2 minute read

REPAIR INSTRUCTIONS

Heat Exchanger Inspection

The heat exchanger uses sea/lake water to transfer heat away from the engine cooling system. The engine coolant is pumped from the engine block and water manifold through the heat exchanger where it is cooled and pumped back to the block and exhaust/turbocharger. To inspect the heat exchanger it is not necessary to remove the unit from its engine bracket, but merely remove the side covers to allow access to the raw water cooling tubes.

1.Close the engine sea water seacock.

2.Drain sea water from the raw water cooling system by separating the outlet hose at the raw water pump.

The entire raw water cooling system will drain back through the removed raw water outlet hose. This system contains many gallons of water. Be prepared to catch the water in buckets or allow the bilge pump to pump it out of the hull.

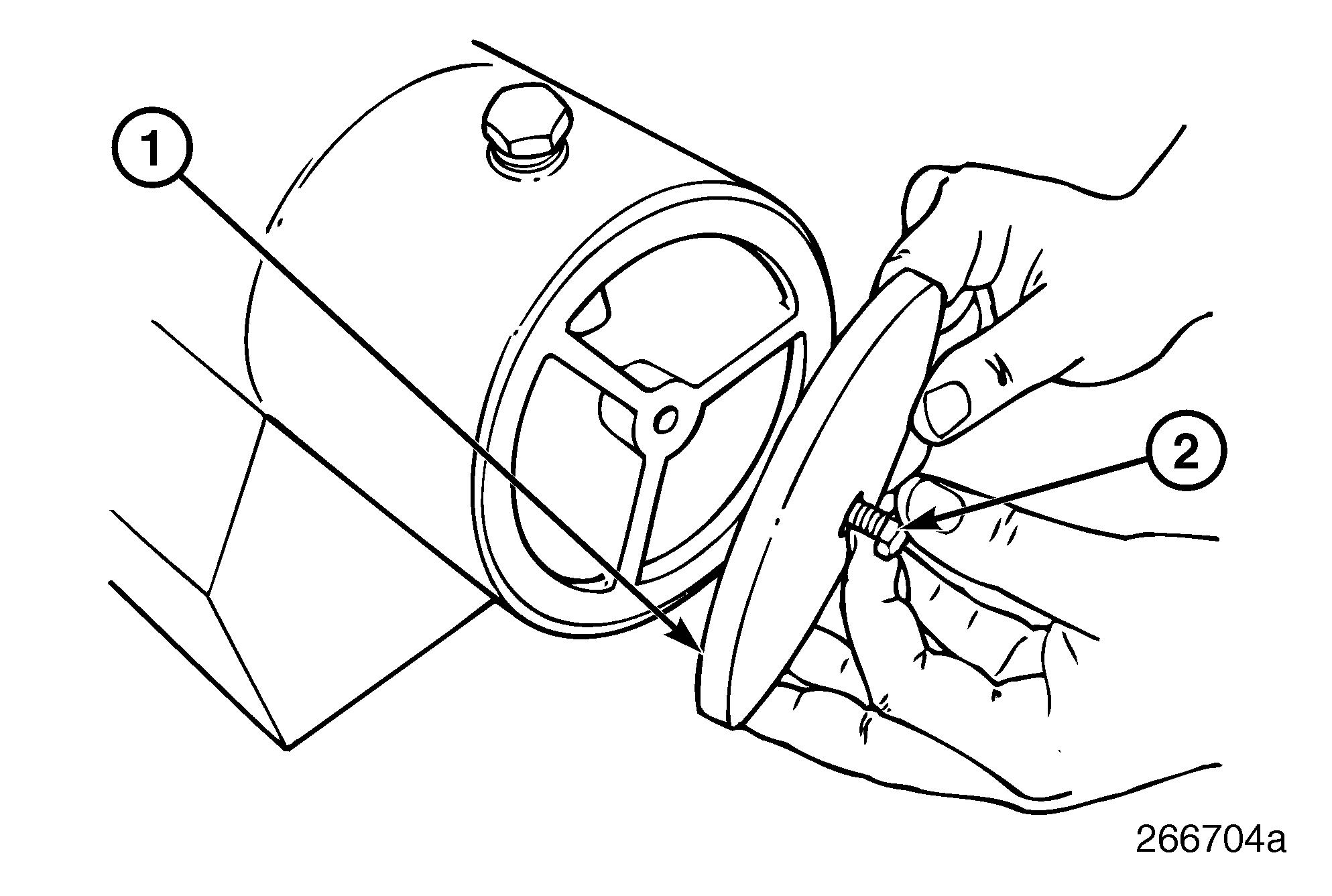

3.Remove the center bolts from both ends of the heat exchanger and remove the covers.

The engine coolant (antifreeze) compartment of the heat exchanger does not need to be drained as the only inspection available is on the raw water side of the system.

