1 minute read

REPAIR INSTRUCTIONS

Honing The Cylinder Sleeve Bore

The height of the cylinder sleeves above the cylinder block deck (under the same cylinder head) can vary as long as all are within the 0.023–0.029-inch (0.584–0.737-mm) specification.

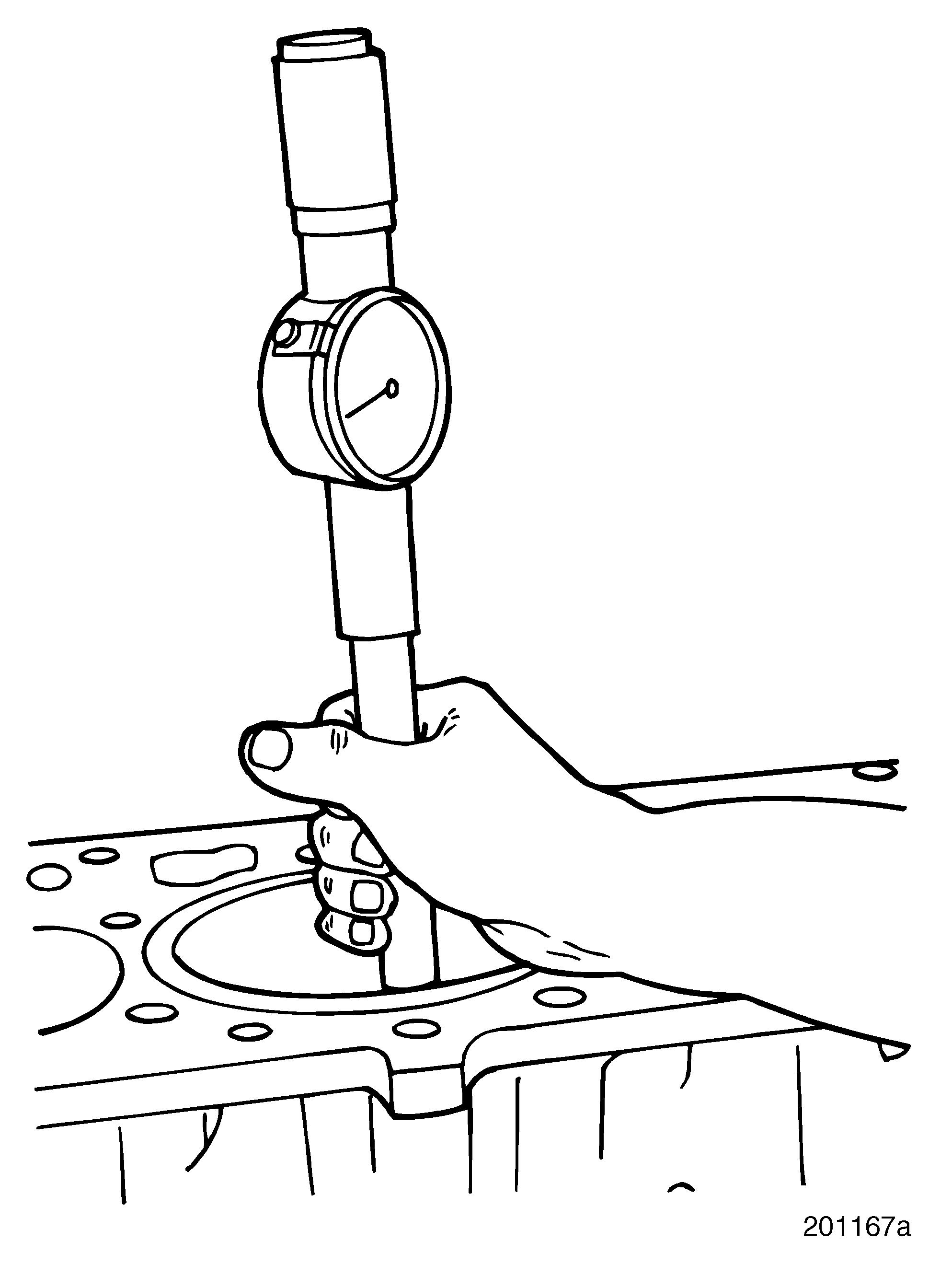

7.Using dial bore gauge J 5347-B, or equivalent, check the cylinder sleeve for outof-round and taper limit (Figure 173). Take readings in two directions, 90 degrees apart, at each of three levels.

Cylinder sleeve ID maximum: 4.877 inches (123.876 mm).

Cylinder sleeve ID minimum: 4.876 inches (123.850 mm). The cylinder sleeve ID may be a minimum 4.872 inches (123.749 mm) at top of sleeve due to close-in from press fit.

173

All MackPower™ engines currently produced have fine precision-finished cylinder sleeves. Because of the precision finish, honing is NOT recommended. Particles from the honing process which become wedged in the pattern are impossible to completely remove and can cause further damage.

Piston Cooling Spray Nozzle

Installation

[219 RV]

SPECIAL TOOL REQUIRED r Two-Piece Piston Cooling Nozzle Aimer

J 39045

INSTALLATION PROCEDURE

Refer to Figure 174.

1.Using a liberal amount of lubricant, install the elastomer sleeve (7) on the locator tube (6).

2.Install a retaining screw (4) in the spray nozzle bracket (3).

3.Position the spray nozzle locator tube (6) in the cylinder block oil passage (2) and using torque wrench J 24406, or equivalent, tighten the retaining screw to the specified torque, 15 lb-ft (20 N•m).

174