1 minute read

AD5 ISVP (#18 of 24 item check Eng. Low (no load) mA Eng. Low (arm relief) mA Eng.High (no load) mA ~’~t~ Eng.High (arm relief) rnA

2.1 MACHINE PREPARATION

A. Tools & Equipment Required

1. Two 700kg/cm 2 (10,000psi) Pressure Gauges. 2. Two 105kg/cm 2 (1,500)psi) Pressure Gauges, 3. One 70kg/cm 2 (1,000 psi) Pressure Gauge. 4. Two 1/4 X 1/4 X 1/4 PT "Tee" adaptor fittings. 5. General Hand or power tools to remove and replace hydraulic fittings and components.

NOTE

It may be necessary to modify hand tools in order to reach certain components for adjustment.

6. Thermometer to read hydraulic oil temperature. 7. Special tools for locking Travel Motors.

B, Machine Settings & Site Conditions 1. Attachment in Hydraulic Oil Check Position. 2. Hydraulic Oil Temperature at 45°C to 550C (113°F to 131°F). 3. KPSS Mode Switch in H-Mode. 4. Throttle Control in "Hi-Idle" position. 5. Firm, level testing site.

MACHINE IN HYDRAUUC OIL CHECK POSITION

FIGURE 2.1

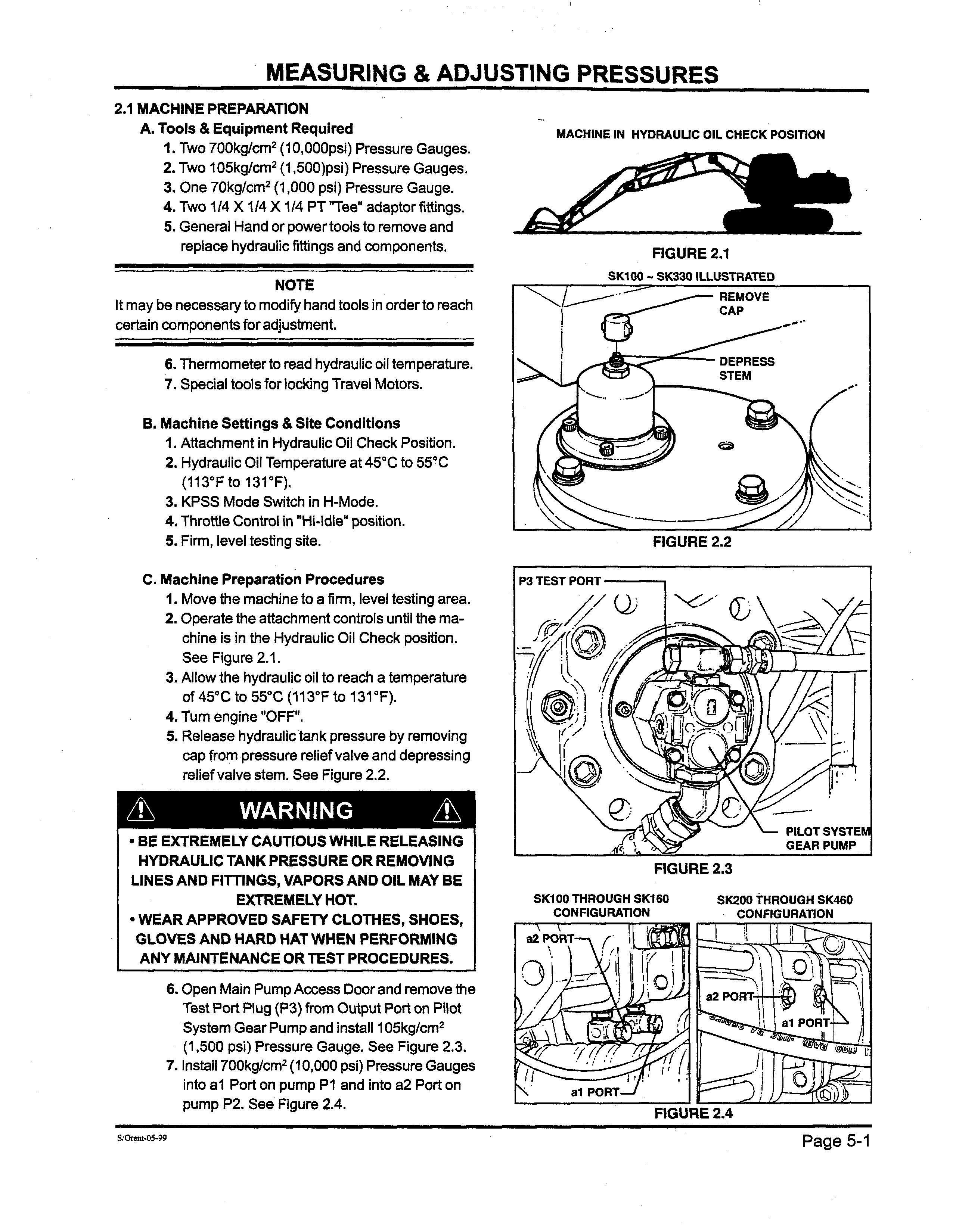

SK100 ~ SK330 ILLUSTRATED

C. Machine Preparation Procedures

1. Move the machine to a firm, level testing area. 2. Operate the attachment controls until the machine is in the Hydraulic Oil Check position. See Figure 2.1. 3. Allow the hydraulic oil to reach a temperature of 45°C to 55°C (113°F to 131°F). 4. Turn engine "OFF". 5. Release hydraulictank pressure by removing cap from pressure relief valve and depressing relief valve stem. See Figure 2.2.

FIGURE 2.2

¯ BE EXTREMELY CAUTIOUS WHILE RELEASING HYDRAULIC TANK PRESSURE OR REMOVING LINES AND FITTINGS, VAPORS AND OIL MAY BE EXTREMELY HOT. ¯ WEAR APPROVED SAFETY CLOTHES, SHOES, GLOVES AND HARD HAT WHEN PERFORMING ANY MAINTENANCE OR TEST PROCEDURES.

6. Open Main Pump Access Door and remove the

Test Port Plug (P3) from Output Port on Pilot

System Gear Pump and install 2 105kg/cm (1,500 psi) Pressure Gauge. See Figure 2.3. 7. Install 700kg/cm 2 (10,000 psi) Pressure Gauges into al Port on pump P1 and into a2 Port on pump P2. See Figure 2.4.

FIGURE 2.3

SK100 THROUGH SK160 SK200 THROUGH SK460 CONFIGURATION CONFIGURATION