4.Using a flashlight, inspect the tubes for corrosion, excessive rust or cracks. Blocked or restricted tubes can be cleaned (rod out) using a rifle (firearm) cleaning kit or a bore brush. First circulate a cleaning solvent such as Powercool 2001 On-Line-Cleaner, or equivalent, through the tubes. Drain the cleaner. Then use a .22 caliber rod with enough extensions to push the rod completely through the tubes. Do not try to reverse direction of the rod as the brush is too large to be reversed in the tube. A pellet gun brush (.18/.19 caliber) should also work. Push the brush through each tube and blow out with compressed air

5.The heat exchanger is not a field-rebuildable unit. If a heat exchanger failure occurs, obtain a new one through the MackPower™ Parts System.

Page 189

Repair Instructions

6.Install the heat exchanger end covers with a new rubber seal and tighten the center bolt to specification.

Raw Water Pump Inspection

1.Close the engine sea water seacock.

2.Remove the six special brass impeller cover capscrews and remove the end cover by prying off with a gasket scrapper. Care should be exercised to avoid scratching or bending the end cover.

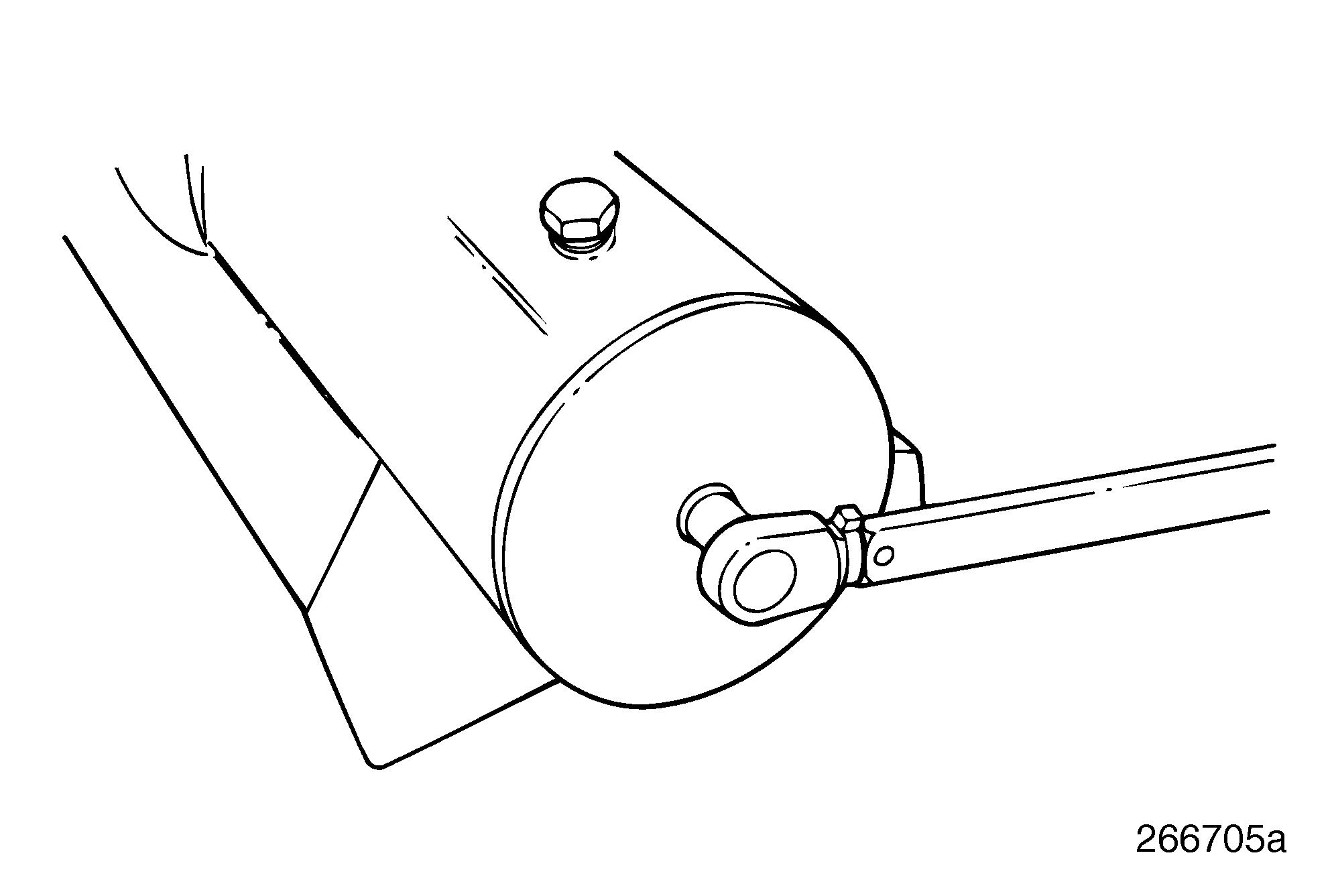

7.Reattach the outlet hose at the raw water pump and position and tighten the clamp until the spring is completely compressed, then tighten two additional turns to specifications.

