1 minute read

REPAIR INSTRUCTIONS

Removal

Crankshaft regrinding by anyone other than Mack Trucks, Inc. is NOT recommended due to the tight control required on maintaining geometrical tolerances, and the hardened characteristics of the crankshaft journals and journal fillets.

If the crankshaft is not serviceable, both new and reground crankshafts are available through the MACK Parts Distribution Centers.

If crankshaft main journals or rod journals are not a standard size, be sure to use properly sized bearing inserts. Bearing inserts are marked with a “P” which follows the part number, and is stamped on the back side of the bearing insert. For example, if a journal is 0.010 inch (0.254 mm) undersize, a 0.010-inch undersize bearing is required and will be stamped “P10.”

Some crankshafts may have journals which are 0.002 inch (0.0508 mm) undersize. They are marked by a streak of white paint adjacent to the journal. Always check journals to ensure using proper size bearing inserts.

Crankshaft Wear Ring Installation

When the service oil seal is to be replaced and the crankshaft flange is worn, the crankshaft can be salvaged by installing a crankshaft wear ring. An oil seal with a larger inside diameter is used with this wear ring.

SPECIAL TOOLS REQUIRED r Crankshaft Rear Seal Installer J 37716-A r Wear Ring Installer J 38880 r Universal Driver Handle J 8092

A limited number of crankshafts were manufactured with a repair sleeve installed on the flange. The repair sleeve is usually not noticeable and is finish ground to standard flange size. If the repair sleeve is damaged or becomes loose, the crankshaft must be replaced. Special care must be taken not to damage the crankshaft flange during wear ring removal.

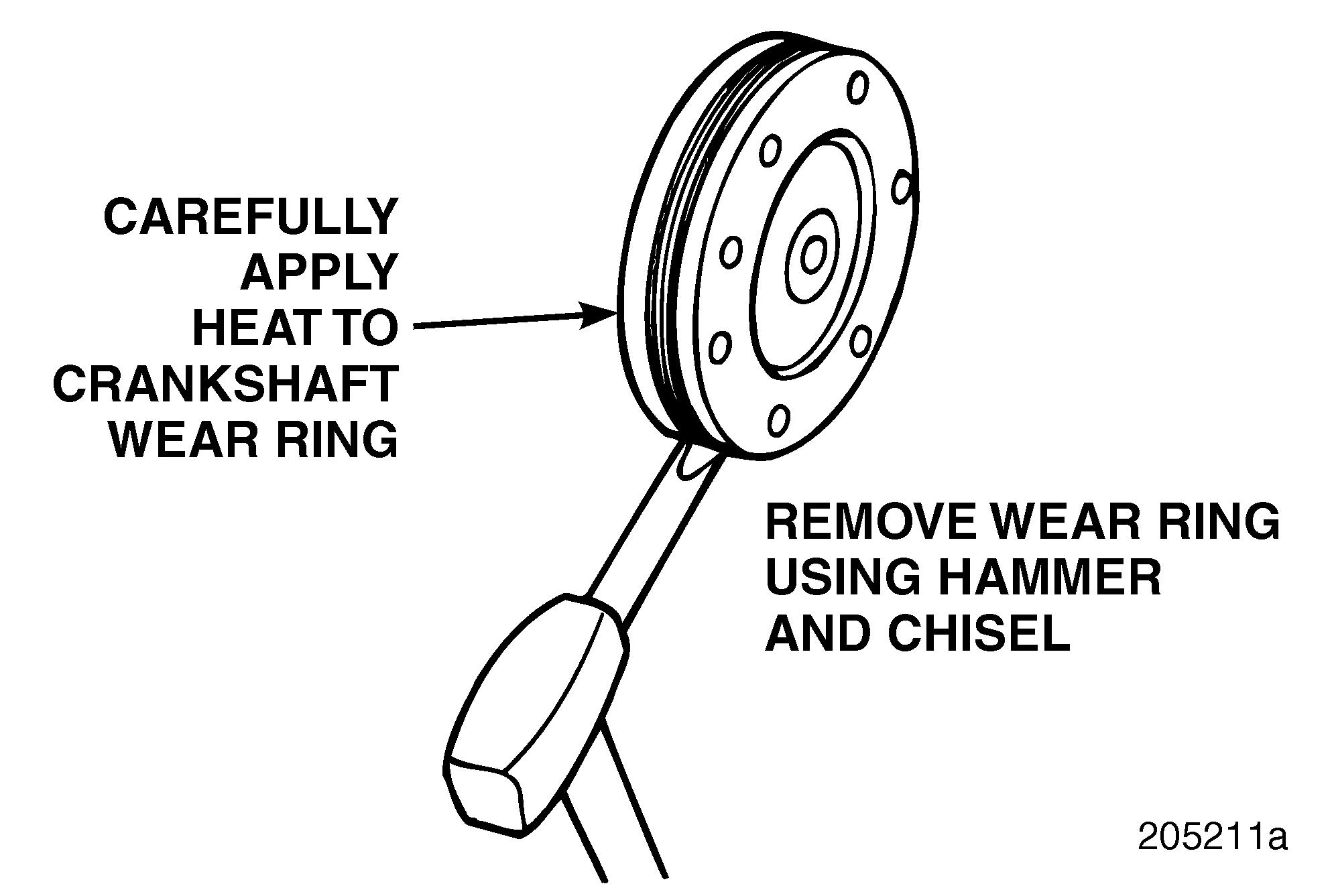

Refer to Figure 186.

1.The wear ring can be removed by carefully applying heat, using a ball-peen hammer to expand the diameter, or by using a chisel to split the wear ring. Use extreme care not to damage the crankshaft flange.

Place the chisel face squarely on the wear ring and carefully strike the chisel with a hammer to cut part-way through the ring. The wear ring will loosen enough to be removed without cutting completely through it. The goal is to carefully remove the wear ring in this manner and not cut, nick or damage the crankshaft flange.

2.Thoroughly clean the flange area of the crankshaft. Check for nicks or scratches and repair any damaged areas with crocus cloth as necessary. 186

Installation

Refer to Figure 187.