1 minute read

REPAIR INSTRUCTIONS

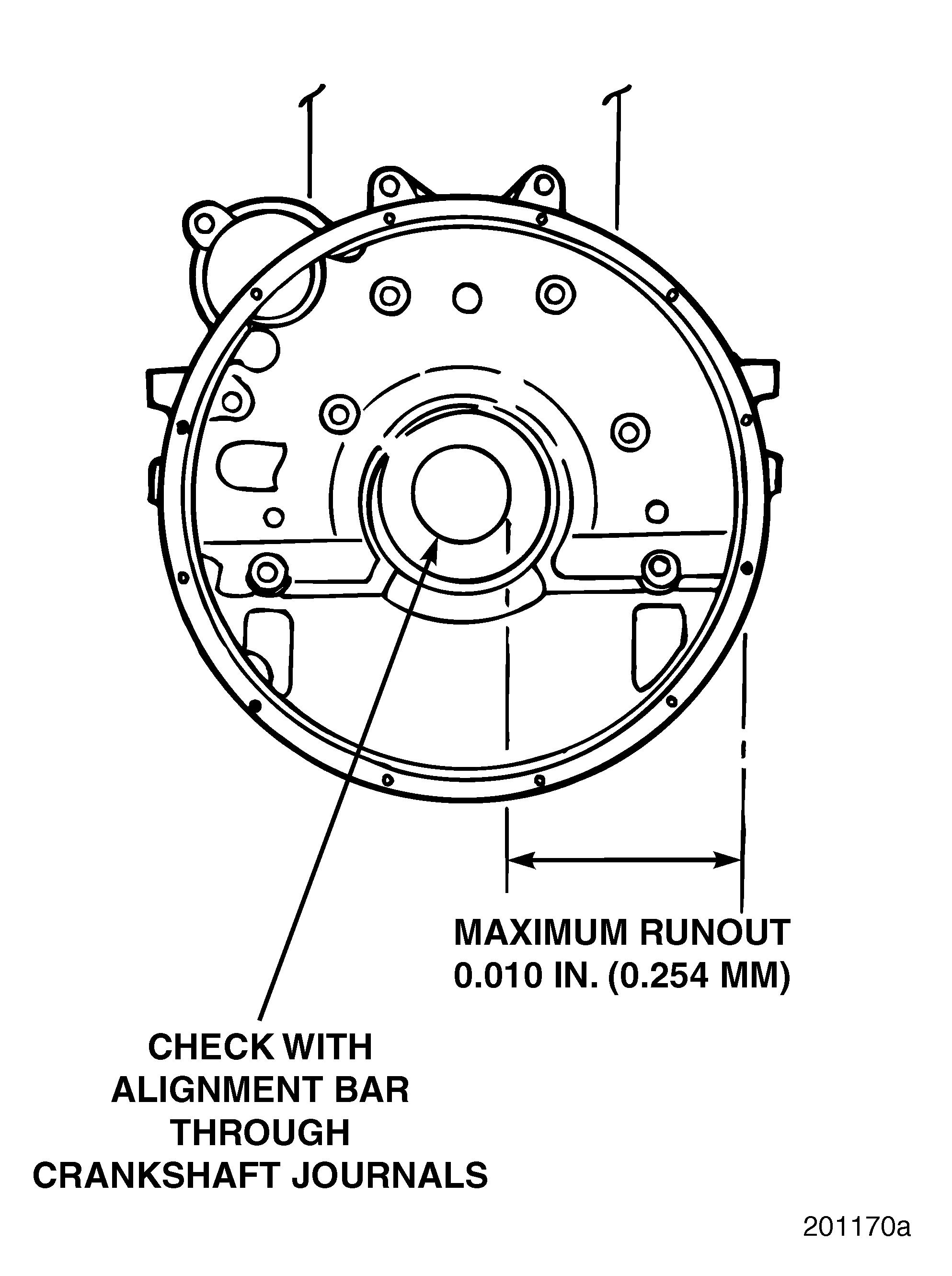

Runout

With the machined dowel method of installation, flywheel housing runout is well within the service specification of 0.010 inch (0.254 mm) Total Indicated Runout (TIR), when checked with an alignment bar through the cylinder block main bearing bores. However, when checking flywheel housing runout using a dial indicator on the crankshaft rear flange or the flywheel, results may exceed 0.010 inch (0.254 mm) due to factors such as crankshaft movement within the bearing clearances and other variables.

The dial indicator is the only method that can be used at this stage of assembly (with crankshaft in place). The machined dowel method requires that crankshaft and piston assemblies be removed.

Flywheel housing runout specifications are as follows: r Runout checked with an alignment bar installed through the cylinder block main bearing bores: 0.010 inch (0.254 mm) TIR maximum. Refer to Figure 284. r Runout checked with a dial indicator (PT5035 with Z adapter PT5035-1) mounted on the crankshaft rear flange or flywheel as shown in Figure 285 is 0.020 inch (0.508 mm) TIR maximum. This way, the runout may appear to be excessive due to crankshaft movement within bearings and other variables.

Page 213

285