1 minute read

Air Bleeding Procedure

from Tadano Faun GR-300EX-2 Rough Terrain Crane (Circuit Diagrams and Data) Service Manual SN 561384

1.3 Main pump (when the tank pressurization tool is used)

[NOTICE]

Advertisement

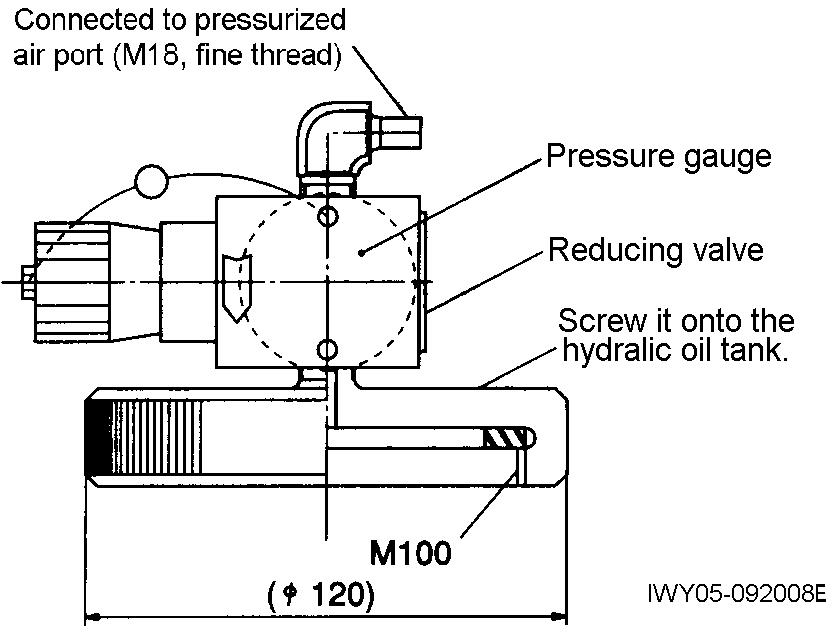

Adjust the pressure setting of the tank pressurization tool to 15 kPa {0.15 kgf/cm²} (2.2 psi). During work, check the pressure gauge so that the pressure is within 15 kPa {0.15 kgf/cm²} (2.2 psi)

Never actuate hydraulic cylinders with the tank pressurization tool attached.

1. After replacing the hydraulic pump or the hydraulic oil, check that the oil level is at the specified level.

2. Remove the air breather on the top of the hydraulic oil tank and attach the tank pressurization tool.

3. Slowly loosen the air-bleed plug on the top of the main pump and let the oil with bubbles flow out.

9. After checking that there are no abnormalities, remove the tank pressurization tool on the top of the hydraulic oil tank and attach the air breather to the original position.

10. Now the bleeding is complete. If the hydraulic pump has been replaced, run-in the pump.

1.4 Tank pressurization tool

1. Valve assy (A)(Part number: 329-806-59100)

4. After making sure that flowing oil contains no more bubbles, tighten the air-bleed plug while the hydraulic oil is flowing out.

5. While the tank is pressurized, turn ON the PTO switch and start the engine. After idling the engine for 5 seconds, turn ON and OFF the PTO switch repeatedly and quickly and check for any abnormal noise.

6. If any abnormality is found, bleed the hydraulic pump again.

7. If there are no abnormal noise, turn ON the PTO switch and idle the engine for 5 minutes with no load.

8. During idling, check for any abnormal noise or heat of the hydraulic pump and oil leaks from the whole system.

1.5 Other (cylinder)

1. When bleeding cylinders thereafter, make the engine speed medium (1000 min-1 or less).

2. If the oil temperature is to be increased for the purpose of pressure adjustment, do so when there are no bubbles in the oil as a result of air bleeding.