1 minute read

REPAIR INSTRUCTIONS

Inspection

Refer to Figure 242.

1.Clean and inspect oil pump housing (4) for scoring, cracks or other damage. If any of these conditions exist, replace oil pump.

2.Check bushings in oil pump housing for burrs, nicks or cracks.

The bushings are an integral part of the oil pump housing. If bushings are damaged, replace oil pump housing.

3.Clean and inspect relief valve spring (12) for breaks. Replace as necessary.

4.Clean and inspect plunger (11) seating surface for burrs or nicks. If seating surface contains burrs or nicks, repair seat as follows: a.Place valve lapping compound on plunger seat. b.Insert plunger in relief valve housing and rotate plunger against seat to smooth seat. c.Remove plunger and clean.

5.Check oil pump idler gear (14) for free play by spinning it on its shaft. If any binding occurs, check housing bore and gear teeth for burrs, nicks or other damage. Replace as necessary.

6.Insert pumping gear in housing and check for free play by spinning. If any binding occurs, check housing and gear teeth for burrs, nicks or other damage. Replace as necessary.

Before proceeding with assembly, check end clearance, side clearance and backlash of drive gears as follows.

End Clearance Check

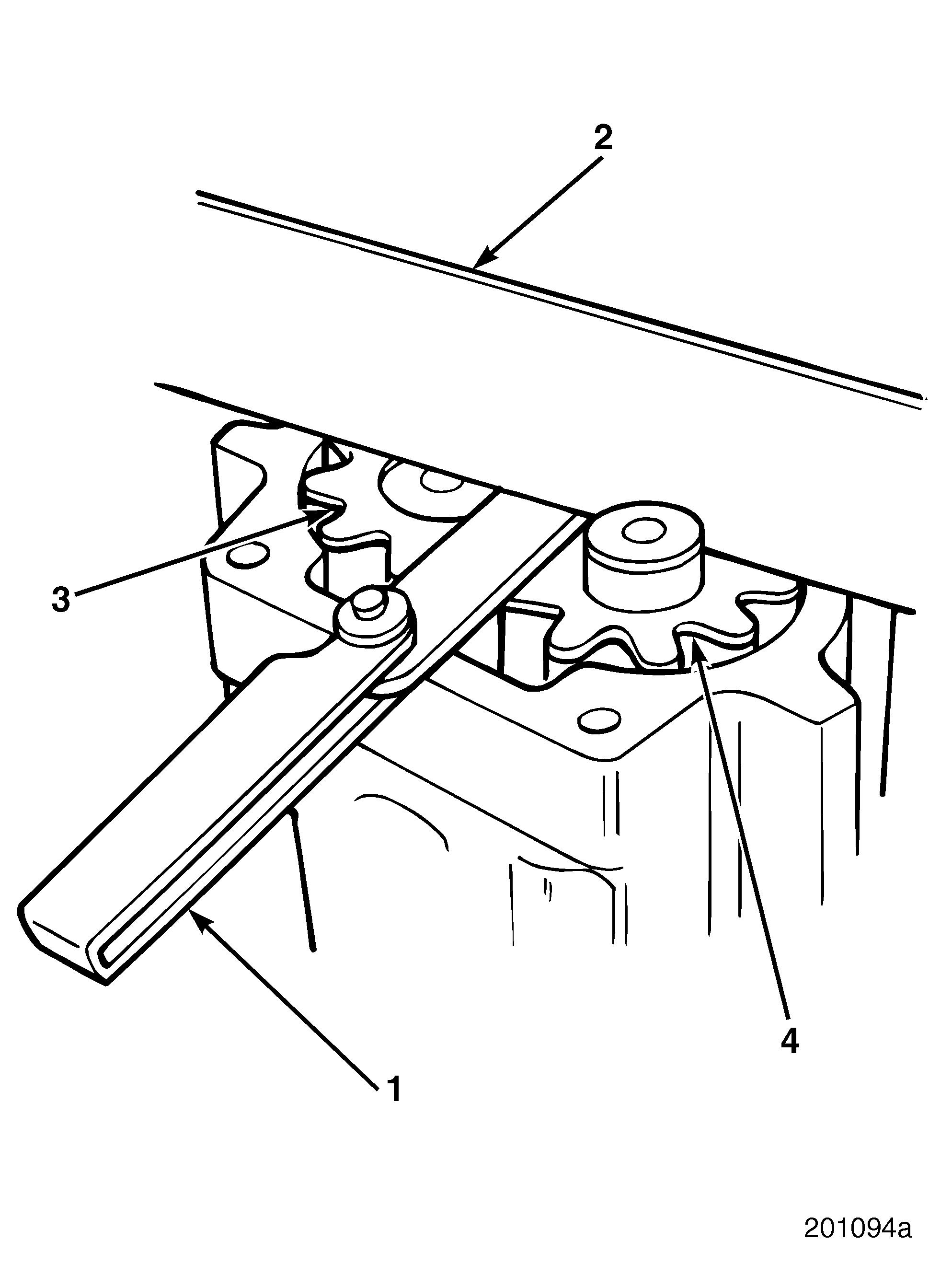

Refer to Figure 243.

1.Low Limit Place a straightedge across face of gears and run a 0.0035-inch (0.089-mm) thickness gauge under straightedge. Gauge should move freely without binding. If binding occurs, check gears for nicks or burrs. Replace as necessary.

2.High Limit With straightedge in place, run a 0.0060-inch (0.152-mm) thickness gauge under straightedge. Gauge should be very tight. If gauge moves freely, replace gears.