1 minute read

Connecting Rods, Pistons & Cylinder Sleeves

The weight of con-rod at the crankshaft and piston is balanced and no material should therefore be removed or added as this would disturb the balance.

Connecting rods are classified by different weight groups of which only the medium group is available for service.

Care should be taken when replacing connecting rods, that all connecting rods of the engine are of same weight group, to keep the crank shaft assembly well balanced.

NOTE: Weights refer to complete connecting rods with bushing, bearing cap and bolts but less securing wire and without bearing halves.

7.CYLINDER SLEEVES

1.REMOVAL a)Remove the piston assemblies as detailed in para 2a. b)Using a suitable sleeve puller withdraw the cylinder sleeves (fig. 13). c)Remove the sealing ring from the groove in the crankcase bore. And discard it.

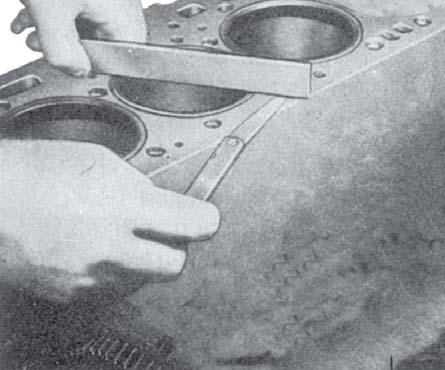

Check cylinder sleeve wear before removal see fig.10.

NOTE: Removal on the cylinder sleeves need only be carried out if inspection proves this necessary.

2.INSPECTION AND REPAIR (See fig.10)

a)With the sleeves in the crankcase measure the bores at the top (A) and the bottom (B&C) at 90 0 to the crankshaft to determine the amount of taper.

b)Compare the readings from op. (a) with those from op. (b) to determine the amount of ovality as per specification.

The cylinder sleeves should be renewed when out of round exceeds 0.20mm and taper exceeds 0.13mm. The old cylinder sleeve should be removed with the help of special service tool