1 minute read

REPAIR INSTRUCTIONS

The isolating oil pan gasket contains 12 integral locating/retaining cones which lock into holes drilled through the oil pan rails, and two large rectangular tabs located directly across from each other on the inner perimeter of the gasket. The cones keep the gasket properly located during oil pan installation, and the rectangular tabs serve as a starting point for locating the gasket on the oil pan rail.

Oil Pan Installation

1.Clean any oil from the cylinder block mounting surface and the oil pan rail. The oil pan must be installed dry.

Oil on the surface of the gasket or the rails of the cylinder block and oil pan during oil pan installation can cause the gasket to bulge out between any two bolts, particularly those at the mid-section corners. This condition may not occur immediately, but can do so at any time after installation. To avoid this occurrence, wipe any oil from the inner walls of the cylinder block crankcase and then clean the rails of the cylinder block and oil pan with a solvent such as lacquer thinner. Dry the cleaned surfaces completely.

2.Position the isolating oil pan gasket on the oil pan rails with ribbed side facing up.

3.Beginning at the center of the pan at one of the rectangular tabs, align rubber locating cones with corresponding holes in the oil pan rails.

Repair Instructions

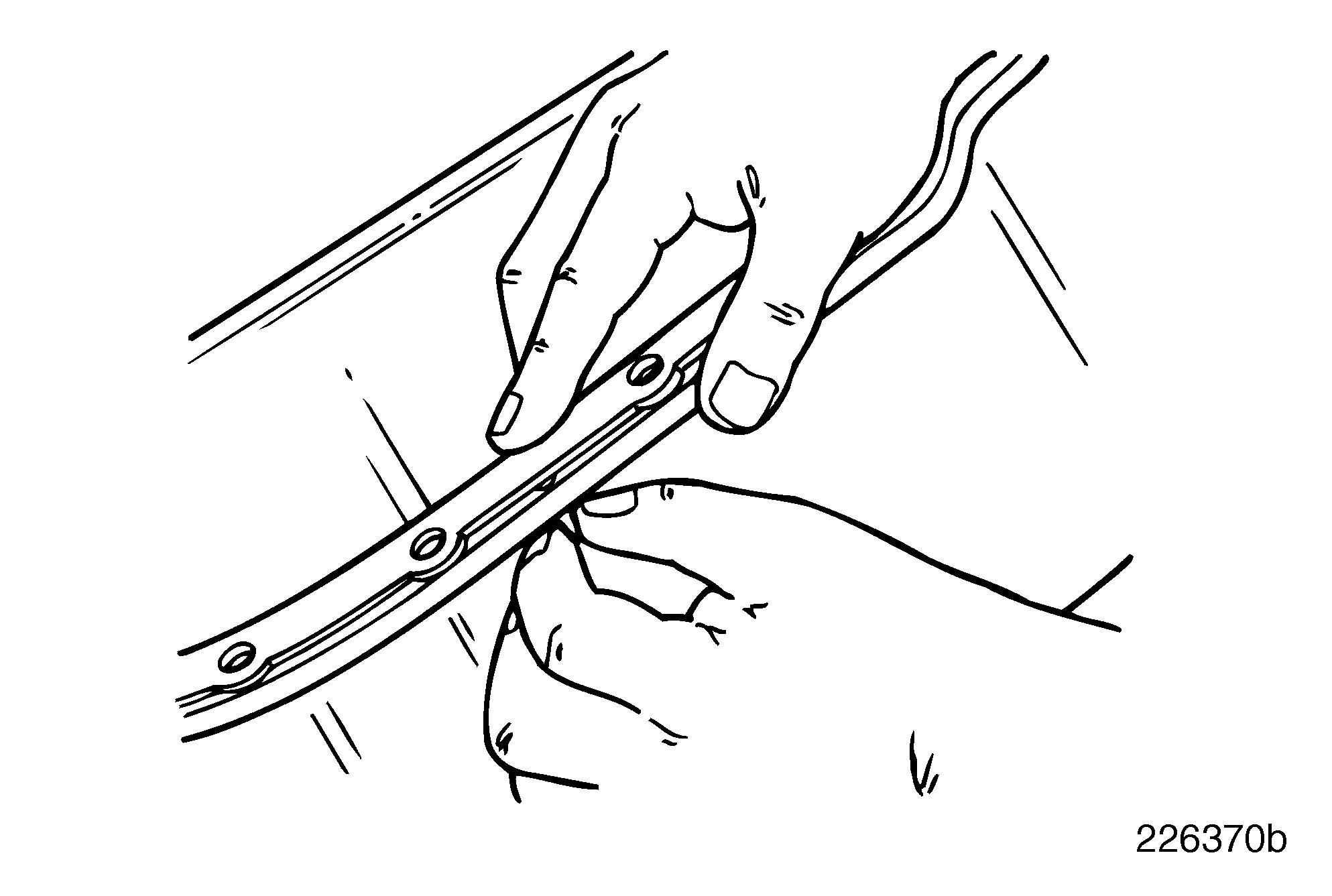

4.In one motion, firmly press upper portion of the gasket with one hand while carefully pulling the rubber cone through the hole with the other hand until seated. Continue this procedure for the remaining locating cones.

