4 minute read

Service Data

from Tadano Faun GR-300EX-2 Rough Terrain Crane (Circuit Diagrams and Data) Service Manual SN 561384

7. Mass table

The dry weights of the major components are shown in the table below. Check the weights, and select appropriate hoisting devices when removing and installing the component

Advertisement

Adjusting Pressure (Hydraulic Pressure)

Y - 2 Adjusting Pressure (Hydraulic Pressure)

1. Winch

[NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

Confirm set pressure on the crane information screen in the maintenance mode of AML. Shift the control lever or switch while the engine is idling, then increase engine speed.

Turn the AML override switch to “Emergency” side.(After adjusting, return the AML override switch to “Normal” side.)

1. Block either of the joints (A1: Aux. winch, A2: Main winch) between hydraulic pilot control valve and hydraulic valve (winch brake).

2. Turn the PTO switch ON.

3. Move the winch lever that is blocked at its full stroke on the hoist-up side while the elevating lever is moved at its full stroke on the lowering side.

4. In this state, set the engine speed to 1900 min-1 and check the pressure.

1. Block either of the joints (B1: Aux. winch, B2: Main winch) between hydraulic pilot control valve and hydraulic valve (winch brake).

2. Turn the PTO switch ON.

3. Move the winch lever that is blocked at its full stroke on the hoist- down side while the elevating lever is moved at its full stroke on the lowering side.

4. In this state, check the pressure.

Adjusting Pressure (Hydraulic Pressure)

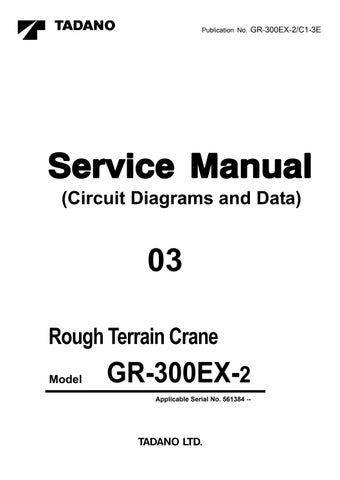

2. Telescoping [NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

Confirm set pressure on the crane information screen in the maintenance mode of AML. Shift the control lever or switch while the engine is idling, then increase engine speed.

1. Turn the PTO switch ON.

2. Fully extend the 2nd boom.

3. Move the telescoping lever at its full stroke on the extension side. ( Do not push the 3rd/top boom extending switch )

4. In this state, set the engine speed to 1900 min-1 and check the pressure.

1. Turn the PTO switch ON.

2. Fully retract the boom.

3. Move the telescoping lever at its full stroke on the retraction side.

4. In this state, set the engine speed to 1900 min-1 and check the pressure.

Adjusting Pressure (Hydraulic Pressure)

