery element that provides welcome, admitting, pre-admit testing, and waiting spaces. The entire exterior of the existing 2008 structure is being reimaged using innovative masonry staining techniques to match the requirements of Mercy’s exterior Brand standards.

Arkansas, Oklahoma, Kansas, Missouri

Over 30 critical pieces of infrastructure equipment replaced at various hospitals. Close coordination was required with the owner, contractor, commissioning agent, and design team as each facility must remain in operation throughout the changeout process. All projects were fully commissioned. Example types included in the program: Chillers, Cooling Towers, Boilers, Generators, Air Handling Units, Heat Exchangers

Over 30 critical pieces of infrastructure equipment replaced at various hospitals. Close coordination was required with the owner, contractor, commissioning agent, and design team as each facility must remain in operation throughout the changeout process. All projects were fully commissioned. Example types included in the program: Chillers, Cooling Towers, Boilers, Generators, Air Handling Units, Heat Exchangers

Ada, Oklahoma

• Replaced 600-ton CT with 800-ton CT on same structure

• Replaced (2) 400-ton water-cooler chillers

• Integrated with existing 600-ton air-cooled chiller. Project replaced existing indoor AHU serving Pharmacy and associated laboratory. The project required removal of an existing fresh air louver to remove the existing AHU and install the new replacement AHU. The AHU included chilled water cooling, steam heating, and HEPA filtration, along with new DDC controls.

Springfield, MO

Replaced existing original boilers and controls with four newer, more efficient condensing boilers and rerouted all intake and exhaust flue ductwork to individual duct each unit.

Fort Smith + Little Rock, AR | $70,000,000

An energy savings performance contract, this engineering-led project included major infrastructure upgrades and replacements at three separate hospital campuses at the same time. Equipment replaced/added included:

• 3 constant-speed water-cooled chillers (3,400 tons)

• 4 variable-speed water-cooled chillers (4,000 tons)

• 2 heat recovery chillers (350 tons)

• 9 cooling towers (24,000 tons)

• One steam boiler (600HP) with stack and blowdown economizers

• New central energy plant Steam-to-Hot Water Heat

Exchangers

• Decommissioned remote building loop shell-andtube HXs

• 30 pumps

• 2 desiccant AHUs

• 137 VFDs

Project included the design and routing of new district heating water piping to multiple steam building entrances, and replacing individual remote shell-and-tube heat exchangers and building pumps with new heating water entrance control valves and backup pumps. Main steam distribution piping was disconnected from buildings and steam supply was pulled back to the central plant, with new flash tank, condensate receiver and pumps, and economizers.

Fort Smith, AR | $186,000,000

Renovation of the existing Emergency Department, as well as a 3-story addition to the hospital, along with a new parking garage and CEP expansion. HVAC scope included an expansion of the central energy plant with new chillers, cooling towers, steam boiler, pumps, fuel storage, and BAS controls, along with the new expansion AHUs, air terminals, exhaust fans, duct, pipe, etc. The new steam boiler was integrated into the existing steam supply piping and equipment. In the penthouse of the new expansion, all new redundant shell-and-tube heat exchangers were designed to use central plant steam to create heating water for the 3-story expansion. Variable speed pumps and control sequences that include temperature and pressure resets help to save energy costs. All steam condensate is collected in new duplex receiver skids and routed back to the central plant for reuse, saving make-up water costs.

Rock, AR

This project added 50,000 SF of imaging space to the existing UAMS campus, extending the campus boundary further to the east. The project consisted of extensive underground utility work to extend the campus district energy system (chilled and heating water) to the new radiation oncology building, and existing bio-ventures building. The solution proposed involved directonal boring under an active roadway to minimize the impact to the campus traffic flow. Additionally, utilities were re-routed under an existing parking deck to allow proper connection to the district energy system. Careful planning and phased commissioning were required to keep the project on schedule, and disruption to existing buildings at a minimum. Critical design challenges that were overcome included, flushing of the new piping to ensure protection of the existing energy infrastructure, strategically placing valves and access points to allow phased construction, and working with the construction team to provide temporary solutions to affected buildings on campus as piping was extended.

