3 minute read

FUNCTION OF KDOC

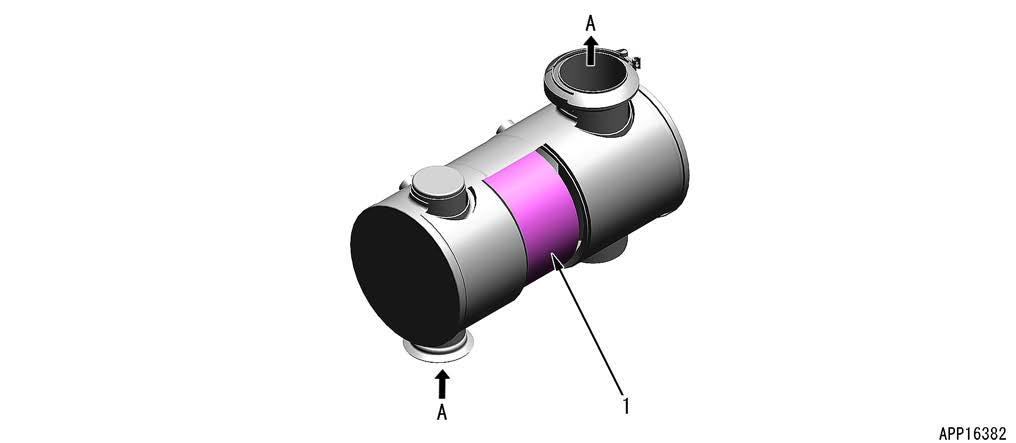

A: Flow of exhaust gas

1: Oxidation catalyst

•KDOC is installed in order to conform to the severe regulations of exhaust gas. KDOC has a function of oxidization of SOF (soluble organic fraction in particles of exhaust gas) , HC (unburnt combustible content), and CO (carbon monoxide) to clean the exhaust gas.

•Function of oxidation catalyst

(1) Oxidizes SOF (soluble organic fraction in particles of exhaust gas)

(2) Oxidizes HC (unburnt combustible content)

(3) Oxidizes CO (carbon monoxide)

Types Of Regeneration Functions

The regeneration function is a function for the urea SCR system to be maintained normally Active regeneration (engine exhaust temperature rise control + fuel dosing)

•Automatic regeneration

•The automatic regeneration is a function that starts the regeneration automatically upon receiving a request from the urea SCR system in order to maintain the urea SCR system normally by the fuel dosing (*2) when the engine controller enters the exhaust temperature rise control (*1) . The automatic regeneration is also performed by the command from the engine controller at a set time after the previous regeneration.

*1: This is a control to increase the exhaust temperature of the engine by controlling the fuel injection timing, variable flow turbocharger, and exhaust throttle valve.

*2: This is a fuel injection performed to accelerate the regeneration by increasing the exhaust temperature.

•Manual stationary regeneration

•The exhaust temperature may not reach a certain level depending on the operating condition of the machine even if the automatic regeneration is performed upon receiving a request from the urea SCR system when the exhaust temperature does not reach a certain level or when the operator disables regeneration. This is a regeneration function that is performed upon receiving a request for the manual stationary regeneration displayed on the machine monitor. This is a regeneration function performed by the operator on the machine monitor screen. There is also another regeneration function that is performed by a technician with operation on the machine monitor screen when replacing the engine controller or troubleshooting. (“Active Regeneration for Service”)

Notice

• For the procedure to start and stop the regeneration of the aftertreatment devices, see Operation and Maintenance Manual for each machine.

•Use ultra low-sulfur diesel fuel. If any fuel other than the specified one is used, the aftertreatment devices may cause a failure.

•Use the engine oil conforming to Komatsu genuine KDPF. If any oil other than the specified one is used, the KDOC performance is deteriorated which leads to the deterioration of the exhaust gas purifying function, and fuel consumption, and the aftertreatment devices may cause a failure.

•Do not modify the aftertreatment devices and exhaust pipe. If modification is performed, the aftertreatment devices cannot operate normally and may cause a failure.

•Do not give the aftertreatment devices strong impact by standing on it, dropping off it, or hitting it, or such. Otherwise the impact may damage the built-in ceramic parts of the aftertreatment devices.

•The white smoke may be discharged through the exhaust pipe outlet for a short time during the “automatic regeneration” and the “manual stationary regeneration”, especially at low temperature, but this is not a failure. Be sure to perform regeneration in a well-ventilated area, since carbon monoxide may be generated.

•The temperature of the gas exhausted from the exhaust pipe may become 650 °C or higher during “automatic regeneration” and “manual stationary regeneration”. Check that there is no combustibles around the exhaust pipe in order to prevent the fire. Thoroughly ensure the safety around the machine by checking that there is no persons at the place where the gas is exhausted to.

Remark

•The engine controller may start “automatic regeneration”. This is a treatment to maintain the function of the urea SCR system normal, and is not a failure. The automatic regeneration or manual stationary regeneration to maintain the normal function of the urea SCR system runs approximately for one hour

•Variable flow turbocharger and exhaust throttle valve are actuated automatically and the engine sounds differently during “automatic regeneration” and “manual stationary regeneration”. Also, as the flow rate of the exhaust gas in the aftertreatment devices changes, the exhaust sound changes, but this is not a failure.

•The exhaust pipe may smell different from usual during the “automatic regeneration” and the “manual stationary regeneration”, but this is not a failure.

•“KDOC dry operation” function is provided to prevent excessive accumulation of unburnt fuel in KDOC when operation is continued at relatively low temperature for long hours.

•This is a function that the engine controller increases the engine exhaust temperature automatically and performs dry operation of KDOC when the set condition is satisfied. When the automatic dry operation is insufficient for the treatment, a manual stationary regeneration may be required.

•The standard temperature of KDPF is shown below.

KDOC_Out (KDOC outlet temperature sensor) While regeneration is not performed (idling state)

KDOC In (KDOC inlet temperature sensor) to 250 °C While regeneration is performed (thermal mode: 1000 rpm)

LUBRICATION SYSTEM