2 minute read

Electrical systems – 5000

Functional description

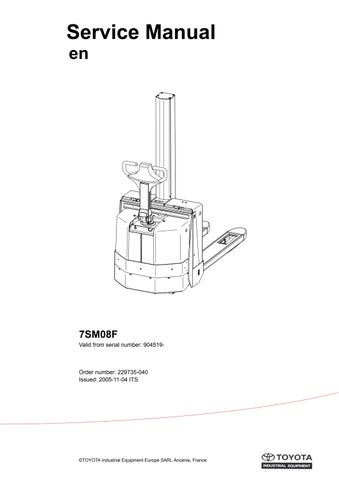

T-codeValid from serial numberDateOrder number 781904519-2005-11-04229735-040

Table 7: Theory of operation

Event: 13. Support arms lowering

Prior event(s) 2 or 12

Action(s)

Influencing elements

Resulting conditions

Event:

Press support arms lower button [A2:S22].

Main contactor [K10].

Support arms lower button [A2:S22].

[A1:OUT.LOWER VALVE] goes {low}, lowering hydraulic valve [Y41] activates.

[A1:OUT.SUPP.ARM VALVE] goes {low}, support arm selection valve [Y52] activates.

14. Click-2-creep (option)

Prior event(s) 2

Action(s)

Influencing elements

Resulting conditions

“Double-operate” [L1] to activate function. Operate [L1] with tiller arm in upright position to drive truck at creep speed (2.5 km/h).

Main contactor [K10].

Setting of parameter #15:0.

[A1:OUT.BRAKE A] goes {low}.

Brake coil [Y1] energises, mechanical brake releases.

Current fed to traction motor field winding (S2 +ve and S1 -ve).

Pulsed current fed to traction motor armature proportional to butterfly deflection. “SLO” displayed (flashing).

Event:

15. Turtle (option)

Prior event(s) 3

Action(s)

Press [S113] to activate function. Move butterfly [L1] in either direction.

Influencing elements Option button 1 [S113].

Resulting conditions

Setting of parameter #1 & #15:1.

[A1:OUT.BRAKE A] goes {low}.

Brake coil [Y1] energises, mechanical brake releases. Current fed to traction motor field winding (S2 +ve and S1 -ve).

Pulsed current fed to traction motor armature proportional to butterfly deflection. Maximum speed limited by parameter #1. “SLO” displayed (constantly on).

11.9.2 Transistor regulator

Curtis 1243 is a regulator [A1] for controlling separately excited motors (SEM). Varying the voltage applied through the armature primarily controls the speed. The voltage is varied through use of pulse-width modulation (PWM). This involves varying the “on” time of the MOS-FET transistors regulating the armature current.

Switching of the rotational direction is achieved by switching the polarity on the field winding (S1-S2). The regulator is fitted with a four-quadrant transistor bridge for the field winding and a single-quadrant transistor bridge for the armature winding.

11.9.3 Spider expansion unit (SEU) (option)

The Spider expansion unit, referred to as the SEU, allows the main control card to handle a greater number of inputs & outputs. The SEU allows up to 8 extra digital inputs and 4 digital outputs which can be addressed and controlled via the CAN bus. Up to two SEU units can be fitted in the truck to handle more complex options. The SEU contains firmware but this is only for internal configuration. No truck control logic is present in the SEU. This means a faulty SEU can be exchanged without affecting the truck’s functions in any way.

There are 3 cases covering the usage of SEU: a) The SEU can be fitted if the truck is modified according to a customer special request, including certain standard options. In this case, correct operation of the modification/option is achieved by adjustment of service parameters 16 to 19. b) The SEU is fitted as standard in certain truck models, to allow control of standard features. Such trucks do not require that service parameters 16 to 19 be activated. (Parameters 16 to 19 shall be set to “0”.) c) Trucks already fitted with an SEU as standard can also have additional modifications using “configurable options”. These additional modifications are controlled by the setting of service parameters 16 to 19.