1 minute read

REPAIR INSTRUCTIONS

r Valve Stem to Seal Lip The inside diameter of the seal lip and outside diameter of the valve stem should be well-lubricated with clean engine oil when installing the seal over the valve stem.

It is essential that the J 42453 Valve Stem Seal Installation tool be used to install the seals. This tool bottoms on the cylinder head rocker arm mounting bracket surface when the seal is installed to the proper depth on the valve guide. Using any non-bottoming type seal driver (such as a socket) may result in distorting the top surface of the seal casing which permanently distorts the seal lip and prevents proper sealing, or in the top rubber portion of the seal being cut off. Also, do not use seal installer J 41150, or seal damage will result.

Before installing valve stem seals, be sure the rotator has been installed. The rotator will not fit over the valve stem seal.

1.Lubricate the valve guides and valve stems with engine oil prior to installation.

2.Install valve spring lower washer (Roto-Coil), over valve guide.

3.Lubricate valve stem seals with engine oil and install seals using valve seal installer J 42453.

4.Install valve into cylinder head.

5.Check valve stem tip for nicks or burrs that may damage valve seal upon installation.

6.Install valve spring, upper washer and keepers. Use tool J 29294-B to install keepers.

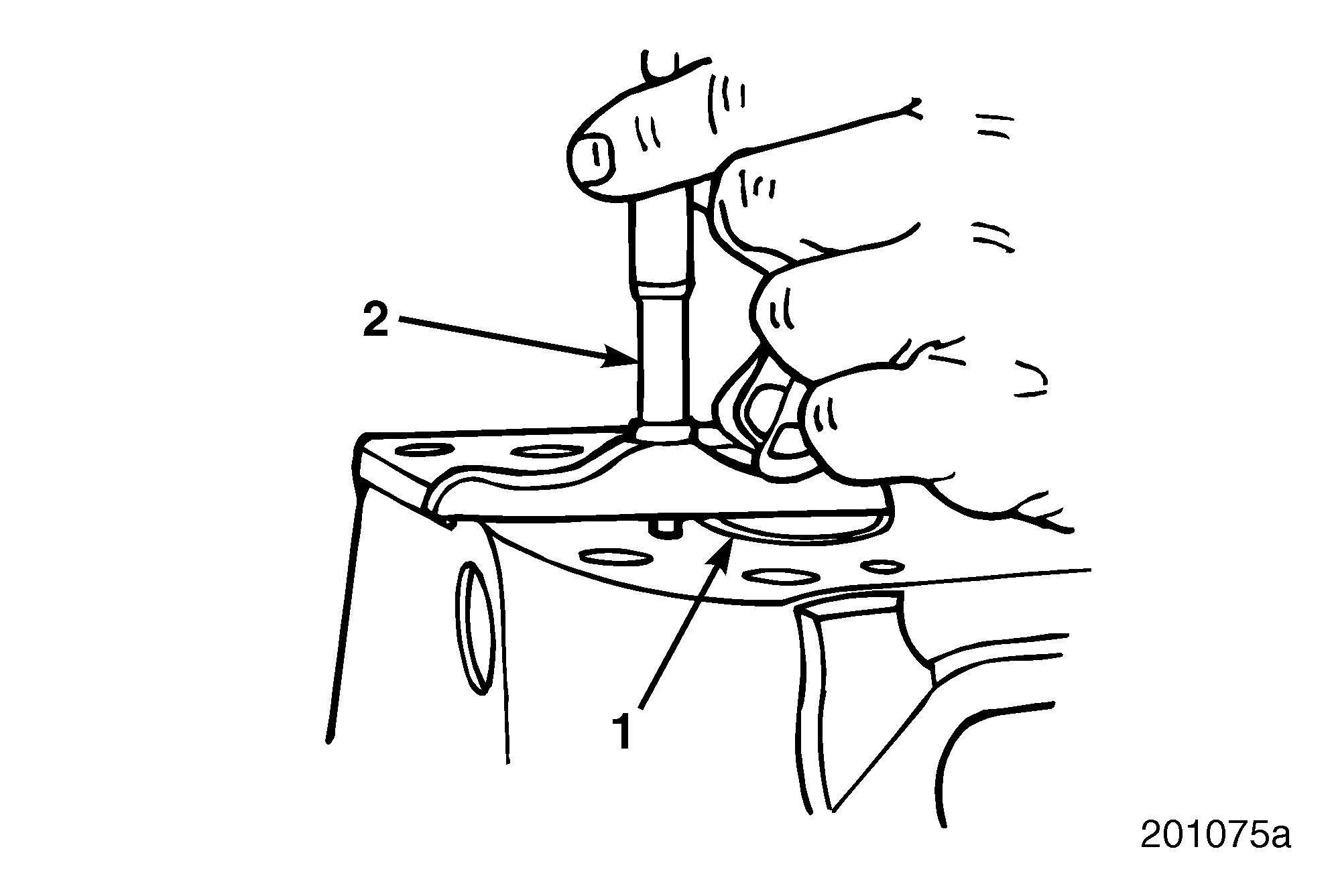

Refer to Figure 235 and Figure 236.

7.After valves are assembled, check each inlet valve for head height above cylinder deck. The protrusion dimension for inlet valves should be 0.0425 ± 0.007 inch (1.0795 ± 0.178 mm). 235

1. Inlet Valve2. Depth/Height Measurement Tool

8.Check each exhaust valve for head depth below cylinder deck. The depth dimension for exhaust valve should be 0.021 ± 0.007 inch (0.553 ± 0.178 mm)

Page 177