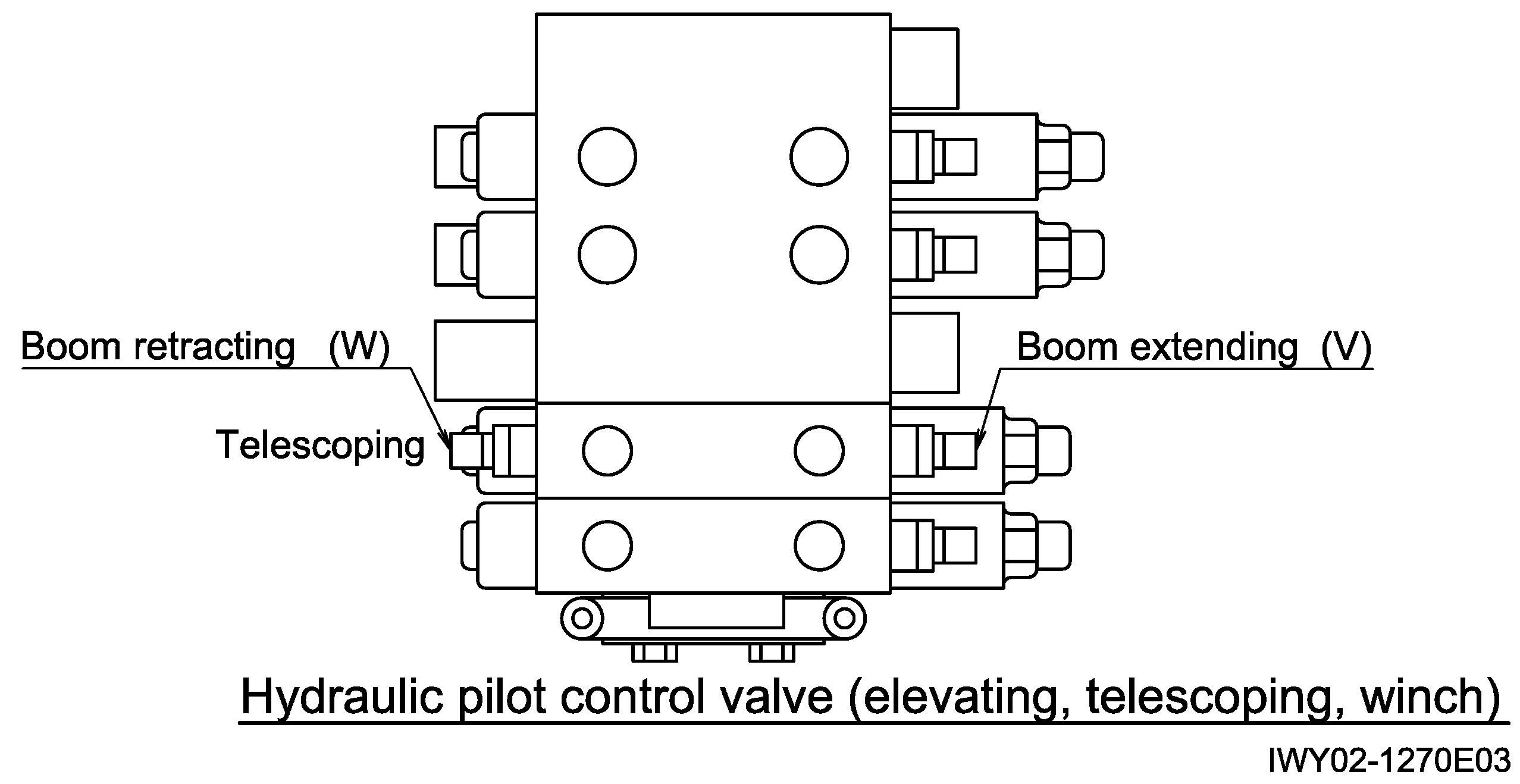

3. Elevating [NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

Confirm set pressure on the crane information screen in the maintenance mode of AML. Shift the control lever or switch while the engine is idling, then increase engine speed.

1. Deactivate the slow stop circuit. (*3)

2. Turn the PTO switch ON

3. Fully extend the elevating cylinder.

4. Move the elevating lever at its full stroke on the raising side.

5. In this state, set the engine speed to 1900 min-1 and check the pressure.

1. Deactivate the slow stop circuit. (*4)

2. Turn the PTO switch ON

3. Fully retract the elevating cylinder.

4. Move the elevating lever at its full stroke on the lowering side.

5. In this state, check the pressure.

(*3): To deactivate the slow stop circuit, disconnect the connector (02) of the elevation proportional solenoid valve. (After adjusting, connect the connector (02).)

(*4): To deactivate the slow stop circuit, disconnect the connector (01) of the elevation proportional solenoid valve. (After adjusting, connect the connector (01).)

Adjusting Pressure (Hydraulic Pressure)

4. Steering [NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL) Shift the control lever or switch while the engine is idling, then increase engine speed.

1. Connect a pressure gauge to the pressure check port.

2. Turn the PTO switch OFF

3. Without jacking up, turn the steering to the right side. Gently move the steering cylinders to the end of the stroke.

4. In this state, set the engine speed to 2500 min-1 and check the pressure by the pressure gauge. (Note): Adjustment is not possible. If the pressure is out of the set pressure range, replace the priority valve.

Adjusting Pressure (Hydraulic Pressure)

5. Swing [NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

Confirm set pressure on the crane information screen in the maintenance mode of AML. Shift the control lever or switch while the engine is idling, then increase engine speed.

1. Turn the PTO switch ON.

2. Shift the swing lock lever to lock side.

3. Move the swing lever at its full stroke on the right and left side.

4. In this state, set the engine speed to 1900 min-1 and check the pressure.

*2 (H) 22.6 230 3270 -

*1 : Relief valve

*2 : Overload relief valve (high pressure)

Already the pressure is set by the valve manufacturer. (Adjustment is not necessary.)

Adjusting Pressure (Hydraulic Pressure)

6. Outrigger [NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL) Shift the control lever or switch while the engine is idling, then increase engine speed.

1. Connect a pressure gauge to the pressure check port.

2. Turn the PTO switch ON.

3. Extend each the jack cylinder at its full stroke while the engine is idling. (And again press the outrigger control switch.)

4. In this state, set the engine speed to 1900 min-1 and check the pressure by the pressure gauge. Then, adjust the pressure.

Adjusting Pressure (Hydraulic Pressure)

7. Lower pilot pressure

[NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

1. Connect a pressure gauge to the pressure check port.

2. Extend each the jack cylinder at its full stroke. (And again press the outrigger control switch.)

3. In this state, check the pressure by the pressure gauge.

Adjusting Pressure (Hydraulic Pressure)

8. Remote control pilot pressure

[NOTICE]

Oil temperature: 50±5°C (113 - 131°F) (Hydraulic oil: TADANO Hydraulic Oil LL)

Shift the control lever or switch while the engine is idling, then increase engine speed.

*1 (K) 2.9 or over 30 or over 420 or over 700 (IDL.)

1. Connect a pressure gauge to the pressure check port.

2. Turn the PTO switch ON.

3. Make sure that constant pressure is being produced while engine is running.

4. And check the pressure by the pressure gauge.

(Note): Adjustment is not possible. If the pressure is out of the set pressure range, replace the valve.

1. Connect a pressure gauge to the pressure check port.

2. Turn the PTO switch ON.

*2 (L) 3.9 or less 40 or less 560 or less 1900 (MAX.)

*1: Low pressure

*2: High pressure

3. In this state, set the engine speed to 1900 min-1 and check the pressure by the pressure gauge. When the set pressure is exceeded, adjust the pressure.

9. Torque converter oil pressure

1. Turn the PTO switch OFF with the air conditioner OFF.

2. Confirm set pressure on the carrier information screen in the maintenance mode of AML.