8.Open the engine seawater seacock.

Raw Water Pump Inspection and Overhaul

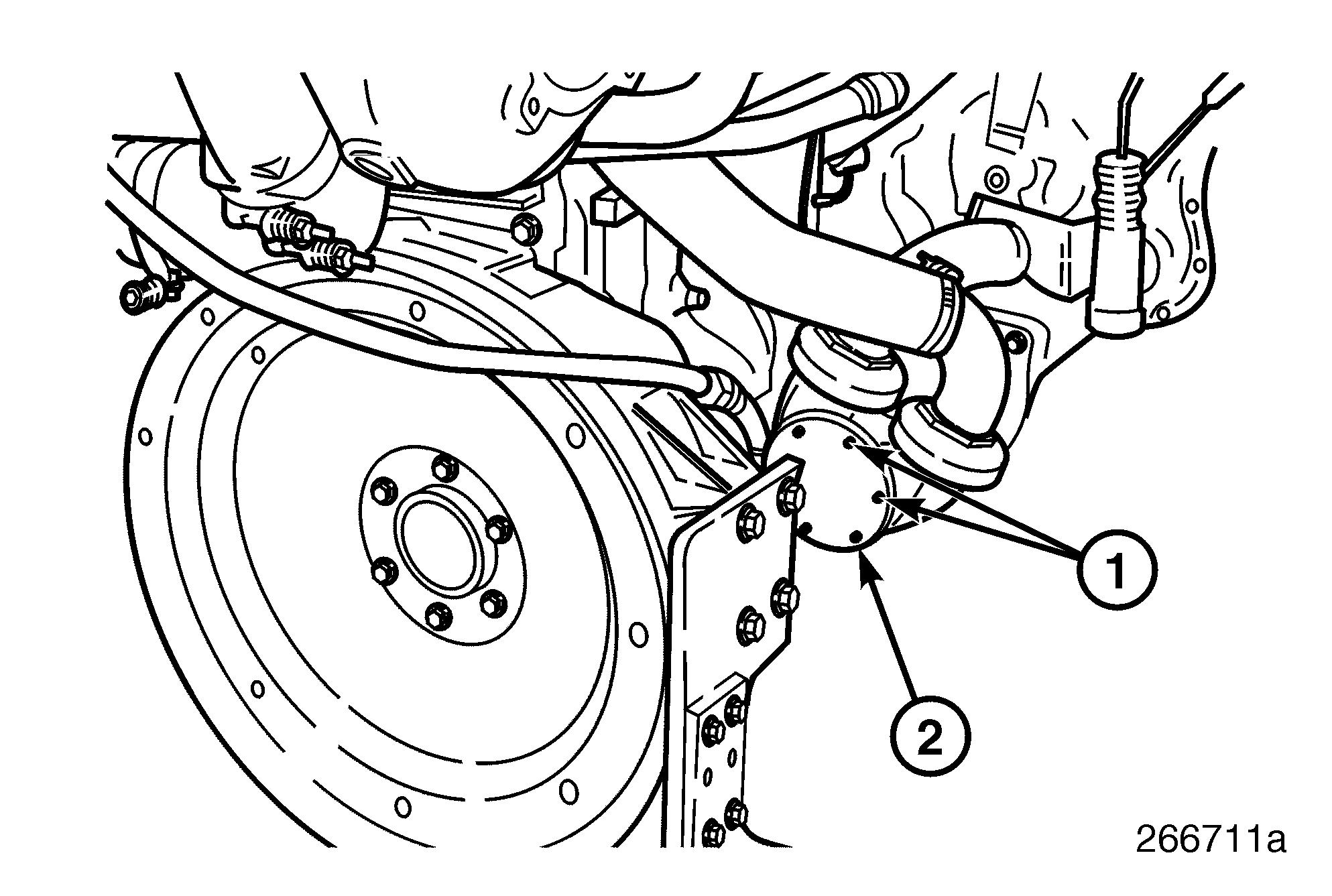

The raw water pump circulates sea/lake water to transfer heat away from the engine intake air, engine cooling and transmission cooling systems. The raw water is pumped in from the hull of the vessel below the water line to the air inlet aftercooler, then to transmission gear oil cooler and on to the engine coolant heat exchanger. After the heat exchanger, the raw water is returned to the sea/lake either directly or through the exhaust/mixer. To inspect the raw water pump, it is not necessary to remove the unit from the engine, but merely remove the rear cover to allow access to the raw pump impeller area.

Refer to Figure 249.

3.Remove the impeller outer wearplate.

4.Grasp hub of impeller (7) with pliers and remove from impeller bore. If impeller O-ring remains on shaft, remove it from shaft.

5.Remove cam/liner (3) from pump body.

6.Remove inner wearplate (9).

7.Clean and inspect all parts for wear. If wear plates are worn, they should be reversed or replaced. If cam/liner thickness is 3/8″ or less at its thickest section, it should be replaced.