1 minute read

REPAIR INSTRUCTIONS

Oil Pump Installation

Make sure the oil pump is in satisfactory condition as covered under Lubrication System Components Inspection.

Because of differences in M-E7 engine oil pump gear set helixes, it is important that the correct component/part is installed.

r An improper drive gear on the oil pump prevents oil pump installation, assuming a correct gear is on the auxiliary shaft.

r If an oil pump and an auxiliary shaft assembly were replaced, two improper gears could be installed, and engine failure would result.

r In replacing any of these critical parts, always refer to part number information in the MACK Parts System to ensure the correct component/part is being used.

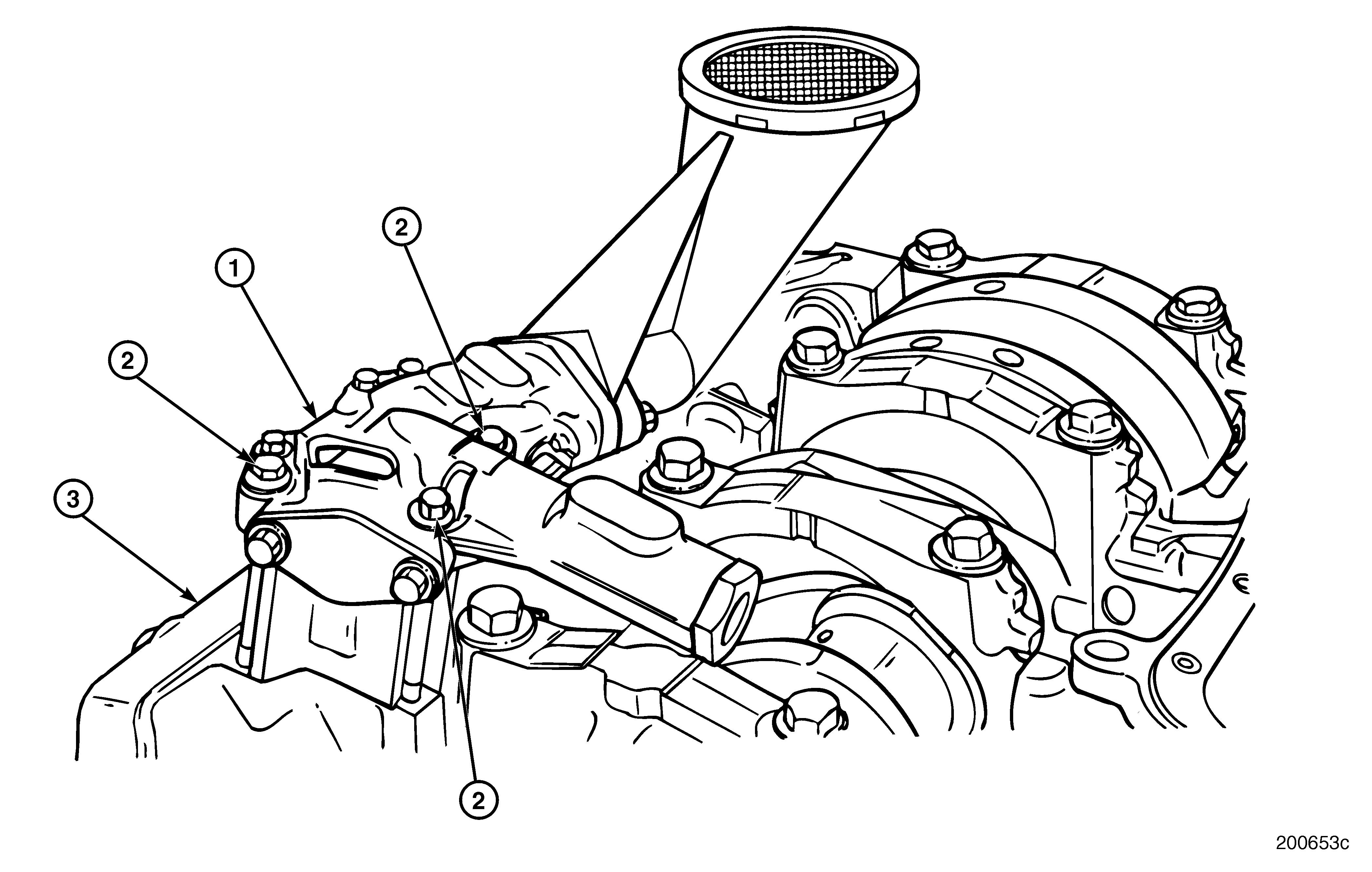

1.Position the oil pump (1) on the cylinder block (3). Refer to Figure 295.

2.Secure the pump in position using the mounting capscrews (2). Tighten the mounting capscrews to the specified torque, 40 lb-ft (54 N•m), using torque wrench J 24407, or equivalent.

Apply Loctite ® 271 to all capscrews used to install the oil pump. 295