St. Louis Heart and Vascular is in Bridgeton, Missouri, a northwestern suburb of St. Louis, and is located close to SSM DePaul Medical Center. The 11 physicians in Paul Sabal’s previous practice engaged my firm in 2013 to design a new facility for them to integrate their clinic and invasive cardiology platforms. Specifically, they wanted to perform many high acuity EP cases in their new facility that they normally performed in the Hospital. In Paul’s role as Principal-in-Charge and Planner for the project, he investigated numerous existing buildings in the vicinity that would meet their project requirements:

• Convenient location for patients and staff

• Maximize visibility and brand identity

• Close to a hospital to address patient safety

• Provide expansion for an additional Cath Lab, Retail Pharmacy and Arrhythmia Monitoring functions

• Build the outpatient Cath Lab as an Ambulatory Surgery Center

• Provide space for all cardiac testing, imaging and treatment modalities

• Segregate surgical, clinical and diagnostic patient flows.

Their solution is the adaptive reuse of an existing 2−story office building located just outside DePaul Medical Center. The newly renovated facility provides 20,000 sf of integrated cardiac care, with the first Hybrid Cath Lab to be licensed as an Ambulatory Surgery Center (ASC) in the state of Missouri on the first floor, and comprehensive cardiac clinics, diagnostics, and treatment services on the second floor. This project was a complete interior renovation of both floors which included relocation of 2 emergency exit stairs, the addition of a passenger elevator, and extensive structural upgrades. The shell of the existing building was reimaged employing a transverse fin wall as a tool to organize, and separate, the major functional elements on each floor − patient pre−surgical prep and recovery from the sterile Hybrid Cath Lab area on the first floor, and cardiac diagnostics from the clinic/administrative spaces on the second floor. The $5.2 million project successfully rebranded an obsolete office building into a sophisticated contemporary healthcare facility that provides a comprehensive slate of cardiac services in an innovative environment.

Crystal City, MO | 232,953 SQ. FT.

This area, which was a rural community when the existing campus was constructed in 1953, is now on the Southern edge of St. Louis metro area. The 60+ year old facility had been expanded over the years to a point where key departments were disjointed, wayfinding was complicated, central plant was failing, and a huge amount of non-revenue generating space was built-in to the floor plans. Mercy Health purchased the Hospital in 2013 and made a significant financial commitment to modernizing the facility. In early 2014, my firm was engaged to develop a comprehensive master facility plan for the Hospital. In my role as PIC and Planner I worked with Hospital leadership to identify essential “must haves” for the project:

• Honor the history of Jefferson County, and the Catholic heritage of Mercy

• Optimize the patient experience by consolidating entries and improving wayfinding.

• Consolidate disjointed D&T departments and enhance staff efficiencies

• Convert non-revenue generating space to specialty clinics

• Convert semi-private beds to all private patient rooms

• Expand women’s services, cancer services and behavioral health services

• Update aging infrastructure and correct code violations

• Expand surface parking

• Conform new construction to Mercy Brand standards

After reviewing numerous options with Hospital leadership, we chose to place a 3-story 90 patient bed tower on the South side of the Hospital connected to the existing facility with gallery spaces which are constructed with glass to allow natural light flood the public spaces. The new patient tower includes a stand-alone mechanical penthouse and is expandable to 3 additional patient bed floors. Existing semi-private rooms will be renovated to private beds after the new tower is operational. A new main Hospital entry on the West reduces the number of entries and provides patients and guests intuitive access to the new bed tower, clinics, and existing bed elevators. Site circulation and wayfinding are all simplified and surface parking expanded to accommodate the projected expansion requirements. All new construction will conform to the Mercy Guidelines and Brand Standards

Bentonville, AR | 12,600 SQ. FT.

SALT Health is a newly-constructed concierge medicine, fitness, and spa facility in Bentonville, AR. The name SALT Health was chosen by the partners because salt is the most diverse mineral in history. It can preserve food, heal wounds, and was used as currency throughout history.

In collaboration with an out-of-state design architect, GSB, we took over the project at the design development phase and provided construction documents, permitting, and construction administration.

Paul Sabal, aia , acha , edac , ncarb , leed ap Principal / Healthcare Practice Leader paul.sabal@hfa-ae.com

479.273.7780 ext 460

Don Ness, aia , ncarb Director of Healthcare

don.ness@hfa-ae.com

479.273.7780 ext 490

Aric Reed, pe Healthcare MEP Program Lead aric.reed@hfa-ae.com 479.273.7780 ext 164

Alex Halloran, pe Team Lead / Mechanical Engineer

alex.halloran@hfa-ae.com 479.273.7780 ext 150