2 minute read

Each 500 Hours Services

from New Holland RG140 RG170 RG200 RG170 AWD RG200 AWD Road Graders Operator's Manual - PDF DOWNLOAD

17- Wheel lean link (B) Lubricate There are two (2) lube points. Lubricate with 4 to 6 shots on each side.

Wheel lean link 19- Engine drive belt Check

Drive belt tensioner

1- Water pump pulley 2- Crankshaft pulley 3- Square hole of 1/2 in (13 mm) 4- Belt tensioner 5- Alternator

Drive belt and tensioner inspection

After removing, examine the belt for damages.

Measure the belt deflection in the most open area between the pulleys. The maximum deflection allowed is from 9.5 to 12.7mm (3/8 to 1/2 in). Remove the drive belt using a 1/2 in square socket wrench handle, to release belt tension.

Engine drive belt

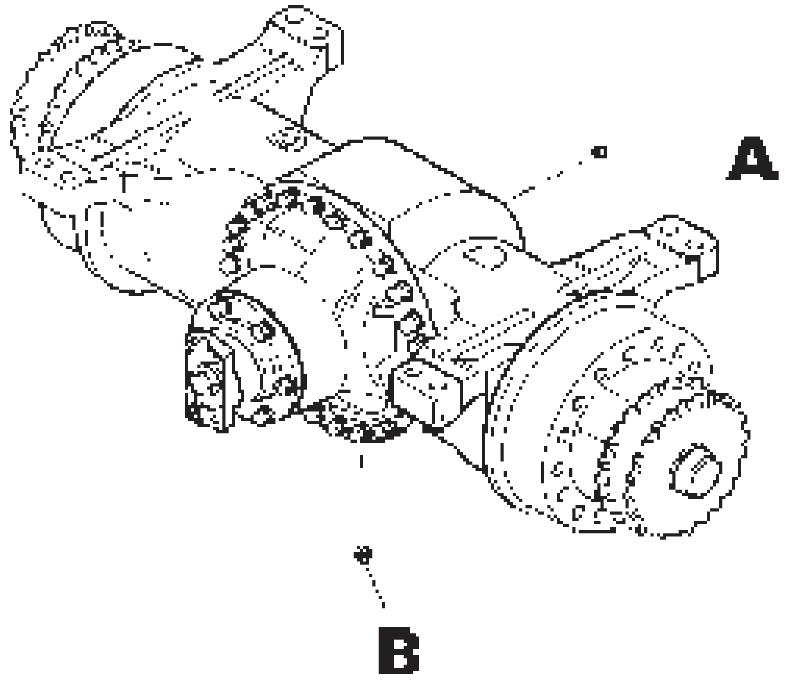

Wheel lean link (AWD - OPT)

18- Front wheel lean cylinder (D) Lubricate There are two (2) lube points. Lubricate with 4 to 6 shots on each side.

Front wheel lean cylinder

Front wheel lean cylinder (AWD - OPT)

Drive belt tensioner

The drive belt tensioner pulley must rotate freely with no point showing resistance, locking up, etc., when turned by hand. Check belt tensioner bearing carefully also.

Re-installing the drive belt

Using a 1/2 in drive socket wrench handle and the tensioner, install the belt carefully, observing that the multi-V's ribs fit perfectly with the existing channels of the alternator pulley and vibration damper.

EACH 500 HOURS SERVICE 21- Rear axle housing center compartment Check oil level

20- Fuel filters Change

These are lock ring type cartridge filters.

Clean the area around the fuel filters C and B.

Remove the filters and clean carefully the area around the filter base gasket.

Change the filters and sealing rings. Fill the filters with fuel and lubricate the sealing rings with engine oil. Fuel filter

Then assemble the new filters and lock them. After this, bleed air from the fuel system as follows:

Loosen a few turns, the bleeder screw (A), on the fuel filters. Then loosen the plug 4 of the fuel pump and pump it several times until fuel flows out of the bleeder screw (A) without air bubbles.

Then tighten the bleeder screw (A) and continue pumping the knob (4), of the fuel pump several more times and finally tighten it.

Remove the filler/level plug. Add fluid as necessary until flows out of the plug hole. Install filler/level plug and tighten.