5.After all cones have been installed, recheck to ensure they are all properly seated.

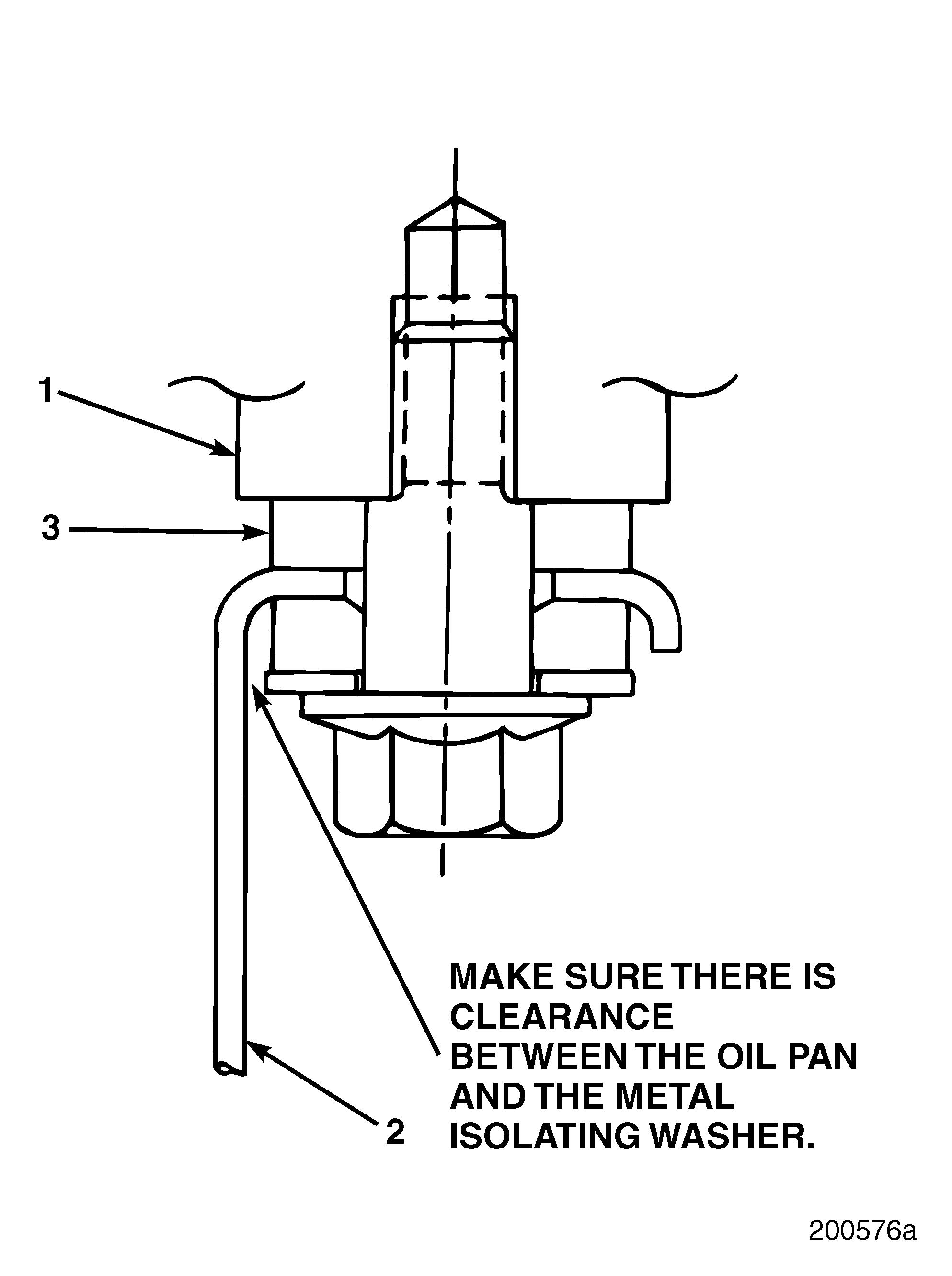

6.When installing oil pan onto the engine, center the pan before tightening fasteners so that the edges of the metal isolator washers do not touch the pan. Refer to Figure 301.

When replacing a timing gear cover or a flywheel housing on an engine equipped with an isolating oil pan gasket, first remove the oil pan to prevent damaging the rubber isolating oil pan gasket. To prevent damaging the threads in the aluminum timing gear cover and the aluminum flywheel housing, be sure to use the designated studs rather than capscrews.