1 minute read

REPAIR INSTRUCTIONS

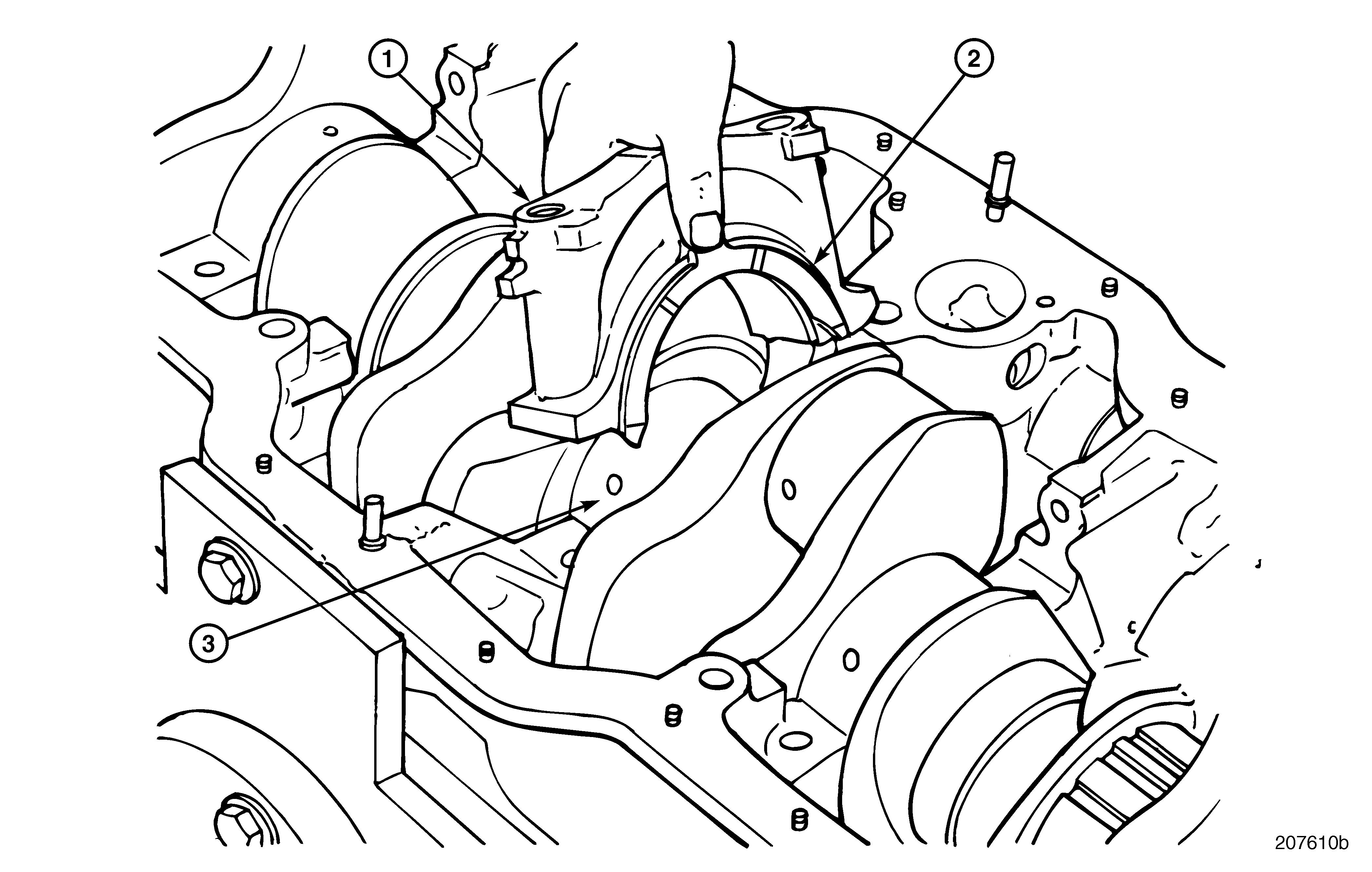

11.Install a magnetic base indicator tool, J 7872, or equivalent, on the block with the plunger against a crankshaft counterweight to check crankshaft end play.

12.Using a suitable pry bar, move the crankshaft either forward or rearward until it stops. Tap the end of the crankshaft with a plastic-faced hammer to seat the thrust washer.

13.Using the pry bar, move the crankshaft in the opposite direction. Tap the end of the crankshaft with a plastic-faced hammer to seat the other thrust washer.

14.Set the dial on the indicator to zero.

15.Using the pry bar, move the crankshaft in the opposite direction and read the dial indicator. Refer to the allowable tolerances under Fits and Limits in the Specifications section.

16.If the end play is out of specification, remove the thrust washers and install properly sized thrust washers, as required, to bring the end play into specification.

The thickness of the thrust washers used in the bearing cap must match the thickness of the thrust washers in the block. Be sure to put the aluminum-faced bearing surface of the thrust washer against the crankshaft when installing the thrust washers.